Introduction and Historical Context

Historical Development

The inception of the vacuum induction furnace traces back to 1917 in Germany, marking a pivotal moment in the evolution of metallurgical technology. This groundbreaking innovation was initially employed for the critical task of melting engines for aircraft and rocket engines, underscoring its early association with high-stakes, high-performance applications.

The development of the vacuum induction furnace was not merely a technological leap but a strategic advancement in materials science, particularly for aerospace and defense sectors. By enabling the melting and refining of metals in a controlled vacuum environment, this technology offered unprecedented precision and purity, essential for the durability and reliability of components operating under extreme conditions.

Initially, the furnace's capabilities were harnessed to address the stringent requirements of early aviation and space exploration. The need for lightweight yet robust materials capable of withstanding the harsh environments of flight and space travel necessitated a melting process that could eliminate impurities and enhance material properties. The vacuum induction furnace fulfilled this need, laying the groundwork for its subsequent widespread adoption across various industries.

As the technology matured, its applications expanded beyond aerospace to include the production of high-temperature alloys, ultra-high strength steels, and specialty alloys demanded by sectors such as atomic energy and electronics. This evolution underscored the versatility and adaptability of vacuum induction melting, positioning it as a cornerstone in modern metallurgy.

In summary, the historical development of the vacuum induction furnace from its inception in 1917 has been marked by continuous innovation and adaptation, driven by the relentless pursuit of material excellence in high-performance applications.

Widespread Usage

The vacuum induction furnace stands as a cornerstone in the realm of vacuum metallurgy, boasting an extensive array of applications across diverse industries. Its versatility and efficiency make it indispensable for the production of high-quality metals and alloys, particularly in sectors where precision and purity are paramount.

In the aerospace and defense industries, the vacuum induction furnace is employed to create high-temperature alloys and ultra-high strength steels, materials that are critical for the performance and safety of aircraft, missiles, and rockets. The stringent requirements for these applications necessitate a melting process that can eliminate impurities and achieve the precise chemical compositions required for optimal performance.

Similarly, the electronics and atomic energy industries rely on the vacuum induction furnace for the production of specialty alloys and stainless steels. These materials are integral to the functioning of advanced electronic components and nuclear reactors, where even minor impurities can lead to catastrophic failures.

The widespread adoption of the vacuum induction furnace is further underscored by its use in the automotive and medical device sectors. In automotive manufacturing, it is used to produce high-performance engine components and structural elements that must withstand extreme conditions. In the medical field, the furnace's ability to produce biocompatible alloys and implants ensures the safety and efficacy of medical devices.

This equipment's broad applicability is a testament to its robust design and the meticulous control it offers over the melting and refining processes. By operating in a vacuum, the furnace eliminates the risk of gas-phase interactions and contamination, thereby ensuring the highest levels of purity and consistency in the final products.

In summary, the vacuum induction furnace's widespread usage is driven by its unparalleled ability to meet the exacting standards of various industries, from aerospace and electronics to automotive and medicine. Its role in producing high-quality, precise, and pure metals and alloys makes it an essential tool in modern metallurgy.

Characteristics and Applications

Material Improvements

The utilization of vacuum induction melting (VIM) furnaces has revolutionized the production of high-temperature alloys, particularly those based on nickel, cobalt, and iron. This advanced melting process not only enhances the hot workability of these alloys but also significantly improves their mechanical properties.

In traditional melting methods, the presence of atmospheric gases can lead to contamination and inconsistent material properties. However, VIM operates in a vacuum environment, which eliminates these issues by preventing gas-phase interactions and pollution. This controlled environment allows for the precise control of the alloy's chemical composition, ensuring that elements with strong affinities for oxygen and nitrogen, such as aluminum, titanium, boron, and zirconium, are maintained within very tight ranges.

The improvements in hot workability are particularly noteworthy. High-temperature alloys processed through VIM exhibit superior ductility and formability, making them easier to shape and manipulate during manufacturing processes. This is crucial for industries that require complex and intricate components, such as aerospace, missiles, rockets, atomic energy, and electronics.

Moreover, the enhanced mechanical properties of these alloys, including increased strength and toughness, make them ideal for applications where durability and reliability are paramount. The ability to produce alloys with consistent and superior properties through VIM has opened new avenues for innovation and performance in various high-tech industries.

