Introduction: An explanation of hot isostatic pressing

Hot isostatic pressing (HIP) is a manufacturing process that uses high temperature and high pressure to improve the mechanical properties of materials. The process involves placing the part in a sealed chamber and subjecting it to high temperatures and pressure. Pressure is applied evenly from all directions, ensuring the part is evenly compressed. High temperatures soften the material, making it prone to deformation. The process is commonly used to increase the strength and ductility of metals, ceramics and composite materials. HIP is a versatile process that can be used to produce complex shapes and improve the performance of materials used in a variety of industries.

Benefits of isostatic pressing

Isostatic pressing is a versatile manufacturing technology that offers several advantages over other traditional techniques. Here are some of the main advantages of isostatic pressing:

Uniform density and microstructure

One of the main advantages of isostatic pressing is its ability to produce parts with uniform density and microstructure. This means the risk of defects is significantly reduced, thus improving the performance and durability of materials and components.

Integration of complex shapes

Isostatic pressing can also consolidate complex shapes, which is particularly useful in industries such as aerospace, medical and automotive applications. The process allows joining different materials, which is important to achieve specific material properties.

Extend fatigue life

Another advantage of isostatic pressing is its ability to increase the fatigue life of components, which is important in high-stress environments. The technology allows for the production of near-net shape parts, minimizing waste and saving costs.

Repairs and renovations

Isostatic pressing can also be used to repair and repair components, extending their service life and reducing the need for replacement. This is particularly useful for expensive components such as turbine blades, medical implants and hip replacements.

Increase productivity and reduce waste

Using isostatic pressing can increase productivity by up to 70% compared to natural cooling processes. This is because thin-walled prestressed windings allow for a uniform and rapid cooling process. Additionally, the process minimizes waste and saves costs.

Improve mechanical properties

The isostatic pressing process can improve the mechanical properties of materials, such as increasing density, ductility, toughness and reducing performance fluctuations. This makes it an effective and efficient manufacturing process that improves the performance and durability of materials and components.

In summary, the benefits of isostatic pressing make it an effective and efficient manufacturing process that improves the performance and durability of materials and components. The ability to produce parts with uniform density and microstructure, integrate complex shapes, repair and repair parts, and increase component fatigue life are just a few of the many benefits of this technology.

Types of isostatic pressure

Isostatic pressing is a powder metallurgy process that provides the greatest possible density and microstructural uniformity to powder compacts. There are two main types of isostatic pressing: cold isostatic pressing (CIP) and hot isostatic pressing (HIP).

Cold isostatic pressing (CIP)

Cold isostatic pressing (CIP) is a process used to compress materials at room temperature. This method is usually used for materials that cannot withstand high temperatures. In CIP, powder is placed into a flexible mold, which is then immersed in a liquid (such as water or oil) and subjected to high pressure from all directions. The main advantage of CIP is its ability to produce large parts with complex shapes and uniform density.

There are two types of CIP: wet isostatic pressing (WIP) and dry isostatic pressing (DIP). In the product, the pre-pressed blank is encapsulated in a flexible rubber or plastic mold, which is then placed in a high-pressure vessel and subjected to high-pressure liquid molding. This method is ideal for obtaining billets of uniform density. DIP, on the other hand, is used to compact green parts at ambient temperature.

Hot isostatic pressing (HIP)

Hot isostatic pressing (HIP) is a process used to apply pressure and heat to a material simultaneously. HIP is effective because it allows for the creation of strong, uniform, and defect-free materials that can withstand high temperatures, high pressures, and other harsh conditions. The process is used to eliminate porosity, increase density and enhance the structural integrity of metals, ceramics and composite materials.

The most common HIP machine types are pneumatic HIP and hot isostatic pressing (HIC). Pneumatic HIP machines use an inert gas, such as argon, to apply pressure and heat to the material. HIC machines use a combination of heat and pressure to compress materials, typically used with powder metallurgy and ceramic materials.

Comparison between CIP and HIP

CIP and HIP have their own unique advantages and disadvantages. CIP is more suitable for materials that cannot withstand high temperatures, and it allows the production of complex shapes and large parts. In contrast, HIP is more suitable for materials that require high temperature and pressure, and it produces strong, uniform, and defect-free materials.

In summary, understanding the differences between CIP and HIP is critical to determining the most appropriate manufacturing technology for a specific material. While both processes have their own advantages and limitations, they are both critical to the field of powder metallurgy and provide engineers with the necessary tools to create high-quality and reliable materials.

Hot isostatic pressing (HIP)

Hot isostatic pressing (HIP) is a technology that revolutionizes the way materials are processed and manufactured. It involves subjecting materials to high temperatures and pressures in an inert gas environment to eliminate porosity, increase density and strength, and enhance the material's properties. The process takes place in a pressure vessel inside a high-temperature furnace. Parts are loaded into a chamber, then heated, pressurized with an inert gas (such as argon), and held at that temperature and pressure for a specified period of time.

How does HIPing work?

