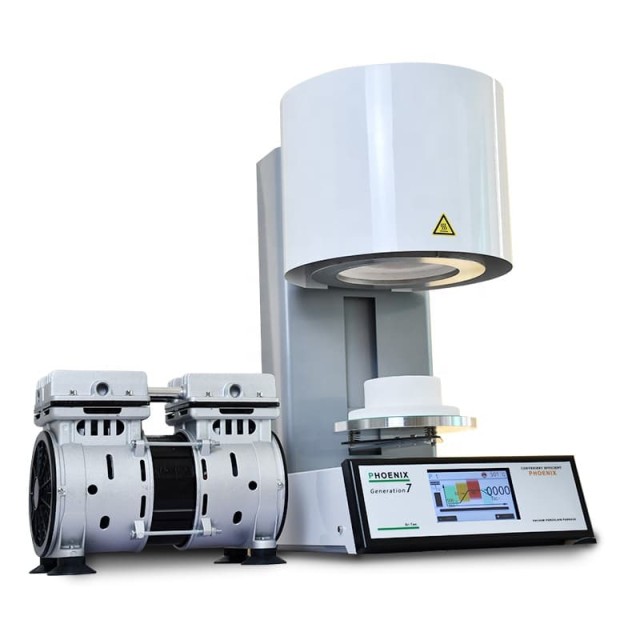

Dental Furnace

Vacuum Dental Porcelain Sintering Furnace

Item Number : KT-DV10

Price varies based on specs and customizations

- Max temperature

- 1200℃ max(2283°F)

- Vacuum level

- 1-101%

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Applications

Vacuum porcelain furnace. Combined firing/pressing furnaces are used for fabricating pressed-ceramic restorations (pressing procedure resembling casting which makes use of pressure and heat to liquefy ceramic blocks and force them into lost, refractory investment moulds) using special firing chambers and pressure plungers.

KinTek Porcelain Furnace is suitable for all kinds of porcelain powder on the market, such as IVOCLAR, VITA, NORITAKE, etc.

Feature

- Hyperbolic ceramic furnace function, the program can be set to single curve mode or hyperbolic mode, hyperbolic mode provides a complete crystallization process for glass-ceramic crystallization.

- Voice prompt function.

- High quality temperature automatic adjustment function, to ensure that the actual temperature error within + / - 1 degrees.

- Precision stepper motor drive, smooth free operation and no jitter.

- Quartz spiral furnace.

- Automatic temperature calibration before each baking procedure.

- Low noise tray, programmable speed.

- True color touch screen, easy to operate.

- 90 custom programs and built-in programs.

- Status indication.

Detail & Parts

Ambient conditions

- Indoor use

- Ambient temperature: 2°C to 40°C

- Relative humidity 80% at 31°C

- Maximum altitude: 1500 m (Special Model:3500m)

- Rated voltage fluctuations must not exceed plus/minus 10% of the rated voltage

Technical specifications

| Heating speed | 200℃/min max. (392°F /minute) |

| Max temperature | 1200℃ max(2283°F) |

| Max temperature holding time | 2 hours |

| Vacuum level | 1-101% |

| Electric power supply | 100-120V 50/60HZ 230V 50/60HZ |

| Rated current | 14.5ampere@110V 7.0ampere@230V |

| Rated output power | max 1500w |

| Dimension | H27cm x W36cm x D53cm |

| Firing chamber diameter | 9cm(3.5") |

| Net weight | 20Kg |

| Weight with package | 23.5Kg |

Standard packing

- 1 Furnace

- 1 firing pan

- 1 connection cable for the mains power supply

- 1 instructions

- 1 Burning rack

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is Dental Furnaces?

What Is A Vacuum Furnace Used For?

What Are The Different Types Of Dental Furnaces?

What Is The Process Of A Vacuum Furnace?

What Is The Purpose Of A Vacuum Hot Press Furnace?

What Is The Temperature Of A Dental Furnace?

What Gas Is Used In A Vacuum Furnace?

What Are The Advantages Of A Vacuum Hot Press Furnace?

What Is The Use Of Porcelain Furnace?

What Is The Heating Element Used In A Vacuum Furnace?

How Does A Vacuum Hot Press Furnace Work?

What Are The Common Applications Of Vacuum Hot Press Furnaces?

What Factors Should Be Considered When Selecting A Vacuum Hot Press Furnace?

