Properties of Zirconia Ceramics

Basic Properties

High-purity zirconia powder exhibits a pristine white hue, while zirconia ceramics possess a characteristic chalky appearance. These materials are distinguished by their unique physical and chemical properties, which make them highly suitable for various applications, particularly in dental restoration.

| Property | Value |

|---|---|

| Relative Molecular Mass | 123.223 g/mol |

| Density | 5.85 g/cm³ |

| Melting Point | 2715°C |

Zirconia's crystalline structure is another crucial aspect, comprising three primary forms:

- Monoclinic: The least stable form, typically observed at room temperature.

- Tetragonal: A more stable form that can exist under certain conditions, often through thermal treatments.

- Cubic: The most stable and densest form, typically achieved at high temperatures.

These crystal structures play a pivotal role in determining zirconia's mechanical properties, particularly its toughness and stability, which are essential for its use in dental applications.

Toughening Mechanisms

The fracture toughness of zirconia ceramics can be significantly enhanced through various toughening strategies. These methods are essential for improving the durability and reliability of zirconia ceramics in dental applications. The primary toughening mechanisms include:

-

Stress-Induced Phase Transformation Toughening: This method involves inducing a phase transformation from the tetragonal to the monoclinic structure under stress, which absorbs energy and impedes crack propagation.

-

Microcrack Toughening: The formation of microcracks around larger cracks can dissipate energy and prevent the growth of the primary crack, thereby enhancing the material's toughness.

-

Microcrack Bending, Bifurcation, and Bridging: These mechanisms involve the bending and branching of microcracks, as well as the bridging of cracks by particles or fibers, which can significantly reduce the stress concentration at the crack tip.

-

Whisker Toughening: Incorporating ceramic whiskers into the zirconia matrix can provide additional reinforcement, similar to how fibers strengthen composite materials.

-

Dispersion Toughening: Adding hard, dispersed particles to the zirconia matrix can impede dislocation movement and crack propagation, thereby improving toughness.

-

Fine Grain Strengthening: Reducing the grain size of the zirconia can increase the density of grain boundaries, which act as barriers to crack propagation.

-

Fiber Toughening: Similar to whisker toughening, the addition of ceramic fibers can provide a reinforcing effect, enhancing the overall toughness of the material.

These toughening mechanisms collectively contribute to the superior mechanical properties of zirconia ceramics, making them an ideal choice for demanding dental applications.

Low-Temperature Oxidation

In a low-temperature and humid environment, the fundamental process governing the aging of zirconia ceramics involves a martensitic phase transformation. This transformation is characterized by a non-thermodynamic, diffusion-free change in the crystal structure, which is distinct from typical thermodynamic phase transitions. The initiation of this process begins with the surface of the material undergoing a t-m phase transition, where the tetragonal (t) phase converts to the monoclinic (m) phase.

This phase transition is critical as it affects the mechanical properties of zirconia ceramics, particularly their toughness and strength. The t-m phase transformation can lead to microstructural changes that enhance the material's resistance to fracture, a property that is highly desirable in dental applications where durability and longevity are paramount.

| Phase Transition | Description |

|---|---|

| Tetragonal to Monoclinic (t-m) | Non-thermodynamic, diffusion-free crystal structure change |

The low-temperature aging process not only alters the surface properties of zirconia but also influences its overall performance in dental restorations. Understanding this phase transformation is essential for optimizing the material's properties to meet the stringent requirements of dental implants and restorations.

