Thin Film Deposition Parts

Thermally Evaporated Tungsten Wire for High Temperature Applications

Item Number : KME08

Price varies based on specs and customizations

- Material

- tungsten

- parameter

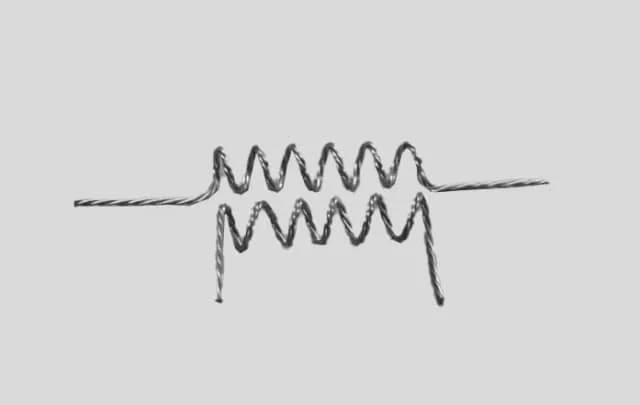

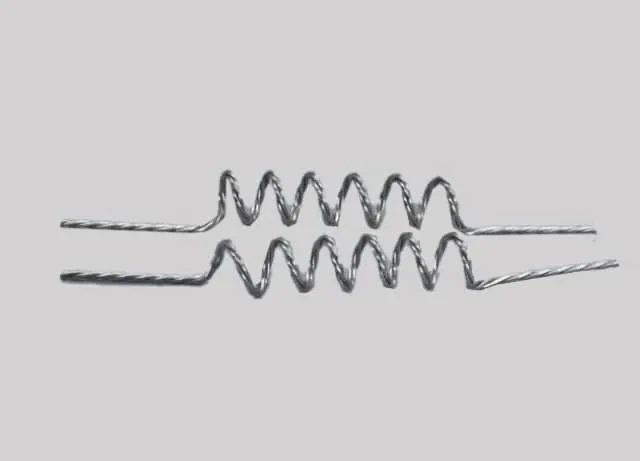

- length 100mm; 6 turns

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

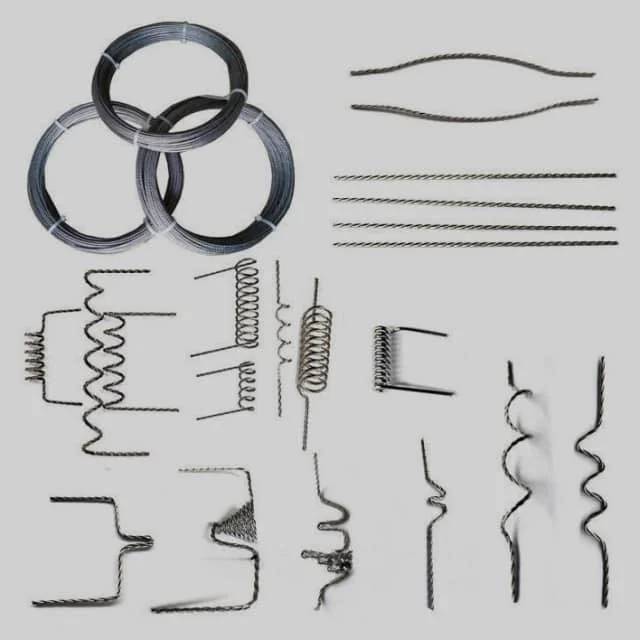

Tungsten wire is made by pressing tungsten powder in a hydrogen atmosphere, sintering, die forging, wire drawing and annealing. This process can cause dramatic changes in the properties of the metal. Tungsten has a high melting point, high electrical resistivity, good strength and low vapor pressure, making it an ideal material for manufacturing heating elements. Multi-strand tungsten wire can be used to produce vacuum wire. Commonly used in electron beam source, vacuum coating, filament, thermal electron emitter, electron gun beam and other fields.

Detail & Parts

Technical specifications

Specifications: length 100mm; 6 turns

The crucibles we show are available in different sizes and custom sizes are available on request.

Advantage

- High melting point, high resistance.

- Low coefficient of thermal expansion.

- Good electrical and thermal conductivity,

- Oxidation and creep resistance

- Extremely high hardness, high tensile strength.

- Lowest vapor pressure of all metals.

Trusted by Industry Leaders

4.9 / 5

The tungsten wire arrived promptly and in perfect condition, meeting all my research specifications. Highly recommend KINTEK SOLUTION for their reliable service.