In summary, the application of vacuum induction melting furnaces in the production of nickel-based, cobalt-based, and iron-based high-temperature alloys represents a significant leap forward in material science and engineering. The improvements in both hot workability and mechanical properties underscore the critical role of VIM in meeting the stringent demands of modern industrial applications.

Industries Served

Vacuum Induction Melting (VIM) is integral to the production of critical components across several high-tech industries. This advanced melting process is particularly indispensable in the aerospace sector, where materials must withstand extreme conditions such as high temperatures and immense pressures. The aerospace industry relies heavily on VIM for manufacturing components like turbine blades, engine parts, and structural elements that demand high-temperature alloys and ultra-high strength steels.

In the realm of defense, VIM plays a pivotal role in the production of missiles and rockets. These applications require materials that not only endure high temperatures but also exhibit exceptional mechanical strength and resistance to corrosion. The atomic energy industry, another key beneficiary of VIM, utilizes these specialized alloys for nuclear reactors and other components that operate under extreme conditions.

The electronics industry also leverages VIM for producing stainless steel and other specialty alloys used in the fabrication of precision components. These materials are essential for ensuring the reliability and longevity of electronic devices, from microprocessors to intricate connectors.

| Industry | Key Applications |

|---|---|

| Aerospace | Turbine blades, engine parts, structural elements |

| Defense | Missiles, rockets, high-temperature and high-strength components |

| Atomic Energy | Nuclear reactors, components operating under extreme conditions |

| Electronics | Precision components, stainless steel, specialty alloys |

VIM's ability to produce high-quality, precisely controlled alloys makes it an indispensable technology across these industries, driving innovation and ensuring the performance and safety of critical applications.

Process Details

Vacuum State Operations

The process of melting, refining, and alloying metals in a vacuum state is a cornerstone of vacuum induction melting. This method ensures that the metal remains uncontaminated by gas-phase interactions, which are prevalent in atmospheric conditions. By operating in a vacuum, the process eliminates the risk of oxidative reactions and the incorporation of impurities such as oxygen, nitrogen, and hydrogen into the molten metal.

In a vacuum environment, the absence of atmospheric gases allows for precise control over the chemical composition of the alloy. This is particularly crucial for metals that are sensitive to the presence of gases, such as nickel-based, cobalt-based, and iron-based high-temperature alloys. The vacuum state not only enhances the purity of the metal but also significantly improves its mechanical properties and hot workability.

Moreover, the vacuum induction melting process is essential for industries that require high-quality, specialized alloys. This includes sectors such as aerospace, missiles, rockets, atomic energy, and electronics, where the performance and reliability of materials are paramount. The ability to produce ultra-high strength steel, stainless steel, and other specialty alloys with minimal impurities is a direct result of the controlled vacuum environment.

In summary, the vacuum state operations in vacuum induction melting are not just a technical requirement but a strategic advantage that ensures the production of high-quality, high-performance alloys free from common atmospheric contaminants.

Chemical Control

In vacuum induction melting, precise control over the chemical composition of the alloy is paramount. This process ensures that elements with high reactivity, such as aluminum (Al), titanium (Ti), boron (B), and zirconium (Zr), are meticulously managed. These elements, known for their strong affinity to oxygen and nitrogen, can significantly alter the properties of the alloy if not controlled within narrow parameters.

The ability to contain these reactive elements within a very small range is crucial for producing high-quality alloys. This level of control is achieved through advanced techniques and equipment that maintain a vacuum environment, thereby minimizing the interaction of these elements with atmospheric gases. The result is a homogenous and stable alloy composition, essential for applications in aerospace, missiles, rockets, atomic energy, and electronics industries, where material integrity is non-negotiable.

To illustrate the importance of this control, consider the following table:

| Element | Affinity to Oxygen/Nitrogen | Impact on Alloy |

|---|---|---|

| Al | High | Increases strength and hardness |

| Ti | High | Enhances corrosion resistance |

| B | Moderate | Improves creep resistance |

| Zr | High | Stabilizes microstructure |

By maintaining these elements within precise limits, vacuum induction melting ensures that the final product meets the stringent requirements of high-performance applications.

