Introduction to Ceramics

Definition and Traditional Concepts

Ceramics, as a class of materials, are derived from clay and other natural minerals, undergoing a series of meticulous processes to transform them into usable products. These processes typically include crushing, mixing, molding, and calcining. The term "ceramics" encompasses a broad spectrum of materials, with traditional ceramics often categorized into two primary types: pottery and porcelain. These materials are integral to the silicate industry, which focuses on the production and application of silicate-based compounds.

In the realm of traditional ceramics, the raw materials—predominantly clay—are subjected to rigorous processing to achieve the desired properties and forms. The transformation begins with the crushing of raw minerals, which is followed by thorough mixing to ensure uniformity. The mixed material is then shaped into various forms through molding techniques, which can range from simple hand-molding to complex mechanical processes. Finally, the shaped material undergoes calcination, a high-temperature heating process that imparts strength and durability, converting the clay into a ceramic product.

This traditional approach to ceramic production has been refined over centuries, resulting in a rich history of craftsmanship and innovation. The categorization of ceramics into pottery and porcelain reflects the diverse applications and aesthetic qualities of these materials. Pottery, often associated with everyday use items like dishes and vases, is characterized by its utility and decorative appeal. In contrast, porcelain, known for its translucence and strength, is typically reserved for more delicate and high-value applications, such as fine tableware and decorative art pieces.

The silicate industry, which encompasses the production of ceramics, plays a crucial role in various sectors, from household goods to architectural applications. The versatility and durability of ceramic materials make them indispensable in both traditional and modern contexts, underscoring their significance in the broader industrial landscape.

Broader Definition of Ceramic Materials

Ceramic materials encompass a vast array of inorganic, non-metallic substances, excluding both organic and metallic elements. This broad definition includes a diverse array of materials, each possessing unique physical and chemical properties that make them suitable for a wide range of applications. The complexity and variety of ceramic materials present significant challenges in their classification, as each type can exhibit vastly different characteristics depending on its composition and processing methods.

For instance, traditional ceramics, such as pottery and porcelain, are derived from clay and natural minerals, while advanced ceramics include oxides, nitrides, carbides, borides, silicides, fluorides, and sulfides. These advanced ceramics are further categorized into functional ceramics, which include piezoelectric and ferroelectric materials, and structural ceramics, known for their high strength and thermal resistance.

The versatility of ceramic materials is highlighted by their use in everything from everyday household items to cutting-edge aerospace technology. This diversity not only underscores the importance of understanding their properties but also the ongoing research and development efforts aimed at harnessing their potential in new and innovative ways.

Classification of Ceramics

Traditional Ceramics

Traditional ceramics, crafted from clay and natural minerals, have been a cornerstone of human civilization for millennia. These materials are processed through time-honored methods, such as shaping by hand or with simple tools, followed by drying and firing in kilns at high temperatures. The resulting products are not only integral to daily life but also find extensive use in construction and decorative arts.

One of the most enduring qualities of traditional ceramics is their stability—both thermally and chemically. This robustness has made them indispensable in early human history, serving as essential tools like cooking vessels, serving dishes, and sculpted figures. The versatility of clay, which can be mixed with other materials such as silica sand to enhance its properties, allows for a wide range of applications.

As technology has progressed, the utility and perception of ceramics have evolved, yet traditional methods remain vital. Today, ceramic products are classified into several categories, each with its unique properties and uses, reflecting the ongoing importance of these ancient materials in modern life.

Advanced Ceramics

Advanced ceramics are meticulously categorized by their chemical composition and performance characteristics, encompassing a diverse array of materials such as oxides, nitrides, carbides, borides, silicides, fluorides, and sulfides. These materials are further classified into functional and structural ceramics based on their specific applications.

Functional ceramics are engineered to exhibit unique electrical, magnetic, or optical properties, making them indispensable in electronic devices, sensors, and actuators. On the other hand, structural ceramics are prized for their exceptional mechanical properties, including high strength, hardness, and wear resistance, which are crucial for applications in aerospace, automotive, and industrial machinery.

