battery material

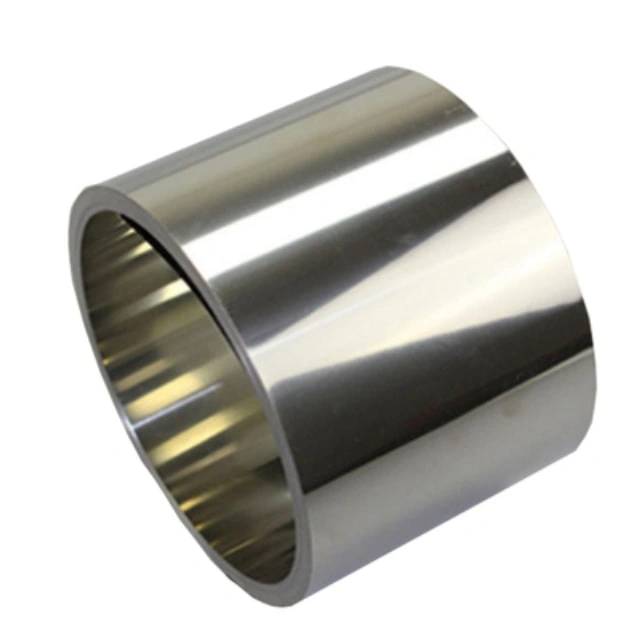

High-Purity Titanium Foil and Sheet for Industrial Applications

Item Number : BC-17

Price varies based on specs and customizations

- material

- titanium

- thickness

- 0.01-0.5mm, 2mm thickness adjustable

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

Titanium has stable chemical properties, with a density of 4.51g/cm, which is higher than aluminum and lower than steel, copper, and nickel, but its specific strength ranks first among metals. Titanium is silvery white, with light weight, high strength, metallic luster, Humid chlorine corrosion resistance and other characteristics. Same with all foils including other metals. It is a thin layer of titanium-based metal. Titanium foil is expensive because titanium itself is a very expensive metal.

- Aerospace industry; its high temperature and corrosion resistance also make it valuable in gas turbine engines and aerospace propulsion systems.

- Chemical industry: The corrosion resistance and chemical stability of titanium foil make it suitable for manufacturing chemical equipment such as reactors, distillation towers, and storage tanks. It is also used in chemical pipelines, valves, carriers of various catalysts, etc.

- Medical field; it is widely used in medical devices such as artificial joints, dental implants, and surgical instruments.

- Shipbuilding, automotive industry; increased ship strength and corrosion resistance, reduced vehicle weight, and improved fuel efficiency.

- Electronics field; it provides electromagnetic shielding and heat dissipation.

- Sporting goods; it enhances the strength and durability of products such as bicycles, golf clubs and tennis rackets.

Detail & Parts

Technical specifications

| Titanium sheet thickness / MM | ||||||

| 0.01 | 0.08 | 0.4 | 1.2 | 5 | 12 | 25 |

| 0.02 | 0.1 | 0.5 | 1.5 | 6 | 13 | 30 |

| 0.03 | 0.15 | 0.6 | 2 | 7 | 14 | 40 |

| 0.04 | 0.2 | 0.7 | 2.5 | 8 | 15 | 50 |

| 0.05 | 0.25 | 0.8 | 3 | 9 | 18 | |

| 0.06 | 0.3 | 1 | 4 | 10 | 20 | |

The products we show are available in different sizes and custom sizes are available on request.

Advantages

- Low density, high specific strength

- corrosion performance

- Good heat resistance

- Good low temperature resistance

- Strong damping resistance

- Non-magnetic, non-toxic

- The strength is close to its yield strength

- Good heat transfer performance

- Low elastic modulus

- Inspiratory performance

Trusted by Industry Leaders

FAQ

What Is Pure Titanium?

What Is Titanium Alloy?

What Are The Commonly Used Titanium Grades?

4.9 / 5

KINTEK's titanium foil is a lifesaver for our research. Its purity and durability are unmatched.

4.8 / 5

The quality of KINTEK's titanium sheets is exceptional. They are a reliable partner for our high-tech needs.

4.7 / 5

KINTEK's titanium foil has revolutionized our lab's experiments. Its consistency and purity are top-notch.

5.0 / 5

KINTEK's titanium sheets are a testament to their commitment to quality. They are a valuable asset to our research.

4.9 / 5

The purity of KINTEK's titanium foil is remarkable. It has significantly improved the accuracy of our experiments.

4.8 / 5

KINTEK's titanium sheets are a game-changer for our lab. They provide unmatched precision and reliability.

5.0 / 5

KINTEK's titanium foil is a lifesaver for our research. Its purity and durability are unmatched.

