Physical and Electrical Properties of Rhenium

High Melting Point of Rhenium

Rhenium's exceptionally high melting point, which stands at approximately 3186°C, significantly influences its behavior during magnetron sputtering. This elevated temperature threshold means that rhenium atoms require substantially more energy to transition from their solid state to a gaseous state. Consequently, under conventional sputtering conditions, particularly at lower power settings, the atoms of rhenium remain relatively stable and are less likely to be excited and released into the plasma.

This characteristic poses a substantial challenge in achieving the necessary ionization and subsequent glow discharge. The high thermal stability of rhenium atoms translates to a lower probability of atom detachment from the target surface, even when subjected to the ion bombardment typical in sputtering processes. As a result, the efficiency of the sputtering process is compromised, making it more difficult to generate the requisite plasma density for a stable glow discharge.

In practical terms, this means that optimizing the sputtering process for rhenium targets often requires more sophisticated techniques and higher energy inputs compared to materials with lower melting points. The high melting point of rhenium underscores the need for careful consideration of power settings and process parameters to overcome these inherent challenges and achieve effective sputtering outcomes.

High Electrical Conductivity

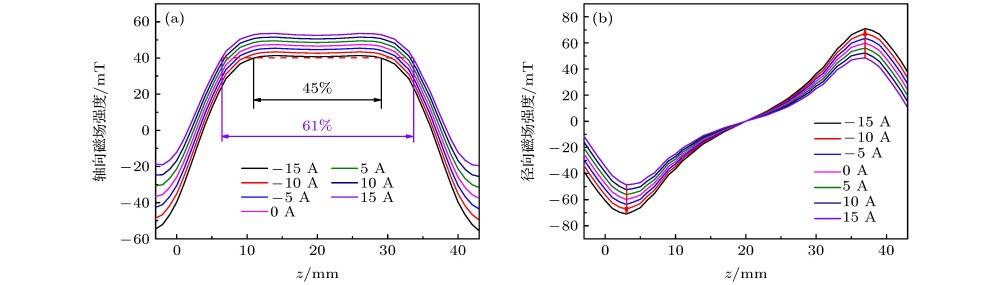

The high electrical conductivity of rhenium is a double-edged sword in magnetron sputtering. While it facilitates efficient electron transport, it also introduces a significant challenge: the uneven distribution of current across the target surface. This unevenness can be attributed to the material's inherent properties, which allow for rapid electron movement but do not ensure uniform current flow. As a result, certain areas of the target may experience higher current densities, while others remain underutilized.

This non-uniform current distribution can severely impact the stability of the glow discharge. The regions with insufficient current density fail to generate the necessary ion bombardment, leading to localized areas of weak discharge. This instability can manifest as flickering or intermittent glows, which are undesirable for consistent and efficient sputtering processes. The lack of uniformity in current density not only hampers the overall efficiency of the sputtering process but also poses a risk of damaging the target material over time due to uneven wear and tear.

To mitigate these issues, several strategies can be employed. One approach involves modifying the target geometry to better distribute the current evenly. Another solution is to incorporate additional electrodes or magnetic field configurations that can guide the current more uniformly across the target surface. These adjustments aim to balance the current density, thereby stabilizing the glow discharge and enhancing the overall performance of the sputtering process.

Environmental Factors

Gas Pressure and Atmosphere

The gas pressure and atmosphere play pivotal roles in the formation of a glow discharge during magnetron sputtering with rhenium targets. The interaction between the gas molecules and the rhenium target is a delicate balance that significantly influences the ionization process necessary for the glow discharge.

At lower gas pressures, the density of gas molecules is reduced, which can lead to insufficient ionization of the gas. This lack of ionized gas particles means that there are not enough charged particles to sustain the glow discharge. Consequently, higher gas pressures are often required to ensure a sufficient concentration of ionized gas particles.

For rhenium targets, specific atmospheres such as argon are particularly effective. Argon, being an inert gas, does not react chemically with rhenium, allowing for a more controlled ionization process. The use of argon under higher pressures helps in creating a more stable and intense glow discharge, which is essential for efficient sputtering.

