Importance of Heating Elements in Vacuum Furnaces

Criteria for Selecting Heating Materials

When selecting heating materials for vacuum furnaces, several critical factors must be considered to ensure optimal performance and longevity. The primary criterion is thermal conductivity, which directly influences the efficiency of heat transfer within the furnace. Materials with high thermal conductivity, such as tungsten and molybdenum, are preferred as they can distribute heat evenly, minimizing hot spots and ensuring consistent temperature across the workpiece.

Another essential aspect is stability at high temperatures. Heating elements must maintain their structural integrity and resist deformation even under extreme conditions. This stability is crucial to prevent any mechanical failure, which could lead to significant downtime and costly repairs. Materials like nickel-chromium alloys are known for their high-temperature stability, making them suitable for demanding applications.

Chemical compatibility is also a key consideration. The heating material should not react with the workpiece or the furnace environment, as such interactions can lead to contamination or degradation of the workpiece. For instance, in vacuum furnaces, where the atmosphere is controlled, materials like molybdenum are ideal due to their inertness and resistance to oxidation.

The cross-sectional area of the heating element plays a pivotal role in its resistance and, consequently, its heat output. For low-power applications, thinner elements are used to increase resistance, while for high-heat applications, thicker elements are preferred to reduce resistance and allow more current to flow. This balance ensures that the heating element can generate the desired heat output without excessive energy consumption or premature wear.

In summary, the selection of heating materials for vacuum furnaces involves a careful balance of thermal conductivity, high-temperature stability, chemical compatibility, and cross-sectional design. By considering these factors, one can choose materials that not only meet the technical requirements but also enhance the overall efficiency and reliability of the furnace operation.

Role of Insulation Screens

Insulation screens play a pivotal role in the operation of vacuum furnaces, primarily by enhancing thermal efficiency and minimizing heat loss. These screens are strategically placed within the furnace to create a barrier that retains heat, thereby reducing the energy required to maintain the desired temperature. The effectiveness of these screens is largely determined by their structural design and the materials used in their construction.

For instance, materials like tungsten and molybdenum, known for their high melting points and excellent thermal conductivity, are often preferred for insulation screens. These materials not only withstand high temperatures but also offer superior resistance to corrosion and oxidation, ensuring long-term performance and reliability. The choice of material directly influences the furnace's overall power consumption and operational efficiency.

Moreover, the configuration of the insulation screens, whether they are butt-jointed or lap-jointed, also impacts their performance. Proper installation techniques, such as using corrugated boards or spacer rings, ensure that the screens are securely positioned and effectively spaced, maximizing their insulating capabilities. This meticulous attention to detail in both material selection and installation methods underscores the critical role that insulation screens play in optimizing the performance of vacuum furnaces.

Types and Properties of Heating Elements

Metal Type Heating Elements

Metal type heating elements encompass a diverse array of materials, each tailored to specific operational requirements and environmental conditions. These materials can be broadly categorized into pure metals and alloys, each offering unique advantages in terms of temperature resistance and vacuum compatibility.

Pure Metals

- Tungsten: Renowned for its exceptionally high melting point (3422 °C or 6192 °F), tungsten is ideal for applications requiring extreme temperature stability. Its high density and excellent electrical conductivity make it a preferred choice in high-vacuum environments.

- Molybdenum: With a melting point of 2623 °C (4753 °F), molybdenum is another prime candidate for high-temperature applications. Its moderate density and good thermal conductivity ensure efficient heat distribution and resistance to deformation.

- Niobium: Characterized by its high melting point (2477 °C or 4491 °F) and ductility, niobium is often used in specialized applications where flexibility and thermal stability are paramount.

Alloys

- Nickel-Chromium (Nichrome): This alloy is widely used due to its excellent resistance to oxidation and corrosion, even at elevated temperatures. Its ability to maintain structural integrity under prolonged exposure to high heat makes it suitable for industrial furnaces and precision heating applications.

- Ferrochrome-Aluminum: Combining the properties of iron, chromium, and aluminum, this alloy offers a balanced mix of strength, corrosion resistance, and thermal stability. It is particularly favored in environments where both high temperatures and chemical resistance are critical.

Specialized Applications

- Cupronickel (CuNi) Alloys: Specifically designed for low-temperature heating applications, these alloys provide reliable performance in milder conditions, ensuring consistent heat output without the need for extreme temperature resistance.

- Etched Foil Elements: Manufactured through a photo-etching process, these elements offer intricate resistance patterns, making them ideal for precision heating in sectors such as medical diagnostics and aerospace. The subtractive process allows for the creation of complex geometries from continuous sheets of metal foil, enhancing their utility in demanding applications.

Each of these materials brings its own set of characteristics to the table, enabling the selection of the most appropriate heating element based on the specific demands of the vacuum furnace environment.

