Thin Film Deposition Parts

Custom Boron Nitride (BN) Ceramic Parts

Item Number : KM-D8

Price varies based on specs and customizations

- Material

- Boron nitride

- Specification

- Customize

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

Boron Nitride (BN) Ceramic Custom Parts are a type of advanced ceramic material that is made from boron and nitrogen. They are known for their exceptional properties, including high temperature resistance, corrosion resistance, and electrical insulation. BN Ceramic Custom Parts are used in a wide range of industries, including aerospace, automotive, and electronics. They are also used in high-temperature applications, such as crucibles for crystal growth and insulators for high-temperature furnaces.

Application

Boron Nitride (BN) ceramics are widely used in various industries due to their exceptional properties, including high-temperature resistance, corrosion resistance, and electrical insulation. These properties make BN ceramics an ideal choice for applications such as:

- Crucibles for crystal growth

- Break rings for horizontal casting machines

- Insulators for high-temperature furnaces

- Electric insulators in vacuum systems

- Feedthroughs for high voltage equipment

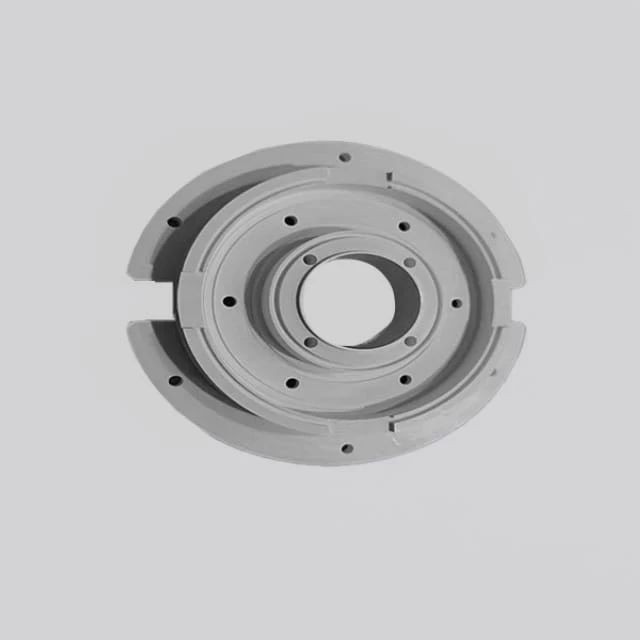

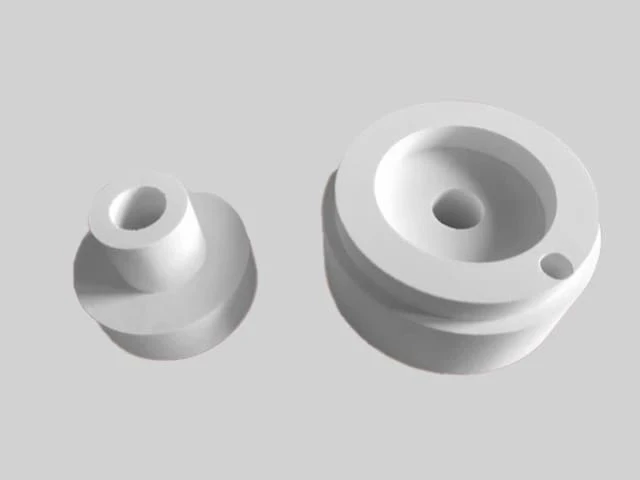

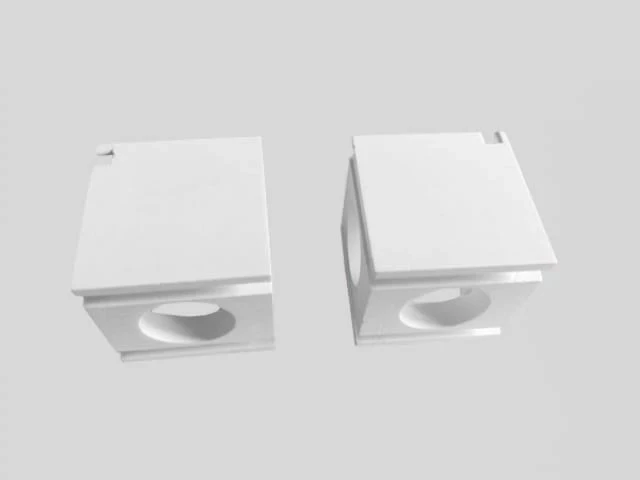

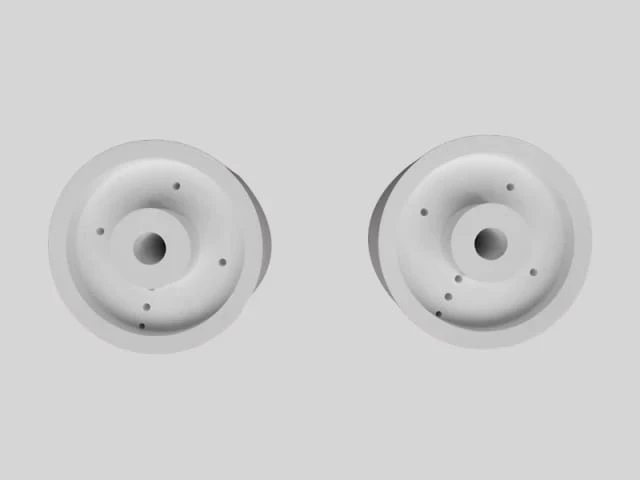

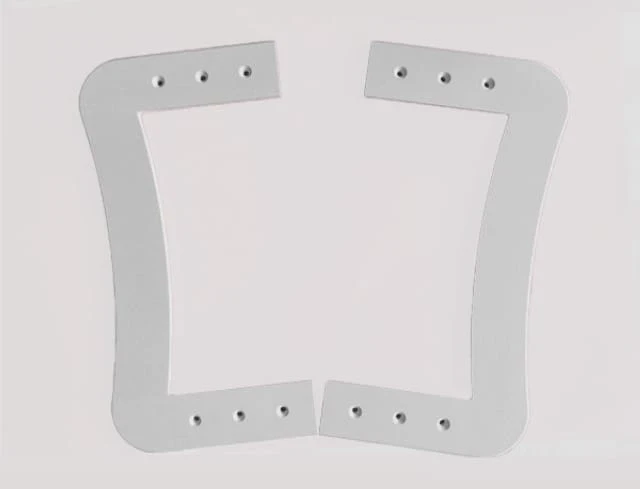

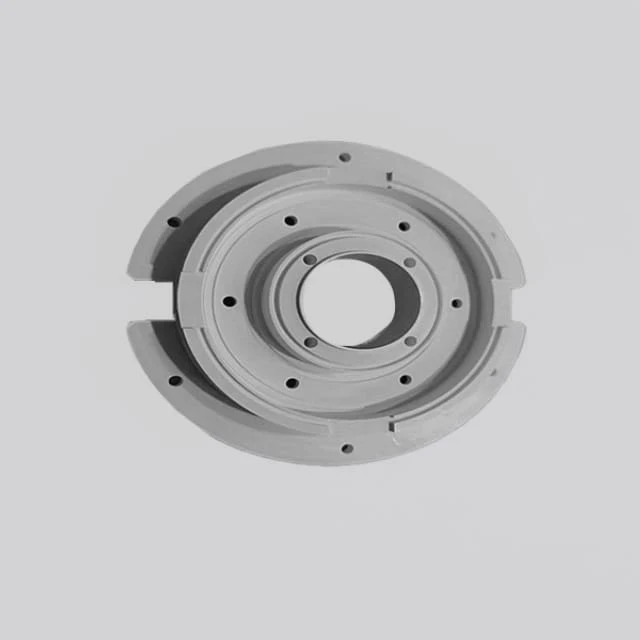

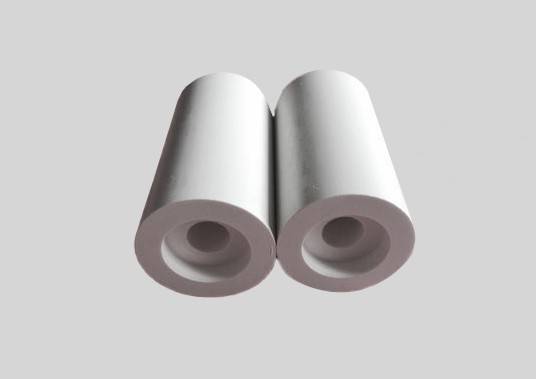

Detail & Parts

This product is a customized product, we can make it according to your needs.

Features

Boron Nitride (BN) Ceramic Custom Parts feature a unique combination of properties that make them ideal for a wide range of applications. These properties include:

- High-temperature resistance: BN ceramics can withstand temperatures up to 1800°C (3272°F), making them suitable for use in high-heat applications such as crucibles, break rings, and insulators.

- Corrosion resistance: BN ceramics are highly resistant to corrosion, making them ideal for use in harsh environments such as chemical processing and vacuum systems.

