Thin Film Deposition Parts

Ceramic Evaporation Boat Set Alumina Crucible for Laboratory Use

Item Number : KME09

Price varies based on specs and customizations

- Material

- ceramic crucible / tungsten wire

- Ceramic crucible size

- 0.25ml / 0.5ml / 1.0ml / 2.0ml / 3.0ml

- tungsten wire size

- 3*0.8 wire / 3*1.0mm wire / 3*0.8 wire

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

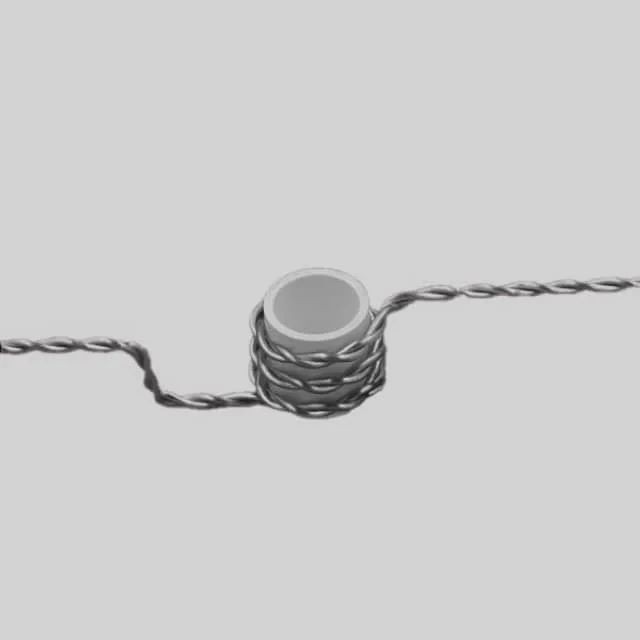

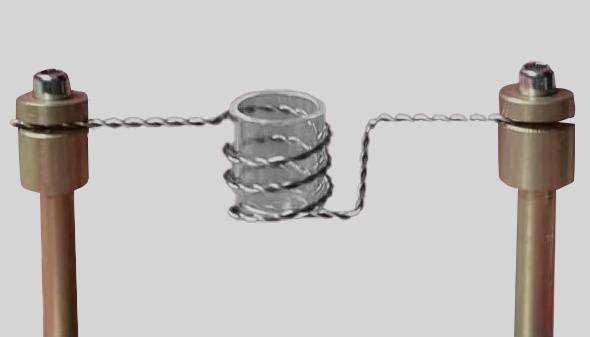

Combo boat components are used in a process called physical vapor deposition (PVD), specifically thermal evaporation. They consist of ceramic boats and tungsten wires. Ceramic evaporation boats are made of materials such as alumina or graphite and are used to hold the material to be evaporated. When the boat is heated, the material changes from a solid to a gas, allowing controlled evaporation. The shape of the boat helps direct the vapor to the substrate for efficient deposition. A tungsten wire is used as a heating coil. It is connected to a power source, and when current passes through it, the wire heats up due to its resistance. The wire has a high melting point and good thermal conductivity, making it suitable for this task. By providing heat, the wire vaporizes the material inside the ceramic boat, thus achieving controlled evaporation.

Detail & Parts

Technical specifications

| Material | ceramic crucible / tungsten wire |

| Ceramic Crucible Size | 0.25ml / 0.5ml / 1.0ml / 2.0ml / 3.0ml |

| Tungsten Wire Size | 3*0.8 wire / 3*1.0 wire / 3*0.8 wire |

The crucibles we show are available in different sizes and custom sizes are available on request.

Advantage

- Precise film deposition control

- Versatility in material deposition

- High temperature resistance

- Efficient heat transfer

- Repeatable and reproducible results

- Cost-effective for thin film deposition

Trusted by Industry Leaders

FAQ

What Are Thermal Evaporation Sources?

What Are The Common Applications Of Alumina Crucibles?

What Are The Advantages Of Using Ceramic Crucibles?

What Are The Main Types Of Thermal Evaporation Sources?

What Are The Advantages Of Using Alumina Crucibles?

What Are Some Common Uses Of Ceramic Crucibles?

How Do Thermal Evaporation Sources Work?

What Are The Common Materials Used For Evaporating Crucibles?

How Should Alumina Crucibles Be Handled And Maintained?

How Can I Choose The Right Ceramic Crucible For My Application?

What Are The Advantages Of Using Thermal Evaporation Sources?

What Are The Advantages Of Using Evaporating Crucibles?

How Should Ceramic Crucibles Be Handled And Maintained?

What Applications Are Thermal Evaporation Sources Used For?

How Should Evaporating Crucibles Be Handled And Maintained?

4.8 / 5

These ceramic boats are a game-changer for my lab. The quality is top-notch and they've held up well.

4.9 / 5

KINTEK's evaporation boats provide precise film deposition control. I highly recommend them for thin film deposition.

4.7 / 5

The versatility of these boats is impressive. They handle various materials with ease, making them a valuable asset in my lab.

4.8 / 5

I'm consistently impressed with the high temperature resistance of these boats. They've become an essential part of my research.

4.9 / 5

The efficient heat transfer of these boats has significantly improved the productivity of my lab. Highly recommended!

4.7 / 5

The repeatable and reproducible results I get with these boats are invaluable. They've made my research much more reliable.

4.8 / 5

The cost-effectiveness of these boats makes them a great value for money. I can achieve high-quality thin film deposition without breaking the bank.

4.9 / 5

The custom size options are a lifesaver. I was able to get boats that perfectly fit my specific needs. Thanks, KINTEK!

4.7 / 5

These boats have become an indispensable tool in my lab. Their durability and performance are unmatched.

4.8 / 5

The technological advancement of these boats has revolutionized my research. I can now achieve results that were previously impossible.

4.9 / 5

The speed of delivery was impressive. I received my order within days of placing it. Thank you for the prompt service!

4.7 / 5

The value for money is exceptional. These boats are worth every penny and have saved me a significant amount in the long run.

4.8 / 5

The quality of these boats is outstanding. They are made from high-quality materials and are built to last.

4.9 / 5

The durability of these boats is amazing. I've been using them for months and they still perform like new.

4.7 / 5

The technological advancement of these boats is impressive. They incorporate the latest technology to deliver exceptional results.

4.8 / 5

These boats are a game-changer for my lab. They've helped me achieve results that I never thought possible.

4.9 / 5

I highly recommend these boats to anyone looking for high-quality and reliable evaporation solutions.

4.7 / 5

These boats have exceeded my expectations. They are a valuable addition to my lab equipment.

4.8 / 5

I'm glad I made the switch to these boats. They've made my research more efficient and productive.

4.9 / 5

These boats are a must-have for any lab conducting thin film deposition. They are reliable, accurate, and easy to use.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

Alumina ceramic crucibles are used in some materials and metal melting tools, and flat-bottomed crucibles are suitable for melting and processing larger batches of materials with better stability and uniformity.

Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

In the journey of scientific exploration and industrial production, every detail is crucial. Our arc-shaped alumina ceramic crucibles, with their excellent high temperature resistance and stable chemical properties, have become a powerful assistant in laboratories and industrial fields. They are made of high-purity alumina materials and manufactured through precision processes to ensure excellent performance in extreme environments.

Evaporation Crucible for Organic Matter

An evaporation crucible for organic matter, referred to as an evaporation crucible, is a container for evaporating organic solvents in a laboratory environment.

High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

Alumina ceramic screws are fastening components made of 99.5% alumina, ideal for extreme applications requiring excellent thermal resistance, electrical insulation and chemical resistance.

High Purity Pure Graphite Crucible for Evaporation

Vessels for high temperature applications, where materials are kept at extremely high temperatures to evaporate, allowing thin films to be deposited on substrates.

Electron Beam Evaporation Coating Tungsten Crucible and Molybdenum Crucible for High Temperature Applications

Tungsten and molybdenum crucibles are commonly used in electron beam evaporation processes due to their excellent thermal and mechanical properties.

Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

High-purity and smooth conductive boron nitride crucible for electron beam evaporation coating, with high temperature and thermal cycling performance.

Electron Beam Evaporation Coating Gold Plating Tungsten Molybdenum Crucible for Evaporation

These crucibles act as containers for the gold material evaporated by the electron evaporation beam while precisely directing the electron beam for precise deposition.

Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

Electron Beam Evaporation Coating Oxygen-Free Copper Crucible enables precise co-deposition of various materials. Its controlled temperature and water-cooled design ensure pure and efficient thin film deposition.

Tungsten Evaporation Boat for Thin Film Deposition

Learn about tungsten boats, also known as evaporated or coated tungsten boats. With a high tungsten content of 99.95%, these boats are ideal for high-temperature environments and widely used in various industries. Discover their properties and applications here.

E Beam Crucibles Electron Gun Beam Crucible for Evaporation

In the context of electron gun beam evaporation, a crucible is a container or source holder used to contain and evaporate the material to be deposited onto a substrate.

Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

Used for gold plating, silver plating, platinum, palladium, suitable for a small amount of thin film materials. Reduce the waste of film materials and reduce heat dissipation.

1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

Looking for a high-temperature tube furnace? Check out our 1700℃ Tube Furnace with Alumina Tube. Perfect for research and industrial applications up to 1700C.

Anion Exchange Membrane for Laboratory Use

Anion exchange membranes (AEMs) are semipermeable membranes, usually made of ionomers, designed to conduct anions but reject gases such as oxygen or hydrogen.

Related Articles

Comparing Chemical Vapor Deposition and Physical Vapor Deposition

Chemical Vapor Deposition (CVD) VS Physical Vapor Deposition (PVD)

A Comparative Study of Evaporation and Sputtering Techniques in Thin Film Deposition

The two most common techniques used for thin film deposition are evaporation and sputtering.

Understanding Evaporation Boats in Vacuum Coating

An in-depth look at evaporation boats, their materials, arrangement, temperature control, and corrosion issues in vacuum coating processes.

Graphite Boats in PECVD for Cell Coating

Exploring the use of graphite boats in PECVD for efficient cell coating.

Electron Beam Evaporation Coating Technology and Material Selection

An in-depth look at the principles and applications of electron beam evaporation coating technology, including material selection and various fields of application.

Electron Beam Evaporation: Advanced Thin Film Creation

Explores the technology and applications of electron beam evaporation in thin film production.

Electron Beam Evaporation Technology in Vacuum Coating

An in-depth look at electron beam evaporation, its types, advantages, and disadvantages in vacuum coating processes.

Electron Beam Evaporation Coating: Principles, Characteristics, and Applications

An in-depth analysis of electron beam evaporation coating technology, its advantages, disadvantages, and applications in thin film manufacturing.

Electron Beam Evaporation Coating: Advantages, Disadvantages, and Applications

An in-depth look at the pros and cons of electron beam evaporation coating and its various applications in industries.

Comprehensive Overview of Vacuum Evaporation Systems

An in-depth look at vacuum evaporation systems, their principles, components, and applications.

Types of Evaporation Sources for Evaporative Coating

Explore different evaporation sources used in thin film deposition, including filaments, crucibles, and evaporation boats.

Understanding Evaporation Plating, Sputtering Plating, and Ion Plating

A detailed comparison of evaporation plating, sputtering plating, and ion plating techniques, their principles, types, and characteristics.