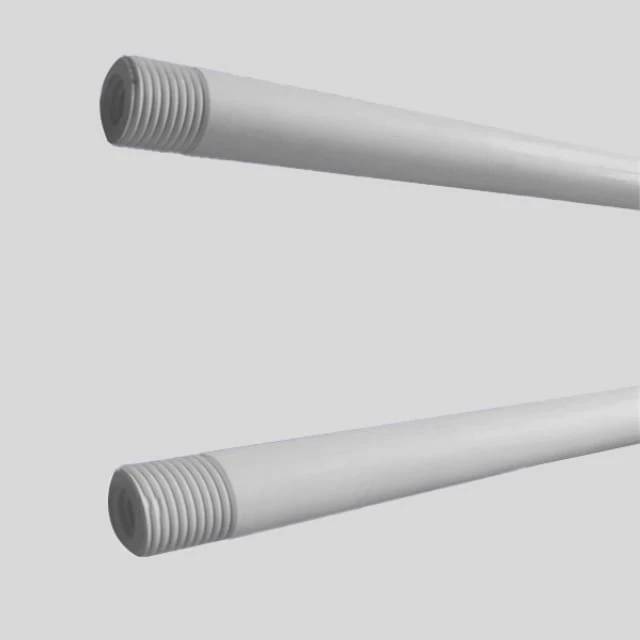

Thin Film Deposition Parts

Boron Nitride (BN) Ceramic Tube

Item Number : KM-D5

Price varies based on specs and customizations

- Material

- Boron nitride

- Specification

- Customizable

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

The boron nitride (BN) tube is made of hot-pressed boron nitride ceramics, which has excellent electrical insulation, and the breakdown voltage is 3-4 times higher than that of alumina ceramics. Suitable for insulation applications, these tubes are resistant to high temperatures and thermal shock. They can operate at temperatures up to 2100°C under atmospheric protection and up to 1900°C under vacuum without rupture. However, their lower hardness makes them unsuitable for abrasion-resistant or high-impact applications.

- High temperature furnace fixture

- Gas Atomizing Nozzle

- Soft magnetic nozzle

- Plasma arc insulator

- Crucible or vessel for melting metal or glass

- Continuous casting broken ring

- Electrical insulators in vacuum equipment

- PVD/CVD vacuum coating equipment

- Semiconductor device

- Thermocouple protection tube

It is also suitable for industries such as semiconductor melting, metallurgy, semiconductor cooling, high temperature bearings, glass forming molds, etc.

Detail & Parts

The products we display are available in different sizes and custom sizes are available upon request.

Advantages

- Low wettability to molten metal

- Low dielectric constant

- High dielectric strength

- High thermal conductivity

- Low coefficient of thermal expansion

- High thermal shock resistance

- Extremely high operating temperature (>3000°C) with inert gas protection

- Suitability for Chemical Vapor Deposition (CVD)

- Good machinability

Trusted by Industry Leaders

FAQ

Performance Comparison Of Boron Nitride Ceramics And Alumina Ceramics.

4.9 / 5

Rapid delivery and professional packaging. The BN tubes are precisely crafted and meet our lab's stringent requirements.

4.8 / 5

Excellent value for money! The quality of the ceramic tubes is top-notch, ensuring accurate and reliable results in our experiments.

4.7 / 5

KINTEK's BN tubes are durable and withstand high temperatures, making them ideal for our demanding research applications.

4.6 / 5

The technological advancement of these ceramic tubes is impressive. They enable us to conduct groundbreaking research with enhanced efficiency.

4.8 / 5

KINTEK's customer service is outstanding. They promptly addressed our queries and provided valuable technical support.

4.9 / 5

The BN tubes arrived in perfect condition, thanks to the secure packaging. KINTEK's commitment to quality is evident in every aspect.

4.7 / 5

The delivery was incredibly fast, and the BN tubes were meticulously packaged. KINTEK's attention to detail is commendable.

4.6 / 5

These ceramic tubes are a game-changer in our lab. Their exceptional quality and durability have significantly improved our research outcomes.

4.8 / 5

KINTEK's BN tubes are a valuable investment. Their superior quality and adaptability make them worth every penny.

4.9 / 5

The technological innovation behind these ceramic tubes is remarkable. They have revolutionized our research capabilities and opened up new avenues for exploration.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

Due to the characteristics of boron nitride itself, the dielectric constant and dielectric loss are very small, so it is an ideal electrical insulating material.

Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

Boron nitride ((BN) is a compound with high melting point, high hardness, high thermal conductivity and high electrical resistivity. Its crystal structure is similar to graphene and harder than diamond.

Hexagonal Boron Nitride HBN Ceramic Ring

Boron nitride ceramic (BN) rings are commonly used in high temperature applications such as furnace fixtures, heat exchangers and semiconductor processing.

