fine ceramics

High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

Item Number : KM-C011

Price varies based on specs and customizations

- Material

- Aluminum Zirconium Oxide

- Specification

- See the form

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

Alumina ceramic screws are made of high-purity alumina or silicon carbide. Known for its high hardness and strength. Withstands continuous use at temperatures up to 1,500°C. Has excellent heat resistance, chemical resistance and electrical insulation. Ceramic components can withstand extreme temperatures without significant deformation or loss of mechanical properties. They are electrically insulating and lightweight compared to metal parts.

- Aerospace: Used for insulation, anti-interference, light weight and high temperature resistance on electronic equipment.

- Electronics: provide insulation, anti-interference, lightweight and other properties for electronic equipment.

- Medical equipment: non-magnetic, environmental protection, insulation, anti-interference, enhanced safety.

- Petrochemical industry: high temperature resistance, chemical resistance, corrosion resistance, prolonging the service life of equipment.

- Communication: insulation, non-magnetic, improve the safety of communication equipment.

- Shipbuilding: resistant to acid, alkali and corrosion, prolonging the service life of equipment.

Other applications include:

- Precision shafts in high wear environments.

- Roller and ball bearings enhance performance.

- Abrasion-resistant lining to protect equipment.

- Semiconductor parts with high temperature resistance, electrical insulation and corrosion resistance.

- Mechanical parts have advantages over traditional materials.

- High temperature and high pressure electrical insulator.

- Wire and wire conduit with insulation and temperature resistance.

- Mechanical seals effectively seal and prevent leaks.

- Professional applications in aerospace, automotive, electronics, semiconductor manufacturing, chemical processing and high temperature equipment.

Detail & Parts

Technical specifications

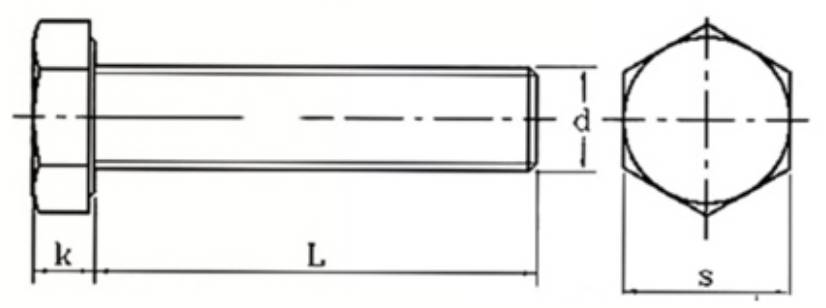

Measurement unit: L*K*Smm K:head thickness; L:thread length; S:the length of the opposite side; D:Thread Diameter/Specification.

| M16 | External hexagon | 100*9.2*24.2 | 7.*9.2*24.2 | 40*9.2*24.2 | |

| M14 | External hexagon | 80*10*22 | 50*7.6*21.9 | 40*9.9*21 | |

| M12 | External hexagon | 75*8.1*18.8 | 50*10.3*18.3 | 25*10.3*18.4 | 15*10*21.2 |