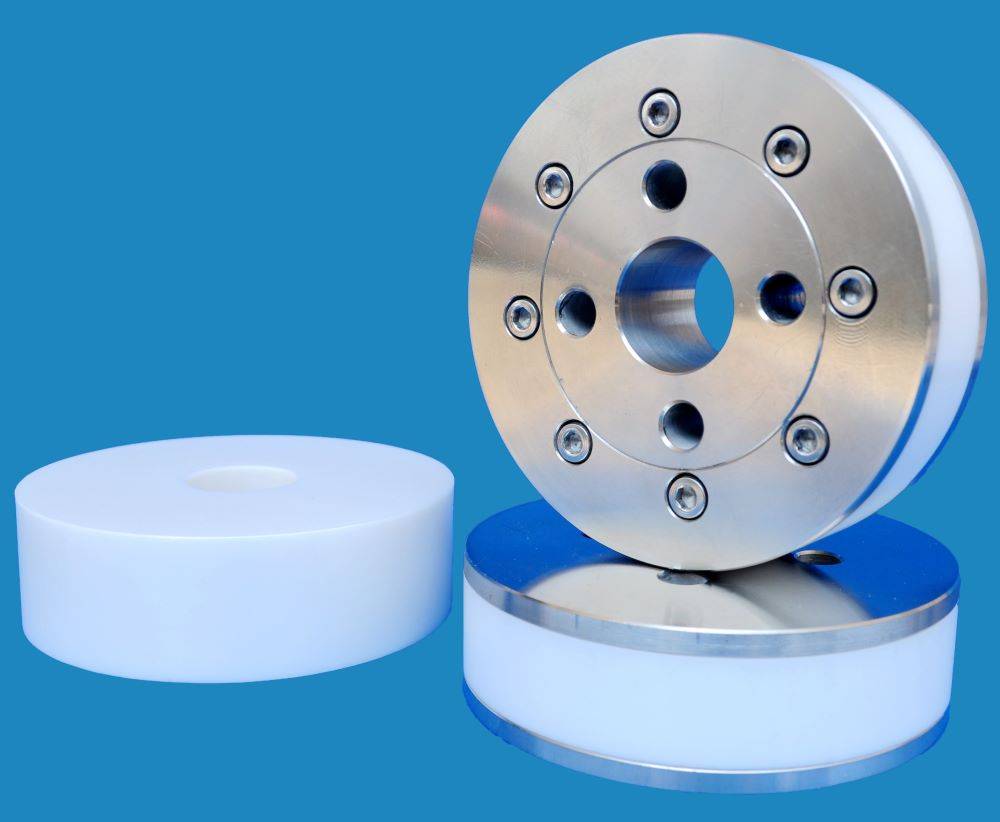

The precision with which these ceramics are manufactured is a testament to their importance in modern technology. Companies like Final Advanced Materials specialize in producing ceramic parts with unparalleled accuracy, using advanced diamond machining techniques to shape dense ceramics from molded or extruded blanks. This meticulous process ensures that the physical characteristics of the ceramic components remain unaltered, maintaining the high purity and performance required for specific applications.

Moreover, the ability to design and machine ceramic prototypes as well as produce them in small and large series further underscores the versatility and strategic value of advanced ceramics in various industrial sectors.

Strategic Importance and Development

Global Strategic Initiatives

Advanced ceramics have garnered significant strategic importance, attracting substantial investments from key global players such as the USA, Japan, and the European Union (EU). These nations recognize the critical role that advanced ceramics play in various high-tech industries, from aerospace to defense, and have initiated comprehensive programs to bolster their research and development efforts.

In the USA, the 'Brittle Materials Design' program stands out as a flagship initiative aimed at enhancing the durability and performance of ceramics in extreme conditions. This program focuses on developing advanced ceramic materials that can withstand high temperatures, pressures, and corrosive environments, making them ideal for applications in aerospace and nuclear industries.

Similarly, Japan's 'Sunshine Program' underscores the nation's commitment to advancing ceramic technologies. This program is particularly notable for its emphasis on industrialization and civil applications, leveraging advanced ceramics to improve energy efficiency, reduce environmental impact, and enhance the quality of life. Japan's strategic investments in this area have positioned it as a leader in the development and commercialization of advanced ceramic technologies.