Non-Metal Type Heating Elements

Non-metal type heating elements are integral to various high-temperature applications, particularly in environments where traditional metal elements may not suffice. These elements are characterized by their unique properties, which make them suitable for specific industrial needs.

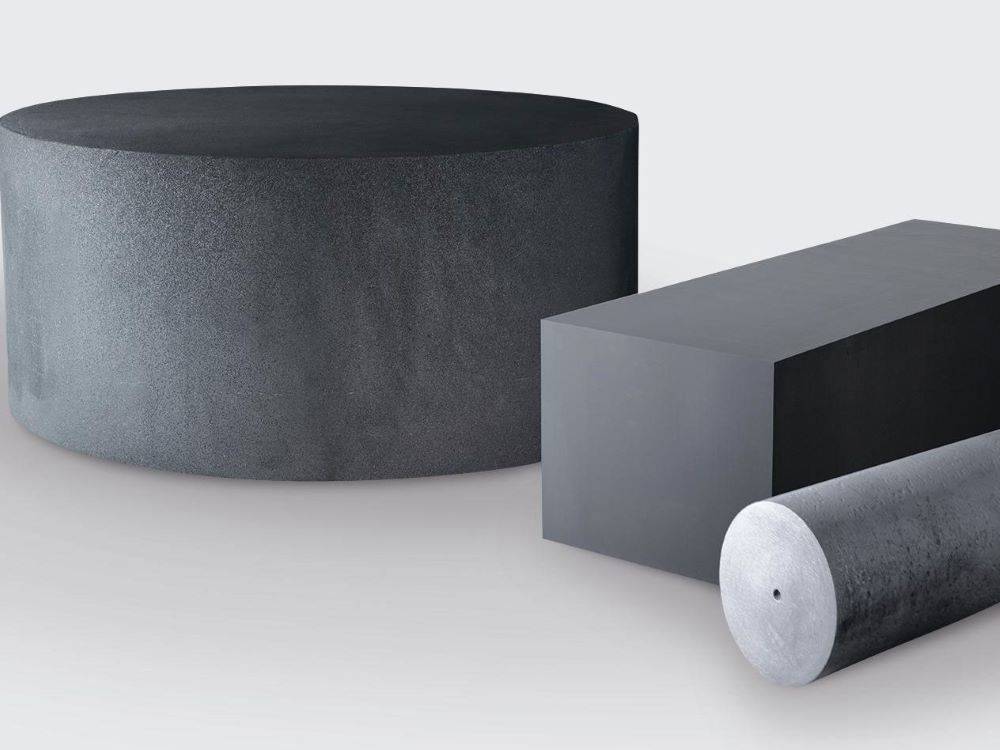

One of the most common non-metal heating elements is graphite, which is known for its low cost, ease of processing, and large radiation area. Graphite elements are primarily used for their excellent thermal impact resistance and the fact that they rely on radiation heat transfer. However, they are volatile at high temperatures and require precautions to prevent vacuum discharge. Graphite's high-temperature resistance, small thermal expansion, and strong thermal shock resistance make it a preferred choice for applications requiring mechanical strength at elevated temperatures. Notably, its mechanical strength improves with temperature, peaking around 1700°C, surpassing all oxides and metals.

Another notable non-metal heating element is molybdenum disilicide (MoSi2), an intermetallic compound that serves as a refractory ceramic. MoSi2 is prized for its moderate density, high melting point (2030°C), and electrical conductivity. At high temperatures, it forms a passivation layer of silicon dioxide, which protects it from further oxidation. This property makes MoSi2 ideal for applications in the glass industry, ceramic sintering, heat treatment furnaces, and semiconductor diffusion furnaces.

| Non-Metal Element | Key Properties | Applications |

|---|---|---|

| Graphite | Low cost, large radiation area, thermal impact resistance | Vacuum furnaces, high-temperature environments |

| MoSi2 | Moderate density, high melting point, electrical conductivity | Glass industry, ceramic sintering, heat treatment furnaces |

In addition to graphite and MoSi2, other non-metal elements like etched foil and cupronickel alloys are also used in specialized heating applications. Etched foil elements, for instance, are crafted through a subtractive photo-etching process, resulting in complex resistance patterns that are ideal for precision heating applications in medical diagnostics and aerospace.

These non-metal heating elements, while not as commonly discussed as their metal counterparts, play a crucial role in ensuring efficient and reliable operation in high-temperature and vacuum environments. Their unique properties and capabilities make them indispensable in industries where conventional heating elements fall short.

Advantages of Tungsten-Molybdenum Insulation Screens

High-Temperature Performance

Tungsten and molybdenum stand out as premier materials for high-temperature applications, primarily due to their exceptionally high melting points. These metals not only withstand extreme temperatures but also exhibit superior thermal stability, ensuring minimal deformation and heat loss. Their unique properties make them indispensable in environments where maintaining consistent heat is critical.