| Inner hexagon | 50*10.5*17.2 | 35/25*10.4*17.1 | 15*12.2*18.1 | 14*12.2*18 | |

| M10 | External hexagon | 70*7*16.8 | 35*6.6*16.6 | ||

| Inner hexagon | 50*9*14.8 | 35*9.1*14.8 | |||

| M8 | Inner hexagon | 70*5.6*14 | 50*4.5*11.7 | 35*5.3*12.9 | 25*5.3*12.9 |

| Inner hexagon | 50*7.6*12.3 | 35*7.9*12.3 | |||

| Flat head inner hexagon | 30*-*13.8 | ||||

| "+"Type | 20*-*14.2 | ||||

| M6 | External hexagon | 55*5.2*9.7 | 40*4.3*9.6 | ||

| Inner hexagon | 40*5.8*9.8 | 25*5.9*10 | 15*5.9*10 | ||

| "+"Type | 40*-*12 | ||||

| Outer hexagon "__" type | 25*3.9*9.8 | ||||

| Round head "__"type with hole | 20*4.8*10 | ||||

| Inner hexagon | 15*-*9.8 | ||||

| M5 | External hexagon | 25*3.5*8 | 20/15*3.6*8 | 10/12*3.6*7.6 | 5*3.6*8 |

| Inner hexagon | 35*4.7*7.8 | 25/20*4.9*8.1 | 15/12*4.9*8.1 | 10/5*4.9*8.1 | |

| Round head "+"type with hole | 25*-*8.6 | 20*-*8.5 | 12*-*8.5 | ||

| Round head Inner hexagon | 25*2.*9.3 | 12*2.8*8.6 | |||

| Round head "__" type | 10*3.4*7.9 | ||||

| "+"Type | 10*-*8.9 | ||||

| Round head "__" type with hole | 6/15*3*10 | ||||

| M4 | External hexagon | 20*3.2*6.8 | 15*3.3*6.8 | 10*3.2*6.8 | |

| Inner hexagon | 25*4*7 | 20*4.1*6.9 | 15*4.1*6.8 | 10*3.2*6.8 | |

| Inner hexagon | 25*-*8.5 | ||||

| "+" Type | 12*-*8.4 | ||||

| Round head "__" type | 8*2.9*7 | 5*2.1*9.3 | |||

| Round head "+"type with hole | 3*4.5*8.9 | ||||

| M3.5 | "+" Type | 9*-*5.3 | |||

| M3 | External hexagon | 10*3*5.5 | 30*3*5.4 | ||

| Inner hexagon | 30*3*5.4 | 20/25*3*5.4 | 15/10*3*5.4 | 8*3*5.4 | |

| "+" Type | 15*-*5.2 | 6*-*5.6 | |||

| Round head "+"type | 6.5*2.7*5.5 | ||||

| M2.5 | "+" Type | 9*-*4.5 | 6*-*3.9 | ||

| M2 | Flat head "__" type half teeth | 22*1.4*3.8 | |||

| Inner hexagon | 14*1.9*3.8 | ||||

| Flat head "__" type | 10*1.4*3.8 | ||||

| "+"thread | 8*1.6*3.5 | ||||

| Round head "+" type | 8*1.5*3.5 | ||||

| External hexagon | 6*1.6*3.8 | ||||

| "+" Type | 6*-*4.2 |

The produce we show are available in different sizes and custom sizes are available on request.

Advantages

- Good insulation performance, high temperature resistance.

- high strength.

- High hardness and wear resistance.

- Low to moderate corrosion.

- Low corrosion, high temperature resistance.

- Excellent electrical insulation.

- Chemical stability and corrosion resistance.

- Meet diverse technical requirements.

Trusted by Industry Leaders

FAQ

What Are Advanced Ceramics?

What Are The Main Applications Of Fine Ceramics?

What Are Engineering Ceramics?

What Are The Main Types Of Advanced Ceramics?

What Are The Main Types Of Fine Ceramics?

What Are The Main Types Of Engineering Ceramics?

What Are The Applications Of Advanced Ceramics?

What Is The Principle Behind Fine Ceramics?

What Are The Applications Of Engineering Ceramics?

How Are Advanced Ceramics Manufactured?

What Are The Advantages Of Using Fine Ceramics?

How Do Engineering Ceramics Differ From Traditional Ceramics?

What Are The Advantages Of Using Advanced Ceramics?

What Are The Advantages Of Using Alumina Ceramics?

What Is The Difference Between Alumina And Zirconia Ceramics?

Why Are Zirconia Ceramics Preferred In Certain Applications?

Why Are Silicon Carbide Ceramics Used In High-temperature Applications?

What Makes Silicon Carbide Ceramics Suitable For High-temperature Applications?

What Makes Boron Nitride Ceramics Unique?

How Are Boron Nitride Ceramics Used In Electronics?

How Do Advanced Ceramics Contribute To Energy Efficiency?

What Is The Manufacturing Process Of Engineering Ceramics?

