Thin Film Deposition Parts

Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

Item Number : KM-D9

Price varies based on specs and customizations

- Material

- Boron nitride

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

Boron nitride is a heat-resistant and chemical-resistant compound, and its electrical insulation and electrical breakdown strength are 3-4 times that of alumina. Low coefficient of friction for use up to 900°C in oxidizing atmospheres and up to 2000°C in vacuum. Boron nitride ceramics have good electrical properties. Since ceramics do not conduct electricity, they can be used as electrical insulators. At the same time, due to the characteristics of boron nitride itself, the dielectric constant and dielectric loss are very small, so it is an ideal material for electrical insulation.

- Sintering and smelting of metal materials, rare earths and ceramics.

- Alternatives to graphite and aluminum ceramics.

- High temperature electric furnace components.

- Metal evaporation crucible.

- Mold parts for casting precious metals or special alloys.

- High temperature support parts and stressed parts.

- Melting metal delivery pipes and nozzles.

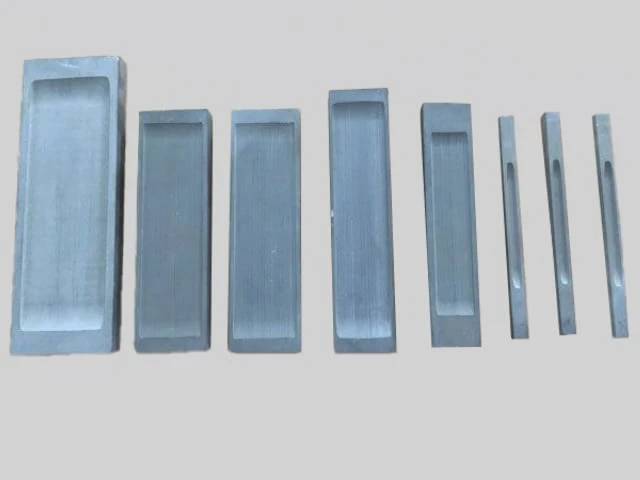

Detail & Parts

The produce we show are available in different sizes and custom sizes are available on request.

Advantages

- Good machinability

- Low dielectric constant

- Excellent dielectric strength

- Low wettability to molten metal

- Relatively high thermal conductivity and low thermal expansion

- High thermal shock resistance compared to other ceramics

- Extremely high operating temperature and proper inert gas protection

Trusted by Industry Leaders

FAQ

What Are The Applications Of Boron Nitride Ceramic Parts?

What Are Advanced Ceramics?

What Are The Advantages Of Using Boron Nitride Ceramic Parts?

What Are The Main Types Of Advanced Ceramics?

What Considerations Should Be Made When Selecting Boron Nitride Ceramic Parts?

What Are The Applications Of Advanced Ceramics?

What Manufacturing Processes Are Used To Produce Boron Nitride Ceramic Parts?

How Are Advanced Ceramics Manufactured?

What Are The Advantages Of Using Advanced Ceramics?

What Is The Difference Between Alumina And Zirconia Ceramics?

Why Are Silicon Carbide Ceramics Used In High-temperature Applications?

What Makes Boron Nitride Ceramics Unique?

How Do Advanced Ceramics Contribute To Energy Efficiency?

4.9 / 5

Quick delivery and the quality is top-notch.

4.7 / 5

Great value for money, performs as expected.

4.8 / 5

Amazing product, exceeded my expectations.

4.6 / 5

Durable and reliable, would recommend.

4.9 / 5

State-of-the-art technology, impressive performance.

4.7 / 5

Easy to use and maintain, a valuable addition to our lab.

4.8 / 5

Great customer service, prompt response to inquiries.

4.6 / 5

Excellent product, worth every penny.

4.9 / 5

Accurate and reliable results, highly recommend.

4.7 / 5

User-friendly interface, makes data analysis a breeze.

4.8 / 5

Versatile and adaptable, meets our diverse needs.

4.6 / 5

Compact and portable, easy to transport and store.

4.9 / 5

Exceptional craftsmanship, built to last.

4.7 / 5

Intuitive and user-friendly, simplifies complex tasks.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

Boron nitride ((BN) is a compound with high melting point, high hardness, high thermal conductivity and high electrical resistivity. Its crystal structure is similar to graphene and harder than diamond.

Custom Boron Nitride (BN) Ceramic Parts

Boron nitride (BN) ceramics can have different shapes, so they can be manufactured to generate high temperature, high pressure, insulation and heat dissipation to avoid neutron radiation.

Hexagonal Boron Nitride HBN Ceramic Ring

Boron nitride ceramic (BN) rings are commonly used in high temperature applications such as furnace fixtures, heat exchangers and semiconductor processing.

Advanced Engineering Fine Ceramics Alumina Ceramic Saggar for Fine Corundum

Alumina sagger products have the characteristics of high temperature resistance, good thermal shock stability, small expansion coefficient, anti-stripping, and good anti-powdering performance.

Advanced Engineering Fine Ceramics Aluminum Nitride (AlN) Ceramic Sheet

Aluminum nitride (AlN) has the characteristics of good compatibility with silicon. It is not only used as a sintering aid or reinforcing phase for structural ceramics, but its performance far exceeds that of alumina.

Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

Cylindrical Crucibles Cylindrical crucibles are one of the most common crucible shapes, suitable for melting and processing a wide variety of materials, and are easy to handle and clean.

High Purity Alumina Granulated Powder for Engineering Advanced Fine Ceramics

Ordinary alumina granulated powder is alumina particles prepared by traditional processes, with a wide range of applications and good market adaptability. This material is known for its high purity, excellent thermal stability and chemical stability, and is suitable for a variety of high-temperature and conventional applications.

Engineering Advanced Fine Ceramics Aluminium Oxide Al2O3 Ceramic Washer for Wear-Resistant Applications

Alumina wear-resistant ceramic washer are used for heat dissipation, which can replace aluminum heat sinks, with high temperature resistance and high thermal conductivity.

Precision Machined Silicon Nitride (SiN) Ceramic Sheet for Engineering Advanced Fine Ceramics

Silicon nitride plate is a commonly used ceramic material in the metallurgical industry due to its uniform performance at high temperatures.

Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

Silicon carbide (sic) ceramic sheet is composed of high-purity silicon carbide and ultra-fine powder, which is formed by vibration molding and high-temperature sintering.

Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

zirconia ceramic ball have the characteristics of high strength, high hardness, PPM wear level, high fracture toughness, good wear resistance, and high specific gravity.

Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

In the journey of scientific exploration and industrial production, every detail is crucial. Our arc-shaped alumina ceramic crucibles, with their excellent high temperature resistance and stable chemical properties, have become a powerful assistant in laboratories and industrial fields. They are made of high-purity alumina materials and manufactured through precision processes to ensure excellent performance in extreme environments.

Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

Zirconia ceramic tweezers are a high-precision tool made of advanced ceramic materials, especially suitable for operating environments that require high precision and corrosion resistance. This type of tweezers not only has excellent physical properties, but is also popular in the medical and laboratory fields because of its biocompatibility.

Precision Machined Yttria Stabilized Zirconia Ceramic Plate for Engineering Advanced Fine Ceramics

Yttrium-stabilized zirconia has the characteristics of high hardness and high temperature resistance, and has become an important material in the field of refractories and special ceramics.

Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

Alumina ceramics have good electrical conductivity, mechanical strength and high temperature resistance, while zirconia ceramics are known for their high strength and high toughness and are widely used.

High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

Alumina ceramic screws are fastening components made of 99.5% alumina, ideal for extreme applications requiring excellent thermal resistance, electrical insulation and chemical resistance.

High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

High temperature wear-resistant insulating alumina plate has excellent insulation performance and high temperature resistance.

High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

High temperature alumina furnace tube combines the advantages of high hardness of alumina, good chemical inertness and steel, and has excellent wear resistance, thermal shock resistance and mechanical shock resistance.

Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

Alumina ceramic crucibles are used in some materials and metal melting tools, and flat-bottomed crucibles are suitable for melting and processing larger batches of materials with better stability and uniformity.

Related Articles

CVD furnace for the growth of carbon nanotubes

Chemical vapor deposition (CVD) furnace technology is a widely used method for growing carbon nanotubes.

Hexagonal Boron Nitride: Enhancing Performance in Composite Ceramic Materials

Explores the role of h-BN in various composite ceramics, highlighting its properties and applications.

The Future of Lab Presses in Research and Development

Lab presses are an essential tool in research and development for a wide range of industries, including pharmaceuticals, materials science, and electronics.

Guidelines for the Use of Boron Nitride Crucibles

Instructions on the proper use, precautions, and compatibility of boron nitride crucibles.

Precision Ceramics in Semiconductor Applications

Exploring the use of precision ceramics in semiconductor equipment, their properties, and manufacturing processes.

Precision Ceramic Materials for Energy Conversion Applications

Overview of various ceramic materials used in energy conversion technologies, including heaters, piezoelectric ceramics, and solid oxide fuel cells.

Structure and Properties of High-Temperature Engineering Ceramics

Explore the applications, structural features, and performance advantages of high-temperature engineering ceramics across various industries.

Engineering Ceramic Materials: Applications in Aerospace, Electronic Information, New Energy, and Environmental Protection

This article explores the diverse applications of engineering ceramic materials across aerospace, electronic information, new energy, and environmental protection sectors.

Understanding Oxide Ceramics: Concepts, Classification, and Applications

This article delves into the concept, classification, and diverse applications of oxide ceramics, highlighting their significance in various high-tech fields.

Mechanical Properties and Structural Enhancements of Ceramics

An in-depth analysis of the mechanical properties of ceramics, including strengths, weaknesses, and methods for improvement.

PTFE's high temperature and corrosion resistance: Why it is indispensable in industry

The unique advantages of polytetrafluoroethylene (PTFE) in high temperature and corrosion resistance analyze why it has become an indispensable material in industry, especially in applications in harsh environments.

Polytetrafluoroethylene (PTFE): How low friction coefficient promotes industrial progress

Explore the unique advantages of polytetrafluoroethylene (PTFE)'s low coefficient of friction and analyze how it promotes progress and innovation in industrial technology in terms of reducing wear and improving equipment efficiency.