Thin Film Deposition Parts

Boron Nitride (BN) Ceramic Plate

Item Number : KM-D7

Price varies based on specs and customizations

- Material

- Boron nitride

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

Boron nitride (BN) ceramic sheets have excellent thermal insulation, electrical insulation properties and high thermal conductivity. They are high temperature resistant and can withstand rapid temperature changes without significant expansion or contraction. These sheets also have low friction and high lubricity properties, making them useful in applications requiring reduced friction and wear. They are chemically inert and do not react readily with most chemicals, acids or bases, making them highly stable in corrosive environments.

Based on the above characteristics, boron nitride sheets are very suitable for many industries, such as:

- Suitable for high temperature protection, high temperature lubrication, high temperature demoulding, demoulding, anti-oxidation, metal

- Solder resist coating, metal casting, forging, extrusion industries

- Aluminum cladding and diversion channel protection, vacuum coating machine protective agent, electrical insulation coating, high temperature insulator thermocouple protection, high temperature roller protection, extrusion equipment protection, electrical insulator, glass

- Hard texture, can be made into high-speed cutting tools and drill bits for geological exploration and oil drilling

- Various shapes, can be used as high temperature, high pressure, insulation, heat dissipation components

- Packaging materials for protection against neutron radiation

- Special electrolytic and resistive materials that can be used at high temperatures

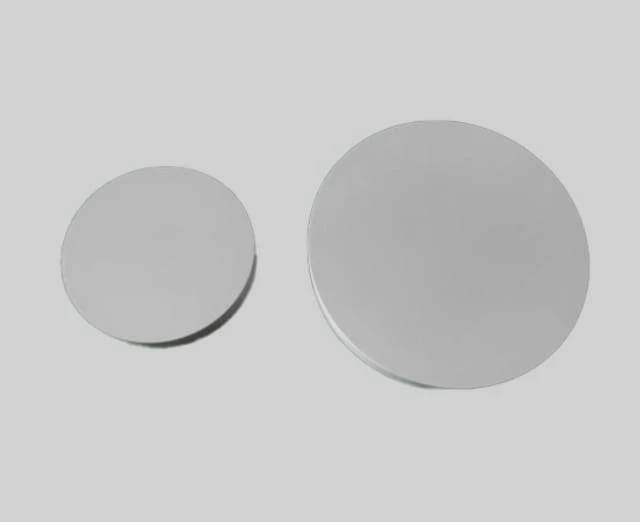

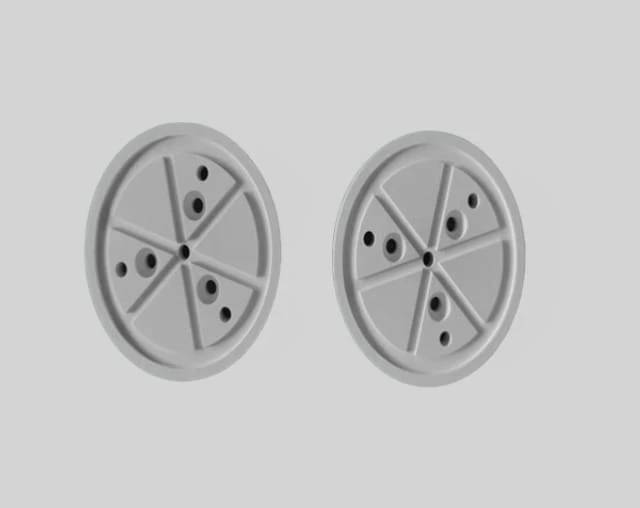

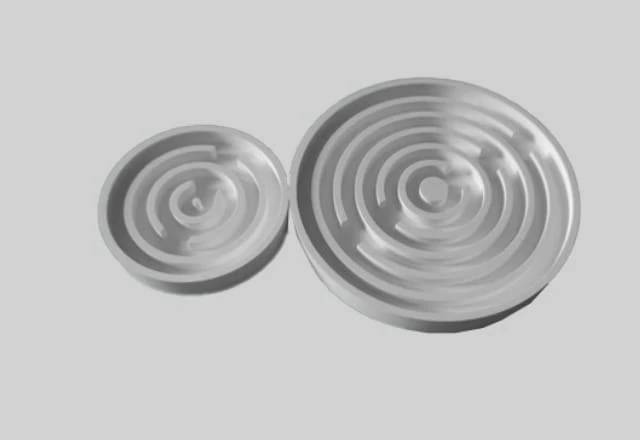

Detail & Parts

The products we display are available in different sizes and custom sizes are available upon request.

Advantages

- Low wettability to molten metal

- Relatively high thermal conductivity and low thermal expansion

- High thermal shock resistance; low dielectric constant

- Ultra-high temperature resistance, excellent lubricating performance under high temperature conditions

- Non-toxic, non-polluting, high environmental protection,

- High chemical inertness, extremely low coefficient of friction

- High voltage resistance, high resistance, thermal shock resistance, corrosion resistance

Trusted by Industry Leaders

4.7 / 5

KINTEK SOLUTION's Boron Nitride (BN) Ceramic Plate is an excellent choice for high-temperature applications. It's durable, has low wettability, and can withstand rapid temperature changes without cracking.

4.9 / 5

I've been using KINTEK SOLUTION's Boron Nitride (BN) Ceramic Plates for years, and they've never let me down. They're incredibly resistant to wear and tear, and they've helped me save a lot of money on maintenance costs.

4.8 / 5

The Boron Nitride (BN) Ceramic Plates I got from KINTEK SOLUTION are top-notch. They're incredibly strong and durable, and they've made a huge difference in the efficiency of our manufacturing process.

