battery material

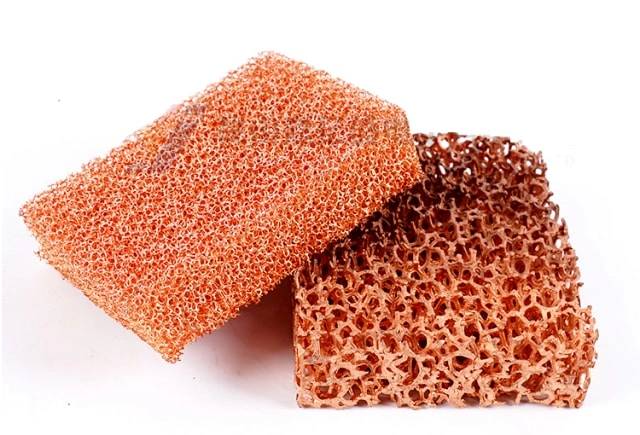

Copper Foam

Item Number : BC-25

Price varies based on specs and customizations

- Specification (mm)

- 1.5*100*100 / 1.5*100*150 / 1.5*150*200

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

Copper foam is a homogeneous three-dimensional network structure, which has the function of filtering, and the flow stability of gas and fluid is super strong. The copper skeleton is hollow and interconnected with each other in a metallurgical state. The porosity is as high as 96-98%, and the bulk density is only one-fiftieth of copper. The specific surface is extremely large, and the good physical and chemical properties of copper are still maintained. Therefore, the excellent characteristics of the new structure Make it a functional new material with a wider application field.

Key Features

- Excellent Thermal & Electrical Conductivity – ideal for electronics, motors, and batteries.

- Ultra-light & High Porosity – 96–98% porous, 1/50 the density of solid copper.

- Filtration & Catalysis – high surface area for medical filters, water purification, and catalyst support.

- Noise & EMI Control – absorbs sound and provides electromagnetic shielding.

- Easy to Process – can be cut, bent, and bonded.

Detail & Parts

Technical specifications

| Aperture: | 0.1mm-10mm (5-130ppi) |

| Porosity: | 50%-98% |

| Through hole rate: | ≥98% |

| Number of holes in inches: | 110 (110PPI) |

| Bulk density: | 0.1-0.8g/cm3 |

| Surface density G/M²: | 280-3000(±30-200) |

| Thickness (MM): | 0.1~40(0.05~1.0) |

| Number of holes PPI: | 13~1300(±5~10) |

| Length/Width/Thickness Dimensions (MM): | 70≤length and width<500(±0.5)thickness 0.1-25mm |

Available Copper Foam Specifications

The products we show are available in different sizes and custom sizes are available on request.

| Dimension (L*W*T) | |||

| 100mm*100mm*5.0mm | 100mm*100mm*6.0mm | 100mm*100mm*7.0mm | 100mm*100mm*8.0mm |

| 100mm*100mm*9.0mm | 100mm*100mm*10.0mm | 200mm*200mm*0.5mm | 200mm*200mm*1.0mm |

| 200mm*200mm*1.2mm | 200mm*200mm*1.5mm | 200mm*200mm*1.8mm | 200mm*200mm*2.0mm |

| 200mm*200mm*2.2mm | 200mm*200mm*2.5mm | 200mm*200mm*2.8mm | 200mm*200mm*3.0mm |

| 200mm*200mm*4.0mm | 200mm*200mm*5.0mm | 200mm*200mm*6.0mm | 200mm*200mm*7.0mm |

| 200mm*200mm*8.0mm | 200mm*200mm*9.0mm | 200mm*200mm*10.0mm | 200mm*300mm*0.5mm |

| 200mm*300mm*1.2mm | 200mm*300mm*1.5mm | 200mm*300mm*1.8mm | 200mm*300mm*2.0mm |

| 200mm*300mm*2.2mm | 200mm*300mm*2.5mm | 200mm*300mm*2.8mm | 200mm*300mm*3.0mm |

| 200mm*300mm*4.0mm | 200mm*300mm*5.0mm | 200mm*300mm*6.0mm | 200mm*300mm*7.0mm |

| 200mm*300mm*8.0mm | 200mm*300mm*9.0mm | 200mm*300mm*10.0mm |

Applications

- Battery & Supercapacitor Electrodes

- Catalyst Carriers & Air Purification

- Heat Sinks & Thermal Management

- Sound Absorption & EMI Shielding

- Filtration & Fluid Pressure Buffering

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is The Difference Between Copper Foam And Nickel Foam?

4.9 / 5

Incredibly lightweight yet robust! Transformed our thermal management system. The porosity is perfect for airflow.

