AI Computing Power Growth

Global Computing Power Trends

AI computing power is the primary catalyst driving the exponential growth of global computing capabilities. By 2030, it is anticipated that AI-driven computing power will exceed 100 times its current capacity, significantly outpacing traditional arithmetic-based computing. This surge is not merely a projection but a tangible reality, as evidenced by the pivotal year of 2022, where the scale of intelligent computing surpassed basic arithmetic, marking a new era where AI is the foremost driver of rapid technological advancement.

This transition is characterized by a shift from conventional computational methods to AI-centric solutions, which are inherently more efficient and capable of handling complex tasks at unprecedented speeds. The dominance of AI in computing is further reinforced by the rapid integration of advanced AI chips, such as GPUs, FPGAs, and ASICs, which are designed to optimize AI workloads. In China, for instance, GPUs accounted for approximately 89% of the AI chip market in 2022, underscoring the widespread adoption and reliance on AI-enhanced computing technologies.

Moreover, the rise of AI computing power is not just about raw processing speed; it also involves a comprehensive upgrade in the underlying infrastructure, including the use of new metal materials that enhance the performance and efficiency of AI chips. These materials, such as high-purity metal targets and microelectronic welding materials, are pivotal in the manufacturing and packaging of semiconductors, ensuring that the chips can withstand the rigorous demands of AI applications.

In summary, the global computing power landscape is rapidly evolving, with AI at the forefront, driving innovations that will shape the future of technology. This transformation is not only about increasing computational capabilities but also about revolutionizing how we approach problem-solving and data processing in an increasingly digital world.

Future Projections

By 2030, the global computing landscape is expected to undergo a significant transformation, with the total arithmetic power projected to surge to an astounding 56 ZettaFLOPS (ZFlops). This growth is primarily driven by the rapid expansion of intelligent arithmetic power, which is anticipated to dominate with a staggering 52.5 ZFlops. This exponential increase, representing an 81% Compound Annual Growth Rate (CAGR) from 2022 to 2030, underscores the pivotal role of AI in shaping the future of computing.

The dominance of intelligent arithmetic power is not merely a quantitative leap but also a qualitative shift in how computing resources are allocated and utilized. This trend is indicative of a broader paradigm shift where AI-driven computations will increasingly become the norm, relegating traditional arithmetic tasks to a secondary role. The implications of this shift are profound, affecting everything from data processing efficiency to the design and manufacturing of AI chips.

Moreover, the projected growth in intelligent arithmetic power will have cascading effects across various sectors, including semiconductor manufacturing, data transmission, and AI chip development. As AI chips continue to evolve, the demand for advanced materials like high-purity metal targets and microelectronic welding materials will surge, driving further innovation and optimization in the semiconductor industry.

In summary, the future projections for global arithmetic power highlight a future where AI-driven computations will be at the forefront, shaping the technological landscape and driving innovation across multiple industries.

AI Chip Development

Types of AI Chips

The landscape of AI chips is diverse, encompassing several key types, each with its own unique strengths and applications. The primary categories include Graphics Processing Units (GPUs), Field-Programmable Gate Arrays (FPGAs), Application-Specific Integrated Circuits (ASICs), and Neural Processing Units (NPUs). Each of these chips plays a crucial role in different facets of AI computing, from general-purpose tasks to specialized, high-performance applications.

In 2022, the China AI chip market was notably dominated by GPUs, which held an impressive 89% share. This dominance is largely attributed to GPUs' exceptional ability to handle parallel processing tasks, making them ideal for the complex, data-intensive computations required in AI and machine learning. GPUs' widespread adoption in this sector underscores their versatility and efficiency in accelerating AI workloads.

However, the market is not solely reliant on GPUs. FPGAs, known for their reconfigurability and low-latency performance, are increasingly being used in scenarios where adaptability and speed are paramount. ASICs, on the other hand, offer optimized performance for specific tasks, making them indispensable in specialized AI applications. NPUs, designed specifically for neural network computations, are gaining traction due to their high efficiency in handling AI-related tasks.

