Usage Conditions

Operating Temperatures

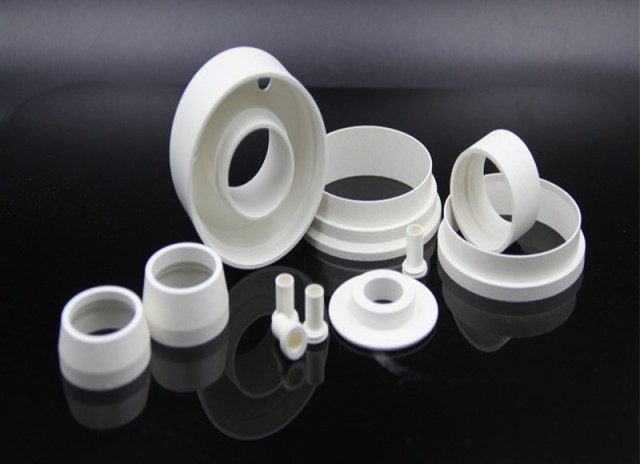

Boron nitride crucibles exhibit exceptional performance across a wide range of temperatures, making them versatile tools in high-temperature applications. These crucibles can be utilized under vacuum conditions at temperatures as high as 1800°C, which is particularly useful for processes requiring an oxygen-free environment. Additionally, they can withstand temperatures up to 2000°C when protected by an inert atmosphere.

For optimal performance and extended service life, it is recommended to use nitrogen or argon atmospheres. These inert gases not only protect the boron nitride crucible from oxidation but also prevent potential contamination from reactive elements in the surrounding environment. The choice of atmosphere is crucial, as it directly impacts the durability and longevity of the boron nitride crucible.

| Condition | Maximum Temperature | Recommended Atmosphere |

|---|---|---|

| Under Vacuum | 1800°C | None |

| Under Atmosphere | 2000°C | Nitrogen or Argon |

By adhering to these operating conditions, users can ensure the maximum utility and lifespan of their boron nitride crucibles, making them a reliable choice for various high-temperature applications.

Thermal Shock Resistance

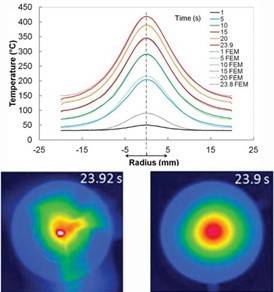

The boron nitride crucible boasts exceptional thermal shock resistance, a property derived from its high thermal conductivity, low thermal expansion, and robust strength. This resistance is crucial in environments where rapid temperature changes are frequent, as these conditions can induce significant thermal stresses in materials. Unlike metals and plastics, which often succumb to such stresses, ceramics like boron nitride are renowned for their superior ability to withstand thermal shocks.

When subjected to extreme temperature fluctuations, the crucible demonstrates remarkable durability. For instance, it can be heated to 1000°C and maintained at that temperature for 20 minutes, followed by immediate cooling via air, without incurring any cracks. Similarly, it can withstand rapid cooling from 1500°C down to room temperature, a process that can be repeated up to 100 times without compromising its structural integrity.

This exceptional thermal shock resistance is attributed to the material's inherent properties. The high thermal conductivity ensures that heat is distributed evenly throughout the crucible, preventing localized hotspots that could lead to cracking. The low thermal expansion coefficient means that the material experiences minimal dimensional changes with temperature variations, further enhancing its ability to resist thermal stresses. Additionally, the crucible's high strength ensures that it can endure the mechanical stresses associated with thermal cycling without fracturing.

In summary, the boron nitride crucible's thermal shock resistance makes it an ideal choice for applications requiring frequent and rapid temperature changes, offering both reliability and longevity.

Precautions

Oxidation Risk

Above 900°C, boron nitride is susceptible to oxidation when exposed to oxygen, leading to potential degradation of the material. This critical temperature threshold underscores the importance of maintaining controlled atmospheres during high-temperature operations. To mitigate this risk, it is advisable to use protective atmospheres such as nitrogen or argon, which are recommended for the longest service life of boron nitride crucibles.

| Temperature Range | Oxidation Risk | Mitigation Strategies |

|---|---|---|

| Below 900°C | Low | No special precautions needed |

| 900°C - 1200°C | Moderate | Use protective atmospheres (N₂, Ar) |

| Above 1200°C | High | Strict control of oxygen exposure; continuous use of protective gases |

In environments where temperatures exceed 1200°C, the risk of oxidation increases significantly. Continuous monitoring and the use of inert gases become essential to prevent oxidation and maintain the integrity of the boron nitride crucible.