4.9 / 5

The quality of KINTEK's titanium sheets is exceptional. They are a reliable partner for our high-tech needs.

4.8 / 5

KINTEK's titanium foil has revolutionized our lab's experiments. Its consistency and purity are top-notch.

5.0 / 5

KINTEK's titanium sheets are a testament to their commitment to quality. They are a valuable asset to our research.

4.9 / 5

The purity of KINTEK's titanium foil is remarkable. It has significantly improved the accuracy of our experiments.

4.8 / 5

KINTEK's titanium sheets are a game-changer for our lab. They provide unmatched precision and reliability.

5.0 / 5

KINTEK's titanium foil is a lifesaver for our research. Its purity and durability are unmatched.

4.9 / 5

The quality of KINTEK's titanium sheets is exceptional. They are a reliable partner for our high-tech needs.

4.8 / 5

KINTEK's titanium foil has revolutionized our lab's experiments. Its consistency and purity are top-notch.

5.0 / 5

KINTEK's titanium sheets are a testament to their commitment to quality. They are a valuable asset to our research.

4.9 / 5

The purity of KINTEK's titanium foil is remarkable. It has significantly improved the accuracy of our experiments.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Platinum Sheet Electrode for Laboratory and Industrial Applications

Elevate your experiments with our Platinum Sheet Electrode. Crafted with quality materials, our safe and durable models can be tailored to fit your needs.

High Purity Zinc Foil for Battery Lab Applications

There are very few harmful impurities in the chemical composition of zinc foil, and the surface of the product is straight and smooth; it has good comprehensive properties, processability, electroplating colorability, oxidation resistance and corrosion resistance, etc.

High Purity Gold Platinum Copper Iron Metal Sheets

Elevate your experiments with our high-purity sheet metal. Gold, platinum, copper, iron, and more. Perfect for electrochemistry and other fields.

High Purity Pure Graphite Crucible for Evaporation

Vessels for high temperature applications, where materials are kept at extremely high temperatures to evaporate, allowing thin films to be deposited on substrates.

Advanced Engineering Fine Ceramics Aluminum Nitride (AlN) Ceramic Sheet

Aluminum nitride (AlN) has the characteristics of good compatibility with silicon. It is not only used as a sintering aid or reinforcing phase for structural ceramics, but its performance far exceeds that of alumina.

Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

Professional tools for cutting lithium sheets, carbon paper, carbon cloth, separators, copper foil, aluminum foil, etc., with round and square shapes and different sizes of blades.

High Purity Alumina Granulated Powder for Engineering Advanced Fine Ceramics

Ordinary alumina granulated powder is alumina particles prepared by traditional processes, with a wide range of applications and good market adaptability. This material is known for its high purity, excellent thermal stability and chemical stability, and is suitable for a variety of high-temperature and conventional applications.

Custom Boron Nitride (BN) Ceramic Parts

Boron nitride (BN) ceramics can have different shapes, so they can be manufactured to generate high temperature, high pressure, insulation and heat dissipation to avoid neutron radiation.

Advanced Engineering Fine Ceramics Alumina Ceramic Saggar for Fine Corundum

Alumina sagger products have the characteristics of high temperature resistance, good thermal shock stability, small expansion coefficient, anti-stripping, and good anti-powdering performance.

Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

Boron nitride ((BN) is a compound with high melting point, high hardness, high thermal conductivity and high electrical resistivity. Its crystal structure is similar to graphene and harder than diamond.

Related Articles

Exploring the Benefits of Using Tungsten for Furnace Heating

Tungsten has a number of properties that make it well-suited for use in high-temperature furnaces.

PTFE gasket: an all-around solution for flange sealing

Polytetrafluoroethylene (PTFE) gaskets have become an ideal choice in the field of flange sealing due to their unique chemical stability and high temperature resistance.

Advanced Surface Treatment: Titanium CVD Coating

Explores the benefits and applications of CVD coatings on titanium alloys, focusing on wear resistance, corrosion resistance, and thermal stability.

Common Sense Points for Vacuum Heat Treatment

Key considerations and practices in vacuum heat treatment processes.

Vacuum Induction Melting: Principles, Processes, and Applications

An in-depth look at the vacuum induction melting process, its characteristics, applications, and equipment structure.

Understanding Hot Presses and Safety Considerations

An overview of hot presses, their applications, advantages, and safety precautions.

Preparation Technologies and Applications of High-Purity Metals

An in-depth look at the definition, preparation technologies, and applications of high-purity metals.

Technological Innovations in the Fused Silica Industry

Explore advancements in fused silica, its applications, and future prospects.