Can Engineering Ceramics Be Customized For Specific Applications?

4.9 / 5

I am impressed by their extreme wear and abrasion resistance, making them perfect for high-temperature applications.

4.8 / 5

I'm pleased with the low corrosion and high-temperature resistance, ensuring long-lasting performance.

4.7 / 5

The delivery was incredibly fast! I received my order within just a few days, which is very impressive.

4.9 / 5

These alumina ceramic screws are worth every penny! They are incredibly durable and have exceeded my expectations.

4.6 / 5

The quality of these screws is top-notch, and they have significantly improved the performance of my equipment.

4.8 / 5

I'm amazed by the technological advancements in these screws. They are truly innovative and have solved many challenges I faced with traditional screws.

4.7 / 5

The Alumina Ceramic Screws are a lifesaver for my high-temperature applications. They are reliable and have never failed me.

4.9 / 5

I'm blown away by the durability of these screws. I've been using them for months now, and they still look brand new.

4.6 / 5

I highly recommend these screws for anyone working with high temperatures. They are a game-changer!

4.8 / 5

The alumina ceramic screws arrived in perfect condition and were exactly as described. Very satisfied with the purchase.

4.7 / 5

The screws are incredibly versatile and have found applications in various projects. Highly impressed with their adaptability.

4.9 / 5

I've been using these Alumina Ceramic Screws for a while now, and they continue to perform exceptionally well. Highly recommended!

4.6 / 5

The screws are easy to install and maintain, saving me valuable time and effort. I'm very pleased with this product.

4.8 / 5

I'm thrilled with the Alumina Ceramic Screws. They offer superior performance and have greatly enhanced the efficiency of my operations.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

High temperature wear-resistant insulating alumina plate has excellent insulation performance and high temperature resistance.

Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

In the journey of scientific exploration and industrial production, every detail is crucial. Our arc-shaped alumina ceramic crucibles, with their excellent high temperature resistance and stable chemical properties, have become a powerful assistant in laboratories and industrial fields. They are made of high-purity alumina materials and manufactured through precision processes to ensure excellent performance in extreme environments.

Advanced Engineering Fine Ceramics Alumina Ceramic Saggar for Fine Corundum

Alumina sagger products have the characteristics of high temperature resistance, good thermal shock stability, small expansion coefficient, anti-stripping, and good anti-powdering performance.

High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

High temperature alumina furnace tube combines the advantages of high hardness of alumina, good chemical inertness and steel, and has excellent wear resistance, thermal shock resistance and mechanical shock resistance.

High Purity Alumina Granulated Powder for Engineering Advanced Fine Ceramics

Ordinary alumina granulated powder is alumina particles prepared by traditional processes, with a wide range of applications and good market adaptability. This material is known for its high purity, excellent thermal stability and chemical stability, and is suitable for a variety of high-temperature and conventional applications.

Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

Alumina ceramics have good electrical conductivity, mechanical strength and high temperature resistance, while zirconia ceramics are known for their high strength and high toughness and are widely used.

Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

Zirconia insulating ceramic gasket has high melting point, high resistivity, low thermal expansion coefficient and other properties, making it an important high temperature resistant material, ceramic insulating material and ceramic sunscreen material.

Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

Boron nitride ((BN) is a compound with high melting point, high hardness, high thermal conductivity and high electrical resistivity. Its crystal structure is similar to graphene and harder than diamond.

Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

Silicon carbide (sic) ceramic sheet is composed of high-purity silicon carbide and ultra-fine powder, which is formed by vibration molding and high-temperature sintering.

High Temperature Aluminum Oxide (Al2O3) Protective Tube for Engineering Advanced Fine Ceramics

Alumina oxide protective tube, also known as high temperature resistant corundum tube or thermocouple protection tube, is a ceramic tube mainly made of alumina (aluminum oxide).

Advanced Engineering Fine Ceramics Aluminum Nitride (AlN) Ceramic Sheet

Aluminum nitride (AlN) has the characteristics of good compatibility with silicon. It is not only used as a sintering aid or reinforcing phase for structural ceramics, but its performance far exceeds that of alumina.

Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

Alumina ceramic crucibles are used in some materials and metal melting tools, and flat-bottomed crucibles are suitable for melting and processing larger batches of materials with better stability and uniformity.

Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

Cylindrical Crucibles Cylindrical crucibles are one of the most common crucible shapes, suitable for melting and processing a wide variety of materials, and are easy to handle and clean.

Engineering Advanced Fine Ceramics Aluminium Oxide Al2O3 Ceramic Washer for Wear-Resistant Applications

Alumina wear-resistant ceramic washer are used for heat dissipation, which can replace aluminum heat sinks, with high temperature resistance and high thermal conductivity.

Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

zirconia ceramic ball have the characteristics of high strength, high hardness, PPM wear level, high fracture toughness, good wear resistance, and high specific gravity.

Advanced Engineering Fine Ceramics Low Temperature Alumina Granulation Powder

Low temperature alumina granulation powder is a kind of alumina particles produced by a special low temperature process, designed to meet the needs of temperature sensitive applications. This material has excellent low temperature performance and good processing characteristics, suitable for a variety of industries that require low temperature processing and treatment.

Precision Machined Yttrium Stabilized Zirconia Ceramic Rod for Engineering Advanced Fine Ceramics

Zirconia ceramic rods are prepared by isostatic pressing, and a uniform, dense and smooth ceramic layer and transition layer are formed at high temperature and high speed.

Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

Due to the characteristics of boron nitride itself, the dielectric constant and dielectric loss are very small, so it is an ideal electrical insulating material.

Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

Zirconia ceramic tweezers are a high-precision tool made of advanced ceramic materials, especially suitable for operating environments that require high precision and corrosion resistance. This type of tweezers not only has excellent physical properties, but is also popular in the medical and laboratory fields because of its biocompatibility.

Related Articles

Advanced Alumina Ceramics: Applications and Manufacturing Techniques

This article discusses the applications and manufacturing techniques of advanced alumina ceramics, including molds, isostatic pressing, and green bodies.

Advanced Alumina Ceramics: Applications and Manufacturing Techniques

Overview of alumina ceramics' applications and manufacturing methods, including molds, isostatic pressing, and green body formation.

Comprehensive Overview of Zirconia Ceramic Materials

A detailed exploration of zirconia ceramics, including properties, history, preparation, molding, sintering, and applications.

Structure and Properties of High-Temperature Engineering Ceramics

Explore the applications, structural features, and performance advantages of high-temperature engineering ceramics across various industries.

The 5 Hottest Advanced Ceramic Powders Currently Available!

An overview of the top 5 advanced ceramic powders: High Purity Aluminum Oxide, Boehmite, Aluminum Nitride, Silicon Nitride, and Spherical Alumina, highlighting their applications and market trends.

Research on Zirconia Ceramics in Dental Restoration

Explores the properties, preparation, and advantages of zirconia ceramics in dental restoration.

Engineering Ceramic Materials: Applications in Aerospace, Electronic Information, New Energy, and Environmental Protection

This article explores the diverse applications of engineering ceramic materials across aerospace, electronic information, new energy, and environmental protection sectors.

The Evolution and Strategic Importance of Advanced Ceramics

An in-depth analysis of the development, classification, and strategic importance of advanced ceramics in various industrial and technological fields.

Precision Ceramic Materials for Energy Conversion Applications

Overview of various ceramic materials used in energy conversion technologies, including heaters, piezoelectric ceramics, and solid oxide fuel cells.

Advancements in Engineering Ceramic Materials

Explores new engineering ceramics with exceptional properties and applications in harsh environments, comparing them to traditional materials.

Mechanical Properties and Structural Enhancements of Ceramics

An in-depth analysis of the mechanical properties of ceramics, including strengths, weaknesses, and methods for improvement.

Selecting Heating Elements for Vacuum Furnaces

Guide on choosing heating elements and insulation screens for efficient vacuum furnace operation.