This diverse ecosystem of AI chips ensures that the rapidly evolving AI landscape has the computational power it needs, whether for general-purpose AI tasks or highly specialized applications. The ongoing advancements in these chips, driven by new metal materials and innovative manufacturing techniques, promise to further enhance their capabilities, paving the way for even more sophisticated AI applications in the future.

Metal Soft Magnetic Powder Core Inductors

Metal soft magnetic powder core inductors are poised to revolutionize AI computing power applications, particularly in the advent of new-generation AI chips. Their suitability for these applications stems from their unique advantages, which include low-voltage operation, high-current capacity, and compact design. These characteristics make them ideal for the stringent demands of AI chip technology, where efficiency and miniaturization are paramount.

In the context of AI computing power growth, these inductors are expected to play a crucial role. As global computing power trends indicate a surge in intelligent computing scale, surpassing basic arithmetic in 2022, the need for advanced components that can handle high-current loads while maintaining low voltage becomes increasingly important. Metal soft magnetic powder core inductors are perfectly aligned with these requirements, making them a key component in the future of AI chip development.

Moreover, the future projections for global arithmetic power, which foresee a significant increase to 56 ZFlops by 2030, with intelligent arithmetic power dominating at 52.5 ZFlops, further underscore the critical role these inductors will play. Their ability to operate effectively in low-voltage, high-current environments ensures that they can support the exponential growth in computing power without compromising on performance or reliability.

In summary, metal soft magnetic powder core inductors are not merely suitable but essential for AI computing power applications. Their integration into new-generation AI chips is expected to be widespread, driven by their superior capabilities in handling the complex and demanding conditions of modern AI technology.

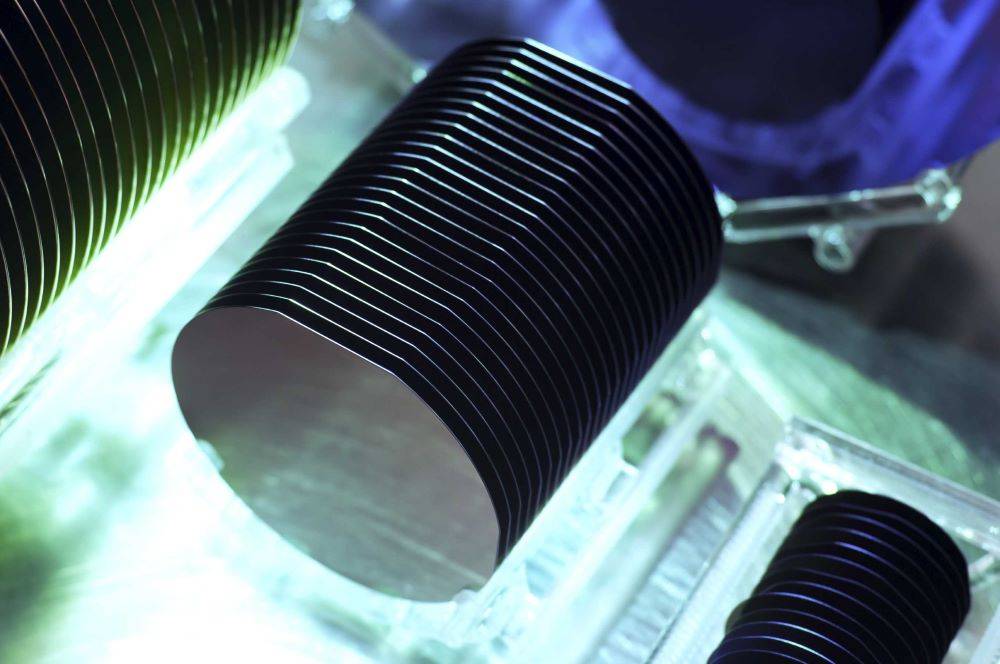

High Purity Metal Targets

High purity metal targets are pivotal raw materials in semiconductor manufacturing, playing a crucial role in the production of advanced AI chips. These targets, which enable the formation of metal films and various compound layers such as oxides, nitrides, and exotic carbides, are essential for creating high-density, high-performance coatings. The demand for these materials is driven by the escalating requirements of AI-driven technologies, which necessitate more efficient and reliable semiconductor components.