4.7 / 5

This furnace has been a game-changer for my laboratory. Its versatility and efficiency have saved me time and resources, allowing me to focus on delivering exceptional results to my clients.

4.8 / 5

The All-in-One vacuum dental furnace is a testament to KINTEK SOLUTION's commitment to innovation. It's a reliable and powerful tool that has transformed my workflow.

4.6 / 5

I've been using this furnace for over a year now, and it's consistently delivered outstanding results. The quality of my restorations has improved significantly, and my clients are thrilled.

4.9 / 5

KINTEK SOLUTION has truly outdone themselves with this furnace. It's a pleasure to use, and the results are simply stunning. Highly recommended!

4.7 / 5

This furnace is an absolute lifesaver. It's fast, efficient, and produces consistently high-quality results. I couldn't imagine my laboratory without it.

4.8 / 5

KINTEK SOLUTION's vacuum dental furnace is a game-changer for dental laboratories. Its advanced features and user-friendly interface make it a joy to use.

4.9 / 5

I'm thoroughly impressed with the All-in-One vacuum dental furnace. It's a powerful and versatile tool that has taken my laboratory to the next level.

4.7 / 5

This furnace is a true investment for any dental laboratory. It's built to last and produces exceptional results time after time.

4.8 / 5

I highly recommend this furnace to any dental laboratory looking for a reliable and efficient solution. It's a game-changer for sure.

4.9 / 5

KINTEK SOLUTION has hit it out of the park with this furnace. It's a must-have for any laboratory that values quality and efficiency.

4.7 / 5

This furnace is a true lifesaver. It's easy to use, produces amazing results, and saves me so much time. I couldn't be happier.

4.8 / 5

I've been using this furnace for a few months now, and I'm still amazed by its capabilities. It's a game-changer for my laboratory.

4.9 / 5

This furnace is a testament to KINTEK SOLUTION's commitment to excellence. It's a top-of-the-line product that delivers exceptional results.

4.7 / 5

I highly recommend this furnace to any dental laboratory. It's a reliable and efficient workhorse that will take your laboratory to the next level.

4.8 / 5

This furnace has exceeded my expectations. It's a pleasure to use and produces consistently high-quality results. I'm thrilled with my purchase.

4.9 / 5

KINTEK SOLUTION has truly outdone themselves with this furnace. It's a must-have for any dental laboratory that values innovation and efficiency.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

Get precise dental results with Dental Vacuum Press Furnace. Automatic temperature calibration, low noise tray, and touch screen operation. Order now!

Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

Experience top-notch sintering with Chairside Sintering Furnace with Transformer. Easy to operate, noise-free pallet, and automatic temperature calibration. Order now!

600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

Discover the 600T Vacuum Induction Hot Press Furnace, designed for high-temperature sintering experiments in vacuum or protected atmospheres. Its precise temperature and pressure control, adjustable working pressure, and advanced safety features make it ideal for nonmetal materials, carbon composites, ceramics, and metal powders.

Vacuum Heat Treat Sintering Brazing Furnace

A vacuum brazing furnace is a type of industrial furnace used for brazing, a metalworking process that joins two pieces of metal using a filler metal that melts at a lower temperature than the base metals. Vacuum brazing furnaces are typically used for high-quality applications where a strong, clean joint is required.

Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

The air pressure sintering furnace is a high-tech equipment commonly used for the sintering of advanced ceramic materials. It combines vacuum sintering and pressure sintering techniques to achieve high-density and high-strength ceramics.

Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

A vacuum molybdenum wire sintering furnace is a vertical or bedroom structure, which is suitable for withdrawal, brazing, sintering and degassing of metal materials under high vacuum and high temperature conditions. It is also suitable for dehydroxylation treatment of quartz materials.

Mesh belt controlled atmosphere furnace

Discover our KT-MB mesh belt sintering furnace - perfect for high-temperature sintering of electronic components & glass insulators. Available for open air or controlled atmosphere environments.

Vacuum Arc Induction Melting Furnace

Discover the power of Vacuum Arc Furnace for melting active & refractory metals. High-speed, remarkable degassing effect, and free of contamination. Learn more now!

Vacuum Heat Treat Furnace with Ceramic Fiber Liner

Vacuum furnace with polycrystalline ceramic fiber insulation liner for excellent heat insulation and uniform temperature field. Choose from 1200℃ or 1700℃ max. working temperature with high vacuum performance and precise temperature control.

