fine ceramics

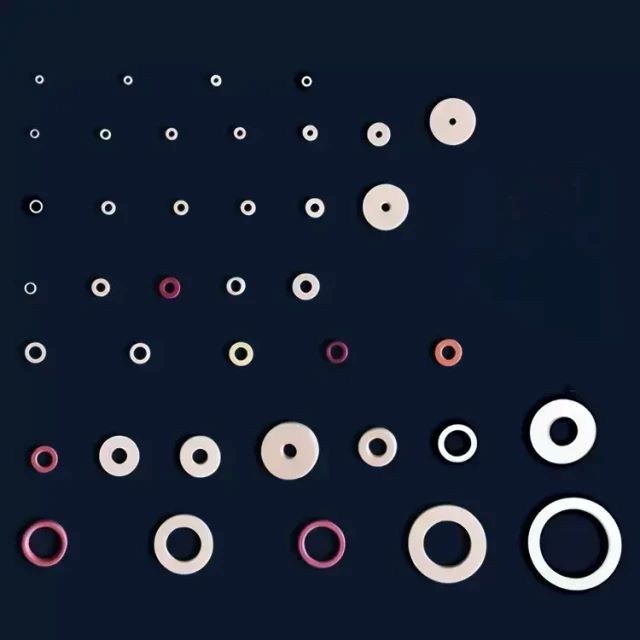

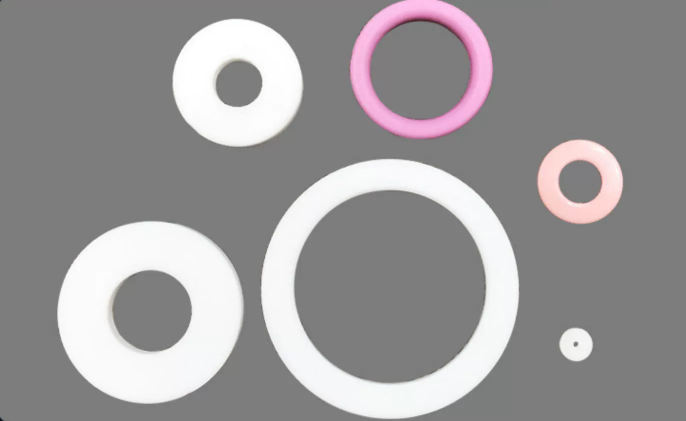

Engineering Advanced Fine Ceramics Aluminium Oxide Al2O3 Ceramic Washer for Wear-Resistant Applications

Item Number : KM-C10

Price varies based on specs and customizations

- Material

- Aluminum oxide

- Specification

- See the form

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

Ceramic gaskets are available in the same shape and configuration as all gaskets and can be produced with flanges, grooves, flats, slots or tube holes. Since the ceramic material can be formed into any size or dimension, alumina ceramic gaskets are the first choice for harsh, stressful and hazardous conditions. All washers have the same function, being a thin plate with holes that distribute the load from a threaded fastener such as a bolt, screw or nut. They are also used as spacers, pads, locking devices and means of dampening vibrations. Capable of being molded and shaped to suit any application, ceramics are ideal for insulating and fixing fittings. It should be noted that ultrasonic cleaning is required. Applications that require a non-conductive material that is resistant to rust, heat and abrasion rely on the strength and durability of ceramics.

- Wires and wire guides: Alumina spacers can be used as guides for wires, ensuring proper alignment and reducing friction during wire processing.

- High Temperature High Voltage Electrical Insulators: These gaskets are suitable for use as insulators in high temperature electrical systems, providing electrical insulation and heat resistance.

- Seals: They are used as seals in various applications to provide a tight and reliable seal against leakage or contamination.

- Furnace body protection tube: Alumina gasket can be used as furnace body protection tube, which has the characteristics of high temperature resistance and chemical corrosion resistance.

- Electronic Substrates: These spacers are used as substrates in electronic components, providing electrical insulation and thermal management.

- Temperature sensor: The temperature sensor can use alumina pads to provide reliable thermal conductivity and high temperature resistance.

- Crucibles: These gaskets are used as crucibles in high temperature applications such as metal melting or chemical reactions.