Preparation of Zirconia Ceramics

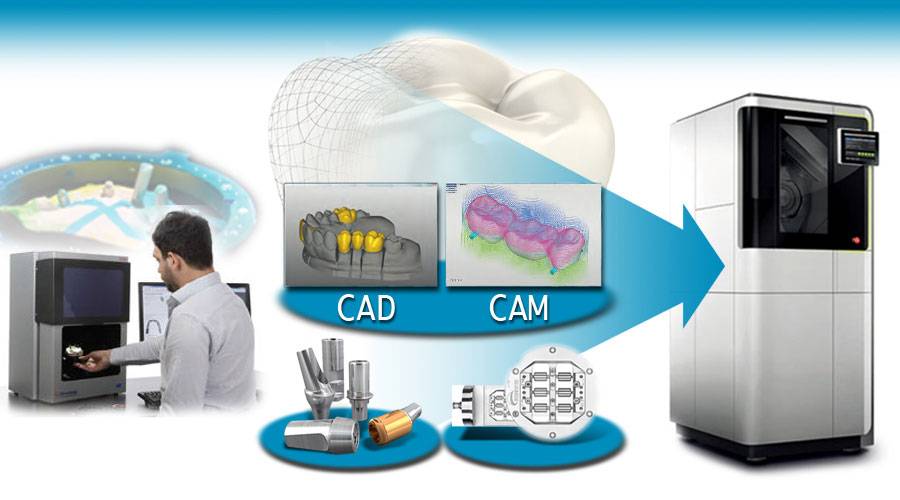

CAD/CAM Grinding Technology

The advent of computer-aided design and manufacturing (CAD/CAM) technology has revolutionized the process of creating dental restorations, making it both more efficient and precise. This technology has significantly streamlined the workflow, meeting the growing demand for high-quality dental solutions. The process begins with traditional methods of pressing and molding the patient's injured part to create an initial model. This model is then digitized through a scanning process, capturing intricate details that are crucial for the restoration's accuracy.

Once the digital model is obtained, CAD/CAM technology takes over, employing sophisticated algorithms to design the restoration. The design phase is followed by the grinding and polishing of a zirconia block, which is meticulously shaped to match the digital blueprint. This automated process not only reduces manual labor but also enhances the precision and quality of the final product. The result is a dental restoration that is not only functional but also aesthetically pleasing, closely resembling the natural tooth structure.

The integration of CAD/CAM technology in dental restoration has numerous advantages. It significantly reduces the time required for the fabrication process, allowing for faster turnaround times and more efficient patient care. Additionally, the use of high-precision grinding and polishing ensures that the restoration fits perfectly, enhancing patient comfort and oral function. This technology also opens up possibilities for customizing restorations to meet individual patient needs, further improving the overall quality of dental care.

3D Printing Technology

In dentistry, 3D printing technology has revolutionized the way tooth models are created, catering to the personalized needs of patients while significantly enhancing production efficiency. This technology has evolved to encompass a variety of sophisticated processing methods, each contributing uniquely to the precision and customization required in dental restorations.

One of the primary methods is inkjet printing technology, which allows for the precise deposition of materials layer by layer, ensuring intricate details are captured accurately. This method is particularly useful for creating complex geometries that are difficult to achieve through traditional means.

Another notable technique is selective laser sintering (SLS), which uses a high-powered laser to fuse small particles of zirconia powder into a solid structure. This method offers high accuracy and strength, making it ideal for producing durable dental models that can withstand the mechanical stresses of oral use.

Stereolithography (SLA) is yet another advanced form of 3D printing, utilizing a UV laser to cure liquid resin into solid layers. This method excels in producing highly detailed and smooth surfaces, which are crucial for the aesthetic appeal of dental restorations.

Lastly, extrusion free molding involves the extrusion of material through a nozzle to build up layers of the model. This technique is versatile and can be adapted to various materials, making it a flexible option for dental applications.

Each of these processing forms leverages the strengths of 3D printing technology to address the specific demands of dental restoration, from precision and durability to aesthetics and biocompatibility.

Advantages of Zirconia Ceramics in Dental Implants

Hygiene

Recent research has highlighted the significant hygienic benefits of zirconia implants, primarily attributed to their poor surface wettability. This characteristic significantly reduces bacterial adhesion and biofilm accumulation, which are common issues with dental implants. In comparison to titanium implants, zirconia implants exhibit markedly lower plaque retention on their surfaces, thereby mitigating the risk of inflammatory reactions in the surrounding tissues.

To further elucidate these findings, a comparative analysis between zirconia and titanium implants reveals key differences in their biofilm formation dynamics:

| Property | Zirconia Implants | Titanium Implants |

|---|---|---|

| Surface Wettability | Poor wettability reduces bacterial adhesion and biofilm formation. | Moderate wettability allows for higher bacterial adhesion and biofilm accumulation. |

| Plaque Retention | Significantly lower plaque retention due to poor surface wettability. | Higher plaque retention, increasing the risk of periodontal issues. |

| Inflammatory Reactions | Lower risk of inflammatory reactions in surrounding tissues. | Higher risk of inflammatory reactions due to increased plaque and biofilm presence. |

| Clinical Outcomes | Improved clinical outcomes with fewer post-operative complications related to hygiene. | More frequent post-operative complications, particularly related to bacterial issues. |

These findings underscore the superior hygienic performance of zirconia implants, making them a preferable choice for dental restoration, especially in environments where minimizing bacterial load and inflammatory risks is paramount.

