Table of Contents

Introduction: The Protective Power of Vacuum Coating

Vacuum coating is a versatile surface treatment process that enhances the performance and aesthetics of metal and plastic components. By depositing a thin layer of material onto the surface of the substrate, vacuum coating imparts desirable properties such as improved wear resistance, corrosion protection, and enhanced electrical conductivity. This process has revolutionized various industries, from automotive to aerospace, electronics to medical devices, enabling the creation of durable, high-performing, and visually appealing products.

Types of Vacuum Coatings

Vacuum coating encompasses various techniques used to deposit thin films onto substrates. These methods play a crucial role in industries such as electronics, optics, and materials science. Here are the key types of vacuum coatings:

1. Physical Vapor Deposition (PVD)

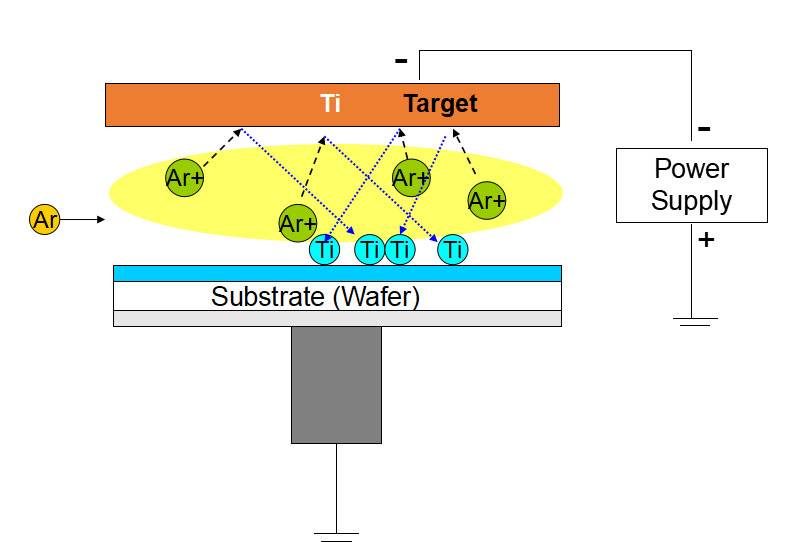

PVD involves the physical transformation of a solid coating material into a vapor and then depositing it as a thin film on the substrate. The material is vaporized either through thermal evaporation or sputtering. In thermal evaporation, the material is heated to a high temperature, causing it to vaporize. In sputtering, a plasma is created in a vacuum chamber, and ions from the plasma bombard the material, ejecting atoms that condense on the substrate.

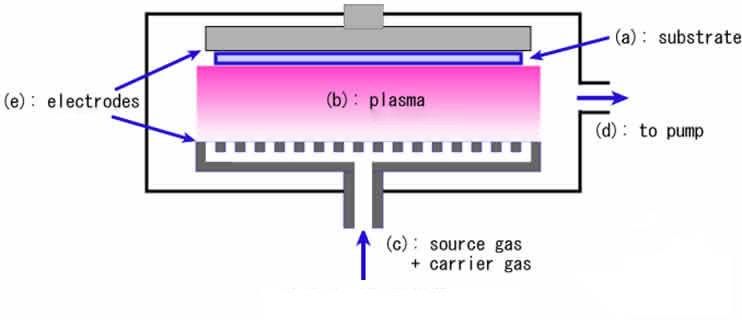

2. Chemical Vapor Deposition (CVD)

CVD involves the chemical reaction of gaseous precursors to form a solid film on the substrate. The precursors are introduced into a vacuum chamber and react with each other or with the substrate surface to form the desired coating. CVD coatings are often used for their high purity, fine grain structure, and excellent adhesion.

3. Sputtering

Sputtering is a specific type of PVD technique where a plasma is created in a vacuum chamber and ions from the plasma bombard a target material, ejecting atoms that condense on the substrate. Sputtering allows for the deposition of a wide range of materials, including metals, alloys, and compounds. It is often used for its ability to produce high-quality, wear-resistant coatings.

Each of these vacuum coating techniques has unique characteristics and applications. PVD is suitable for depositing thin films with high hardness and wear resistance, while CVD is preferred for coatings with high purity and fine grain structure. Sputtering offers versatility in depositing a broad range of materials and is known for its high deposition rates.