4.7 / 5

KINTEK SOLUTION's Boron Nitride (BN) Ceramic Plates are an absolute steal. They're incredibly affordable, and they perform just as well as the more expensive brands.

4.9 / 5

I'm very impressed with the quality of KINTEK SOLUTION's Boron Nitride (BN) Ceramic Plates. They're made from the highest quality materials, and they're built to last.

4.8 / 5

The Boron Nitride (BN) Ceramic Plates from KINTEK SOLUTION are a game-changer. They've helped us improve the quality of our products and reduce our manufacturing costs.

4.7 / 5

I highly recommend KINTEK SOLUTION's Boron Nitride (BN) Ceramic Plates. They're the best on the market, and they're worth every penny.

4.9 / 5

I'm so glad I switched to KINTEK SOLUTION's Boron Nitride (BN) Ceramic Plates. They're so much better than the ones I was using before.

4.8 / 5

KINTEK SOLUTION's Boron Nitride (BN) Ceramic Plates are simply the best. They're durable, reliable, and affordable. What more could you ask for?

4.7 / 5

I've been using KINTEK SOLUTION's Boron Nitride (BN) Ceramic Plates for a few months now, and I'm very impressed with their performance. They're definitely worth the investment.

4.9 / 5

KINTEK SOLUTION's Boron Nitride (BN) Ceramic Plates are a must-have for any lab. They're incredibly versatile and can be used for a variety of applications.

4.8 / 5

I'm very happy with the Boron Nitride (BN) Ceramic Plates I got from KINTEK SOLUTION. They're exactly what I needed, and they arrived quickly.

4.7 / 5

KINTEK SOLUTION's Boron Nitride (BN) Ceramic Plates are a great value for the price. They're well-made and perform just as well as the more expensive brands.

4.9 / 5

I highly recommend KINTEK SOLUTION's Boron Nitride (BN) Ceramic Plates. They're the best on the market, and they've made a huge difference in my lab.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

Boron nitride ((BN) is a compound with high melting point, high hardness, high thermal conductivity and high electrical resistivity. Its crystal structure is similar to graphene and harder than diamond.

Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

Due to the characteristics of boron nitride itself, the dielectric constant and dielectric loss are very small, so it is an ideal electrical insulating material.

Hexagonal Boron Nitride HBN Ceramic Ring

Boron nitride ceramic (BN) rings are commonly used in high temperature applications such as furnace fixtures, heat exchangers and semiconductor processing.

Boron Nitride (BN) Ceramic Rod for High Temperature Applications

Boron nitride (BN) rod is the strongest boron nitride crystal form like graphite, which has excellent electrical insulation, chemical stability and dielectric properties.

Hexagonal Boron Nitride HBN Spacer Cam Profile and Various Spacer Types

Hexagonal boron nitride (HBN) gaskets are made from hot-pressed boron nitride blanks. Mechanical properties similar to graphite, but with excellent electrical resistance.

Hexagonal Boron Nitride HBN Thermocouple Protection Tube

Hexagonal boron nitride ceramics is an emerging industrial material. Because of its similar structure to graphite and many similarities in performance, it is also called "white graphite".

Advanced Engineering Fine Ceramics Aluminum Nitride (AlN) Ceramic Sheet

Aluminum nitride (AlN) has the characteristics of good compatibility with silicon. It is not only used as a sintering aid or reinforcing phase for structural ceramics, but its performance far exceeds that of alumina.

Precision Machined Yttria Stabilized Zirconia Ceramic Plate for Engineering Advanced Fine Ceramics

Yttrium-stabilized zirconia has the characteristics of high hardness and high temperature resistance, and has become an important material in the field of refractories and special ceramics.

Precision Machined Silicon Nitride (SiN) Ceramic Sheet for Engineering Advanced Fine Ceramics

Silicon nitride plate is a commonly used ceramic material in the metallurgical industry due to its uniform performance at high temperatures.

High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

Alumina ceramic screws are fastening components made of 99.5% alumina, ideal for extreme applications requiring excellent thermal resistance, electrical insulation and chemical resistance.

Advanced Engineering Fine Ceramics Alumina Ceramic Saggar for Fine Corundum

Alumina sagger products have the characteristics of high temperature resistance, good thermal shock stability, small expansion coefficient, anti-stripping, and good anti-powdering performance.

Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

Experience top-notch sintering with Chairside Sintering Furnace with Transformer. Easy to operate, noise-free pallet, and automatic temperature calibration. Order now!

Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

Zirconia insulating ceramic gasket has high melting point, high resistivity, low thermal expansion coefficient and other properties, making it an important high temperature resistant material, ceramic insulating material and ceramic sunscreen material.

Silicon Carbide (SIC) Ceramic Plate for Engineering Advanced Fine Ceramics

Silicon nitride (sic) ceramic is an inorganic material ceramic that does not shrink during sintering. It is a high-strength, low-density, high-temperature-resistant covalent bond compound.

Related Articles

Hexagonal Boron Nitride: Enhancing Performance in Composite Ceramic Materials

Explores the role of h-BN in various composite ceramics, highlighting its properties and applications.

Dos and don'ts during the installation of molybdenum disilicide (MoSi2) heating element

Precautions when installing MoSi2 heating elements

Comparison of Pyrolytic Graphite and Pyrolytic Boron Nitride Crucibles

A detailed comparison of pyrolytic graphite and pyrolytic boron nitride crucibles, focusing on their preparation processes, characteristics, and applications.

Guidelines for the Use of Boron Nitride Crucibles

Instructions on the proper use, precautions, and compatibility of boron nitride crucibles.

Detailed Processes and Parameters of PECVD for TiN and Si3N4 Deposition

An in-depth exploration of the PECVD processes for TiN and Si3N4, including equipment setup, operational steps, and key process parameters.