Aesthetics

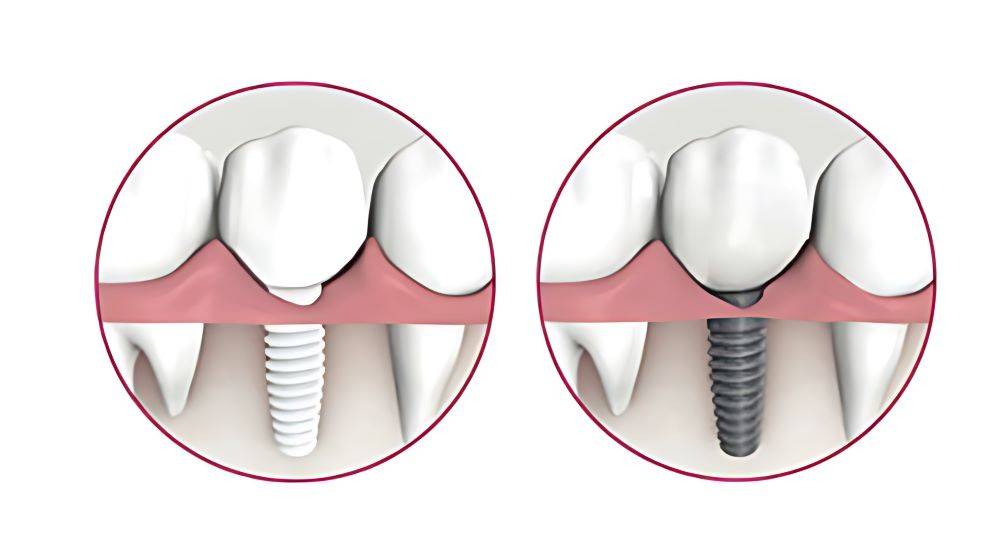

The aesthetic appeal of zirconia is one of its most compelling advantages in dental restoration. Zirconia's bright, white color closely mimics the natural hue of teeth, making it an ideal material for tooth root replacements. This similarity in color ensures that zirconia implants blend seamlessly with the surrounding teeth, enhancing the overall appearance of the dental restoration.

In contrast to metal implants, zirconia not only provides a more natural look but also eliminates the risk of gum line darkening, a common aesthetic concern associated with metal-based dental implants. This is particularly significant for patients who desire a more uniform and natural-looking smile. The absence of metal in zirconia implants means that there is no risk of discoloration or unsightly gray lines along the gum line, which can be a source of embarrassment for patients.

Moreover, zirconia's aesthetic benefits extend beyond just color. Its smooth surface texture further contributes to a more natural appearance, reducing the visibility of the implant even at close range. This makes zirconia an excellent choice for both anterior and posterior restorations, where aesthetics are a primary concern.

In summary, zirconia's ability to provide a natural, aesthetically pleasing result without the drawbacks of metal implants makes it a superior choice for dental restorations, particularly in cases where the patient's appearance and confidence are paramount.

Strength

Zirconia implants exhibit mechanical strength on par with titanium implants, making them a robust choice for dental applications. Beyond mere comparability, zirconia boasts exceptional fracture toughness and superior wear resistance, attributes that are crucial for the longevity and durability of dental implants. The fracture toughness of zirconia can be enhanced through various toughening mechanisms, such as stress-induced phase transformation toughening and microcrack toughening, which contribute to its resilience against mechanical stresses.

Moreover, zirconia's wear resistance ensures that the implant maintains its structural integrity over time, reducing the risk of degradation or failure due to constant masticatory forces. This combination of mechanical strength and wear resistance not only meets but exceeds the stringent strength requirements demanded by dental implants, making zirconia a preferred material in modern dental restoration practices.

Biocompatibility

Zirconia is renowned for its exceptional biocompatibility, making it a preferred material in dental restoration. As a bioinert substance, zirconia exhibits minimal interaction with biological tissues, ensuring that it remains non-toxic to the body. This inertness is crucial in preventing adverse reactions, such as allergic responses or inflammatory conditions, which are common with other materials used in dental implants.

The biocompatibility of zirconia is further supported by its ability to integrate seamlessly with bone tissue. Studies have demonstrated that zirconia implants exhibit bone contact and integration levels comparable to those of titanium implants, indicating a robust and stable interface between the implant and the surrounding bone. This integration is facilitated by zirconia's stable chemical properties and high corrosion resistance, which allow it to endure the harsh oral environment without degradation or adverse reactions.

In addition to its inertness and bone integration capabilities, zirconia's biocompatibility is enhanced by its poor surface wettability, which reduces bacterial adhesion and biofilm accumulation. This characteristic not only minimizes the risk of peri-implantitis but also contributes to the overall hygiene and longevity of the implant. The combination of these factors underscores zirconia's suitability as a biocompatible material for dental applications, offering a safe and effective solution for patients in need of restorative dentistry.