Detail & Parts

Technical specifications

| Inner 1 outer 7 thick 1.6 | 4 inside, 8 outside, 4 thick | Inner 6.5 outer 15.5 thick 10 | Inner 8 outer 18 thick 8.5 | Inner 9.2 outer 14.5 thick 3.5 | Inner 13 outer 21 thick 5 |

| Inner 1.6 outer 6 thick 1.5 | Inner 4 outer 10 thick 2/3/5 | Inner 7 outer 10 thick 3 | Inner 8 outer 20 thick 2.5/4 | Inside 9.2 outside 14.5 thick 4 | Inner 14.3 outer 21.2 thick 2 |

| Inside 2 outside 4 thick 1 | Inner 5 outer 10 thick 2.5 | Inner 7 outer 14 thick 2.7 | Inner 8.2 outer 25 thick 3/5 | Inside 9.5 outside 18 thick 3 | Inner 14 outer 42 thick 5.5 |

| Inner 2 outer 16 thick 4.5 | Inner 5 outer 10 thick 2/3 | Inner 7 outer 25 thick 5 | Inside 8.5 outside 16 thick 3 | Inside 9 outside 31 thick 10 | Inside 15.5 outside 27 thick 3.5 |

| Inside 3 outside 6 thick 1 | Inner 5 outer 17.8 thick 10 | Inner 7.2 outer 15.5 thick 2.1/2.4 | Inner 8.6 outer 14 thick 1/1.5 | Inner 10 outer 25 thick 3/5 | Inner 16 outer 23 thick 0.8 |

| Inner 3 outer 6 thick 1.5 | Inner 5.5 outer 14 thick 3/5 | Inner 8 outer 12 thick 4 | Inner 8.6 outer 14 thick 2/3/4 | Inside 10 outside 27 thick 0.6 | Inner 16 outer 23 thick 2.5/4 |

| Inner 3 outer 6 thick 2/3/5 | Inside 5.5 outside 14 thick 3/10 | Inner 8.1 outer 13 thick 3 | Inner 8.6 outer 14 thick 5 | Inside 10 outside 36.5 thick 5 | Inner 16 outer 23 thick 5/7.7 |

| Inner 3 outer 10 thick 1.5/2/3/5 | Inner 6 outer 12 thick 2 | Inner 8 outer 13 thick 4 | Inside 9 outside 31 thick 5 | Inner 10 outer 50 thick 5 | Inner 16.5 outer 37 thick 5/10 |

| Inner 3.2 outer 7.8 thick 3.8 | Inner 6 outer 12 thick 3/4/5 | Inner 8 outer 15 thick 1 | Inner 9.2 outer 14.5 thick 2 | Inner 10.5 outer 18 thick 2 | Inner 17 outer 40 thick 3.5 |

| Inner 4 outer 6 thick 1 | Inside 6.5 outside 10 thick 4 | Inner 8 outer 17 thick 8.5 | Inner 9.2 outer 14.5 thick 2.5 | Inner 12.5 outer 25.5 thick 3 | Inner 23 outer 39 thick 3.5/5/10 |

| Inner 4 outer 7 thick 2.5 | Inner 6.5 outer 14 thick 2/4 | Inner 8 outer 18 thick 2 | Inner 9.2 outer 14.5 thick 3 | Inner 12.5 outer 25.5 thick 5 | Inner 31 outer 50.5 thick 3.5 |

The produce we show are available in different sizes and custom sizes are available on request.

Advantages

- Wear-resistant: Aluminum oxide gaskets have high wear resistance

- Excellent Dielectric Properties: These gaskets have excellent electrical insulation properties

- Refractory: Alumina gaskets have a high melting point and can withstand high temperatures without deformation or degradation.

- Strong acid and strong alkali corrosion resistance: These gaskets have strong resistance to strong acid and strong alkali corrosion.

- Good Thermal Conductivity: Enables it to efficiently transfer heat in applications requiring heat dissipation or thermal management.

- Excellent Size and Shape Capability: These gaskets can be precisely manufactured to meet specific size and shape requirements, ensuring a proper fit and an effective seal.

- High Strength and Rigidity: Provides mechanical stability and resistance to deformation under pressure.