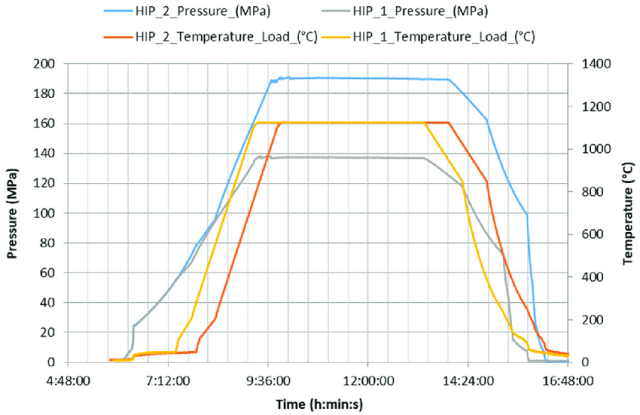

Heat and pressure are applied evenly to the part (isotropically), forcing porosity to disappear. The HIPing process can also include pressurized rapid cooling, which functions as a quenching step. A HIP cycle may take 8 to 12 hours or more.

What are the benefits of HIP?

The HIP process is highly customizable, allowing the production of complex shapes and designs that would be difficult to achieve using other methods. Overall, HIP has proven to be an effective and efficient technique for improving the performance and quality of materials, making it a valuable tool for researchers, manufacturers, and engineers alike.

What can be done with HIP?

HIP can be used to process a variety of materials, including metals, ceramics and composites, and has applications in a variety of industries including aerospace, automotive, medical and energy.

HIP for 3D printed parts

HIPing is now used for post-processing of metal 3D printed parts, typically those produced via powder bed-based processes such as laser powder bed fusion (LPBF) and binder jetting, although directed energy deposition (DED) parts are sometimes also Processed this way. The printed part—either severed or still on its build plate—is loaded into a basket and transferred to the chamber of the HIP furnace. HIPing "recipes" are customized based on the specific material and desired final properties.

Advantages of HIP Technology

Hot isostatic pressing (HIP) technology offers several advantages that make it an essential manufacturing process for high-performance materials. Some of the main advantages of HIP technology are:

The structure is denser and more uniform

HIP technology subjects materials to high temperatures and pressures simultaneously, resulting in a denser, more uniform structure. The process improves the material's mechanical properties, including strength, hardness, and resistance to wear and corrosion. Materials produced using HIP technology have uniform strength, making them more efficient and reliable.

Ability to produce complex shapes and parts

HIP technology can be used to produce complex shapes and parts that may be difficult or impossible to achieve using other methods. This advantage of HIP technology is particularly useful in the aerospace, automotive and medical industries, where the production of complex shapes and parts is critical.

Efficient

HIP technology is highly efficient and is ideal for mass production of components. The technology can be used to produce large quantities of high-quality materials in a short time, making it a cost-effective process for manufacturers.

Join disparate materials together

HIP technology can be used to join disparate materials together to form composite structures with unique properties and properties. This advantage of HIP technology is particularly useful in the aerospace and automotive industries, where lightweight and strong materials are essential.

Versatility

HIP technology is versatile and can be used on a variety of materials, including metals, ceramics and composites. The ability to use HIP technology with different materials makes it a valuable process for producing a wide range of high-performance materials for various industries.

In summary, the advantages of HIP technology make it an important manufacturing process for high-performance materials. The ability to produce complex shapes and parts, improve the mechanical properties of materials, join disparate materials together, and work with a variety of materials makes HIP technology a valuable process across various industries.

Applications of HIP Technology

Hot Isostatic Pressing (HIP) is a manufacturing process that offers a wide range of applications across several industries. The process can improve the properties of various materials by reducing or eliminating porosity, improving density, and increasing strength.

Aerospace Industry

One of the most significant applications of HIP technology is in the aerospace industry. The process is used to create turbine blades for jet engines that require high strength and durability. The use of HIP technology ensures that the turbine blades can withstand the extreme temperature and pressure conditions that they are exposed to during operation.

Automotive Industry

HIP-made components are also used in the automotive industry, particularly in engines, transmissions, and suspension systems, to improve their performance. The process improves the strength and durability of these components, ensuring that they can withstand the harsh conditions and stress they are subjected to during operation.

Medical Industry

HIP technology is also widely used in the medical industry. It is used to create orthopedic implants, dental implants, and other medical devices that require high strength and biocompatibility. The use of HIP technology ensures that the implants can withstand the high stresses and loads they are subjected to while in use.

New Material Development

HIP technology is also used in developing new materials, such as metal matrix composites. These materials have a wide range of applications in aerospace, automotive, and medical industries. The use of HIP technology ensures that the new materials have the required strength and durability to perform their intended functions.

Other Applications

Apart from the above-mentioned applications, HIP technology is also used in other industries such as oil and gas, defense, and power generation. In the oil and gas industry, HIP technology is used to create components that can withstand high-pressure and high-temperature conditions. In the defense industry, it is used to create components for missiles, rockets, and other defense applications. In the power generation industry, it is used to create components for turbines and boilers.

In conclusion, the HIP technology is one of the most effective manufacturing processes for improving material properties. Its wide range of applications and its ability to develop new materials make it a valuable tool for many industries.

Related Products

- Warm Isostatic Press for Solid State Battery Research

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

Related Articles

- Zirconia Ceramic Rod Production Processes: Isostatic Pressing vs. Dry Pressing

- Isostatic Pressing Technology for Solid-State Batteries

- How Isostatic Presses Improve the Efficiency of Material Processing

- Understanding the Basics of Isostatic Pressing

- How Isostatic Presses Help Eliminate Defects in Materials