Ceramic Heaters

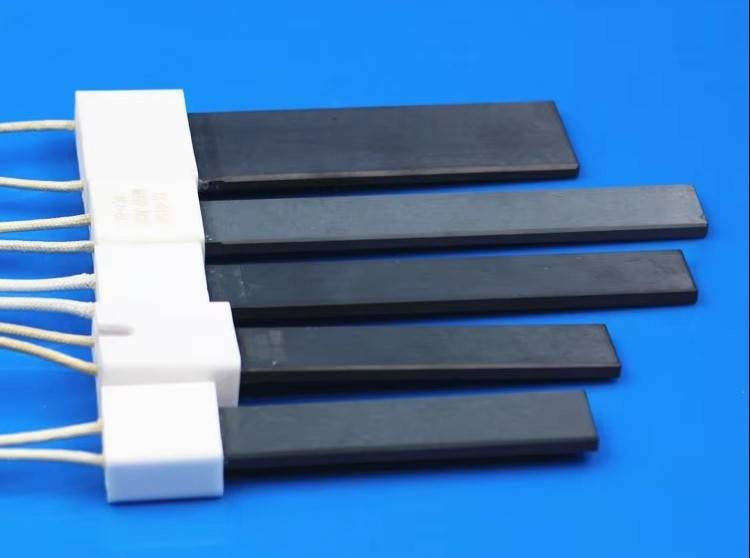

Silicon Nitride Heaters

Silicon nitride heaters are gaining prominence in diverse applications, particularly in the automotive and electronics industries. One of the primary uses of silicon nitride heaters is in diesel engine start-up preheating, where they ensure rapid and efficient ignition, even in cold conditions. These heaters are also integral in high-temperature gas ignition systems, facilitating the combustion process in various industrial settings.

Emerging applications of silicon nitride heaters extend to advanced manufacturing processes, such as curved glass processing for 5G smartphones. The unique properties of silicon nitride, including its strong anti-oxidant capacity and corrosion resistance, make it an ideal material for these demanding applications. Silicon nitride heaters not only prevent self-oxidation and aging but also offer automatic cleaning functions, ensuring that the heating elements remain efficient by shedding accumulated scale when it reaches a critical thickness.

Moreover, the corrosion resistance of silicon nitride heating elements is up to ten times stronger than that of stainless steel, significantly extending their service life to between 5,000 and 15,000 hours. This durability is crucial in environments where high temperatures and corrosive substances are prevalent, such as in gas furnaces and diesel engine glow plugs. These heating elements can reach temperatures as high as 1,400 °C, making them quick to ignite gas, diesel, or kerosene, thereby enhancing operational efficiency and reliability.

Aluminum Oxide Heaters

Aluminum oxide heaters stand out as highly reliable industrial components, capable of withstanding extreme temperatures up to 1,000°C. This advanced ceramics material's exceptional thermal resistance and stability make it an ideal choice for a variety of high-temperature applications.

One of the most innovative uses of aluminum oxide heaters is in the realm of smart toilets, where precise temperature control is essential for user comfort and hygiene. These heaters ensure consistent warmth, enhancing the overall experience of modern bathroom technology.

In addition to smart toilets, aluminum oxide heaters play a critical role in gas sensor technology. Their ability to maintain high temperatures without degradation is crucial for the accurate and reliable operation of gas sensors, which are integral to environmental monitoring and safety systems.

| Application | Temperature Range | Key Benefits |

|---|---|---|

| Smart Toilet Heaters | Up to 1,000°C | Ensures consistent warmth and hygiene |

| Gas Sensor Heaters | Up to 1,000°C | Maintains high temperatures for sensor accuracy |

The robust performance of aluminum oxide heaters across these diverse applications underscores their versatility and reliability in demanding industrial environments.

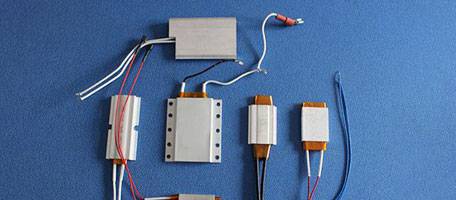

PTC Ceramic Heaters

PTC (Positive Temperature Coefficient) ceramics are renowned for their unique thermal properties, particularly their positive temperature coefficient of resistance, which means their resistance increases with temperature. Unlike conventional ceramics that exhibit a negative coefficient, PTC ceramics, often composed of barium titanate and lead titanate composites, demonstrate a highly nonlinear thermal response. Above a certain threshold temperature, their resistance escalates rapidly, making them self-regulating heaters. This intrinsic property allows PTC ceramics to function as efficient thermostats, conducting current when cool and ceasing conductivity when heated.