Equipment Structure

Main Components

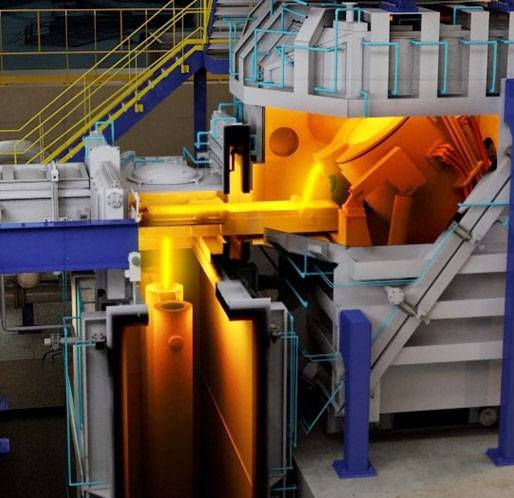

The vacuum induction melting (VIM) furnace is a sophisticated piece of equipment designed for precise metal melting and refining processes. Its core components include the furnace shell, inductor, crucible, tilting mechanism, ingot mold mechanism, power supply device, and water-cooling system. Each of these components plays a crucial role in ensuring the efficiency and accuracy of the melting process.

-

Furnace Shell: This is the outer casing of the furnace, designed to maintain the vacuum environment necessary for the melting process. It is typically made of high-strength, heat-resistant materials to withstand the high temperatures and pressures involved.

-

Inductor: The inductor is a coil that generates a magnetic field, inducing a current in the metal charge placed within the crucible. This current heats the metal to its melting point, making the inductor a vital part of the heating mechanism.

-

Crucible: The crucible is where the metal charge is placed and melted. It must be made of materials that can withstand high temperatures and are chemically inert to prevent contamination of the molten metal.

-

Tilting Mechanism: This mechanism allows the furnace to tilt, facilitating the pouring of molten metal into ingot molds. It is essential for controlling the flow of metal and ensuring a smooth pouring process.

-

Ingot Mold Mechanism: The ingot mold mechanism is where the molten metal solidifies into ingots. The design of the molds can affect the final shape and quality of the ingots.

-

Power Supply Device: This device provides the electrical energy needed to power the inductor, ensuring that the metal charge reaches and maintains its melting temperature.

-

Water-Cooling System: The water-cooling system is crucial for dissipating the heat generated during the melting process. It prevents the furnace components from overheating and ensures their longevity.

Each of these components is meticulously designed and integrated to ensure the smooth operation of the vacuum induction melting process, contributing to the production of high-quality, pure metals.

Design Considerations

The structural design of the vacuum induction melting furnace is paramount to preventing vacuum discharge, a critical issue that could compromise the integrity of the entire process. This necessitates meticulous insulation of all charged bodies within the furnace shell. The insulation materials must be carefully selected to withstand the high temperatures and vacuum conditions, ensuring that they do not degrade or cause any unintended reactions.

To achieve this, the design must incorporate advanced insulation technologies such as multi-layer insulation (MLI) systems, which are commonly used in aerospace applications due to their superior thermal and vacuum performance. Additionally, the use of high-purity refractory materials, such as alumina and zirconia, is essential to maintain the integrity of the furnace environment.

| Design Element | Consideration |

|---|---|

| Insulation Material | High-purity refractory materials like alumina and zirconia. |

| Multi-Layer Insulation (MLI) | Used to enhance thermal and vacuum performance. |

| Temperature Resistance | Materials must withstand high temperatures without degradation. |

| Vacuum Integrity | Ensures no unintended reactions or vacuum discharge. |

Moreover, the design must also account for the thermal expansion and contraction of materials under varying temperature conditions. This requires the incorporation of flexible insulation layers that can adapt to these changes without compromising the vacuum seal. The overall goal is to create a robust, yet flexible, insulation system that can maintain the vacuum state throughout the melting process.

Process Flow

Crucible Selection and Preparation

The selection and preparation of the crucible are pivotal in the vacuum induction melting process, directly influencing both the productivity of the equipment and the quality of the finished metal. Given the unique nature of each operation—varying furnace types, alloys, metallurgical treatments, and pouring arrangements—choosing the optimal crucible is a complex, individualized task.

