Table of Contents

Introduction to Electrode Fixtures

Electrode fixtures are crucial components in electrical systems, acting as electrical conductors that bridge the gap between nonmetallic circuit components. They play a vital role in diverse industries, including electroplating, welding, and electrochemical cells. This comprehensive guide will delve into the world of electrode fixtures, exploring their types, design considerations, and indispensable applications.

Types of Electrode Fixtures

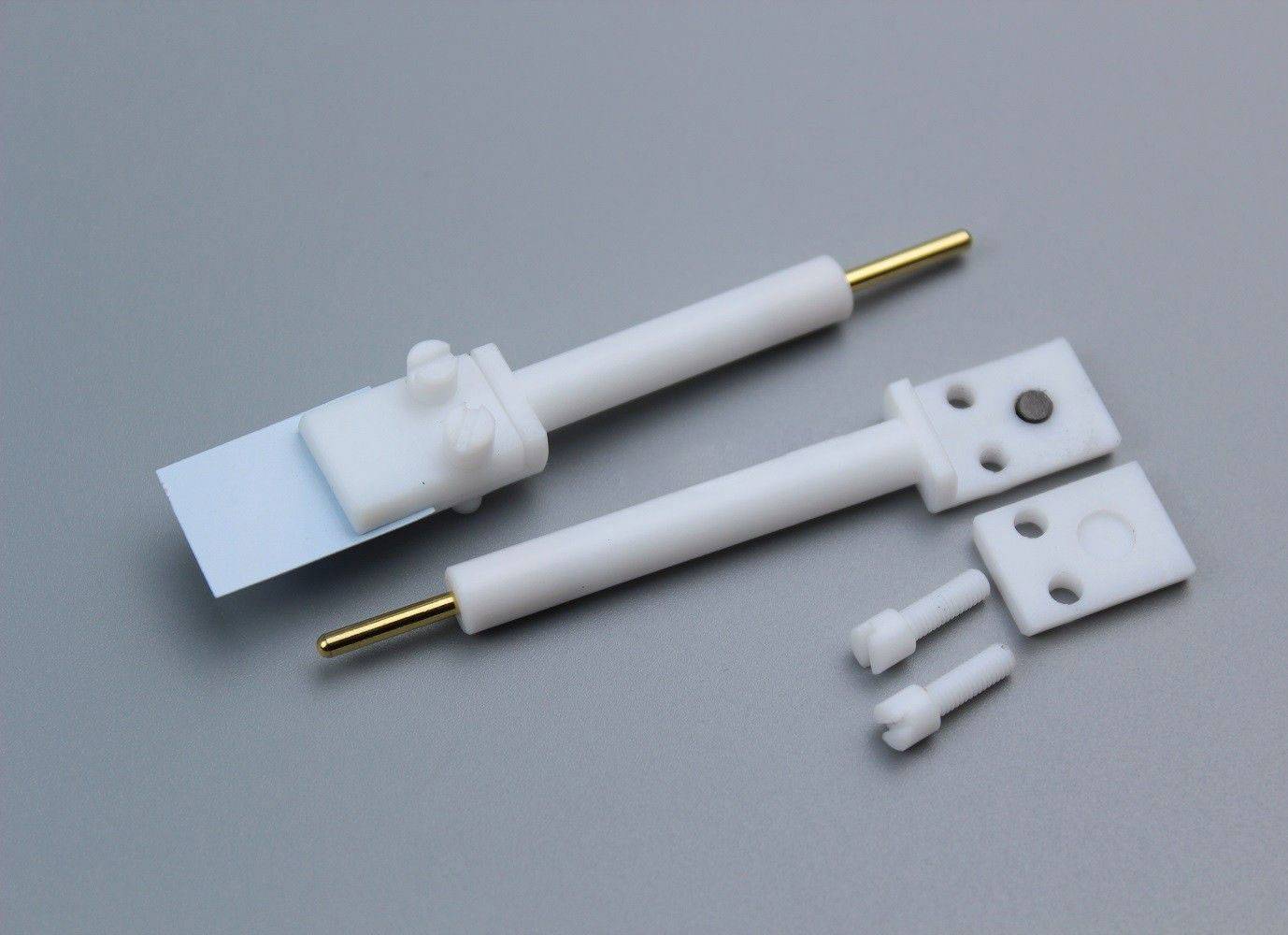

Electrode fixtures play a crucial role in electrochemistry, providing support and electrical connectivity for electrodes. They come in various types, each designed for specific applications.

Conductive Copper Tiles

Conductive copper tiles are flat, rectangular plates that serve as a base for mounting electrodes. They are made of high-conductivity copper to minimize electrical resistance and ensure efficient current flow. Copper tiles are commonly used in electroplating and electrorefining processes.

Copper Tubes

Copper tubes are cylindrical structures that provide a pathway for electrical current to reach the electrode. They are often used in conjunction with conductive copper tiles or electrode clamping devices to create a complete electrical circuit. Copper tubes are suitable for applications where high current densities are required.

