Hot Press Sintering of Advanced Ceramics

Challenges in Boron Carbide Sintering

The sintering of pure boron carbide presents significant challenges due to its highly covalent bonding nature, which necessitates temperatures exceeding 2200°C for effective densification. Traditional sintering methods, despite their widespread use, typically achieve only 80-87% relative density, falling short of the desired material properties. This limitation stems from the low diffusion coefficient inherent in boron carbide, making it difficult to achieve adequate densification through conventional means.

To overcome these hurdles, the incorporation of sintering additives and the adoption of specialized processes have become essential. These additives serve to either reduce surface energy or increase surface area, facilitating better densification. Among the various techniques, hot pressing sintering has emerged as the most effective method for manufacturing boron carbide and its composites. This method, when combined with appropriate additives, can significantly enhance the densification rate, resulting in materials that approach their theoretical density.

Experimental data further underscore the effectiveness of these approaches. For instance, hot-pressing and sintering at 2150°C for just 10 minutes have been shown to yield boron carbide ceramics with a relative density of 91.6%. This improvement is reflected not only in the density but also in the mechanical properties, such as a Young's modulus of 292.5 GPa and a Poisson's ratio of 0.16 at room temperature. Additionally, within the temperature range of 0-1000°C, the linear expansion coefficient remains proportional to temperature, while thermal conductivity exhibits a decreasing trend.

| Sintering Condition | Relative Density (%) | Young's Modulus (GPa) | Poisson's Ratio |

|---|---|---|---|

| 2150°C, 10 min | 91.6 | 292.5 | 0.16 |

The use of hot pressing sintering with additives not only addresses the densification challenges but also paves the way for the production of high-performance boron carbide ceramics, which are crucial for various engineering applications.

Advantages of Hot Press Sintering

Hot press sintering with additives plays a pivotal role in enhancing the densification rates and overall product properties of boron carbide ceramics. This technique achieves remarkable improvements, reaching up to 91.6% relative density, which is a significant leap from traditional methods that typically yield only 80-87% relative density.

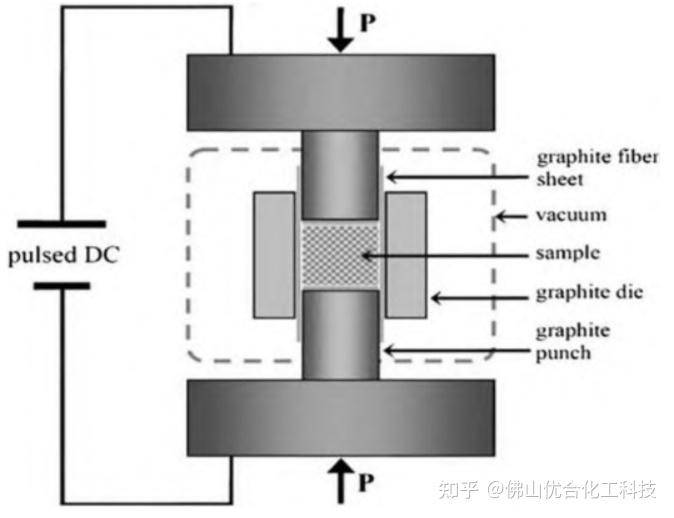

Hot press sintering involves simultaneous heating and pressurization, which significantly reduces the sintering temperature by approximately 100°C to 150°C compared to normal pressure sintering. This reduction in temperature is complemented by a substantial increase in the driving force for sintering, which is 20 to 100 times greater than under normal pressure conditions. The process leverages the thermoplastic state of the powder, where deformation resistance is minimal, facilitating easy plastic flow and densification. Consequently, the required molding pressure is only about 1/10 of that needed for cold pressing methods.

The benefits of hot press sintering extend beyond mere densification. The simultaneous application of heat and pressure aids in the mass transfer processes between powder particles, including contact, diffusion, and flow. This not only shortens the sintering time but also inhibits grain growth, resulting in a fine-grained structure. Moreover, this method can produce sintered bodies that are nearly at theoretical density, with porosity approaching zero, making it highly effective for creating high-quality ceramics.

In summary, hot press sintering stands out for its ability to achieve superior densification and product quality, making it an indispensable technique in the realm of advanced ceramics.

Target Hot Press Sintering

Powder Metallurgy for Target Preparation

Powder metallurgy, particularly vacuum hot pressing, plays a crucial role in the preparation of refractory metal and inorganic non-metallic targets. This method is indispensable for materials that cannot be effectively produced using traditional melt casting techniques. For instance, when dealing with alloys composed of metals with significantly different melting points and densities, melt casting often results in non-uniform compositions. Similarly, inorganic non-metallic targets and composite materials present challenges that are best addressed through powder metallurgy.

