Introduction: Explanation of Isostatic Pressing

Isostatic pressing is a manufacturing process that uses high pressure to compress powdered materials into a specific shape or form. The process involves placing the powder into a flexible container, which is then subjected to high pressure from all directions. The pressure is applied uniformly, allowing the powder to flow and fill any gaps or voids in the mold. This results in a high-density product with a uniform microstructure and minimal distortion. Isostatic pressing is commonly used in the production of complex components such as ceramic parts, aerospace components, and medical devices.

Table of Contents

Benefits of Isostatic Pressing:

Isostatic pressing is a versatile method of forming materials that offers many advantages over traditional extrusion methods. Here are some of the benefits of isostatic pressing:

Uniform Pressure Distribution

One of the major advantages of isostatic pressing is that it ensures a uniform distribution of pressure throughout the material. This results in a more consistent density and fewer defects in the finished product. As a result, isostatic pressing is widely used in the production of high-performance materials, such as ceramics and composites.

Complex Shape Formation

Isostatic pressing can be used to form complex shapes, including hollow and thin-walled structures, which are difficult or impossible to achieve using other methods. This makes it a popular choice for the aerospace and automotive industries, where complex parts with high precision are required.

Environmentally Friendly

Isostatic pressing is a more environmentally friendly option, as it uses less material and generates less waste than extrusion. The process also requires less energy and fewer resources, making it a more sustainable alternative.

Production Efficiency

Isostatic pressing offers cost savings due to its ability to produce large quantities of parts in a single cycle, reducing production time and labor costs. This technique allows manufacturers to produce parts with high accuracy and precision, while also reducing the need for secondary operations.

Improved Mechanical Properties

The high pressure applied during isostatic pressing can improve the mechanical properties of the material, resulting in increased strength, ductility, and toughness. This makes isostatic pressing a popular choice for the production of parts that require high mechanical performance, such as aerospace components and medical implants.

Metallurgical Bonding

Isostatic pressing can also be used to form metallurgical bonds between different materials, such as ceramics and metals. This technique is widely used in the production of advanced materials for the aerospace and defense industries.

In conclusion, isostatic pressing offers many benefits over traditional extrusion methods, including uniform pressure distribution, complex shape formation, cost savings, and improved mechanical properties. This technique is widely used in various industries, including aerospace, automotive, and medical, to produce high-performance materials with high accuracy and precision.

Advantages over Extrusion:

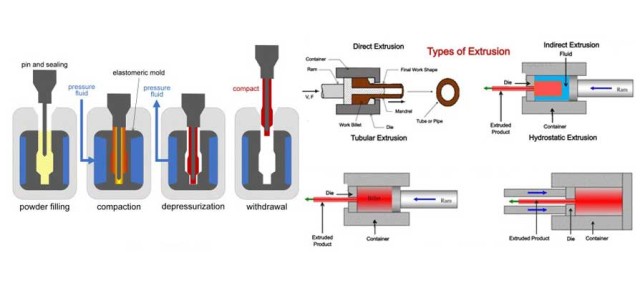

Isostatic pressing is a low distortion alternative to extrusion that offers several advantages over extrusion. In this section, we will discuss the advantages of isostatic pressing over extrusion in detail.

Lower level of distortion

One of the primary advantages of isostatic pressing over extrusion is the lower level of distortion that it produces. Extrusion typically results in a significant amount of distortion, which can reduce the strength and performance of the material. Isostatic pressing, on the other hand, produces a much more uniform and consistent material, which results in higher strength and better performance.

Near-net-shape parts

Another advantage of isostatic pressing is the ability to produce near-net-shape parts. This means that the parts produced by isostatic pressing require minimal additional machining or finishing, which reduces the overall cost and time required to produce the parts. Additionally, isostatic pressing can produce parts with a better surface finish than extrusion, which reduces the need for additional surface treatments.

Complex shapes

Isostatic pressing can produce complex shapes, and it is ideal for materials that are difficult to extrude or that have poor extrusion properties. Isostatic pressing applies a uniform, equal force over the entire product, regardless of shape or size. This makes it practical to produce shapes and dimensions that are difficult or impossible to produce by other methods.