4.8 / 5

Excellent value for money! The tungsten wire's exceptional quality has enhanced our lab's research capabilities. Thank you, KINTEK SOLUTION, for providing such a cost-effective solution.

4.7 / 5

KINTEK SOLUTION's tungsten wire is of impeccable quality, ensuring precise and reliable results in our experiments. Highly satisfied with the product's performance and durability.

5.0 / 5

The tungsten wire's exceptional durability has exceeded our expectations. It has withstood countless experiments, maintaining its structural integrity and delivering consistent results. Highly recommend!

4.9 / 5

The tungsten wire's technological advancement has revolutionized our research. Its unique properties have enabled groundbreaking discoveries and pushed the boundaries of our scientific understanding.

4.7 / 5

KINTEK SOLUTION's tungsten wire has been an invaluable asset to our lab. Its consistent quality and exceptional performance have contributed to the success of numerous experiments.

5.0 / 5

The tungsten wire's rapid delivery was a lifesaver! It arrived just in time for a crucial experiment, ensuring our research stayed on schedule. Thank you, KINTEK SOLUTION, for your outstanding service.

4.8 / 5

The tungsten wire's versatility has been remarkable. We've used it in various applications, and it has consistently exceeded our expectations. A must-have for any lab.

4.9 / 5

The tungsten wire's exceptional quality has enhanced our lab's research capabilities. Highly satisfied with the product's performance and durability.

5.0 / 5

The tungsten wire's exceptional durability has exceeded our expectations. It has withstood countless experiments, maintaining its structural integrity and delivering consistent results. Highly recommend!

4.9 / 5

The tungsten wire's technological advancement has revolutionized our research. Its unique properties have enabled groundbreaking discoveries and pushed the boundaries of our scientific understanding.

4.7 / 5

KINTEK SOLUTION's tungsten wire has been an invaluable asset to our lab. Its consistent quality and exceptional performance have contributed to the success of numerous experiments.

5.0 / 5

The tungsten wire's rapid delivery was a lifesaver! It arrived just in time for a crucial experiment, ensuring our research stayed on schedule. Thank you, KINTEK SOLUTION, for your outstanding service.

4.8 / 5

The tungsten wire's versatility has been remarkable. We've used it in various applications, and it has consistently exceeded our expectations. A must-have for any lab.

4.9 / 5

The tungsten wire's exceptional quality has enhanced our lab's research capabilities. Highly satisfied with the product's performance and durability.

5.0 / 5

The tungsten wire's exceptional durability has exceeded our expectations. It has withstood countless experiments, maintaining its structural integrity and delivering consistent results. Highly recommend!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Electron Beam Evaporation Coating Tungsten Crucible and Molybdenum Crucible for High Temperature Applications

Tungsten and molybdenum crucibles are commonly used in electron beam evaporation processes due to their excellent thermal and mechanical properties.

Tungsten Evaporation Boat for Thin Film Deposition

Learn about tungsten boats, also known as evaporated or coated tungsten boats. With a high tungsten content of 99.95%, these boats are ideal for high-temperature environments and widely used in various industries. Discover their properties and applications here.

High Purity Pure Graphite Crucible for Evaporation

Vessels for high temperature applications, where materials are kept at extremely high temperatures to evaporate, allowing thin films to be deposited on substrates.

Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

High-purity and smooth conductive boron nitride crucible for electron beam evaporation coating, with high temperature and thermal cycling performance.

Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

The small vacuum tungsten wire sintering furnace is a compact experimental vacuum furnace specially designed for universities and scientific research institutes. The furnace features a CNC welded shell and vacuum piping to ensure leak-free operation. Quick-connect electrical connections facilitate relocation and debugging, and the standard electrical control cabinet is safe and convenient to operate.

Custom Boron Nitride (BN) Ceramic Parts

Boron nitride (BN) ceramics can have different shapes, so they can be manufactured to generate high temperature, high pressure, insulation and heat dissipation to avoid neutron radiation.

Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

Used for gold plating, silver plating, platinum, palladium, suitable for a small amount of thin film materials. Reduce the waste of film materials and reduce heat dissipation.

1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

Looking for a tube furnace for high-temperature applications? Our 1400℃ Tube Furnace with Alumina Tube is perfect for research and industrial use.