4.8 / 5

Arrived faster than expected! The quality is exceptional, and it was so easy to cut to the exact size we needed.

4.7 / 5

A fantastic value for such a high-tech material. Our battery prototypes are performing better than ever.

4.9 / 5

The EMI shielding properties are outstanding. A truly advanced material that's surprisingly simple to work with.

4.8 / 5

So durable! It's holding up perfectly in our harsh filtration environment. Exceeded all our expectations.

4.7 / 5

The high surface area is a game-changer for our catalysis research. The material is consistently high-quality.

4.9 / 5

Perfect for sound absorption panels. The delivery was lightning-fast, and the product is precisely as described.

4.8 / 5

An incredible material that's both lightweight and highly conductive. Excellent value for the performance.

4.7 / 5

I'm amazed by how well it handles heat dissipation. A must-have for any serious electronics project.

4.9 / 5

The technological advancement in this foam is palpable. It integrated seamlessly into our prototype design.

4.8 / 5

Cutting and shaping it was a breeze. The structural integrity is impressive for something so light.

4.7 / 5

Fast shipping and a product that delivers on every promise. Our heat sink efficiency has skyrocketed.

4.9 / 5

The purity and consistency of the copper foam are remarkable. A premium product that's worth every penny.

4.8 / 5

Its versatility is astounding. We're using it for filtration and EMI shielding with fantastic results.

4.7 / 5

A revolutionary material. The high porosity makes it ideal for advanced fluid dynamics applications.

4.9 / 5

The quality is unmatched. This foam has significantly improved the longevity of our components.

4.8 / 5

Incredibly easy to process. We bonded it to other materials without any issues. Highly recommended!

4.7 / 5

Perfect for pressure buffering. The three-dimensional structure is beautifully uniform throughout.

4.9 / 5

A technological marvel. The combination of low density and high conductivity is simply brilliant.

4.8 / 5

Durable, efficient, and arrived ahead of schedule. This foam has become an essential component for us.

4.7 / 5

The value for money is exceptional. We've tested several foams, and this one outperforms them all.

4.9 / 5

The electrical conductivity is phenomenal. It's perfect for our high-performance battery electrodes.

4.8 / 5

An absolute pleasure to work with. The material is both innovative and incredibly reliable.

4.7 / 5

Fast delivery and a product that is clearly built to last. It has excellent corrosion resistance.

4.9 / 5

The pore structure is perfectly interconnected. It's the ideal catalyst support for our chemical processes.

4.8 / 5

A top-tier material that is surprisingly affordable. It has revolutionized our approach to thermal design.

4.7 / 5

The sound absorption qualities are impressive. It's a versatile material that solves multiple problems.

4.9 / 5

The quality control is evident. Every sheet we've received has been flawless and ready for immediate use.

4.8 / 5

A fantastic product backed by great service. The custom size option was a huge benefit for our project.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Copper Nickel Foam Metal Sheet

Discover the benefits of foam metal sheets for electrochemical tests. Our foam copper/nickel sheets are ideal for current collectors and capacitors.

High Purity Zinc Foil for Battery Lab Applications

There are very few harmful impurities in the chemical composition of zinc foil, and the surface of the product is straight and smooth; it has good comprehensive properties, processability, electroplating colorability, oxidation resistance and corrosion resistance, etc.

High-Purity Titanium Foil and Sheet for Industrial Applications

Titanium is chemically stable, with a density of 4.51g/cm3, which is higher than aluminum and lower than steel, copper, and nickel, but its specific strength ranks first among metals.

High Purity Gold Platinum Copper Iron Metal Sheets

Elevate your experiments with our high-purity sheet metal. Gold, platinum, copper, iron, and more. Perfect for electrochemistry and other fields.

Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

Discover the power of Molybdenum Disilicide (MoSi2) Heating Element for high-temperature resistance. Unique oxidation resistance with stable resistance value. Learn more about its benefits now!

Cylindrical Press Mold with Scale for Lab

Discover precision with our Cylindrical Press Mold. Ideal for high-pressure applications, it molds various shapes and sizes, ensuring stability and uniformity. Perfect for lab use.

Special Shape Press Mold for Lab

Discover high-pressure special shape press molds for diverse applications, from ceramics to automotive parts. Ideal for precise, efficient molding of various shapes and sizes.

Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

Zirconia insulating ceramic gasket has high melting point, high resistivity, low thermal expansion coefficient and other properties, making it an important high temperature resistant material, ceramic insulating material and ceramic sunscreen material.

Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

The PTFE funnel is a piece of laboratory equipment used primarily for filtration processes, particularly in the separation of solid and liquid phases in a mixture. This setup allows for efficient and rapid filtration, making it indispensable in various chemical and biological applications.

Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

PTFE mesh sieve is a specialized test sieve designed for particle analysis in various industries, featuring a non-metallic mesh woven from PTFE filament. This synthetic mesh is ideal for applications where metal contamination is a concern . PTFE sieves are crucial for maintaining the integrity of samples in sensitive environments, ensuring accurate and reliable results in particle size distribution analysis.

Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

Experience the advantages of Silicon Carbide (SiC) Heating Element: Long service life, high corrosion and oxidation resistance, fast heating speed, and easy maintenance. Learn more now!

Copper Sulfate Reference Electrode for Laboratory Use

Looking for a Copper Sulfate Reference Electrode? Our complete models are made of high-quality materials, ensuring durability and safety. Customization options available.

Platinum Sheet Electrode for Laboratory and Industrial Applications

Elevate your experiments with our Platinum Sheet Electrode. Crafted with quality materials, our safe and durable models can be tailored to fit your needs.

Vacuum Hot Press Furnace Machine for Lamination and Heating

Experience clean and precise lamination with Vacuum Lamination Press. Perfect for wafer bonding, thin-film transformations, and LCP lamination. Order now!

Gold Disc Electrode

Looking for a high-quality gold disc electrode for your electrochemical experiments? Look no further than our top-of-the-line product.

Hexagonal Boron Nitride HBN Ceramic Ring

Boron nitride ceramic (BN) rings are commonly used in high temperature applications such as furnace fixtures, heat exchangers and semiconductor processing.

Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

The horizontal autoclave steam sterilizer adopts the gravity displacement method to remove the cold air in the inner chamber, so that the inner steam and cold air content is less, and the sterilization is more reliable.

Silicon Carbide (SIC) Ceramic Sheet Flat Corrugated Heat Sink for Engineering Advanced Fine Ceramics

Silicon carbide (sic) ceramic heat sink not only does not generate electromagnetic waves, but also can isolate electromagnetic waves and absorb part of electromagnetic waves.

Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

Silicon carbide (sic) ceramic sheet is composed of high-purity silicon carbide and ultra-fine powder, which is formed by vibration molding and high-temperature sintering.

Related Articles

All About ACTIVATED CARBON THERMAL REGENERATION

Introduction, method and selection of activated carbon regeneration

Electrode Fixture Guide: Types, Design, and Applications

Discover the comprehensive guide to electrode fixtures, covering various types, design considerations, and their indispensable role in industries like electroplating, welding, and electrochemical cells.

Understanding Cold Isostatic Pressing: Process, Advantages and Types

Cold Isostatic Pressing (CIP), also known as cold isostatic compaction, is a materials processing technique that involves subjecting a material to uniform pressure from all sides. This is achieved by immersing the material in a high-pressure fluid medium and applying hydraulic pressure. CIP is particularly effective for shaping and consolidating powdered materials, allowing for the creation of intricate shapes and achieving high green density.

Understanding Hot Isostatic Pressing: Uses, Applications, and Specifications

Hot Isostatic Pressing (HIP) is a powerful manufacturing process that plays a crucial role in enhancing the density of ceramic materials and reducing porosity in metals. It is widely utilized in various industries, including aerospace, powder metallurgy, and component manufacturing.

The Benefits of Cold Isostatic Pressing

Cold Isostatic Pressing (CIP) is a process used to compact powders into a specific shape or size. This method involves subjecting the powders to high pressure, typically between 100 and 200 MPa, in a liquid medium.

Isostatic Pressing A Low Distortion Alternative to Extrusion

Isostatic pressing is a manufacturing process that uses high pressure to compress powdered materials into a specific shape or form.

What Makes Hot Isostatic Pressing So Effective

Hot Isostatic Pressing (HIP) is a manufacturing process that uses high temperature and pressure to improve the mechanical properties of materials. The process involves placing a part in a sealed chamber and subjecting it to high temperatures and pressures.

Isostatic Presses for Aerospace Applications

Isostatic pressing is a manufacturing process that uses pressure to create uniform parts with consistent density and strength. The process involves placing a material in a flexible container, which is then pressurized from all sides to create a uniform shape.

The Silent Geometry of Voltage: Respecting the Limits of Electrolysis

Electrolysis relies on strict electrical boundaries. Learn why exceeding rated current and voltage isn't just inefficient—it's destructive.

The Architecture of Silence: Why Material Choice Defines Electrochemical Truth

Explore how High Borosilicate Glass, PTFE, and POM create the perfect chemically inert environment for accurate electrochemical testing.