Uniform density and microstructure

Isostatic pressing results in a uniform density and a uniform microstructure of the material. The powder or preform is placed in a flexible container, which is then subjected to high pressure from all sides. This produces a more uniform and consistent material that results in higher strength and better performance. Uniform density also means that the resulting compacted piece will have uniform shrinkage during sintering or hot isostatic pressing with little or no warpage.

Applicable to difficult-to-compact materials

Isostatic pressing is applicable to difficult-to-compact and expensive materials such as superalloys, titanium, tool steels, stainless steel, and beryllium, with material utilization that is highly efficient. For materials like copper where yield stress is a function of the normal stress on the shear plane, the radial pressure remains less than the axial pressure. Although the pressure distribution within a cold-pressed compact may become isostatic, the pressure vs. density relationship should be identical with that of isostatic compacting only if the density distribution is equally uniform.

In conclusion, isostatic pressing has several advantages over extrusion, such as lower level of distortion, near-net-shape parts, ability to produce complex shapes, uniform density and microstructure, and applicability to difficult-to-compact materials. These advantages make isostatic pressing a valuable process for many industries, including ceramics, metals, composites, plastics, and carbon.

Range of Products Created with Isostatic Pressing:

Isostatic pressing is a versatile manufacturing process that has a wide range of applications in various industries. It is used to produce high-performance materials with low distortion, making it a popular alternative to extrusion. Here are some of the products that can be created using isostatic pressing:

Ceramics:

Isostatic pressing is widely used in the production of ceramic components. It allows for the creation of complex shapes that are difficult to achieve through other manufacturing methods. The process also produces ceramic components with high-density and uniformity, resulting in improved mechanical and thermal properties.

Aerospace Parts:

Isostatic pressing is used in the production of aerospace parts, particularly in the creation of engine components. It is used to produce high-performance metals such as titanium and nickel alloys, which are known for their strength and resistance to corrosion. The process produces parts with minimal distortion, making it ideal for the production of complex shapes.

Fuel Cells:

Isostatic pressing is a critical part of the fuel cell manufacturing process. It is used to create solid oxide fuel cell components, which are known for their high efficiency and durability. The process produces components with high-density and uniformity, resulting in improved performance and longevity.

Pharmaceuticals:

Isostatic pressing is widely used in the pharmaceutical industry for compressing pharmaceutical particles and raw materials into predetermined shapes. This pressurizing system ensures a uniform compaction pressure throughout the powder mass and a homogeneous density distribution in the final product.

Explosives:

Isostatic pressing is used in the production of explosive materials. It is used to produce dense, uniform components that are critical in explosive devices. The process produces components with high-density and uniformity, resulting in improved safety and reliability.

Nuclear Fuel:

Isostatic pressing is used in the production of nuclear fuel pellets. It is used to create dense, uniform pellets that are critical in the operation of nuclear reactors. The process produces pellets with high-density and uniformity, resulting in improved performance and safety.

In conclusion, isostatic pressing is a reliable and effective way to produce a wide range of products with minimal distortion. It is a versatile manufacturing process that has numerous applications in various industries, including aerospace, pharmaceuticals, and nuclear fuel. Its ability to produce high-density and uniform components makes it an important technique in the field of laboratory equipment.

Technical Considerations:

Isostatic pressing (IP) is a promising alternative to extrusion for shaping metal parts. Unlike extrusion, which involves forcing metal through a die to create a specific shape, IP uses equal pressure on all sides of the material to form it into the desired shape. This results in a more uniform distribution of stress throughout the material, leading to less distortion and improved mechanical properties.

Pressure Medium

The choice of pressure medium is an important technical consideration in the isostatic pressing process. The pressure medium can be gas or liquid, and the choice depends on the specific requirements of the application. Gas is often used for low-pressure applications, while liquid is used for higher pressure applications. The pressure medium should be chosen based on its ability to uniformly transmit pressure to the material being pressed.

