Vacuum Furnace

Vacuum Induction Melting Spinning System Arc Melting Furnace

Item Number : KT-VIS

Price varies based on specs and customizations

- Capacity

- 20-1000 g

- Belt width

- 1-70 mm

- Spinner size

- φ200-φ300 mm

- Speed

- 3000r/min

- Vacuum

- 6.7*10-4pa

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Applications

Vacuum melt spinning system is a special equipment for preparing and developing metastable materials (such as amorphous materials and microcrystalline materials). With the induction melting technology, melt spinning furnace can rapidly melt target metal materials, and rapidly cool molten metals or alloys to form thin ribbons or wires, so that it can continue to maintain its liquid disordered structure when solidification at room temperature, inhibit crystallization, and obtain amorphous metastable materials.

Vacuum melt spinning system is applicable to the research and experimental work of various amorphous and microcrystalline materials, and is widely used in the development and research of new rare earth permanent magnetic materials, amorphous soft magnetic materials and nano materials.

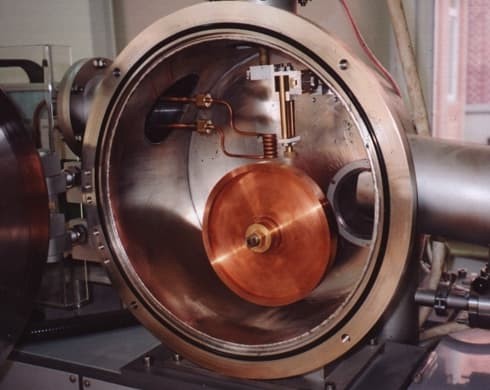

Vacuum melt spinning system component

- High vacuum stainless steel chamber with observation window

- Induction smelting device with Boron Nitride crucible or Quartz crucible

- High-speed water-cooled copper spinning wheel

- Belt or wire collection device

- Induction power supply

- Pneumatic lifting device

- Temperature sensor device,

- Circulating water chiller

- High vacuum system

Features

- 304 stainless steel chamber design, smooth surface and free from rust

- Horizontal side door opening structure, convenient loading and unloading

- Large observation window is configured to observe smelting conditions in real time

- High smelting temperature is above 1700 ℃, graphite crucible can be above 2100 ℃

- Multi functions with one furnace,smelting and casting, vacuum wire and belt making

- IGBT high-frequency power supply is adopted, excellent smelting effect and low noise

- Two-stage control system is used to achieve high vacuum, up to 5.0*10-3pa

- Equipped with an operation simulation screen, the operation is intuitive and simple

- The belt throwing system is controlled by a servo motor, which overcomes the problems of vibration and unstable motor speed of ordinary frequency conversion motors.

- Strong scalability, can increase the function of spray casting

Technical specifications

| Model | KT-VIS2 | KT-VIS15 | KT-VIS50 | KT-VIS100 |

| Capacity | 20g | 150g | 500g | 1000g |

| Crucible | Boron Nitride/Quartz | |||

| Belt width | 1-10mm | 1-30mm | 1-40mm | 1-70mm |

| Spinner size | φ200mm | φ220mm | Φ300mm | Φ300mm |

| Speed | 3000r/min | |||

| Vacuum | 6.7*10-4pa | |||

| Insert gas | Ar | |||

| Rated power | 7kw | 15kw | 25kw | 35kw |

| Power supply | AC110-480V 50/60HZ | |||

| Optional part | Infrared temperature meter, recirculating chiller,Spray casting copper mold | |||

| Other requirement can be customized | ||||

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is A Vacuum Induction Furnace And How Does It Work?

What Is A Vacuum Furnace Used For?

How Does A Vacuum Induction Melting Furnace Work?

What Is Vacuum Arc Melting Process?

What Are The Main Applications Of Vacuum Induction Furnaces?

What Is The Process Of A Vacuum Furnace?

What Are The Advantages Of Vacuum Induction Melting?

What Is VAR Vacuum Arc Remelting (VAR)Furnace?

What Are The Advantages Of Using A Vacuum Induction Furnace?

What Gas Is Used In A Vacuum Furnace?

How Does Vacuum Help In Induction Melting Furnace?

How Does Vacuum Arc Melting Furnace Work?

What Types Of Materials Can Be Processed In A Vacuum Induction Furnace?

What Is The Heating Element Used In A Vacuum Furnace?

What Is Vacuum Induction Melting Furnace?

What Are The Applications Of Vacuum Arc Melting Furnaces?

