Introduction to Vacuum Induction Melting Furnace

High-Temperature Melting Capabilities

The vacuum induction melting furnace stands out for its exceptional ability to achieve heating temperatures that can soar up to 1700°C. This capability is pivotal in various high-vacuum or protective atmosphere melting and casting processes. By operating under these conditions, the furnace effectively mitigates the risk of oxidation and the formation of inclusions within the molten metal. This ensures that the final product maintains a high level of purity and structural integrity.

In more detail, the furnace's high-temperature melting capabilities are not just a technical feat but a necessity for processing a wide array of materials, from high-temperature alloys to rare earth metals. The high vacuum environment, coupled with the furnace's ability to maintain such extreme temperatures, allows for the precise control of alloy composition and the purification of materials. This is particularly crucial in industries where material purity is non-negotiable, such as in aerospace and semiconductor manufacturing.

Moreover, the furnace's design incorporates advanced features like electromagnetic stirring and high vacuum degassing, which further enhance its ability to produce high-quality alloys. These features not only aid in homogenizing the molten metal but also in removing any residual gases that could compromise the material's properties. This dual-pronged approach ensures that the final product not only meets but exceeds industry standards for purity and consistency.

In summary, the vacuum induction melting furnace's high-temperature melting capabilities are a cornerstone of its effectiveness in material research and production. By enabling high-vacuum or protective atmosphere melting and casting, it ensures that the materials processed are free from oxidation and inclusions, thereby maintaining their integrity and purity.

Alloy Composition Control and Purification

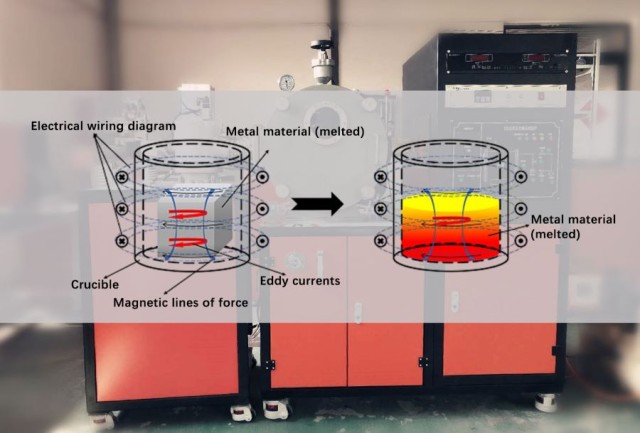

The vacuum induction melting furnace incorporates advanced technologies such as electromagnetic stirring and high vacuum degassing, which are pivotal for maintaining precise control over alloy composition and ensuring material purity. Electromagnetic stirring facilitates uniform mixing of the molten metal, preventing segregation of elements and promoting a homogeneous distribution of alloy constituents. This process is crucial for creating alloys with consistent properties, which is essential for both research and industrial applications.

High vacuum degassing, on the other hand, removes dissolved gases and impurities from the molten metal, enhancing its overall quality. This purification process is particularly significant for materials that are sensitive to oxidation and contamination, such as high-temperature alloys and rare earth metals. By operating in a high vacuum environment, the furnace effectively minimizes the risk of inclusions and other defects, thereby improving the integrity and performance of the final product.

These features not only enable the production of high-purity alloys but also support the development of advanced materials with tailored properties, making the vacuum induction melting furnace an indispensable tool in material research and production.

Applications in Material Research and Production

Experimental Equipment for Material Research

The vacuum induction melting furnace is an indispensable tool in material research, particularly for the melting and purification of high-temperature alloys, rare earth metals, nano-materials, and other specialized materials. Operating in a high vacuum environment, this equipment effectively mitigates oxidation, thereby enhancing the purity of the end products. This is crucial for materials that are highly susceptible to oxidation, such as titanium and zirconium alloys, which require an inert atmosphere to maintain their structural integrity and mechanical properties.

In addition to preventing oxidation, the vacuum induction melting furnace employs advanced techniques to ensure the homogeneity and purity of the melted materials. Electromagnetic stirring, for instance, ensures uniform mixing of the alloy components, while high vacuum degassing removes any residual gases that could compromise the material's quality. These processes are essential for achieving precise alloy compositions and purifying the materials, making the furnace an invaluable asset in both research and production settings.

The versatility of the vacuum induction melting furnace extends to its ability to handle a wide range of materials, from refractory metals like tungsten and molybdenum to precious metals such as gold and platinum. This adaptability, combined with its high temperature and high vacuum capabilities, allows researchers and manufacturers to explore new material compositions and properties, pushing the boundaries of what is possible in material science.

Advantages in Material Processing

The vacuum induction melting furnace offers a suite of advanced features that significantly enhance material processing capabilities. These features include high temperature environments, high vacuum conditions, high power density, and rapid heating/cooling cycles. These attributes collectively enable the furnace to achieve rapid melting and thorough mixing of materials, ensuring a homogenous alloy composition.

Key Features and Benefits

-

High Temperature Capabilities: The furnace can operate at temperatures exceeding 1700°C, facilitating the melting of a wide range of materials, from high-temperature alloys to rare earth metals, without the risk of oxidation.

-

High Vacuum Conditions: By maintaining a high vacuum, the furnace prevents the introduction of impurities and inclusions, thereby enhancing the purity and quality of the final product.

-

High Power Density: The high power density ensures efficient energy transfer, allowing for rapid heating and cooling cycles. This is crucial for processes that require precise temperature control and quick transitions.

-

Rapid Heating/Cooling: The ability to rapidly heat and cool materials allows for precise control over the alloy composition and microstructure, making it ideal for both research and production environments.

These features not only streamline the material processing workflow but also provide adaptability to various research and production needs, making the vacuum induction melting furnace a versatile tool in the field of material science and industrial applications.

Specific Uses and Customization

Melting and Purification of Special Metals

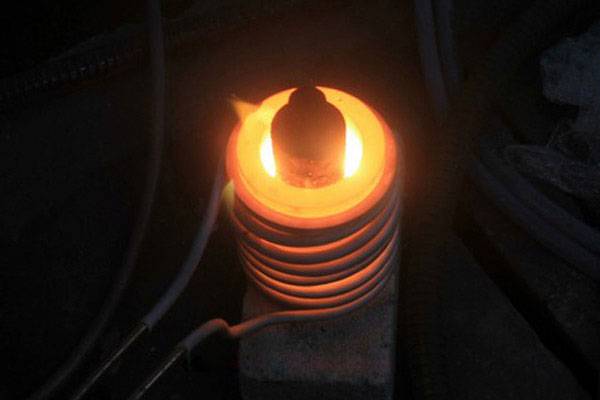

The vacuum induction melting furnace is uniquely suited for the melting and purification of special metals, including refractory metals, precious metals, and copper alloys. This process is particularly effective due to the customization options available, such as the medium frequency power supply, which facilitates high-frequency operations. This high-frequency capability ensures rapid heating, significantly reducing the time required for melting and purification processes.

Moreover, the high limiting temperature of the furnace allows for precise control over the melting point, which is crucial for maintaining the integrity and purity of these specialized metals. The combination of high-frequency heating and high limiting temperature not only accelerates the melting process but also enhances the overall quality of the final product by minimizing impurities and ensuring uniform alloy composition.

In summary, the vacuum induction melting furnace's customization features, particularly the medium frequency power supply, play a pivotal role in efficiently melting and purifying special metals, thereby meeting the stringent requirements of material research and production.

Operational Efficiency and Design

The design of the vacuum induction melting furnace is meticulously crafted to ensure both operational efficiency and long-term stability. One of the standout features is the incorporation of a low noise, high efficiency power supply, which not only reduces operational noise but also significantly enhances energy efficiency. This design choice is pivotal in maintaining a quiet working environment while minimizing energy consumption, thereby reducing operational costs over time.

Additionally, the furnace employs coaxial electrode heating, a technology that ensures even and rapid heating across the entire melting chamber. This method of heating is particularly advantageous as it allows for precise temperature control, which is crucial for maintaining the integrity and uniformity of the molten materials. The coaxial electrode setup also contributes to the furnace's overall durability and reliability, ensuring that it can withstand extended periods of operation without compromising performance.

These design elements collectively contribute to the furnace's ability to operate seamlessly over long durations, making it an ideal choice for both research and industrial applications where sustained, high-quality performance is paramount.

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

Related Articles

- How Vacuum Induction Melting Prevents Catastrophic Material Failures in Critical Components

- How Vacuum Induction Melting Outperforms Traditional Methods in Advanced Alloy Production

- How Vacuum Induction Melting (VIM) Transforms High-Performance Alloy Production

- Vacuum Induction Melting Furnace: Principle, Advantages, and Applications

- Melting process and maintenance of vacuum induction melting furnace