Definition of dental furnace

A dental furnace is a specialized piece of equipment used in dentistry to heat materials to high temperatures. It is typically used to manipulate metal alloys or ceramics, such as those used in crowns, bridges, and other restorative treatments.

The furnace is used to carefully control the temperature of these materials to ensure that they are properly shaped and hardened for use in the mouth. Dental furnaces are an essential tool in many dental practices and are used to provide patients with high-quality, durable restorations that can improve their oral health and function.

How Kindle Tech Dental Furnace Improves Dental Work

Dental furnaces are specialized ovens that are used in the dental industry to heat and melt materials like wax, porcelain, and other dental alloys. They are used in a variety of applications, including the fabrication of crowns, bridges, and other restorative dental devices. There are several ways in which a dental furnace can improve dental work:

- Improved accuracy: Kindle Tech Dental furnaces are designed to heat materials to precise temperatures, which can help ensure that the finished dental work is of high quality and fits correctly in the patient's mouth.

- Enhanced durability: Dental alloys and other materials that are heated and formed in a Kindle Tech dental furnace are often stronger and more durable than those that are formed using other methods. This can help improve the longevity of the dental work.

- Greater aesthetic appeal: Kindle Tech Dental furnaces can be used to create dental work that is more aesthetically pleasing. For example, porcelain veneers that are fired in a dental furnace can have a natural, lifelike appearance.

- Faster turnaround time: Kindle Tech Dental furnaces can help reduce the time it takes to create and place dental work, which can be beneficial for both the dentist and the patient.

Overall, dental furnaces play an important role in the production of high-quality dental work, and they can help improve the overall outcome of dental procedures.

Types of Dental Furnaces

There are several types of dental furnaces available, each of which is designed for specific applications. Some common types of dental furnaces include:

- Porcelain furnaces: These furnaces are used to heat and melt porcelain, which is a type of ceramic material that is commonly used in the production of dental crowns, veneers, and other restorative devices. Porcelain furnaces typically have a temperature range of up to 1,800 degrees Fahrenheit.

- Sintering furnace with SiC heaters: A sintering furnace with SiC heaters is a type of furnace that is used to sinter, or heat and compact, a variety of materials. The SiC heaters, which are made of silicon carbide, are used as a heating element in the furnace. SiC heaters are known for their high thermal conductivity, high temperature tolerance, and ability to withstand harsh environments, making them well-suited for use in sintering furnaces. Sintering furnaces with SiC heaters can be used in a variety of industries, including the dental industry, where they may be used to sinter dental alloys and other materials.

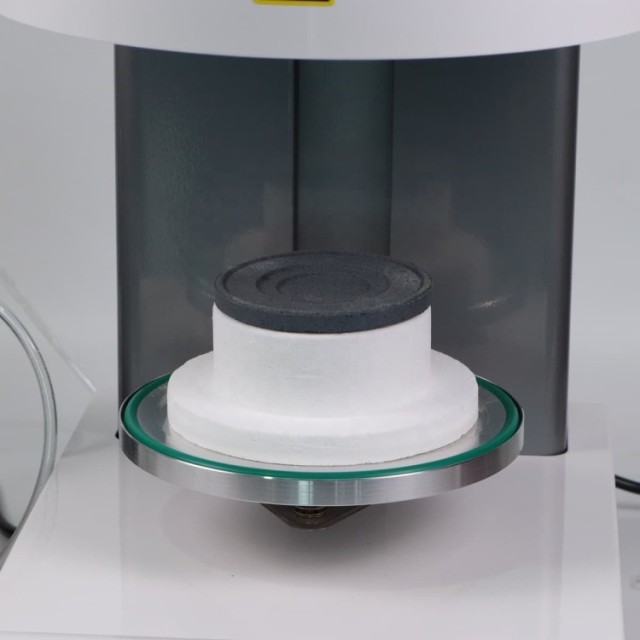

- Dental vacuum press furnace is a specialized oven that is used in the dental industry to heat and form materials like porcelain, ceramic, and other dental alloys. The furnace is equipped with a vacuum pump, which creates a vacuum inside the heating chamber. This vacuum helps to remove air bubbles and other impurities from the material being heated, resulting in a more homogeneous and consistent finished product. Dental vacuum press furnaces are typically used in the production of crowns, bridges, and other restorative dental devices. The furnace is used to heat and form the material into the desired shape, and then the finished product is cooled and removed from the furnace.

Choosing the Right Dental Furnace for Your Practice

There are several factors to consider when choosing the right dental furnace for your practice. Here are a few tips to help you make the best decision:

- Determine your needs: The first step is to assess your specific needs and determine what type of dental furnace will best meet those needs. Consider the types of materials you will be working with, the size and shape of the finished products, and any other factors that may be relevant.

- Research different models: Once you have a good understanding of your needs, start researching different models of dental furnaces to see which ones might be a good fit. Look for reviews and comparisons online, and consider reaching out to other dental professionals for recommendations.

- Consider the size and layout of your practice: Make sure to consider the size and layout of your practice when choosing a dental furnace. You'll need to have enough space to accommodate the furnace, and you'll also want to consider the accessibility and placement of the furnace in relation to your other equipment and workspace.

- Think about maintenance and repair: Consider the maintenance and repair needs of the furnace when making your decision. Some models may require more frequent servicing and repairs, which could be a burden on your practice.

- Evaluate the cost: Finally, consider the cost of the dental furnace, including the initial purchase price, installation fees, and any ongoing maintenance and repair costs. Make sure to compare prices and options to find the best value for your practice.

By carefully evaluating these factors, you can make an informed decision about which dental furnace is the best fit for your practice.

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vertical Laboratory Tube Furnace