These ceramics find extensive applications across various sectors, including automotive, air-conditioning, heating fans, and dryers. In the automotive industry, thin films of PTC ceramics are integral to rear-window defrost heaters, ensuring clear visibility in adverse weather conditions. In more premium applications, such as high-end hair dryers and space heaters, honeycomb-shaped PTC elements are utilized for their superior heat distribution and rapid temperature stabilization. These elements can reach temperatures as high as 950-1000 °C, making them ideal for industrial heating applications that require precise temperature control at lower wattages and voltages.

The versatility of PTC ceramic heaters extends to industrial settings where traditional furnaces are not feasible. These heaters, while operating at lower temperatures compared to industrial furnaces, offer unparalleled precision in temperature regulation, making them suitable for point heating applications that demand consistent and controlled heat. This adaptability underscores the broad utility of PTC ceramics in modern heating technologies.

Piezoelectric Ceramics

Application Areas

Piezoelectric ceramics are versatile materials that facilitate the conversion of mechanical energy into electrical energy and vice versa. Their unique properties make them indispensable in a variety of applications across different industries.

-

Resonators: Piezoelectric ceramics are integral to the functioning of resonators, which are critical components in electronic devices such as oscillators and filters. These resonators ensure stable and precise frequency control, essential for the operation of communication systems and signal processing equipment.

-

Sensors: The ability of piezoelectric ceramics to generate an electric charge in response to mechanical stress makes them ideal for use in sensors. These sensors are employed in applications ranging from medical diagnostics to industrial automation, providing accurate measurements of pressure, force, and acceleration.

-

Ultrasonic Transducers: Piezoelectric ceramics are the backbone of ultrasonic transducers, which convert electrical signals into ultrasonic waves. These transducers are used in medical imaging, non-destructive testing, and underwater sonar systems, enabling precise detection and analysis of objects and materials.

-

Actuators: In the realm of actuators, piezoelectric ceramics convert electrical energy into mechanical motion. This capability is leveraged in micro-positioning systems, precision robotics, and adaptive optics, where fine control and high precision are paramount.

The multifaceted applications of piezoelectric ceramics underscore their significance in modern technology, driving advancements in various fields and contributing to the development of innovative solutions.

Common Materials

In the realm of piezoelectric ceramics, several materials stand out due to their unique properties and widespread applications. Barium titanate is a classic choice, known for its high dielectric constant and excellent piezoelectric properties, making it ideal for use in resonators and sensors. Its ability to convert mechanical stress into electrical energy and vice versa is unparalleled in many applications.

Lead zirconate titanate (PZT), often referred to as the workhorse of piezoelectric ceramics, offers a superior combination of piezoelectric coefficients and mechanical quality factors. PZT is extensively used in ultrasonic transducers, actuators, and high-precision sensors due to its robust performance and reliability. The material's versatility allows it to be tailored for specific applications by adjusting the ratio of zirconium to titanium.

Another notable material is lead niobium magnesium oxide (PMN), which exhibits exceptional piezoelectric properties, particularly in high-sensitivity applications. PMN is often used in advanced sensors and actuators where minute mechanical changes need to be accurately detected and converted into electrical signals. Its unique crystal structure contributes to its high sensitivity and low hysteresis, making it a preferred choice in cutting-edge technologies.

| Material | Key Properties | Applications |

|---|---|---|

| Barium Titanate | High dielectric constant, excellent piezoelectric properties | Resonators, Sensors |

| Lead Zirconate Titanate (PZT) | High piezoelectric coefficients, mechanical quality factors | Ultrasonic Transducers, Actuators |

| Lead Niobium Magnesium Oxide (PMN) | High sensitivity, low hysteresis | Advanced Sensors, Actuators |

These materials are not only foundational in the development of piezoelectric devices but also continue to drive innovation in various energy conversion technologies.

Solid Oxide Fuel Cells (SOFC)

Applications

Solid Oxide Fuel Cells (SOFCs) are renowned for their ability to efficiently convert chemical energy into electricity, making them a versatile solution across multiple sectors. These fuel cells are particularly advantageous in environments where reliable and sustainable energy is crucial.

One of the primary applications of SOFCs is in communication base stations. These stations require a continuous and stable power supply to ensure uninterrupted communication services. SOFCs provide a dependable energy source, especially in remote or off-grid locations where traditional power infrastructure is either unavailable or unreliable.

In residential settings, SOFCs can be integrated into home energy systems to provide both electricity and heat. This dual functionality makes them an attractive option for homeowners seeking to reduce their carbon footprint and energy costs. The quiet operation and minimal maintenance requirements further enhance their appeal in domestic applications.

Commercial establishments also benefit from the deployment of SOFCs. Businesses, particularly those in sectors requiring continuous operation, such as data centers and manufacturing facilities, can leverage SOFCs to ensure uninterrupted power supply. The high efficiency of SOFCs translates into significant cost savings and reduced environmental impact, making them a strategic investment for commercial entities.