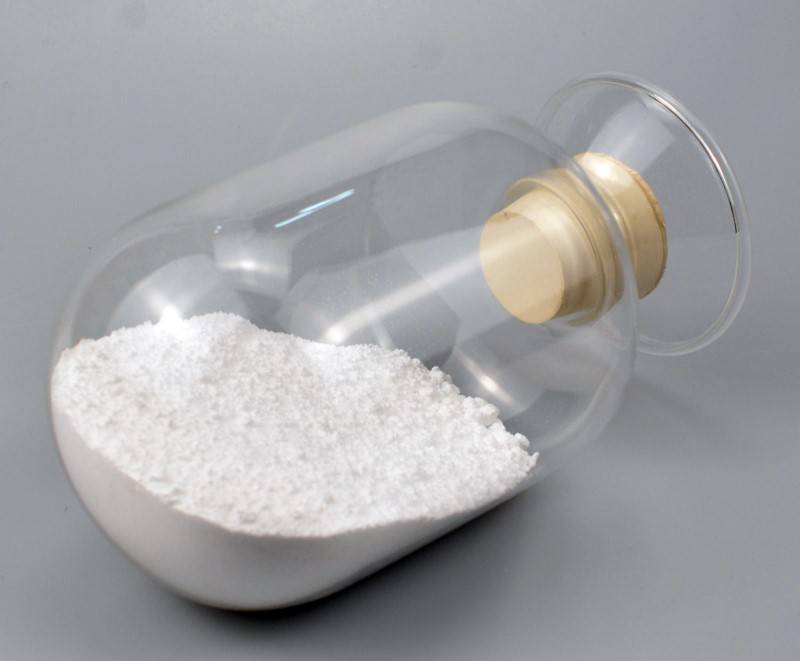

Storage and Maintenance

When storing boron nitride crucibles, it is crucial to avoid environments where moisture is prevalent. Moisture can compromise the integrity and performance of the crucibles. For this reason, sealed storage is highly recommended to protect the crucibles from humidity and other environmental factors that could lead to deterioration.

Cleaning the crucibles requires a method that does not involve water. Water can react with the crucible material, leading to potential damage. Instead, sandpaper or similar abrasive materials should be used to clean dirty surfaces. This method ensures that the crucible remains intact while effectively removing any dirt or residue that may have accumulated.

Substitution for Other Crucibles

Boron nitride crucibles offer a versatile alternative to traditional crucibles, making them a preferred choice in various industrial applications. They can effectively replace tungsten, molybdenum, aluminum oxide, and graphite crucibles, each of which has its own set of limitations and challenges.

Comparative Advantages

| Traditional Crucible | Limitation/Challenge | BN Crucible Advantage |

|---|---|---|

| Tungsten | High density and brittleness, limited by high melting point. | Lower density, better thermal shock resistance. |

| Molybdenum | Susceptible to oxidation and embrittlement. | Resistant to oxidation, maintains structural integrity. |

| Aluminum Oxide | Prone to thermal shock and cracking. | Excellent thermal shock resistance, durable. |

| Graphite | Oxidizes easily, limited by low melting point. | High-temperature stability, minimal oxidation. |

Key Benefits of BN Crucibles

- Thermal Stability: Boron nitride crucibles can operate under vacuum at 1800°C and under atmosphere protection at 2000°C, making them suitable for high-temperature applications.

- Chemical Resistance: They are resistant to oxidation above 900°C when protected from oxygen, ensuring longer service life.

- Compatibility: Compatible with a wide range of materials, including ferrous and non-ferrous metals, glass, silicon, and various alloys.

By leveraging these advantages, boron nitride crucibles provide a robust and reliable solution for industries requiring high-performance crucibles.

Compatible Materials

Ferrous and Non-Ferrous Metals

Boron nitride crucibles exhibit exceptional compatibility with a wide array of ferrous and non-ferrous metals, making them a versatile choice for various industrial applications. These metals include:

-

Ferrous Metals:

- Iron

- Stainless Steel

- Nickel

-

Non-Ferrous Metals:

- Copper

- Bismuth

- Germanium

- Aluminum

- Antimony

- Tin

- Cadmium

- Lead

- Zinc

- Brass

- Indium

- Magnesium

This compatibility ensures that the crucibles can be used in diverse metalworking processes without compromising the integrity of the crucible or the purity of the metal. The ability to handle both ferrous and non-ferrous metals underscores the broad applicability of boron nitride crucibles in the metallurgical industry.