In summary, optimizing the gas pressure and selecting an appropriate atmosphere like argon are critical steps in overcoming the challenges associated with achieving a glow discharge with rhenium targets in magnetron sputtering.

Target Surface Condition

Surface contaminants or oxidized layers on rhenium targets can significantly impede ion impact, thereby inhibiting effective reaction and the formation of glow discharge. These surface conditions are critical factors that can undermine the efficiency of magnetron sputtering processes.

To illustrate, consider the following scenarios:

| Surface Condition | Impact on Ion Impact | Effect on Glow Discharge |

|---|---|---|

| Clean, uncontaminated | Minimal hindrance | Enhanced formation |

| Oxidized layers | Significant hindrance | Diminished formation |

| Contaminated | Moderate hindrance | Reduced formation |

Oxidized layers, in particular, pose a substantial challenge as they can shield the rhenium surface from ion bombardment. This shielding effect reduces the probability of ion-target interactions, which are essential for initiating the glow discharge. Similarly, surface contaminants can create irregularities that scatter incoming ions, further disrupting the necessary conditions for discharge formation.

In summary, maintaining a pristine target surface is paramount for optimizing the performance of rhenium targets in magnetron sputtering. Any deviation from this ideal condition can lead to suboptimal results, highlighting the need for rigorous surface preparation and maintenance protocols.

Operational Settings

Sputtering Power Setting

The power setting in magnetron sputtering is a critical parameter that directly influences the formation of glow discharge. When the power is set too low, the energy supplied to the rhenium target may be insufficient to generate the necessary ionization required for a stable glow discharge. This low-energy scenario often results in a weak or intermittent discharge, complicating the process of achieving a consistent and effective sputtering operation.

Conversely, setting the power too high can lead to detrimental effects. Excessive power can cause the rhenium target to overheat, which not only affects the stability of the glow discharge but also risks damaging the target material. The high temperatures can accelerate the formation of surface oxides or other contaminants, further hindering the sputtering process. This overheating can also lead to an uneven distribution of sputtered material, reducing the quality and uniformity of the deposited film.

To optimize the power setting, it is essential to strike a balance between providing enough energy to sustain a stable glow discharge without causing thermal stress to the rhenium target. This balance is particularly challenging given rhenium's high melting point and low sputtering efficiency, which necessitate careful calibration of the power settings to ensure both effective sputtering and target longevity.

Sputtering Efficiency

Rhenium's low sputtering efficiency, which hovers around 30% in an argon atmosphere, significantly hampers the process of achieving a glow discharge. This inefficiency stems from the reduced number of atoms released from the target material during sputtering, a phenomenon that is markedly different from metals with higher sputtering efficiencies, such as aluminum.

Sputtering, at its core, involves the transfer of momentum from incident ions to the target surface. This process is influenced by several key parameters, including the energy, angle, and mass of the incident particles, as well as the binding energy between the target atoms. When ions collide with the target surface, they can either be absorbed or reflected. As the energy of these ions increases, they begin to penetrate the target material's atomic network, causing surface degradation. Only when the energy reaches a certain threshold do atoms start to escape from the surface.

In the case of rhenium, the low efficiency means that fewer atoms are liberated, which in turn makes it more challenging to sustain a stable glow discharge. This is particularly problematic in magnetron sputtering, where a continuous and efficient release of target atoms is critical for maintaining the plasma necessary for the glow discharge. The disparity in sputtering efficiency between rhenium and more efficient metals like aluminum underscores the technical hurdles faced in achieving consistent and reliable glow discharges with rhenium targets.

Related Products

- Thermally Evaporated Tungsten Wire for High Temperature Applications

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

- Electron Beam Evaporation Coating Tungsten Crucible and Molybdenum Crucible for High Temperature Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

Related Articles

- Exploring the Benefits of Using Tungsten for Furnace Heating

- Isostatic Pressing A Low Distortion Alternative to Extrusion

- Types of Evaporation Sources for Evaporative Coating

- Comprehensive Guide to Muffle Furnace Resistance Wire Design

- Challenges in the Development and Application of Tantalum in Vacuum Deposition Equipment