Bone Integration Performance

Recent studies have demonstrated that zirconia implants exhibit bone contact and integration levels that are nearly indistinguishable from those of traditional titanium implants. This similarity in bone integration performance underscores the potential of zirconia as a viable alternative in dental implantology. The bone-to-implant contact (BIC) ratios for zirconia implants have been reported to be on par with those of titanium alloys, suggesting that zirconia can achieve robust and stable osseointegration.

The comparable bone integration performance of zirconia implants can be attributed to several factors. Firstly, zirconia's bioinert nature ensures minimal adverse reactions with surrounding bone tissues, facilitating a smoother integration process. Secondly, the material's mechanical properties, such as its high fracture toughness and wear resistance, contribute to its long-term stability within the oral environment. These attributes not only enhance the durability of the implant but also promote better bone adhesion over time.

Moreover, the chemical stability of zirconia plays a crucial role in maintaining the integrity of the implant-bone interface. Unlike some metals, zirconia does not undergo corrosion or degradation in the oral environment, which could otherwise compromise bone integration. This stability is particularly important in ensuring that the implant remains firmly anchored, even under the mechanical stresses experienced during chewing and other oral activities.

In summary, the research findings indicate that zirconia implants not only match the bone integration performance of titanium implants but also offer additional benefits such as enhanced biocompatibility and chemical stability. These characteristics collectively contribute to the establishment of a stable and durable bone-implant interface, making zirconia a promising material for dental restorations.

Stable Chemical Properties

Zirconia exhibits remarkable stability in the complex oral environment, making it an ideal material for dental restorations. Its chemical inertness ensures that it does not react with saliva, food particles, or other components typically found in the mouth. This stability is crucial for the longevity of dental implants and restorations, as it prevents any adverse interactions that could compromise the integrity of the material over time.

Moreover, zirconia's strong corrosion resistance is a key factor in its durability. Unlike some other materials, zirconia does not degrade or corrode when exposed to acidic or alkaline conditions, which are common in the oral cavity. This property allows zirconia to maintain its structural and aesthetic qualities, ensuring that dental restorations remain functional and aesthetically pleasing for many years.

In summary, zirconia's stable chemical properties and robust corrosion resistance enable it to withstand the harsh conditions of the oral environment, making it a reliable choice for long-term dental applications.

Conclusion

Future Prospects

In recent years, zirconia has emerged as a focal point of research in the realm of dental restorations, primarily due to its superior aesthetic and mechanical properties. This burgeoning interest underscores the significant potential that zirconia ceramics hold within the dental restoration sector. As advancements continue to refine the anti-aging properties of dental zirconia ceramics, and as the demand for healthier, more functional materials grows, the scope of zirconia's application in the biomedical field is poised to expand even further.

The future of zirconia in dental restorations is not merely limited to its current applications but extends into innovative domains. For instance, the integration of zirconia with emerging technologies such as 3D printing and CAD/CAM systems promises to revolutionize the manufacturing process, making it more efficient and tailored to individual patient needs. This technological synergy could lead to the creation of more precise and durable dental implants, enhancing both the functionality and longevity of restorative treatments.

Moreover, ongoing research into the biocompatibility and bone integration performance of zirconia indicates that it could become a preferred material for dental implants, rivaling or even surpassing traditional materials like titanium. The stable chemical properties of zirconia, coupled with its strong corrosion resistance, ensure that it can withstand the harsh oral environment without degradation, making it a reliable long-term solution for dental restorations.

In summary, the future prospects of zirconia in dental restorations are bright, with potential applications that could significantly enhance the field's capabilities and outcomes. As research and development continue to push the boundaries of what zirconia can achieve, the material's role in the biomedical sector is expected to grow, offering new possibilities for improved dental care.

Related Products

- Precision Machined Yttria Stabilized Zirconia Ceramic Plate for Engineering Advanced Fine Ceramics

- Precision Machined Yttrium Stabilized Zirconia Ceramic Rod for Engineering Advanced Fine Ceramics

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

Related Articles

- Top 5 Features of a High-Quality Zirconia Sintering Oven

- The Latest Advancements in Zirconia Sintering Furnaces for Dental Applications

- Isostatic Pressing of Ceramics: Process and Precision

- Understanding the Process and Benefits of Zirconia Ceramic Cold Isostatic Pressing

- Unveiling the Exceptional Properties and Applications of Optical Quartz Plates