Polytetrafluoroethylene (PTFE) has become a "star" in the field of engineering materials due to its unique low friction coefficient (0.01–0.10). This feature not only reduces the energy loss of mechanical systems, but also spawns revolutionary applications in the fields of sealing, bearings, aerospace, etc., becoming a key support for the efficient operation of modern industry.

I. The scientific basis of low friction coefficient

In the molecular structure of PTFE, the carbon chain is tightly wrapped by fluorine atoms, forming a weak intermolecular force, and the surface molecules are easy to slide, thus showing extremely low friction. Studies have found that its friction coefficient remains almost stable in the range from ultra-low temperature to melting point (327°C), and only increases significantly when the surface temperature exceeds the melting point. It is worth noting that in extremely low temperature environments (such as liquid nitrogen), the amorphous part of PTFE will vitrify, the movement of the molecular chain is hindered, and the friction coefficient increases. However, at conventional industrial temperatures, the heat generated by the friction interface can partially soften the material, further reducing the friction coefficient. In addition, the static friction coefficient of PTFE is lower than the dynamic friction coefficient, which can reduce the starting resistance in bearings and other components to ensure smooth operation.

II. Multi-dimensional breakthroughs in industrial applications

1. Sealing technology innovation

The low friction characteristics of PTFE seals (friction coefficient of about 0.04) directly reduce the energy loss of equipment. For example, in high-speed machinery, the reduction of friction resistance can improve the operating efficiency by more than 20%, while reducing wear and extending the life of the equipment. Its self-lubricating property can maintain low friction even in oil-free conditions, which is crucial for oil-free environments (such as oxygen production equipment).

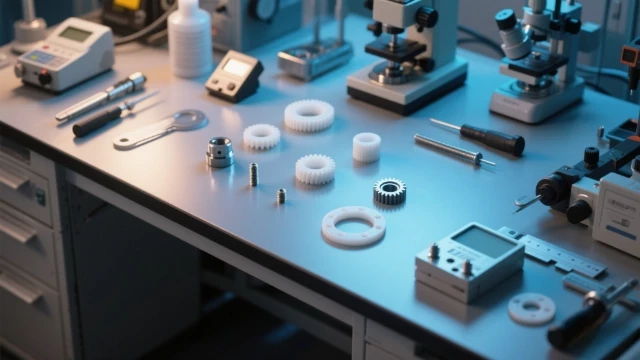

2. Bearing and transmission system optimization

PTFE coatings or composite materials are widely used in bearing manufacturing. Its low friction coefficient can reduce starting resistance and remain stable under high loads (>0.8 MPa), significantly reducing maintenance costs. For example, in chemical pumps, PTFE bearings can withstand strong acid corrosion and reduce failures caused by friction.

3. Aerospace and high-end manufacturing

In aircraft moving parts, PTFE's low friction characteristics reduce wear and improve fuel efficiency. In addition, its high temperature resistance (-200°C to 260°C) and chemical inertness make it an ideal choice for rocket fuel valve seals, ensuring reliability in extreme environments.

III. Comprehensive benefits and future directions

The energy-saving effect brought by the low friction coefficient is significant. Taking the petrochemical industry as an example, the application of PTFE seals can reduce equipment energy consumption by about 15%, while reducing safety accidents caused by leakage. Its corrosion resistance also extends the service life of equipment in strong acid and strong alkali environments. In the future, through nano-modification and composite material development (such as adding carbon fiber or graphene), PTFE's wear resistance and mechanical properties will be further improved to meet the needs of emerging fields such as nuclear energy and deep-sea equipment.

Conclusion

PTFE takes low friction as its core, combined with high temperature resistance and corrosion resistance, to build an "invisible engine" for industrial progress. From microscopic molecular design to macroscopic engineering applications, this material continues to promote efficient, environmentally friendly and safe industrial transformation, and its potential still needs to be deeply explored in the wave of new material technology.

Related Products

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Custom PTFE Teflon Parts Manufacturer for PTFE Bottle Oil Fume Sampling Tube

- Custom PTFE Teflon Parts Manufacturer for Hydrothermal Synthesis Reactor Polytetrafluoroethylene Carbon Paper and Carbon Cloth Nano-growth

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

Related Articles

- The Art of the Non-Spontaneous: Precision in Electrolytic Circuits

- The Silent Dialogue: Mastering Control in Electrolytic Cells

- The key role of PTFE in semiconductor manufacturing: from gas pipelines to electrical insulation

- The Art of Resistance: Why Your Electrolytic Cell Needs Breathing Room

- PTFE's high temperature and corrosion resistance: Why it is indispensable in industry