The EU, too, has not been left behind in this race. European countries have launched several initiatives aimed at harnessing the potential of advanced ceramics for specific applications and machinery. These initiatives are part of a broader strategy to maintain technological leadership and ensure that European industries remain competitive on the global stage.

| Country | Strategic Initiative | Focus Area |

|---|---|---|

| USA | Brittle Materials Design | Aerospace, Nuclear |

| Japan | Sunshine Program | Industrialization, Civil Applications |

| EU | Various Initiatives | Specific Applications, Machinery |

These global strategic initiatives reflect a concerted effort to harness the unique properties of advanced ceramics, driving innovation and paving the way for future technological advancements.

Leading Countries in Advanced Ceramics

The global landscape of advanced ceramics is dominated by a few key players, each excelling in distinct areas due to their unique strategic initiatives and technological advancements. The United States stands out in aerospace and nuclear applications, leveraging its robust research and development programs to pioneer new materials like transparent ceramics for defense and high-temperature structural ceramics for aerospace. These innovations have solidified the U.S. position as a leader in materials critical for national security and space exploration.

Japan, on the other hand, excels in the industrialization and civil fields of ceramics. The country's 'Sunshine Program' has been instrumental in driving advancements in ceramic preparation technologies, particularly in heat-resistant structural ceramics and high-strength, high-toughness ceramics. This focus has not only enhanced industrial applications but also permeated into civil sectors, improving daily life through innovations in consumer goods and infrastructure.

The European Union (EU) plays a pivotal role in specific applications and machinery, where precision and durability are paramount. The EU's strategic investments in advanced ceramics have led to breakthroughs in machinery components, medical devices, and environmental technologies. These specialized applications underscore the EU's commitment to integrating advanced materials into high-performance systems that drive economic growth and environmental sustainability.

Russia, with its rich history in material science, leads in the development of structural ceramics and composites. These materials, known for their exceptional strength and durability, are crucial in sectors such as defense and energy. Russia's advancements in this field reflect its strategic emphasis on leveraging advanced ceramics to enhance the performance and longevity of critical infrastructure and military assets.

Each of these countries contributes uniquely to the global advancement of ceramics, highlighting the diverse applications and strategic importance of this material in modern technology and industry.

Technological Advancements

Research and Development Programs

Countries such as the United States and the European Union have established comprehensive long-term development programs aimed at advancing ceramic materials. These initiatives are pivotal in driving innovation and technological progress within the field of advanced ceramics. Specifically, the U.S. has been at the forefront of research in transparent ceramics, which are integral to defense applications due to their unique optical properties and durability. These materials are designed to withstand extreme conditions, making them ideal for use in high-stress environments such as military optics and armor.

Similarly, the EU has been heavily investing in high-temperature structural ceramics, which are essential for aerospace applications. These materials exhibit exceptional thermal stability and mechanical strength, allowing them to endure the harsh conditions encountered in space and high-altitude flights. The development of such ceramics is not only enhancing the performance of current aerospace technologies but also paving the way for future innovations in space exploration and satellite technology.

| Country | Focus Area | Application |

|---|---|---|

| USA | Transparent Ceramics | Defense, Military Optics |

| EU | High-Temperature Structural Ceramics | Aerospace, Space Exploration |

These research and development programs underscore the strategic importance of advanced ceramics in modern technology and defense sectors, reflecting a global commitment to harnessing the unique properties of these materials for groundbreaking advancements.

Preparation Technologies

Japan remains at the forefront of ceramic preparation technologies, particularly in the development of heat-resistant structural ceramics and ceramics with high strength and toughness. These materials are essential for applications requiring durability under extreme conditions, such as in aerospace and industrial machinery. The meticulous research and innovation in Japan are driven by a commitment to enhancing the performance and reliability of these ceramics, making them indispensable in high-stress environments.