Benefits of Vacuum Coating

Vacuum coating offers numerous advantages, making it a versatile and effective technique for improving the properties of various materials. These benefits include:

1. Enhanced Wear Resistance and Durability:

Vacuum coating creates a thin, uniform layer over the base material, protecting it from wear, abrasion, and impact. This enhanced durability extends the lifespan of products and reduces maintenance costs.

2. Corrosion Protection:

Vacuum coatings provide a barrier against corrosive elements, such as moisture, oxygen, and chemicals. This protection prevents rust, oxidation, and other forms of corrosion, ensuring the longevity of metal components.

3. Improved Electrical Conductivity:

Vacuum deposition can deposit conductive materials onto the substrate, enhancing its electrical conductivity. This process is particularly useful for patterning conductive films used in electronic devices, such as electrodes and interconnects.

4. Enhanced Aesthetic Appeal:

Vacuum coatings can alter the appearance of materials, making them more visually appealing. They can create reflective surfaces, enhance colors, and provide a protective layer that prevents scratches and fading.

5. Wide Range of Applications:

Vacuum coating finds applications in various industries, including:

- Automotive: Enhancing the durability and appearance of car parts

- Aerospace: Protecting aircraft components from corrosion and wear

- Electronics: Creating conductive films and improving optical properties

- Medical: Providing corrosion resistance and biocompatibility to medical devices

- Solar Energy: Enhancing the efficiency of solar cells

- Decorative: Creating decorative finishes on jewelry, furniture, and other items

Applications of Vacuum Coating

Vacuum coating is a versatile technology that finds applications in a wide range of industries, including automotive, aerospace, electronics, and medical devices. By depositing a thin film of material onto a substrate in a vacuum environment, vacuum coating can improve the properties of the substrate, such as its durability, corrosion resistance, and electrical conductivity.

In the automotive industry, vacuum coating is used to enhance the performance and appearance of various components. For example, vacuum-coated brake calipers provide improved corrosion resistance and heat dissipation, while vacuum-coated exhaust systems reduce noise and emissions. Vacuum coating is also used to create decorative finishes on automotive parts, such as chrome-plated bumpers and trim.

In the aerospace industry, vacuum coating is used to protect critical components from the harsh conditions of space. For example, vacuum-coated solar panels are used to generate electricity for satellites and spacecraft, while vacuum-coated thermal blankets protect spacecraft from extreme temperatures. Vacuum coating is also used to create anti-reflective coatings on optical components, such as lenses and mirrors.

In the electronics industry, vacuum coating is used to create thin films of conductive materials, such as copper and aluminum, on printed circuit boards (PCBs). These thin films provide electrical connections between the various components on the PCB. Vacuum coating is also used to create dielectric layers on capacitors and transistors, which improve the performance and reliability of these devices.

In the medical device industry, vacuum coating is used to create thin films of biocompatible materials on surgical implants and medical devices. These thin films improve the biocompatibility of the implants and devices, reducing the risk of rejection and infection. Vacuum coating is also used to create anti-microbial coatings on medical devices, which help to prevent the growth of bacteria and other microorganisms.

The applications of vacuum coating are constantly expanding as new technologies are developed. As the technology continues to improve, vacuum coating is likely to play an increasingly important role in a wide range of industries.

Vacuum Coating Equipment and Processes

Vacuum coating is a thin-film technology that deposits thin films and coatings by creating a sub-atmospheric pressure environment and an atomic or molecular condensable vapor source. Physical vapor deposition (PVD) and chemical vapor deposition (CVD) are considered the most attractive vacuum coating technologies.

Vacuum Chambers

The vacuum chamber is the core component of a vacuum coating system. It is a sealed enclosure in which the coating process takes place. The chamber is typically made of stainless steel or aluminum and is designed to maintain a vacuum of 10^-6 Torr or lower.

Deposition Sources

The deposition source is the component that generates the vaporized material that is deposited on the substrate. There are two main types of deposition sources: evaporative sources and sputtering sources.

Evaporative sources vaporize the coating material by heating it to a high temperature. The most common type of evaporative source is the electron beam evaporator, which uses an electron beam to heat the coating material.

Sputtering sources vaporize the coating material by bombarding it with ions. The most common type of sputtering source is the magnetron sputtering source, which uses a magnetic field to confine the plasma and increase the ionization efficiency.

Control Systems

The control system monitors and controls the vacuum coating process. It is responsible for maintaining the vacuum, temperature, and deposition rate. The control system also monitors the thickness and quality of the coating.