How Does The Vacuum Environment In A Vacuum Induction Furnace Improve Material Properties?

What Are The Advantages Of Using Vacuum Arc Melting Furnaces?

What Safety Precautions Should Be Followed When Using A Vacuum Arc Melting Furnace?

4.8 / 5

The vacuum induction melting system is a must-have for our lab. It's easy to use, efficient, and produces high-quality results.

4.9 / 5

Our lab recently purchased the Vacuum Induction Melting Spinning System Arc Melting Furnace, and we couldn't be happier with it. The system is well-built, easy to use, and produces excellent results.

4.7 / 5

The vacuum induction melting furnace has improved the efficiency of our lab significantly. It's a valuable investment that has paid for itself in no time.

4.8 / 5

The vacuum induction melting system is a game-changer for our lab. It has allowed us to produce high-quality materials that were previously impossible to achieve.

4.9 / 5

The vacuum induction melting furnace is a must-have for any lab that needs to produce high-quality materials. It's easy to use, efficient, and produces excellent results.

4.7 / 5

The vacuum induction melting furnace has been a valuable addition to our lab. It has allowed us to produce new materials that were previously impossible to create.

4.8 / 5

The vacuum induction melting system is a great investment for our lab. It has helped us to improve the quality of our research and has saved us time and money.

4.9 / 5

The vacuum induction melting furnace is a top-notch piece of equipment. It's well-built, easy to use, and produces excellent results. I highly recommend it to any lab that needs to produce high-quality materials.

4.7 / 5

The vacuum induction melting system has been a game-changer for our lab. It has allowed us to produce new materials that were previously impossible to create.

4.8 / 5

The vacuum induction melting furnace is a must-have for any lab that needs to produce high-quality materials. It's easy to use, efficient, and produces excellent results.

4.9 / 5

The vacuum induction melting furnace is a great investment for our lab. It has helped us to improve the quality of our research and has saved us time and money.

4.7 / 5

The vacuum induction melting system has been a game-changer for our lab. It has allowed us to produce new materials that were previously impossible to create.

4.8 / 5

The vacuum induction melting furnace is a must-have for any lab that needs to produce high-quality materials. It's easy to use, efficient, and produces excellent results.

4.9 / 5

The vacuum induction melting furnace is a great investment for our lab. It has helped us to improve the quality of our research and has saved us time and money.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Vacuum Arc Induction Melting Furnace

Discover the power of Vacuum Arc Furnace for melting active & refractory metals. High-speed, remarkable degassing effect, and free of contamination. Learn more now!

Lab-Scale Vacuum Induction Melting Furnace

Get precise alloy composition with our Vacuum Induction Melting Furnace. Ideal for aerospace, nuclear energy, and electronic industries. Order now for effective smelting and casting of metals and alloys.

Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

Experience precise melting with our Vacuum Levitation Melting Furnace. Ideal for high melting point metals or alloys, with advanced technology for effective smelting. Order now for high-quality results.

Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

IGBT experimental graphitization furnace, a tailored solution for universities and research institutions, with high heating efficiency, user-friendliness, and precise temperature control.

Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

A vacuum molybdenum wire sintering furnace is a vertical or bedroom structure, which is suitable for withdrawal, brazing, sintering and degassing of metal materials under high vacuum and high temperature conditions. It is also suitable for dehydroxylation treatment of quartz materials.

Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

Discover the versatility of Laboratory Rotary Furnace: Ideal for calcination, drying, sintering, and high-temperature reactions. Adjustable rotating and tilting functions for optimal heating. Suitable for vacuum and controlled atmosphere environments. Learn more now!

Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

Experience efficient material processing with our vacuum-sealed rotary tube furnace. Perfect for experiments or industrial production, equipped with optional features for controlled feeding and optimized results. Order now.

Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

The air pressure sintering furnace is a high-tech equipment commonly used for the sintering of advanced ceramic materials. It combines vacuum sintering and pressure sintering techniques to achieve high-density and high-strength ceramics.

Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

Reduce forming pressure & shorten sintering time with Vacuum Tube Hot Press Furnace for high-density, fine-grain materials. Ideal for refractory metals.

Graphite Vacuum Furnace Negative Material Graphitization Furnace

Graphitization furnace for battery production has uniform temperature and low energy consumption. Graphitization furnace for negative electrode materials: an efficient graphitization solution for battery production and advanced functions to enhance battery performance.