Glass and Silicon

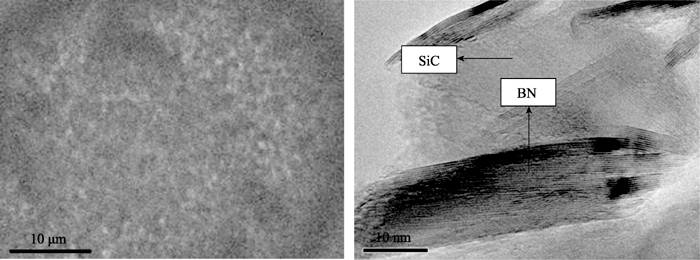

Boron nitride crucibles exhibit exceptional compatibility with a variety of materials, particularly those commonly used in high-temperature applications such as glass and silicon processing. These crucibles are designed to withstand the rigors of handling glass melts, including sodium glass and cryolite, which are integral components in the production of various glass products. Additionally, they are fully compatible with silicon, a key element in the semiconductor industry, ensuring that the purity and integrity of silicon ingots remain uncompromised during the melting and casting processes.

Moreover, boron nitride crucibles are adept at managing molten salts such as slag fluoride, which are often used in metallurgical processes. This compatibility extends to a wide array of materials, making boron nitride crucibles a versatile choice for industries requiring high-temperature crucible solutions.

Alloys

Boron nitride crucibles exhibit remarkable compatibility with a variety of alloys, making them a versatile choice for high-temperature applications. Two notable examples of compatible alloys are the FE-CO-NI-SI and CO-ZR-NB alloys.

The FE-CO-NI-SI alloy, which typically includes iron (Fe), cobalt (Co), nickel (Ni), and silicon (Si), is known for its strength and resistance to corrosion. This alloy is particularly suitable for use in boron nitride crucibles due to its ability to maintain structural integrity under extreme temperatures. The crucibles provide a stable environment for the alloy, preventing any adverse reactions that could compromise the material's properties.

Similarly, the CO-ZR-NB alloy, composed of cobalt (Co), zirconium (Zr), and niobium (Nb), is another excellent candidate for use in boron nitride crucibles. This alloy is prized for its high melting point and excellent mechanical properties, which are preserved when processed in a boron nitride crucible. The crucible's inert nature ensures that the alloy remains unaffected by the crucible material, allowing for precise and controlled processing.

In summary, boron nitride crucibles are highly compatible with both FE-CO-NI-SI and CO-ZR-NB alloys, making them ideal for a range of high-temperature applications where material integrity and process control are paramount.

Incompatible Materials

Oxidizing Compounds

Boron nitride crucibles are highly reactive with several oxidizing compounds, which can lead to significant degradation and potential failure of the crucible. Specifically, the crucibles should be handled with extreme caution when in contact with antimony trioxide, chromium heptaoxide, molybdenum trioxide, arsenic trioxide, and titanium carbide. These compounds can cause severe chemical reactions that compromise the structural integrity and performance of the crucible.

| Incompatible Compound | Potential Reaction |

|---|---|

| Antimony Trioxide | Reacts violently, leading to rapid erosion and loss of material. |

| Chromium Heptaoxide | Can form chromium compounds that are highly corrosive to boron nitride. |

| Molybdenum Trioxide | Causes significant oxidation and weakening of the crucible walls. |

| Arsenic Trioxide | Leads to the formation of volatile arsenic compounds, damaging the crucible. |

| Titanium Carbide | Reacts to form titanium nitride, which can further react with boron nitride, causing structural damage. |

Avoiding exposure to these oxidizing compounds is crucial for maintaining the longevity and effectiveness of boron nitride crucibles. Proper handling and storage protocols should include stringent measures to prevent contact with these hazardous materials.

High Leaded Vitreous Enamel

High leaded vitreous enamel presents a specific challenge when used in conjunction with boron nitride crucibles. At temperatures ranging from 800°C to 950°C, these materials are incompatible in air. The interaction between high leaded vitreous enamel and boron nitride crucibles under these conditions can lead to undesirable reactions, compromising the integrity of both materials.