The advantages of powder metallurgy in target preparation are manifold. It facilitates the creation of a uniform fine crystal structure, which is essential for enhancing the performance of sputtering targets. Additionally, this technique offers high production efficiency and material savings, making it both cost-effective and resource-efficient. As a result, powder metallurgy has become the predominant method for preparing sputtering targets, particularly in industries requiring high precision and performance.

| Advantage | Description |

|---|---|

| Uniform Fine Crystal Structure | Ensures consistent material properties, crucial for high-performance targets. |

| High Production Efficiency | Accelerates the manufacturing process, meeting industrial demands efficiently. |

| Material Savings | Reduces waste and raw material usage, contributing to cost-effectiveness. |

In summary, powder metallurgy, with its ability to overcome the limitations of conventional methods, stands out as the preferred technique for preparing sputtering targets. Its ability to deliver uniform, high-quality materials at a reduced cost and with increased efficiency makes it an indispensable tool in advanced manufacturing processes.

Vacuum Hot Pressing Applications

Vacuum hot pressing is a versatile technique primarily utilized for manufacturing large, high-density planar targets, effectively surpassing the limitations inherent in traditional melt casting methods. This process is particularly advantageous for materials that require a pore-free state, ensuring optimal mechanical, thermal, or optical properties.

Key Applications

- Ceramic Materials: Vacuum hot pressing is extensively used in the production of various ceramic materials, including:

- Composite Materials: Materials like Metal Matrix Composites (MMCs) and Ceramic Matrix Composites (CMCs) are manufactured with this technique.

- Advanced Ceramics: This includes silicon nitride, mixed ceramics of Al2O3, TiC/TiN, and sialon, which are crucial for cutting tools, heavy-duty valve components, bearings, and wear-resistant parts in process technology.

- Boron Carbide (B4C): Known for its extreme wear resistance, B4C is used in armor applications and high-stress wear parts.

- Functional Ceramics: Materials like PLZT (lead-lanthanum-zirconate-titanate) and other advanced functional ceramics are processed under controlled atmospheres, such as O2.

Process Capabilities

- Shape Complexity: While primarily suited for simple shapes like plates, blocks, and cylinders, vacuum hot pressing can accommodate more complex geometries with advanced die designs.

- Pressing Force and Temperature: The process operates within a broad range of pressures (50 kN to 800 tons) and temperatures (up to 2600°C), making it adaptable to a wide array of materials and component sizes (up to Ø 1500mm).

Advantages Over Traditional Methods

- Densification: Under high temperature and pressure, raw material particles bond, leading to significant grain growth and a reduction in voids and grain boundaries. This results in a compact, polycrystalline sintered body with a specific microstructure, enhancing material density and performance.

- Versatility: The process can accommodate various heating elements, such as graphite, molybdenum, and induction heating, and can be configured for one-way or two-way pressurization, providing flexibility in material processing.

Vacuum hot pressing thus emerges as a critical technology in the realm of advanced ceramics, offering precision and efficiency in the production of high-performance materials.

Metal/Ceramic Diffusion Welding Connection

Challenges in Metal/Ceramic Welding

The integration of metals and ceramics through welding presents significant challenges due to the inherent differences in their chemical bonding structures and thermal properties. Ceramics typically exhibit covalent or ionic bonding, while metals are characterized by metallic bonding. This fundamental difference in bonding mechanisms leads to disparate mechanical and thermal behaviors, complicating the welding process.

One of the primary difficulties is the large coefficients of linear expansion between ceramics and metals. Ceramics generally have lower coefficients of thermal expansion compared to metals, which can lead to substantial thermal stresses during the welding process. These stresses can cause cracking or delamination in the ceramic component, or even failure of the weld joint. To mitigate these issues, it is often necessary to incorporate thermal stress relief mechanisms, such as controlled heating and cooling cycles, to minimize the risk of thermal shock.

In addition to thermal stresses, the need for intermediate layers cannot be overstated. These layers serve as a bridge between the dissimilar materials, facilitating better adhesion and reducing the risk of thermal mismatch. Commonly used intermediate layers include materials like titanium or nickel alloys, which have properties that are more compatible with both ceramics and metals. The selection of an appropriate intermediate layer is crucial, as it must possess good thermal conductivity, mechanical strength, and chemical compatibility with both the ceramic and metal components.

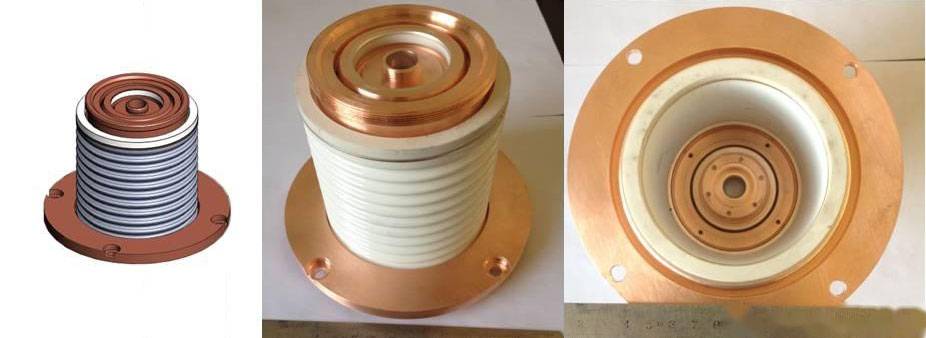

The use of vacuum hot press sintering furnaces can play a pivotal role in addressing these challenges. By applying controlled pressure and temperature in a vacuum environment, these furnaces can enhance the diffusion bonding process, ensuring a more uniform and robust weld joint. This method not only helps in managing thermal stresses but also improves the overall quality and reliability of the weld, making it suitable for high-temperature and high-stress applications.