High Temperature Resistant Optical Quartz Glass Sheet

Discover the power of optical glass sheets for precise light manipulation in telecommunications, astronomy, and beyond. Unlock advancements in optical technology with exceptional clarity and tailored refractive properties.

High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

High temperature alumina furnace tube combines the advantages of high hardness of alumina, good chemical inertness and steel, and has excellent wear resistance, thermal shock resistance and mechanical shock resistance.

Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

Zirconia insulating ceramic gasket has high melting point, high resistivity, low thermal expansion coefficient and other properties, making it an important high temperature resistant material, ceramic insulating material and ceramic sunscreen material.

1400℃ Muffle Oven Furnace for Laboratory

Get precise high-temperature control up to 1500℃ with KT-14M Muffle furnace. Equipped with a smart touch screen controller and advanced insulation materials.

1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

Looking for a high-temperature tube furnace? Check out our 1700℃ Tube Furnace with Alumina Tube. Perfect for research and industrial applications up to 1700C.

Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

In the journey of scientific exploration and industrial production, every detail is crucial. Our arc-shaped alumina ceramic crucibles, with their excellent high temperature resistance and stable chemical properties, have become a powerful assistant in laboratories and industrial fields. They are made of high-purity alumina materials and manufactured through precision processes to ensure excellent performance in extreme environments.

Horizontal High Temperature Graphite Vacuum Graphitization Furnace

Horizontal Graphitization Furnace: This type of furnace is designed with the heating elements placed horizontally, allowing for uniform heating of the sample. It's well-suited for graphitizing large or bulky samples that require precise temperature control and uniformity.

Large Vertical Graphite Vacuum Graphitization Furnace

A large vertical high-temperature graphitization furnace is a type of industrial furnace used for the graphitization of carbon materials, such as carbon fiber and carbon black. It is a high-temperature furnace that can reach temperatures of up to 3100°C.

Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

Discover the versatility of Laboratory Rotary Furnace: Ideal for calcination, drying, sintering, and high-temperature reactions. Adjustable rotating and tilting functions for optimal heating. Suitable for vacuum and controlled atmosphere environments. Learn more now!

Infrared Thermal Imaging Temperature Measurement Double-Sided Coated Germanium Ge Lens

Germanium lenses are durable, corrosion-resistant optical lenses suited for harsh environments and applications exposed to the elements.

Related Articles

Exploring the Benefits of Using Tungsten for Furnace Heating

Tungsten has a number of properties that make it well-suited for use in high-temperature furnaces.

A Guide to Choosing the Right Temperature for Warm Isostatic Press

Warm Isostatic Pressing (WIP) is a process used to eliminate porosity and improve the mechanical properties of materials. In this process, the material is subjected to high pressure and temperature in an inert gas environment.

A Comprehensive Guide to Vacuum Coating: Enhancing Performance and Aesthetics

Discover the world of vacuum coating, a process that creates protective and aesthetic layers on metal and plastic surfaces. Explore its types, uses, and benefits, including enhanced performance, extended lifespan, and improved aesthetics.

Isostatic Pressing A Low Distortion Alternative to Extrusion

Isostatic pressing is a manufacturing process that uses high pressure to compress powdered materials into a specific shape or form.

How to Ensure Molding Quality and Efficiency with Warm Isostatic Press

Warm Isostatic Press (WIP) is a type of isostatic press that uses a combination of heat and pressure to create high-quality parts. The WIP process involves placing a part inside a flexible mold, which is then filled with a gas or liquid media.

Types of Evaporation Sources for Evaporative Coating

Explore different evaporation sources used in thin film deposition, including filaments, crucibles, and evaporation boats.

Comprehensive Guide to Muffle Furnace Resistance Wire Design

Detailed analysis of resistance wire design principles, parameters, and calculation techniques for muffle furnace applications.

Challenges in the Development and Application of Tantalum in Vacuum Deposition Equipment

This article discusses the role of tantalum in vacuum deposition equipment, focusing on its properties, manufacturing challenges, and its critical applications in industries like OLED screen production.

Challenges in Achieving Glow Discharge with Rhenium Targets in Magnetron Sputtering

Explores reasons why rhenium targets struggle to glow during magnetron sputtering and offers optimization suggestions.

Common Laboratory Melting Methods

An overview of three primary laboratory melting techniques: Arc Melting, Induction Melting, and Suspension Melting.

Selecting Heating Elements for Vacuum Furnaces

Guide on choosing heating elements and insulation screens for efficient vacuum furnace operation.