Vertical High Temperature Graphite Vacuum Graphitization Furnace

Vertical high temperature graphitization furnace for carbonization and graphitization of carbon materials up to 3100℃.Suitable for shaped graphitization of carbon fiber filaments and other materials sintered in a carbon environment.Applications in metallurgy, electronics, and aerospace for producing high-quality graphite products like electrodes and crucibles.

Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

Bottom-out graphitization furnace for carbon materials, ultra-high temperature furnace up to 3100°C, suitable for graphitization and sintering of carbon rods and carbon blocks. Vertical design, bottom discharging, convenient feeding and discharging, high temperature uniformity, low energy consumption, good stability, hydraulic lifting system, convenient loading and unloading.

1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

KT-17A Controlled atmosphere furnace: 1700℃ heating, vacuum sealing technology, PID temperature control, and versatile TFT smart touch screen controller for laboratory and industrial use.

Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

Efficiently produce batches with excellent temperature uniformity using our Bottom Lifting Furnace. Features two electric lifting stages and advanced temperature control up to 1600℃.

Graphite Vacuum Continuous Graphitization Furnace

High-temperature graphitization furnace is a professional equipment for graphitization treatment of carbon materials. It is a key equipment for the production of high-quality graphite products. It has high temperature, high efficiency and uniform heating. It is suitable for various high-temperature treatments and graphitization treatments. It is widely used in metallurgy, electronics, aerospace, etc. industry.

1700℃ Muffle Oven Furnace for Laboratory

Get superior heat control with our 1700℃ Muffle Furnace. Equipped with intelligent temperature microprocessor, TFT touch screen controller & advanced insulation materials for precise heating up to 1700C. Order now!

Vertical Laboratory Tube Furnace

Elevate your experiments with our Vertical Tube Furnace. Versatile design allows for operation under various environments and heat treatment applications. Order now for precise results!

Related Articles

Application of Hot Isostatic Pressing Technology in Nickel-Based Casting High-Temperature Alloys

Explores the use of hot isostatic pressing to enhance the properties of nickel-based casting high-temperature alloys in aerospace applications.

Unlocking the Potential: Vacuum Levitation Induction Melting Furnace Explained

Discover the working principles, applications, and advantages of vacuum levitation induction melting furnaces. Learn how this technology revolutionizes metal smelting, ensuring purity, efficiency, and environmental friendliness.

Vacuum Induction Melting Furnace: Principle, Advantages, and Applications

Discover the Vacuum Induction Melting Furnace, a specialized equipment that employs vacuum and induction heating to refine metals and alloys, ensuring high purity and precise composition control. Explore its principle, advantages, applications, and components in this comprehensive guide.

Vacuum Melting Furnace: A Comprehensive Guide to Vacuum Induction Melting

Discover the intricacies of vacuum induction melting furnaces, their components, operation, advantages, and applications. Explore how these furnaces revolutionize metal processing and achieve exceptional material properties.

Vacuum Laboratory Furnaces in Advanced Materials Research

In addition to size, there are several other key differences between industrial-scale and laboratory vacuum furnaces

Vacuum Induction Melting Furnace vs Arc Melting Furnace: Choosing the Right Equipment for Your Process

Learn about the key differences between vacuum induction melting furnaces and arc melting furnaces, including their advantages and applications, to help you choose the best equipment for your specific needs.

Melting process and maintenance of vacuum induction melting furnace

Melting process and maintenance of vacuum induction melting furnace

Materials Science with the Lab Vacuum Furnace

A vacuum furnace is a specialized type of furnace that is designed to operate in a vacuum environment. This means that the furnace is sealed and the air inside is pumped out, creating a low pressure or vacuum inside.

PECVD Furnace A Low-Power and Low-Temperature Solution for Soft Matter

PECVD (Plasma Enhanced Chemical Vapor Deposition) furnaces have become a popular solution for the deposition of thin films on soft matter surfaces.

Biomass Pyrolysis Equipment A Sustainable Solution for Waste Management

Biomass pyrolysis has gained increased attention as a sustainable solution for waste management and renewable energy generation.

Unveiling Vacuum Graphite Furnaces: Performance, Applications, and Expert Insights

Delve into the world of vacuum graphite furnaces, exploring their exceptional performance, diverse applications, and crucial considerations. Our expert insights empower you to make informed decisions for your laboratory's high-temperature material treatment needs.

Vacuum Induction Melting Furnace: Introduction and Applications

Overview of vacuum induction melting furnace features, capabilities, and applications in material research and production.