Crucibles come in a diverse array of sizes, shapes, and materials, each designed to handle specific sets of temperature, chemical, and physical parameters. For instance, they can range from small, teacup-sized vessels to large containers capable of holding several tons of metal. They may be fixed within a furnace structure or designed for easy removal for pouring, and can be used in various types of furnaces, including fuel-fired, electric resistance, and induction furnaces.

The modern crucible is typically a heterogeneous, graphite-based composite material, engineered to meet the performance requirements through precise control of its material composition and the structural alignment of the graphite. This design ensures that the crucible can withstand the rigorous conditions of metal melting and holding, providing maximum performance for the specific application.

Selecting the right crucible involves a thorough understanding of these performance characteristics and a collaborative effort between metal melters and crucible suppliers. This partnership ensures that the crucible not only meets the technical boundaries of the operation but also enhances the overall efficiency and quality of the metal production process.

Charge Preparation

Preparation of raw materials for vacuum induction melting is a critical step that directly impacts the quality and purity of the final product. The process involves meticulous testing and selection of materials to ensure they meet stringent criteria, especially given the challenges posed by the vacuum environment.

In vacuum induction melting, the removal of certain elements such as phosphorus and sulfur is particularly difficult. These elements, which can significantly affect the mechanical properties of the alloy, must be strictly controlled. Therefore, the raw materials must be carefully screened to limit their content of these impurities.

Additionally, the selection process includes evaluating the compatibility of the materials with the melting conditions. This involves assessing factors such as the reactivity of the materials under vacuum, their thermal stability, and their ability to maintain structural integrity during the melting process.

To further ensure the quality of the charge, advanced analytical techniques are employed. These include spectrometry, microscopy, and chemical analysis to identify and quantify any trace elements that could potentially contaminate the melt. By implementing these rigorous testing protocols, manufacturers can guarantee that the raw materials are of the highest purity, thereby enhancing the overall performance and reliability of the final product.

Melting and Refining

In the initial stage of melting, a batch of materials containing all inactive alloying elements is introduced into the furnace. It is crucial that this batch includes a controlled amount of carbon. The presence of carbon serves a dual purpose: it facilitates the deoxidation process during melting and ensures that the metal attains the desired properties.

During the refining phase, the molten metal is transferred to an AOD (Argon-Oxygen Decarburization) or VOD/VD (Vacuum Oxygen Decarburization/Vacuum Degassing) vessel. These advanced refining techniques are essential for producing high-quality stainless steels and other specialty alloys. For particularly demanding applications, the metal may undergo further processing in a Vacuum Induction Melting (VIM) furnace, followed by Vacuum Arc Remelting (VAR) or Electroslag Remelting (ESR). This multi-stage refining process ensures that the final product meets stringent purity and composition requirements.

Pouring

The pouring process is a critical juncture in the vacuum induction melting cycle, directly influencing the final quality of the product. This stage requires meticulous attention to several key factors to ensure optimal outcomes.

Firstly, the precise control of pouring temperature is paramount. The temperature must be carefully calibrated to ensure that the liquid metal maintains excellent fluidity. This fluidity is essential for the metal to fill the mold completely and evenly, thereby preventing defects such as incomplete filling or cold shuts. The ideal pouring temperature ensures that the metal flows smoothly without causing thermal stresses that could lead to cracking or other structural issues.

Moreover, the timing of the pour is equally crucial. The delay between the melting phase and the pouring phase should be minimized to prevent the metal from cooling excessively, which could compromise its fluidity. Additionally, the pouring technique itself—whether gravity pouring or using a ladle—must be executed with precision to avoid turbulence and ensure a smooth, even distribution of the metal within the mold.

In summary, the pouring process in vacuum induction melting is a delicate balance of temperature control, timing, and technique, all of which play a pivotal role in determining the final quality and integrity of the metal product.

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

Related Articles

- Melting process and maintenance of vacuum induction melting furnace

- How Vacuum Induction Melting Elevates High-Performance Alloy Production

- How Vacuum Induction Melting Outperforms Traditional Methods in Advanced Alloy Production

- Vacuum Induction Melting Furnace: Principle, Advantages, and Applications

- Application of Hot Isostatic Pressing Technology in Nickel-Based Casting High-Temperature Alloys