Boron Nitride (BN) Ceramic Plate

Boron nitride (BN) ceramic plates do not use aluminum water to wet, and can provide comprehensive protection for the surface of materials that directly contact molten aluminum, magnesium, zinc alloys and their slag.

Boron Nitride (BN) Ceramic Rod for High Temperature Applications

Boron nitride (BN) rod is the strongest boron nitride crystal form like graphite, which has excellent electrical insulation, chemical stability and dielectric properties.

Hexagonal Boron Nitride HBN Thermocouple Protection Tube

Hexagonal boron nitride ceramics is an emerging industrial material. Because of its similar structure to graphite and many similarities in performance, it is also called "white graphite".

Hexagonal Boron Nitride HBN Spacer Cam Profile and Various Spacer Types

Hexagonal boron nitride (HBN) gaskets are made from hot-pressed boron nitride blanks. Mechanical properties similar to graphite, but with excellent electrical resistance.

Advanced Engineering Fine Ceramics Aluminum Nitride (AlN) Ceramic Sheet

Aluminum nitride (AlN) has the characteristics of good compatibility with silicon. It is not only used as a sintering aid or reinforcing phase for structural ceramics, but its performance far exceeds that of alumina.

High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

High temperature alumina furnace tube combines the advantages of high hardness of alumina, good chemical inertness and steel, and has excellent wear resistance, thermal shock resistance and mechanical shock resistance.

Precision Machined Silicon Nitride (SiN) Ceramic Sheet for Engineering Advanced Fine Ceramics

Silicon nitride plate is a commonly used ceramic material in the metallurgical industry due to its uniform performance at high temperatures.

Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

Experience efficient material processing with our vacuum-sealed rotary tube furnace. Perfect for experiments or industrial production, equipped with optional features for controlled feeding and optimized results. Order now.

Precision Machined Yttrium Stabilized Zirconia Ceramic Rod for Engineering Advanced Fine Ceramics

Zirconia ceramic rods are prepared by isostatic pressing, and a uniform, dense and smooth ceramic layer and transition layer are formed at high temperature and high speed.

Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

Zirconia insulating ceramic gasket has high melting point, high resistivity, low thermal expansion coefficient and other properties, making it an important high temperature resistant material, ceramic insulating material and ceramic sunscreen material.

Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

Experience top-notch sintering with Chairside Sintering Furnace with Transformer. Easy to operate, noise-free pallet, and automatic temperature calibration. Order now!

Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

KT-CTF14 Multi Heating Zones CVD Furnace - Precise Temperature Control and Gas Flow for Advanced Applications. Max temp up to 1200℃, 4 channels MFC mass flow meter, and 7" TFT touch screen controller.

Related Articles

CVD furnace for the growth of carbon nanotubes

Chemical vapor deposition (CVD) furnace technology is a widely used method for growing carbon nanotubes.

Hexagonal Boron Nitride: Enhancing Performance in Composite Ceramic Materials

Explores the role of h-BN in various composite ceramics, highlighting its properties and applications.

Molybdenum Vacuum Furnace: High-Temperature Sintering and Heat Treatment

Explore the advanced features and applications of molybdenum vacuum furnaces in high-temperature sintering and heat treatment. Learn about their construction, control systems, and maintenance tips.

Guidelines for the Use of Boron Nitride Crucibles

Instructions on the proper use, precautions, and compatibility of boron nitride crucibles.

Comparison of Pyrolytic Graphite and Pyrolytic Boron Nitride Crucibles

A detailed comparison of pyrolytic graphite and pyrolytic boron nitride crucibles, focusing on their preparation processes, characteristics, and applications.

Applications and Advances in Vacuum Hot Press Sintering Furnaces for Precision Ceramics

Explores the use of vacuum hot press sintering for advanced ceramics, metal/ceramic welding, and industry trends.

Structure and Properties of High-Temperature Engineering Ceramics

Explore the applications, structural features, and performance advantages of high-temperature engineering ceramics across various industries.

Common Sense Points for Vacuum Heat Treatment

Key considerations and practices in vacuum heat treatment processes.

Why Your Ceramic Furnace Tubes Keep Cracking—And How to Choose the Right One

Tired of failed experiments from cracked ceramic tubes? Learn the real reason it happens and how to select the correct material (Alumina, Quartz) for your lab.

Entropy and the Alumina Tube: The Art of Precision Maintenance

Discover the disciplined approach to cleaning alumina furnace tubes. Learn how to prevent thermal shock, remove residue with acid, and extend equipment life.

Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit

Frustrated by failed experiments? Learn why your furnace tube material—not your process settings—is the critical variable causing inconsistent results.