In vacuum furnaces, tungsten and molybdenum serve as robust thermal barriers, effectively protecting the internal components from excessive heat. Their ability to reduce heat convection is a significant advantage, as it helps in maintaining a stable temperature within the furnace. This characteristic is particularly important in processes that require precise temperature control, such as metal forging and semiconductor manufacturing.

Moreover, the use of tungsten and molybdenum in high-temperature settings extends beyond mere temperature resistance. These materials are also known for their excellent thermal conductivity, which ensures uniform heat distribution throughout the furnace. This even distribution is crucial for preventing hotspots, which can lead to uneven heating and potential damage to the workpiece.

In summary, tungsten and molybdenum's combination of high melting points, thermal stability, and superior heat protection makes them ideal for high-temperature environments, particularly in vacuum furnaces where maintaining a consistent and controlled heat environment is paramount.

Corrosion and Oxidation Resistance

Both tungsten and molybdenum exhibit exceptional resistance to corrosion and oxidation, which is a critical factor in their suitability for long-term use in high-temperature environments. This resistance is attributed to their dense, tightly-packed atomic structures, which create a formidable barrier against chemical侵蚀. In practical applications, this means that these materials can maintain their integrity and functionality even under extreme conditions, ensuring the longevity and reliability of heating elements and insulation screens in vacuum furnaces.

To further illustrate their corrosion and oxidation resistance, consider the following comparative table:

| Material | Oxidation Temperature | Corrosion Resistance |

|---|---|---|

| Tungsten | Above 500°C | Very High |

| Molybdenum | Above 400°C | Very High |

| Nickel-Chromium | Below 400°C | High |

| Ferrochrome-Aluminum | Below 400°C | High |

These materials are often used in environments where other metals would quickly degrade, making them indispensable in industries requiring high-temperature processes. However, it is crucial to note that while tungsten and molybdenum have superior resistance to oxidation, they must still be used in controlled atmospheres, such as vacuum or inert environments, to prevent rapid oxidation at elevated temperatures. This precaution ensures that the materials can continue to perform effectively without compromising the integrity of the furnace or the quality of the workpiece.

Installation and Use of Tungsten-Molybdenum Thermal Barriers

Installation Methods

Tungsten-molybdenum heat-insulating screens are typically installed using riveting techniques, offering both durability and precision in the assembly process. The riveting method allows for two primary joint configurations: butt-jointed and lap-jointed. In a butt-joint configuration, the edges of the screens are aligned and riveted together, creating a seamless connection that minimizes heat loss. Conversely, a lap-joint configuration involves overlapping the edges of the screens before riveting, which enhances the joint's strength and thermal efficiency.

For effective spacing between the screens, several auxiliary materials can be employed. Corrugated board provides a flexible yet robust spacer, allowing for adjustments in the thermal barrier's thickness. U-shaped grid strips offer a more structured approach, ensuring uniform spacing and stability. Alternatively, spacer rings can be used to create a consistent gap between the screens, optimizing the insulation properties of the thermal barrier. Each of these spacing methods contributes to the overall performance of the tungsten-molybdenum heat-insulating screens, ensuring they function optimally within the vacuum furnace environment.

Oxidation Considerations

When selecting tungsten and molybdenum parts for use in vacuum furnaces, it is crucial to consider their oxidation behavior. Both materials are highly susceptible to rapid oxidation at elevated temperatures, specifically above 500°C for tungsten and 400°C for molybdenum. This rapid oxidation can lead to significant degradation of the materials, compromising their structural integrity and performance.

To mitigate this risk, it is essential to employ these materials in environments where oxidation can be effectively controlled. This typically involves operating in a vacuum or an inert atmosphere, such as argon or nitrogen. In such controlled environments, the exposure of tungsten and molybdenum to oxygen is minimized, thereby preventing the formation of oxides that could impair their functionality and longevity.

| Material | Oxidation Temperature Threshold | Recommended Environment |

|---|---|---|

| Tungsten | Above 500°C | Vacuum or inert atmosphere |

| Molybdenum | Above 400°C | Vacuum or inert atmosphere |

Ensuring that tungsten and molybdenum parts are used under these conditions not only preserves their mechanical properties but also maintains the efficiency and reliability of the vacuum furnace. This proactive approach to oxidation management is a key aspect of optimizing the performance and lifespan of heating elements and insulation screens in high-temperature applications.

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

Related Articles

- Molybdenum Vacuum Furnace: High-Temperature Sintering and Advanced Applications

- How Vacuum Induction Melting Ensures Unmatched Reliability in Critical Industries

- How Vacuum Induction Melting Outperforms Traditional Methods in Advanced Alloy Production

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- Your Furnace Hit the Right Temperature. So Why Are Your Parts Failing?