However, this incompatibility is not universal. When exposed to nitrogen or inert gases, high leaded vitreous enamel does not react with boron nitride crucibles. This suggests that the issue primarily arises in the presence of oxygen, which is a common component of air. Therefore, to mitigate potential risks, it is advisable to operate boron nitride crucibles in an oxygen-free environment when handling high leaded vitreous enamel at elevated temperatures.

To summarize, while high leaded vitreous enamel and boron nitride crucibles can coexist under certain conditions, careful consideration of the operating environment is crucial. Maintaining an inert atmosphere can prevent adverse reactions, ensuring the safe and effective use of both materials.

Boron Phosphate and Potassium Phosphate

When considering the use of boron nitride crucibles, it is crucial to be aware of the materials that can cause significant degradation. Boron phosphate (BPO₄) is particularly detrimental, as it initiates erosion of BN at elevated temperatures, specifically around 1400°C. This erosion can lead to structural weakening and potential failure of the crucible under prolonged exposure.

Similarly, potassium phosphate (K₃PO₄) poses a threat at slightly lower temperatures, reacting with BN between 800-900°C. This reaction not only compromises the integrity of the crucible but also alters its chemical composition, rendering it less effective for high-temperature applications.

To mitigate these risks, it is advisable to avoid using boron nitride crucibles in environments where boron phosphate or potassium phosphate are present, especially at the aforementioned temperatures. Alternative crucible materials or protective measures should be considered to ensure the longevity and safety of your high-temperature processes.

Titanium Dioxide

When using boron nitride crucibles, it's crucial to be aware of their compatibility with various materials, particularly those that can cause slight erosion at high temperatures. One such material is titanium dioxide.

Titanium dioxide, a common industrial chemical, can cause minor erosion on boron nitride crucibles when exposed to elevated temperatures. This erosion can be attributed to the chemical interactions between titanium dioxide and the boron nitride structure, which can lead to a gradual degradation of the crucible's integrity over time.

To mitigate this issue, it is advisable to limit the exposure of boron nitride crucibles to titanium dioxide, especially in high-temperature applications. Additionally, regular inspections and maintenance can help identify any signs of erosion early, allowing for timely replacement or repair to ensure the crucible's longevity and effectiveness.

| Material | Compatibility |

|---|---|

| Titanium Dioxide | Slight erosion at high temperatures |

Understanding the potential for erosion from materials like titanium dioxide is essential for maintaining the performance and lifespan of boron nitride crucibles in various industrial applications.

Alkalis and Chlorine Gas

Boron nitride crucibles exhibit specific reactivity under certain conditions, particularly with hot concentrated or molten alkalis and hot chlorine gas. When exposed to these materials, the crucibles can undergo significant chemical reactions that may affect their structural integrity and performance.

Reactivity with Alkalis

Hot concentrated or molten alkalis, such as sodium hydroxide (NaOH) and potassium hydroxide (KOH), pose a notable risk to boron nitride crucibles. These alkalis can penetrate the crucible material, leading to degradation and potential failure. The severity of the reaction is exacerbated by high temperatures, which can accelerate the chemical interaction between the alkalis and the boron nitride.

Reactivity with Chlorine Gas

Similarly, hot chlorine gas can also induce adverse reactions with boron nitride crucibles. Chlorine gas, when heated, can react with the crucible material, causing erosion and weakening of the crucible walls. This reaction is particularly concerning in industrial settings where chlorine gas is used in high-temperature processes.

| Material | Reactivity |

|---|---|

| Hot Concentrated Alkalis | Significant degradation and potential failure due to chemical penetration. |

| Hot Molten Alkalis | Accelerated chemical interaction at high temperatures. |

| Hot Chlorine Gas | Erosion and weakening of crucible walls due to chemical reaction. |

Understanding these reactions is crucial for ensuring the safe and effective use of boron nitride crucibles. Operators should take appropriate precautions to avoid exposing the crucibles to these incompatible materials, thereby preserving their integrity and extending their service life.

Related Products

- Boron Nitride (BN) Crucible for Phosphorous Powder Sintered

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Boron Nitride (BN) Ceramic Tube

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

- Boron Nitride (BN) Ceramic Rod for High Temperature Applications

Related Articles

- Comparison of Pyrolytic Graphite and Pyrolytic Boron Nitride Crucibles

- Comprehensive Guide to Spark Plasma Sintering Furnaces: Applications, Features, and Benefits

- Fused Silica Crucible: Properties, Applications, and Preparation Process

- The Role and Types of Crucibles in Scientific Experiments

- Applications and Importance of Hydraulic Press in Laboratories