Process Steps

The vacuum coating process typically involves the following steps:

- Substrate preparation: The substrate is cleaned and prepared to receive the coating.

- Vacuum chamber preparation: The vacuum chamber is evacuated to a low pressure.

- Deposition: The coating material is vaporized and deposited on the substrate.

- Post-deposition treatment: The coating may be annealed or cured to improve its properties.

Applications

Vacuum coating is used in a wide variety of applications, including:

- Optical coatings: Vacuum coating is used to produce optical coatings for lenses, mirrors, and other optical components.

- Protective coatings: Vacuum coating is used to produce protective coatings for cutting tools, medical devices, and other products.

- Decorative coatings: Vacuum coating is used to produce decorative coatings for jewelry, furniture, and other products.

Quality Control and Testing

Vacuum coating involves depositing a thin layer of material onto a substrate under vacuum conditions. This process is used to improve the properties of the substrate, such as its corrosion resistance, wear resistance, and electrical conductivity. Quality control is essential in vacuum coating to ensure the reliability and performance of coated parts.

Surface Preparation

The surface of the substrate must be properly prepared before coating to ensure good adhesion of the coating. This typically involves cleaning the surface to remove any contaminants, such as dirt, oil, and grease. The surface may also be roughened to increase the surface area for adhesion.

Coating Thickness Measurement

The thickness of the coating is a critical factor in determining its properties. The coating thickness can be measured using a variety of methods, such as stylus profilometry, eddy current testing, and X-ray fluorescence.

Adhesion Testing

Adhesion testing is used to measure the strength of the bond between the coating and the substrate. This is important to ensure that the coating will not peel or flake off during use. Adhesion testing can be performed using a variety of methods, such as the scratch test, the peel test, and the tape test.

Quality Control Standards

There are a number of quality control standards that have been developed for vacuum coating. These standards include:

- ISO 9001:2015: This is a general quality management standard that can be applied to any industry.

- ASTM B530: This standard covers the measurement of coating thickness.

- ASTM D3359: This standard covers the adhesion testing of coatings.

By following these quality control standards, manufacturers can ensure that their vacuum-coated parts meet the required specifications.

Benefits of Quality Control in Vacuum Coating

There are a number of benefits to implementing quality control in vacuum coating, including:

- Improved product quality: Quality control helps to ensure that coated parts meet the required specifications. This results in improved product quality and reliability.

- Reduced costs: Quality control can help to reduce costs by preventing the production of defective parts. This can also lead to reduced warranty costs.

- Increased customer satisfaction: Quality control can help to increase customer satisfaction by ensuring that they receive high-quality products. This can lead to increased sales and repeat business.

Trends and Future Developments in Vacuum Coating

Vacuum coating technology continues to evolve, driven by advancements in materials science, process engineering, and equipment design. Emerging trends include:

Nanocoatings: Nanocoatings are ultra-thin coatings with thicknesses ranging from a few nanometers to several hundred nanometers. They offer exceptional properties such as high strength, low friction, improved corrosion resistance, and enhanced optical properties. Nanocoatings are increasingly used in electronics, optics, aerospace, and biomedical applications.

Multi-Layer Coatings: Multi-layer coatings consist of multiple layers of different materials deposited sequentially. This allows for the creation of coatings with tailored properties that cannot be achieved with single-layer coatings. Multi-layer coatings are used in a wide range of applications, including optical filters, anti-reflection coatings, and protective coatings.

Sustainable Coating Processes: Sustainability is becoming increasingly important in vacuum coating. Researchers are developing new processes that minimize environmental impact and reduce energy consumption. These processes include the use of environmentally friendly materials, closed-loop recycling systems, and energy-efficient equipment.

Advanced Characterization Techniques: Advanced characterization techniques are essential for understanding the properties and performance of vacuum coatings. These techniques include atomic force microscopy (AFM), scanning electron microscopy (SEM), and X-ray diffraction (XRD). They provide valuable insights into the coating's thickness, morphology, composition, and crystal structure.

Future Directions: Future developments in vacuum coating include the integration of artificial intelligence (AI) and robotics to optimize the coating process and improve quality control. Researchers are also exploring the use of novel materials, such as graphene and carbon nanotubes, to create coatings with exceptional properties. Additionally, the development of new coating techniques, such as atomic layer deposition (ALD) and molecular beam epitaxy (MBE), is expected to further expand the capabilities of vacuum coating technology.

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications