Factors Restricting the Development of China's Vacuum Vapor Deposition Equipment

Tantalum Raw Material

Tantalum, a shiny, silver-colored metal, is renowned for its high melting point, low vapor pressure, and exceptional chemical stability. These attributes make it indispensable for vacuum evaporation processes, particularly in the production of OLED screens. The high melting point of tantalum, which stands at an impressive 5,462.6 °F (3,017 °C), ensures that it remains stable under the extreme conditions required for vapor deposition. Additionally, its low vapor pressure allows for precise control over the deposition process, critical for achieving uniform and high-quality OLED displays.

High-purity tantalum is essential for these applications, as even minor impurities can significantly impact the performance and longevity of the final product. The metal's chemical inertness, particularly its resistance to corrosion and acid attack (except hydrofluoric acid), further underscores its suitability for use in vacuum deposition equipment. This stability is due to a thin oxide film that naturally forms on the surface of tantalum, providing a protective barrier against chemical reactions.

The extraction and purification of tantalum are complex processes, often involving electrolysis or reduction techniques to separate it from niobium, which it commonly occurs with in nature. Once purified, tantalum is used in various forms, including tantalum crucibles and evaporation sources, where its unique properties can be fully leveraged.

| Property | Value |

|---|---|

| Atomic Number | 73 |

| Atomic Symbol | Ta |

| Atomic Weight | 180.94788 |

| Melting Point | 5,462.6 °F (3,017 °C) or 3290 K |

| Boiling Point | 9,856.4 °F (5,458 °C) or 5728 K |

| Resistance to Corrosion | Extremely High |

| Common Sources | Canada, Australia, Brazil, Nigeria, Portugal, Mozambique, Thailand, Democratic Republic of Congo |

The strategic importance of tantalum in advanced manufacturing processes, particularly in the electronics industry, cannot be overstated. Its ability to maintain structural integrity under high temperatures and harsh chemical environments makes it a preferred material for critical components in vacuum deposition equipment. As technology continues to advance, the demand for high-purity tantalum is expected to grow, driving further innovation in its extraction and application methods.

Difficulties in Machining Tantalum Parts

Machining tantalum parts for evaporation sources presents significant challenges due to the material's intrinsic properties. Tantalum's high hardness and reactivity make traditional machining methods inefficient and often impractical. The high hardness of tantalum results in rapid tool wear, increasing production costs and reducing the precision of the final product. Additionally, tantalum's reactivity with various atmospheric gases necessitates controlled environments to prevent surface contamination and degradation.

To address these challenges, advanced techniques such as 3D printing and specialized surface treatments have been developed. 3D printing, or additive manufacturing, allows for the precise creation of complex geometries directly from CAD models, minimizing material waste and reducing the need for multiple machining operations. This method also enables the fabrication of parts with intricate internal structures that would be difficult or impossible to achieve through conventional machining.

Specialized surface treatments, such as chemical vapor deposition (CVD) and physical vapor deposition (PVD), are employed to enhance the surface properties of tantalum parts. These treatments can improve the material's resistance to wear, corrosion, and oxidation, extending the operational life of the parts and ensuring their performance in high-stress environments. By combining these innovative techniques, manufacturers can overcome the inherent difficulties in machining tantalum, making it feasible to produce high-quality evaporation sources for critical applications in industries such as OLED screen production.

Difficulties in Welding Tantalum Material

Welding tantalum presents a formidable challenge due to its intrinsic properties, which include high reactivity and exceptional thermal conductivity. These characteristics necessitate meticulous handling and specialized techniques to ensure successful welds without compromising the material's integrity.

Tantalum's high reactivity with oxygen and nitrogen at elevated temperatures means that welding must be conducted in a controlled atmosphere, typically a vacuum or an inert gas environment. This requirement adds a layer of complexity to the process, as it necessitates sophisticated equipment and precise environmental control.

Moreover, tantalum's thermal conductivity is significantly higher than many other metals, which means that heat dissipates rapidly during welding. This rapid heat dissipation can lead to uneven heating and cooling, potentially causing warping or cracking in the weld area. To mitigate these issues, welding methods that offer high precision and control over heat input, such as laser welding and electron beam welding, are preferred. These techniques allow for localized heating, minimizing the risk of thermal damage to the surrounding material.

In addition to the technical challenges, the cost and availability of the necessary welding equipment and materials also pose significant barriers. The specialized nature of tantalum welding equipment and the high purity of the tantalum itself contribute to the elevated costs associated with this process.

Overall, while tantalum's unique properties make it indispensable for applications in vacuum deposition equipment, particularly in industries like OLED screen production, its welding challenges underscore the need for advanced techniques and stringent process controls.

Applications of Vacuum Evaporation Technology

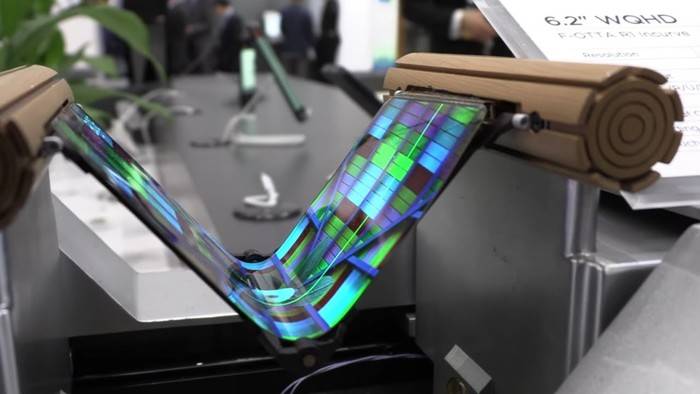

OLED Screen Production

Vacuum evaporation stands as a pivotal process in the manufacturing of OLED screens, playing a crucial role in the precise and uniform deposition of organic light-emitting materials onto glass substrates. This method ensures that the layers of organic materials are laid down with the utmost accuracy, which is essential for the performance and longevity of the OLED screens.

The vacuum environment is indispensable in this process, as it prevents any contamination from airborne particles that could compromise the integrity of the deposited layers. Additionally, the controlled conditions within the vacuum allow for the evaporation of materials at lower temperatures, preserving the structural and chemical properties of the organic compounds.

To achieve the desired uniformity and precision, advanced techniques such as shadow masks and automated alignment systems are often employed. These technologies help in directing the evaporated materials to specific areas of the substrate, ensuring that each pixel is correctly positioned and functional. The meticulous control over the deposition process is what ultimately enables the creation of high-quality OLED displays with vibrant colors, sharp images, and efficient energy usage.

Related Products

- Electron Beam Evaporation Coating Tungsten Crucible and Molybdenum Crucible for High Temperature Applications

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Electron Beam Evaporation Coating Gold Plating Tungsten Molybdenum Crucible for Evaporation

- Molybdenum Vacuum Heat Treat Furnace

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

Related Articles

- Electron Beam Evaporation: Advanced Thin Film Creation

- A Comparative Study of Evaporation and Sputtering Techniques in Thin Film Deposition

- Electron Beam Evaporation Technology in Vacuum Coating

- Vacuum Melting Furnace: A Comprehensive Guide to Vacuum Induction Melting

- Electron Beam Evaporation Coating Technology and Material Selection