In contrast, the United States focuses on nanoceramic technology and ceramic armor, leveraging advancements in nanotechnology to create materials with superior properties. Nanoceramics offer enhanced mechanical, thermal, and electrical properties, making them ideal for cutting-edge applications in defense and electronics. The emphasis on ceramic armor reflects the strategic importance of these materials in modern warfare, where lightweight yet robust protection is crucial.

| Country | Focus Area | Applications |

|---|---|---|

| Japan | Heat-resistant structural ceramics | Aerospace, Industrial machinery |

| High-strength, high-toughness ceramics | ||

| USA | Nanoceramic technology | Defense, Electronics |

| Ceramic armor |

This dual focus highlights the global race to harness the potential of advanced ceramics, each nation capitalizing on its strengths to drive innovation and secure a competitive edge in various sectors.

Applications and Future Prospects

Wide-Ranging Applications

Advanced ceramics are indispensable across a spectrum of high-tech industries, each leveraging their distinct properties to achieve unparalleled performance and durability. In the defense sector, these materials are pivotal for creating armor and protective gear that can withstand extreme conditions and high-velocity impacts. Their high strength and hardness make them ideal for safeguarding personnel and equipment in combat scenarios.

In aerospace, advanced ceramics are utilized in the construction of engines and heat shields, where their thermal stability and resistance to high temperatures are crucial for maintaining structural integrity during space missions and re-entry into Earth's atmosphere. These properties also make them essential for the development of hypersonic vehicles, which require materials that can endure the intense heat generated at such speeds.

The biomedical field benefits significantly from advanced ceramics, particularly in the development of prosthetics and implants. Their biocompatibility, combined with high strength and wear resistance, ensures long-term durability and minimal risk of rejection by the human body. This makes them an ideal choice for applications such as hip replacements, dental implants, and bone grafts.

Beyond these sectors, advanced ceramics find applications in electronics, where their insulating properties and resistance to thermal shock are essential for the manufacturing of semiconductors and other sensitive components. In the energy sector, they are used in the production of fuel cells and gas turbines, contributing to more efficient and sustainable energy solutions.

The versatility of advanced ceramics is further exemplified in their use in environmental technologies, such as catalytic converters and filters, which help in reducing emissions and improving air quality. Their ability to withstand harsh chemical environments makes them suitable for these critical applications in pollution control.

In summary, the unique combination of high strength, high hardness, and thermal stability that defines advanced ceramics positions them as a cornerstone material in a multitude of high-tech fields, driving innovation and performance across industries.

Impact on Industry Development

The development of advanced ceramics is not merely a technological advancement but a cornerstone for the progression of various industries. These materials, with their unique properties such as high strength, thermal stability, and chemical inertness, have become indispensable in sectors ranging from aerospace and defense to biomedicine and electronics.

In the aerospace industry, advanced ceramics are integral to the design of heat shields and turbine blades, enhancing the efficiency and durability of aircraft engines. Similarly, in the defense sector, ceramic armor provides superior protection against ballistic threats, significantly improving the safety and effectiveness of military personnel and equipment.

Biomedical applications also benefit from advanced ceramics, which are used in implants and prosthetics due to their biocompatibility and resistance to corrosion. Moreover, in electronics, ceramic substrates are essential for high-performance circuits, supporting the miniaturization and efficiency of modern devices.

The influence of advanced ceramics extends beyond these specific applications. Their development spurs innovation across the supply chain, driving advancements in manufacturing techniques, quality control, and material science. This ripple effect underscores the strategic importance of investing in the research and development of advanced ceramics, positioning them as a critical driver of future technological and industrial progress.

Related Products

- Precision Machined Yttrium Stabilized Zirconia Ceramic Rod for Engineering Advanced Fine Ceramics

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Silicon Carbide (SIC) Ceramic Plate for Engineering Advanced Fine Ceramics

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

Related Articles

- Top 5 Features of a High-Quality Zirconia Sintering Oven

- Isostatic Pressing of Ceramics: Process and Precision

- Dos and don'ts during the installation of molybdenum disilicide (MoSi2) heating element

- The Latest Advancements in Zirconia Sintering Furnaces for Dental Applications

- Dental Furnaces The Perfect Solution for Porcelain Processing