Lab-Scale Vacuum Induction Melting Furnace

Get precise alloy composition with our Vacuum Induction Melting Furnace. Ideal for aerospace, nuclear energy, and electronic industries. Order now for effective smelting and casting of metals and alloys.

Laboratory High Pressure Vacuum Tube Furnace

KT-PTF High Pressure Tube Furnace: Compact split tube furnace with strong positive pressure resistance. Working temp up to 1100°C and pressure up to 15Mpa. Also works under controller atmosphere or high vacuum.

Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

Experience efficient material processing with our vacuum-sealed rotary tube furnace. Perfect for experiments or industrial production, equipped with optional features for controlled feeding and optimized results. Order now.

Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

IGBT experimental graphitization furnace, a tailored solution for universities and research institutions, with high heating efficiency, user-friendliness, and precise temperature control.

High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

KT-MD High temperature debinding and pre-sintering furnace for ceramic materials with various molding processes. Ideal for electronic components such as MLCC and NFC.

Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

Reduce forming pressure & shorten sintering time with Vacuum Tube Hot Press Furnace for high-density, fine-grain materials. Ideal for refractory metals.

Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

Discover the versatility of Laboratory Rotary Furnace: Ideal for calcination, drying, sintering, and high-temperature reactions. Adjustable rotating and tilting functions for optimal heating. Suitable for vacuum and controlled atmosphere environments. Learn more now!

Vacuum Hot Press Furnace Machine for Lamination and Heating

Experience clean and precise lamination with Vacuum Lamination Press. Perfect for wafer bonding, thin-film transformations, and LCP lamination. Order now!

Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

KT-CTF14 Multi Heating Zones CVD Furnace - Precise Temperature Control and Gas Flow for Advanced Applications. Max temp up to 1200℃, 4 channels MFC mass flow meter, and 7" TFT touch screen controller.

Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

Efficiently produce batches with excellent temperature uniformity using our Bottom Lifting Furnace. Features two electric lifting stages and advanced temperature control up to 1600℃.

Related Articles

Dental Furnaces The Perfect Solution for Porcelain Processing

The dental furnaces are designed explicitly for the firing process of dental porcelain, which is a crucial step in the dental restoration process.

The Future of Porcelain Furnaces in Dental Laboratories

Porcelain furnaces play a crucial role in the dental laboratory industry as they are used for firing ceramic materials that are commonly used for restorations.

Comprehensive Guide to Vacuum Hot Press Furnace Application

The Vacuum Hot Press Furnace is a versatile tool especially suited for sintering experiments involving non-metallic materials, carbon composites, ceramic materials and metal powder materials.

The Latest Advancements in Zirconia Sintering Furnaces for Dental Applications

Zirconia sintering furnaces are designed to give dental professionals the ability to create dental restorations with the highest level of precision and accuracy.

The Role of a Porcelain Furnace in Dental Restorations

Porcelain furnaces play a crucial role in the creation of dental restorations, as they are used to fire ceramic materials, such as porcelain, to create durable and natural-looking dental prosthetics.

Dental Ceramic Furnaces The Science Behind It

Dental ceramic furnaces play a crucial role in the production of dental restorations such as crowns, bridges, and veneers.

Understanding the Function of a Dental Ceramic Furnace

Dental ceramic furnaces are specialized equipment used in the dental laboratory to create high-quality dental restorations, such as crowns, bridges, and veneers.

How to Choose the Best Porcelain Furnace Dental

Dental porcelain furnaces are essential devices in dental labs. They are used to create high-quality dental restorations that meet the specific needs of patients.

Top 5 Features of a High-Quality Zirconia Sintering Oven

Investing in a high-quality sintering oven is crucial for dental laboratories that want to produce high-quality zirconia restorations consistently.

Enhancing Dental Work with a High-Quality Dental Furnace

A dental furnace is a specialized piece of equipment used in dentistry to heat materials to high temperatures. It is typically used to manipulate metal alloys or ceramics, such as those used in crowns, bridges, and other restorative treatments.

Evaluating the Pros and Cons of External Vacuum Heat Treatment Furnaces

we evaluate the pros and cons of using external vacuum heat treatment furnaces to help manufacturers determine if it is the right choice for their specific process.

Dental Sintering Furnaces The Impact on Restoration Quality and Durability

Dental sintering furnaces play a crucial role in the manufacturing process of dental crowns and other restorations.