- Electrical resistance: BN ceramics are excellent electrical insulators, making them suitable for use in high-voltage applications such as feedthroughs and insulators.

- Machinability: BN ceramics can be easily machined into complex shapes, making them suitable for use in a wide range of applications.

Trusted by Industry Leaders

FAQ

What Are The Applications Of Boron Nitride Ceramic Parts?

What Are The Advantages Of Using Boron Nitride Ceramic Parts?

What Considerations Should Be Made When Selecting Boron Nitride Ceramic Parts?

What Manufacturing Processes Are Used To Produce Boron Nitride Ceramic Parts?

4.9 / 5

I highly recommend this product! It's durable and performs well under high temperatures.

4.7 / 5

This product is a great value for the price. It's well-made and has exceeded my expectations.

4.8 / 5

I'm amazed by the quality of this product. It's a game-changer for my laboratory.

4.6 / 5

This product has significantly improved the efficiency of my laboratory. I highly recommend it.

4.9 / 5

I'm thoroughly impressed with this product's performance. It's a must-have for any laboratory.

4.8 / 5

This product is a testament to the company's commitment to quality. It's a valuable addition to my laboratory.

4.7 / 5

I'm highly satisfied with the durability of this product. It's a reliable choice for demanding applications.

4.9 / 5

This product's technological advancements have revolutionized my laboratory work. Highly recommended!

4.8 / 5

I'm amazed by the speed of delivery. It arrived much sooner than expected. Thank you for the excellent service.

4.7 / 5

The quality of this product is exceptional. It's a testament to the company's dedication to manufacturing excellence.

4.9 / 5

This product has exceeded my expectations. It's a valuable investment for any laboratory.

4.8 / 5

I'm highly impressed with the durability of this product. It's a reliable choice for demanding applications.

4.7 / 5

This product has revolutionized my laboratory work. It's a must-have for any laboratory manager.

4.9 / 5

The technological advancements in this product are remarkable. It's a game-changer for my laboratory.

4.8 / 5

I'm thrilled with the value for money this product offers. It's an excellent investment for any laboratory.

4.7 / 5

This product has significantly improved the efficiency of my laboratory. I highly recommend it.

4.9 / 5

I'm amazed by the speed of delivery. It arrived much sooner than expected. Thank you for the excellent service.

4.8 / 5

The quality of this product is exceptional. It's a testament to the company's dedication to manufacturing excellence.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Square Lab Press Mold for Laboratory Applications

Create uniform samples easily with Square Lab Press Mold - available in various sizes. Ideal for battery, cement, ceramics, and more. Custom sizes available.

Related Articles

CVD furnace for the growth of carbon nanotubes

Chemical vapor deposition (CVD) furnace technology is a widely used method for growing carbon nanotubes.

The Benefits of Cold Isostatic Pressing

Cold Isostatic Pressing (CIP) is a process used to compact powders into a specific shape or size. This method involves subjecting the powders to high pressure, typically between 100 and 200 MPa, in a liquid medium.

The Future of Lab Presses in Research and Development

Lab presses are an essential tool in research and development for a wide range of industries, including pharmaceuticals, materials science, and electronics.

Hexagonal Boron Nitride: Enhancing Performance in Composite Ceramic Materials

Explores the role of h-BN in various composite ceramics, highlighting its properties and applications.

Guidelines for the Use of Boron Nitride Crucibles

Instructions on the proper use, precautions, and compatibility of boron nitride crucibles.

Introduction to Various Ceramic Crucibles

An overview of different types of ceramic crucibles, their properties, and applications.

Precision Ceramics in Semiconductor Applications

Exploring the use of precision ceramics in semiconductor equipment, their properties, and manufacturing processes.

Applications and Advances in Vacuum Hot Press Sintering Furnaces for Precision Ceramics

Explores the use of vacuum hot press sintering for advanced ceramics, metal/ceramic welding, and industry trends.

Advancements in Engineering Ceramic Materials

Explores new engineering ceramics with exceptional properties and applications in harsh environments, comparing them to traditional materials.

Comparison of Pyrolytic Graphite and Pyrolytic Boron Nitride Crucibles

A detailed comparison of pyrolytic graphite and pyrolytic boron nitride crucibles, focusing on their preparation processes, characteristics, and applications.

Precision Ceramic Materials for Energy Conversion Applications

Overview of various ceramic materials used in energy conversion technologies, including heaters, piezoelectric ceramics, and solid oxide fuel cells.

Structure and Properties of High-Temperature Engineering Ceramics

Explore the applications, structural features, and performance advantages of high-temperature engineering ceramics across various industries.