Overall, the versatility and efficiency of SOFCs make them a promising technology for a wide range of applications, from telecommunications to residential and commercial energy solutions.

Common Solid Electrolytes

In the realm of Solid Oxide Fuel Cells (SOFC), several ceramic materials serve as pivotal components, particularly in the role of solid electrolytes. Among these, Zirconia (ZrO₂), Ceria (CeO₂), and Bismuth Oxide (Bi₂O₃)-based electrolytes have garnered significant attention due to their unique properties and potential applications. Zirconia, stabilized with yttria, is renowned for its high ionic conductivity at elevated temperatures, making it a preferred choice for SOFCs. Ceria, on the other hand, exhibits excellent oxygen ion conductivity and can operate at lower temperatures, which is particularly beneficial for reducing the overall system complexity and cost. Bismuth oxide-based electrolytes, though less common, offer high conductivity and are being explored for their potential to enhance the performance of SOFCs.

In addition to these, Lanthanum Strontium Gallate (LSGM) and Lanthanum Molybdate (La₂Mo₂O₉) are also noteworthy. LSGM is celebrated for its stability and conductivity across a wide range of oxygen partial pressures and temperatures, making it a versatile option for various SOFC configurations. However, its susceptibility to sulfur poisoning and carbon deposition remains a critical area of research. La₂Mo₂O₉, while less studied, demonstrates promising conductivity and stability, particularly in reducing environments, which could expand its applicability in diverse SOFC systems.

Each of these materials presents distinct advantages and challenges, driving ongoing research to optimize their performance and integrate them more effectively into SOFC technology.

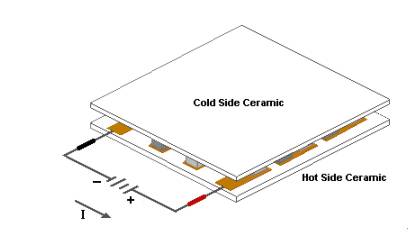

Thermoelectric Cooling Modules

Application Areas

Thermoelectric cooling modules find extensive application across multiple industries, each leveraging their unique capabilities for precise temperature control. In the semiconductor industry, these modules are indispensable for maintaining optimal operating conditions of sensitive electronic components, ensuring consistent performance and longevity.

In consumer electronics, thermoelectric cooling is utilized to enhance user experiences by preventing overheating in devices such as laptops, gaming consoles, and smartphones. This technology not only extends the lifespan of these devices but also ensures uninterrupted performance during extended use.

The automotive sector employs thermoelectric cooling modules to manage temperatures in various components, from engine control units to infotainment systems. This precise temperature control is crucial for enhancing vehicle reliability and performance, especially under extreme environmental conditions.

Additionally, in the communication industry, these modules play a vital role in maintaining the functionality of critical infrastructure such as base stations and network equipment. By ensuring stable operating temperatures, thermoelectric cooling helps in maintaining uninterrupted communication services, which is essential for both urban and remote areas.

| Industry | Application Examples |

|---|---|

| Semiconductor | Maintaining optimal operating temperatures for electronic components |

| Consumer Electronics | Preventing overheating in laptops, gaming consoles, and smartphones |

| Automotive | Managing temperatures in engine control units and infotainment systems |

| Communication | Ensuring stable operation of base stations and network equipment |

These diverse applications underscore the versatility and critical role of thermoelectric cooling modules in modern technology, ensuring efficient and reliable performance across various sectors.

Related Materials

In the realm of thermoelectric cooling modules, several ceramic materials play a pivotal role in enhancing energy conversion efficiency. Aluminum Oxide (Al2O3), Beryllium Oxide (BeO), and Aluminum Nitride (AlN) are integral components in these modules, each contributing unique properties that optimize thermal conductivity and electrical insulation.

Bismuth telluride-based alloys, on the other hand, are frequently employed as semiconductor thermoelectric materials. These alloys are renowned for their ability to efficiently convert temperature differences into electrical energy, making them ideal for applications requiring precise temperature control in sectors such as semiconductor manufacturing, consumer electronics, automotive, and communication industries.

| Material | Key Properties | Applications |

|---|---|---|

| Al2O3 | High thermal conductivity, electrical insulation | Thermoelectric modules |

| BeO | Excellent thermal conductivity, low dielectric constant | Advanced thermoelectric applications |

| AlN | High thermal conductivity, good electrical insulation | High-performance thermoelectric modules |

| Bismuth Telluride | Efficient temperature-to-energy conversion | Semiconductor thermoelectric materials |

These materials are not only essential for the functionality of thermoelectric cooling modules but also drive innovation in energy-efficient technologies across various industries.

Related Products

- Precision Machined Silicon Nitride (SiN) Ceramic Sheet for Engineering Advanced Fine Ceramics

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High Temperature Aluminum Oxide (Al2O3) Protective Tube for Engineering Advanced Fine Ceramics

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element