Electrode Clamping Devices

Electrode clamping devices are mechanical fixtures that hold electrodes securely in place. They ensure good electrical contact between the electrode and the electrical circuit. Clamping devices can be adjustable to accommodate electrodes of different sizes and shapes.

Protective Sleeves

Protective sleeves are cylindrical or tubular structures that fit over electrodes to protect them from damage. They are made of chemically inert materials, such as Teflon or glass, and prevent the electrode from coming into direct contact with the electrolyte. Protective sleeves are essential for applications where the electrode is exposed to corrosive or hazardous environments.

Cooling Water Channels

Cooling water channels are incorporated into electrode fixtures to dissipate heat generated during electrochemical reactions. They are typically made of copper or stainless steel and allow cooling water to circulate around the electrode, preventing it from overheating. Cooling water channels are necessary for high-power applications where excessive heat can damage the electrode.

Hanging Parts

Hanging parts are used to suspend electrodes from the electrode fixture. They are typically made of conductive materials, such as copper or brass, and can be adjustable to accommodate different electrode lengths. Hanging parts allow for precise positioning of the electrode in the electrolyte and facilitate electrode removal for maintenance or replacement.

Design Considerations for Electrode Fixtures

Electrode fixtures play a pivotal role in facilitating electrical connections within various laboratory setups. Their design entails careful consideration of several crucial factors to ensure optimal performance and safety.

Conductive Materials Selection

The choice of conductive materials for electrode fixtures is paramount to minimize electrical resistance and maximize current flow. Typically, materials with high electrical conductivity, such as copper, aluminum, or silver, are employed. These materials exhibit low resistivity, enabling efficient transfer of electrical signals or power.

Secondary Voltage Adjustment

In certain applications, it becomes necessary to adjust the secondary voltage of the power source to accommodate specific experimental requirements. For instance, in ferroalloy production, the secondary voltage of the furnace transformer must be adjusted based on the type of ferroalloy being produced. This adjustment optimizes the electrical conditions for efficient and safe operation.

Minimization of Conductive Busbar Length

The length of the conductive busbars connecting the power source to the electrode fixtures should be minimized whenever possible. This is because longer busbars introduce additional resistance into the circuit, leading to voltage drop and potential energy losses. By reducing the busbar length, electrical efficiency is enhanced, and power delivery to the electrodes is maximized.

Transformer Placement

The placement of the transformer relative to the electrode fixtures significantly impacts electrical performance. Ideally, the transformer should be positioned as close as feasible to the submerged arc furnace to minimize the length of the busbars and reduce energy losses. This arrangement ensures efficient power transmission and minimizes voltage drop.

Electrode Lifting and Pressing

Electrode lifting and pressing devices are essential for adjusting the electrode insertion depth. These devices enable precise control over the electrodes' position, ensuring optimal electrical contact and minimizing arcing or other electrical hazards. Various gripping methods are employed, including pressure ring grippers, electrode combination grippers, and conical ring grippers, each tailored to specific electrode configurations.

Cooling and Protection

To prevent overheating and ensure the longevity of electrode fixtures, adequate cooling mechanisms are incorporated into their design. Cooling water channels are often integrated to dissipate heat generated during electrical operation. Additionally, protective sleeves or enclosures may be employed to safeguard the fixtures from external elements or harsh environmental conditions.

Applications of Electrode Fixtures in Electroplating

Electrode fixtures play a crucial role in electroplating, enabling the precise deposition of materials like copper, platinum, and gold onto surfaces. These fixtures serve as the interface between the electrical current and the workpiece, ensuring efficient and uniform plating.

Selective Plating Applications:

Electrode fixtures offer increased masking potential, allowing manufacturers to selectively plate specific areas of a workpiece while leaving others uncoated. This is particularly advantageous for applications where selective plating is required, such as in electronics and jewelry manufacturing.

Energy Savings:

Gold plating, which commonly employs electrode fixtures, requires a low-voltage electrical current for electrodeposition. This is in contrast to physical vapor deposition (PVD), which often operates at high temperatures, resulting in increased energy consumption and higher project costs.

Auxiliary Electrodes:

Auxiliary electrodes, often made from electrochemically inert materials like gold, platinum, or carbon, are used in electroplating setups. They facilitate the electrical connection between the electrolyte and the working electrode, allowing for precise current control. In two-electrode systems, the auxiliary electrode functions as a cathode when the working electrode operates as an anode, and vice versa.

Electrodeposition Technique:

Electrodeposition is a versatile technique used to deposit a wide range of materials, including copper, platinum, nickel, and gold. By controlling the current and other parameters, it is possible to deposit even a single layer of atoms. The resulting films are mechanically robust, highly flat, and uniform, exhibiting unique electrical properties due to their increased surface areas. These films find applications in various industries, including batteries, fuel cells, solar cells, and magnetic read heads.

Role of Electrode Fixtures in Welding

Electrode fixtures play a crucial role in welding processes, ensuring the efficient consumption of electrodes and the proper filling of electrode shells with electrode paste. These fixtures consist of various components that work together to optimize welding operations.

Conductive Components:

- Conductive Copper Tiles and Tubes: These components provide a low-resistance path for electrical current to flow through the electrode.