Trusted by Industry Leaders

FAQ

What Are The Main Applications Of Fine Ceramics?

What Are The Main Types Of Fine Ceramics?

What Is The Principle Behind Fine Ceramics?

What Are The Advantages Of Using Fine Ceramics?

4.9 / 5

I was blown away by the incredibly fast delivery of my Aluminium Oxide Washer. It arrived within 2 days, much earlier than expected. Thank you, KINTEK SOLUTION!

4.8 / 5

Excellent value for money! The quality of this washer is top-notch, and it's incredibly durable. I highly recommend it to anyone in need of a reliable washer.

4.9 / 5

I am thoroughly impressed with the quality of this Aluminium Oxide Washer. It's made with high-quality materials and has exceeded my expectations in terms of durability and performance.

4.8 / 5

I've been using this washer for a few months now, and it shows no signs of wear or damage. It's incredibly durable, and I'm confident it will last for many years to come.

4.7 / 5

I was pleasantly surprised by the technological advancements incorporated into this washer. It's a game-changer in terms of efficiency and performance.

4.7 / 5

The Aluminium Oxide Washer has been a game-changer for my laboratory. It's a testament to the innovative and cutting-edge solutions offered by KINTEK SOLUTION.

4.8 / 5

KINTEK SOLUTION never disappoints! This washer is another example of their commitment to quality and customer satisfaction. It's a must-have for any laboratory.

4.9 / 5

The washer's exceptional resistance to wear and corrosion has made it an invaluable asset in our laboratory. It's a testament to KINTEK SOLUTION's dedication to providing top-tier products.

4.7 / 5

The washer's ability to withstand high temperatures and its excellent dielectric properties make it an indispensable tool in our laboratory. Thank you, KINTEK SOLUTION, for delivering such a remarkable product.

4.8 / 5

The washer's precise manufacturing and its ability to meet our specific requirements have made it an integral part of our laboratory setup. KINTEK SOLUTION's attention to detail is truly commendable.

4.9 / 5

The washer's high strength and rigidity have been a lifesaver in our laboratory. It has enabled us to conduct experiments with confidence, knowing that the washer will perform flawlessly.

4.8 / 5

The washer's excellent thermal conductivity has made it an essential component in our laboratory's heat dissipation system. It's a testament to KINTEK SOLUTION's commitment to providing innovative solutions.

4.7 / 5

The washer's versatility and its ability to be customized to our specific needs have made it an indispensable tool in our laboratory. KINTEK SOLUTION's customer-centric approach is truly commendable.

4.8 / 5

The washer's remarkable durability and resistance to deformation have made it a reliable workhorse in our laboratory. KINTEK SOLUTION has set a new standard for quality and performance.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

High temperature wear-resistant insulating alumina plate has excellent insulation performance and high temperature resistance.

High Temperature Aluminum Oxide (Al2O3) Protective Tube for Engineering Advanced Fine Ceramics

Alumina oxide protective tube, also known as high temperature resistant corundum tube or thermocouple protection tube, is a ceramic tube mainly made of alumina (aluminum oxide).

High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

Alumina ceramic screws are fastening components made of 99.5% alumina, ideal for extreme applications requiring excellent thermal resistance, electrical insulation and chemical resistance.

Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

In the journey of scientific exploration and industrial production, every detail is crucial. Our arc-shaped alumina ceramic crucibles, with their excellent high temperature resistance and stable chemical properties, have become a powerful assistant in laboratories and industrial fields. They are made of high-purity alumina materials and manufactured through precision processes to ensure excellent performance in extreme environments.

High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

High temperature alumina furnace tube combines the advantages of high hardness of alumina, good chemical inertness and steel, and has excellent wear resistance, thermal shock resistance and mechanical shock resistance.

Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

Silicon carbide (sic) ceramic sheet is composed of high-purity silicon carbide and ultra-fine powder, which is formed by vibration molding and high-temperature sintering.

Advanced Engineering Fine Ceramics Alumina Ceramic Saggar for Fine Corundum

Alumina sagger products have the characteristics of high temperature resistance, good thermal shock stability, small expansion coefficient, anti-stripping, and good anti-powdering performance.

Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

Insulated alumina rod is a fine ceramic material. Alumina rods have excellent electrical insulating properties, high chemical resistance and low thermal expansion.

Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

zirconia ceramic ball have the characteristics of high strength, high hardness, PPM wear level, high fracture toughness, good wear resistance, and high specific gravity.

Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

Cylindrical Crucibles Cylindrical crucibles are one of the most common crucible shapes, suitable for melting and processing a wide variety of materials, and are easy to handle and clean.

High Purity Alumina Granulated Powder for Engineering Advanced Fine Ceramics

Ordinary alumina granulated powder is alumina particles prepared by traditional processes, with a wide range of applications and good market adaptability. This material is known for its high purity, excellent thermal stability and chemical stability, and is suitable for a variety of high-temperature and conventional applications.

Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

TGA/DTA thermal analysis vessels are made of aluminum oxide (corundum or aluminum oxide). It can withstand high temperature and is suitable for analyzing materials that require high temperature testing.

Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

Zirconia insulating ceramic gasket has high melting point, high resistivity, low thermal expansion coefficient and other properties, making it an important high temperature resistant material, ceramic insulating material and ceramic sunscreen material.

Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

Alumina ceramics have good electrical conductivity, mechanical strength and high temperature resistance, while zirconia ceramics are known for their high strength and high toughness and are widely used.

Advanced Engineering Fine Ceramics Aluminum Nitride (AlN) Ceramic Sheet

Aluminum nitride (AlN) has the characteristics of good compatibility with silicon. It is not only used as a sintering aid or reinforcing phase for structural ceramics, but its performance far exceeds that of alumina.

Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

Alumina ceramic crucibles are used in some materials and metal melting tools, and flat-bottomed crucibles are suitable for melting and processing larger batches of materials with better stability and uniformity.

Silicon Carbide (SIC) Ceramic Plate for Engineering Advanced Fine Ceramics

Silicon nitride (sic) ceramic is an inorganic material ceramic that does not shrink during sintering. It is a high-strength, low-density, high-temperature-resistant covalent bond compound.

Precision Machined Silicon Nitride (SiN) Ceramic Sheet for Engineering Advanced Fine Ceramics

Silicon nitride plate is a commonly used ceramic material in the metallurgical industry due to its uniform performance at high temperatures.

Precision Machined Yttria Stabilized Zirconia Ceramic Plate for Engineering Advanced Fine Ceramics

Yttrium-stabilized zirconia has the characteristics of high hardness and high temperature resistance, and has become an important material in the field of refractories and special ceramics.

Related Articles

Dos and don'ts during the installation of molybdenum disilicide (MoSi2) heating element

Precautions when installing MoSi2 heating elements

Advanced Alumina Ceramics: Applications and Manufacturing Techniques

This article discusses the applications and manufacturing techniques of advanced alumina ceramics, including molds, isostatic pressing, and green bodies.

Advanced Alumina Ceramics: Applications and Manufacturing Techniques

Overview of alumina ceramics' applications and manufacturing methods, including molds, isostatic pressing, and green body formation.

Comprehensive Overview of Zirconia Ceramic Materials

A detailed exploration of zirconia ceramics, including properties, history, preparation, molding, sintering, and applications.

Understanding Oxide Ceramics: Concepts, Classification, and Applications

This article delves into the concept, classification, and diverse applications of oxide ceramics, highlighting their significance in various high-tech fields.

Advancements in Engineering Ceramic Materials

Explores new engineering ceramics with exceptional properties and applications in harsh environments, comparing them to traditional materials.

Defects and Solutions for Isostatically Pressed Ceramic Balls

This article discusses various defects in isostatically pressed ceramic balls and provides solution strategies for each type of defect.

Precision Ceramic Materials for Energy Conversion Applications

Overview of various ceramic materials used in energy conversion technologies, including heaters, piezoelectric ceramics, and solid oxide fuel cells.

Advanced Surface Treatment: Titanium CVD Coating

Explores the benefits and applications of CVD coatings on titanium alloys, focusing on wear resistance, corrosion resistance, and thermal stability.

The Ritual of Clarity: A Systemic Approach to Cleaning Furnace Tubes

Cleaning a furnace tube isn't just maintenance; it's calibration. Learn the diagnostic process for quartz and alumina tubes to prevent contamination.