Temperature and Time

The temperature and time of the pressing are also important technical considerations in isostatic pressing. The temperature and time should be chosen based on the properties of the material being pressed. Higher temperatures can help to improve the densification of the material, while longer pressing times can help to improve the uniformity of the material. The temperature and time should be optimized to achieve the desired properties of the final product.

Tooling Design

The design of the tooling used to hold the material in place during isostatic pressing is another important technical consideration. The tooling should be designed to apply equal pressure to all sides of the material being pressed. The tooling should also be able to withstand the high pressures and temperatures involved in the process. The choice of tooling material and design should be optimized to achieve the desired properties of the final product.

Applications

Isostatic pressing is particularly useful for producing complex shapes with thin walls or intricate internal features and is often used in the aerospace, medical, and automotive industries. The ability to produce high-quality, low-distortion parts makes isostatic pressing a valuable alternative for certain applications. While isostatic pressing can be more time-consuming and expensive than extrusion, the benefits of improved mechanical properties and less distortion make it a promising alternative for many applications.

In summary, the technical considerations for isostatic pressing include the choice of pressure medium, the temperature and time of the pressing, and the design of the tooling used to hold the material in place. Isostatic pressing is a promising alternative to extrusion for shaping metal parts, particularly for complex shapes with thin walls or intricate internal features. The ability to produce high-quality, low-distortion parts makes isostatic pressing a valuable alternative for certain applications.

Disadvantages of Isostatic Pressing:

Need for Specialized Equipment and Molds

One of the main disadvantages of isostatic pressing is the need for specialized equipment and molds, which can be expensive to acquire and maintain. The process requires a pressure vessel, which can withstand high pressure and has a hydraulic system capable of generating uniform pressure from all directions. Furthermore, specialized molds are required to hold the powder or preform in place during the process and to ensure even pressure distribution. These molds can be costly and time-consuming to design and manufacture.

Time-Consuming and Requires Careful Monitoring

The isostatic pressing process can be time-consuming and requires careful monitoring to ensure that the pressure is evenly distributed throughout the material. This process involves filling the mold with a powder or preform and then subjecting it to high pressure for several hours. During this time, the pressure must be carefully monitored to ensure that it remains uniform and that the material is not over-pressed or under-pressed.

Unsuitable for Complex Geometries or Low Strength Materials

Isostatic pressing may not be suitable for all materials, particularly those with complex geometries or low strength. The process works best with materials that can withstand high pressure and that have a simple shape. Materials with complex geometries may not be able to withstand the high pressure required for isostatic pressing, or the process may result in distortion or cracking. Additionally, materials with low strength may not be able to withstand the pressure required for isostatic pressing, which can lead to deformation or failure.

Expensive Compared to Other Forming Techniques

Isostatic pressing can be expensive compared to other forming techniques such as extrusion, casting, or die pressing. The need for specialized equipment and molds, as well as the time-consuming nature of the process, can increase the overall cost of production. Furthermore, the process may not be suitable for all applications, which can limit its usefulness in certain industries.

Despite these limitations, isostatic pressing remains a valuable technique in the manufacturing industry, particularly for producing high-performance components that require minimal distortion and maximum strength. As such, it is important for manufacturers to carefully consider the advantages and disadvantages of isostatic pressing when selecting a manufacturing process for their products.

Conclusion: Recap of Benefits and Advantages

Isostatic pressing is a versatile manufacturing process that offers several benefits over traditional extrusion. Isostatic pressing can create products with a higher level of uniformity and consistency, resulting in less waste and lower production costs. Additionally, isostatic pressing can create complex shapes that are difficult to produce with extrusion. Despite its advantages, there are also some technical considerations to keep in mind, such as the need for specialized equipment and the potential for material contamination. Overall, isostatic pressing is a low distortion alternative to extrusion that offers a range of benefits and advantages for manufacturers.

Related Products

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

Related Articles

- Understanding the Isostatic Pressing Process and its Types

- Zirconia Ceramic Rod Production Processes: Isostatic Pressing vs. Dry Pressing

- Selecting Isostatic Pressing Equipment for High-Density Molding

- Comprehensive Guide to Isostatic Pressing: Types, Processes, and Features(3)

- Comprehensive Guide to Isostatic Pressing:Processes, and Features