In summary, the welding of metals and ceramics is fraught with challenges, primarily stemming from their differing chemical bonding structures and thermal expansion coefficients. Effective solutions often involve the use of thermal stress relief techniques and the incorporation of intermediate layers, facilitated by advanced sintering technologies like vacuum hot press sintering. These strategies collectively aim to create a stable and durable weld joint, capable of withstanding the rigors of various industrial applications.

Solid-Phase Diffusion Connection

Solid-phase diffusion connection stands out as a robust welding technique, particularly valued for its ability to create joints with exceptional stability and high strength. This method is particularly well-suited for environments that demand resilience against extreme temperatures and corrosive agents. However, the effectiveness of this technique hinges on the meticulous preparation of surface conditions and the utilization of specialized equipment.

For instance, the precise alignment and surface preparation of the materials are crucial to ensure that the diffusion process occurs uniformly, thereby enhancing the joint's durability. This level of precision is often facilitated by advanced machinery that can control temperature and pressure with high accuracy, ensuring that the materials undergo the necessary transformations without compromising their structural integrity.

Moreover, the application of solid-phase diffusion connection in high-temperature and corrosive environments is not without its challenges. The materials involved must be selected carefully to ensure compatibility, and intermediate layers may be necessary to mitigate the differences in thermal expansion coefficients between the ceramic and metal components. Despite these complexities, the method's ability to produce high-quality, reliable joints makes it a preferred choice in industries where performance under severe conditions is paramount.

Hot Press Sintering Technology Development Trends

Current Applications and Challenges

Hot press sintering, while widely utilized, faces significant hurdles due to its high operational costs and technical complexities. Despite these limitations, it has proven to be indispensable in niche sectors such as nuclear and military industries, where stringent material requirements are paramount. The technique's success in these fields underscores its potential, even as it grapples with economic and technological constraints.

In the realm of advanced ceramics, hot press sintering has been particularly effective in achieving high densification rates, as evidenced by its application in boron carbide ceramics. However, the process often necessitates the use of additives to enhance densification, which can add to the overall cost and complexity. This dual-edged sword—effective yet expensive—highlights the ongoing challenges in making hot press sintering more accessible and cost-effective for broader industrial applications.

Moreover, the technical constraints of hot press sintering are not just limited to cost. The process often requires precise temperature control and pressure application, which can be challenging to manage consistently. These technical hurdles necessitate advanced equipment and skilled operators, further complicating its widespread adoption. Despite these challenges, the method's ability to produce high-quality, dense ceramics makes it a valuable tool in industries where material integrity is critical.

Future Directions

The future of vacuum hot press sintering furnaces lies in the integration of cutting-edge technologies such as digital modeling and artificial intelligence (AI) automation. These advancements are poised to revolutionize the field, addressing existing technical challenges and enhancing the efficiency and precision of the sintering process.

One of the primary areas where AI can make a significant impact is in the optimization of isostatic pressing molds. Current methods often struggle with achieving uniform pressure distribution, which can lead to inconsistencies in the final product. AI-driven simulations and predictive models can analyze vast amounts of data to identify optimal pressure distribution patterns, ensuring that every part of the mold receives the necessary pressure. This not only improves the quality of the sintered ceramics but also reduces the likelihood of defects and failures.

Moreover, AI can be leveraged to automate the monitoring and control of sintering parameters. By continuously analyzing real-time data from sensors embedded within the furnace, AI systems can make instant adjustments to temperature, pressure, and other critical variables. This dynamic control ensures that the sintering process remains within the optimal range, leading to more consistent and high-quality outcomes.

In addition to AI, advancements in digital modeling are expected to play a crucial role. Computer-aided design (CAD) and finite element analysis (FEA) can be used to simulate the sintering process before it even begins. These simulations can predict how different materials will behave under various conditions, allowing engineers to fine-tune their processes and materials selection. This preemptive approach can significantly reduce the time and cost associated with trial-and-error experimentation, accelerating the development of new and improved ceramic products.

The convergence of these technologies is not just about overcoming current limitations; it is about setting the stage for entirely new possibilities in the field of vacuum hot press sintering. As these tools become more sophisticated and accessible, they will enable researchers and manufacturers to push the boundaries of what is possible, leading to innovations that could transform industries reliant on advanced ceramics.

Related Products

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Dental Porcelain Sintering Furnace

Related Articles

- How Vacuum Induction Melting Ensures Unmatched Reliability in Critical Industries

- Exploring the Advanced Capabilities of Spark Plasma Sintering (SPS) Furnaces

- Comprehensive Guide to Vacuum Hot Press Furnace Application

- How Vacuum Induction Melting (VIM) Transforms High-Performance Alloy Production

- How Vacuum Induction Melting Outperforms Traditional Methods in Advanced Alloy Production