- Electrode Clamping Devices: These devices securely hold the electrode in place, ensuring proper contact with the workpiece.

- Protective Sleeves: These sleeves protect the electrode from external damage and contamination.

Cooling System:

- Cooling Water Channels: These channels circulate cooling water around the electrode to prevent overheating and maintain optimal operating temperatures.

Electrode Manipulation:

- Electrode Lifting and Pressing Device: This device adjusts the depth of electrode insertion by hanging the entire electrode and applying pressure.

- Grippers: These devices grip the electrode according to its gripping method, including pressure ring grippers, electrode combination grippers, and conical ring grippers.

Electrode Consumption and Shell Filling:

As the electrode is consumed during welding, the electrode shell must be filled with electrode paste accordingly. This ensures a continuous supply of electrode material and maintains the desired welding characteristics.

Types of Electrode Fixtures:

Depending on the welding process and electrode type, different types of electrode fixtures are used. These include:

- Stick Welding Electrode Holders: These holders are designed to hold and guide stick electrodes.

- TIG Welding Torch: The TIG welding torch acts as an electrode fixture, providing a controlled environment for the tungsten electrode.

- MIG Welding Gun: The MIG welding gun feeds and guides the continuously fed wire electrode.

Significance of Electrode Fixtures:

Properly designed and maintained electrode fixtures are essential for:

- Efficient Electrode Consumption: Optimizing the consumption of electrode material, reducing waste and production costs.

- Consistent Welding Results: Ensuring consistent welding quality by maintaining the correct electrode shape and position.

- Safety and Reliability: Providing a safe and reliable means of handling electrodes, minimizing the risk of accidents or equipment damage.

Electrode Fixtures in Electrochemical Cells

Electrochemical cells are devices that convert chemical energy into electrical energy or vice versa. They consist of two electrodes, an anode and a cathode, immersed in an electrolyte solution. The anode is the negative electrode, where oxidation occurs, and the cathode is the positive electrode, where reduction occurs.

Electrode fixtures are used to hold the electrodes in place and to ensure good electrical contact between the electrodes and the external circuit. They are typically made of a conductive material, such as copper or platinum, and are designed to minimize the resistance to the flow of current.

The design of the electrode fixtures will vary depending on the specific application. In some cases, the electrodes may be simply held in place by a clamp or screw. In other cases, the electrodes may be welded or soldered to the fixture. The choice of material for the fixture will also depend on the specific application. For example, if the cell is to be used in a corrosive environment, the fixture will need to be made of a material that is resistant to corrosion.

Electrode fixtures play an important role in the performance of electrochemical cells. By ensuring good electrical contact between the electrodes and the external circuit, they help to maximize the efficiency of the cell. They also help to protect the electrodes from damage.

Function of Electrode Fixtures

The primary function of electrode fixtures is to provide a secure and reliable connection between the electrodes and the external circuit. This is essential for ensuring the efficient flow of electrons between the electrodes and the circuit. Without a proper connection, the cell would not be able to function properly.

In addition to providing a secure connection, electrode fixtures also help to protect the electrodes from damage. The electrodes are typically made of delicate materials that can be easily damaged if they are not properly secured. The fixtures help to protect the electrodes from mechanical damage, such as bending or breaking, and from chemical damage, such as corrosion.

Design of Electrode Fixtures

The design of electrode fixtures will vary depending on the specific application. However, there are some general design principles that are common to most fixtures.

- The fixture should be made of a conductive material. This is essential for ensuring the efficient flow of electrons between the electrodes and the circuit.

- The fixture should be designed to minimize the resistance to the flow of current. This is important for maximizing the efficiency of the cell.

- The fixture should be able to securely hold the electrodes in place. This is essential for preventing the electrodes from moving during operation, which could damage the cell.

- The fixture should be able to protect the electrodes from damage. This includes protection from mechanical damage, such as bending or breaking, and from chemical damage, such as corrosion.

Materials for Electrode Fixtures

The choice of material for electrode fixtures will depend on the specific application. However, some of the most common materials used include:

- Copper is a good choice for electrode fixtures because it is a highly conductive material that is also relatively inexpensive.

- Platinum is another good choice for electrode fixtures because it is a highly conductive material that is also resistant to corrosion.

- Gold is a good choice for electrode fixtures when the cell is to be used in a corrosive environment.

- Stainless steel is a good choice for electrode fixtures when the cell is to be used in a high-temperature environment.

Conclusion

Electrode fixtures are an important part of electrochemical cells. They provide a secure and reliable connection between the electrodes and the external circuit, and they help to protect the electrodes from damage. The design of the electrode fixtures will vary depending on the specific application, but there are some general design principles that are common to most fixtures.

Related Products

- Electrode Fixture for Electrochemical Experiments

- Metal Disc Electrode Electrochemical Electrode

- Graphite Disc Rod and Sheet Electrode Electrochemical Graphite Electrode

- Gold Electrochemical Sheet Electrode Gold Electrode

- Platinum Sheet Electrode for Laboratory and Industrial Applications