The production of high purity metal targets is fraught with challenges, particularly in ensuring process control and repeatability. These challenges extend beyond the extraction and purification of raw materials, encompassing macroscopic failure modes that are as diverse as the formation technologies themselves. As AI continues to drive the growth of computing power, the need for domestic substitution of these critical materials is accelerating, aiming to reduce dependency on foreign suppliers and enhance the resilience of the supply chain.

In summary, high purity metal targets are not just components but integral parts of the thin film technology that underpins the semiconductor industry's ability to meet the demands of AI-driven advancements. Their importance is underscored by the complexities involved in their production and the strategic imperative of securing a robust domestic supply chain to support the rapid evolution of AI technologies.

Microelectronic Welding Materials

Microelectronic welding materials are foundational components in semiconductor packaging, playing a crucial role in ensuring the reliability and performance of integrated circuits. The increasing demand for AI computing power has significantly elevated the need for advanced semiconductor packaging solutions, thereby driving the acceleration of domestic substitution efforts.

This surge in AI computing power is not just a trend but a transformative force that is reshaping the semiconductor industry. As AI applications become more sophisticated, the requirements for semiconductor devices become more stringent. High-end incremental markets are emerging, demanding materials that can withstand higher thermal and electrical stresses while maintaining compact form factors.

Microelectronic welding materials, with their superior properties, are poised to meet these exacting standards. These materials are expected to be at the forefront of innovation, enabling the production of more efficient and reliable semiconductor devices. The transition towards domestic substitution in this sector is not merely a response to geopolitical dynamics but a strategic move to capture the burgeoning high-end market driven by AI computing power enhancement.

In summary, microelectronic welding materials are not just passive components but active enablers of technological advancement in the semiconductor industry. Their role in facilitating the transition to domestic substitutes and penetrating high-end markets is a testament to their critical importance in the era of AI-driven computing power.

Data Transmission Enhancements

Indium Phosphide Substrate

The indium phosphide (InP) substrate has emerged as a cornerstone in the evolution of optical module devices, positioning itself at the forefront of technological advancements driven by 5G communications, data centers, and the burgeoning demands of AI computing power. As the global landscape of data transmission and processing undergoes a seismic shift, the role of InP substrates is poised to become increasingly pivotal.

InP substrates are renowned for their superior optical properties, which make them indispensable in the fabrication of high-speed optical devices. These substrates enable the creation of components that can handle the immense data throughput required by 5G networks, which promise to deliver unprecedented speeds and connectivity. The integration of InP-based optical modules in 5G infrastructure is not merely a technological upgrade but a necessity to meet the escalating demands for bandwidth and latency reduction.

Moreover, the exponential growth in data center operations, fueled by the proliferation of cloud services and the increasing reliance on remote work, further underscores the importance of InP substrates. Data centers require efficient and reliable data transmission solutions to manage the vast volumes of information processed daily. The use of InP substrates in these environments ensures that data can be transmitted with minimal loss and at speeds that align with the stringent performance requirements of modern data centers.

The advent of AI has introduced a new dimension to the computational landscape, demanding not only higher processing power but also more efficient data transmission mechanisms. AI algorithms, particularly those involving deep learning and neural networks, generate and process colossal datasets. The deployment of InP substrates in AI-driven systems facilitates the seamless flow of data, enabling faster training times and more accurate model predictions. This synergy between InP substrates and AI computing power is set to redefine the boundaries of what is achievable in terms of data processing and analysis.

In summary, the indium phosphide substrate is not just a technological component; it is a catalyst for the next wave of advancements in optical communication and computing. Its role in enhancing the capabilities of 5G, data centers, and AI systems marks it as a critical element in the ongoing digital transformation.

Tungsten-Copper Substrate Material

In the realm of optical modules, particularly within high computing power scenarios, the demand for effective heat dissipation is paramount. The tungsten-copper substrate material stands out as a superior solution to this challenge, offering a unique combination of properties that make it ideal for these demanding environments.

One of the key advantages of the tungsten-copper substrate is its low thermal expansion coefficient. This characteristic ensures that the material remains stable under varying temperatures, preventing any distortion or damage that could compromise the performance of the optical modules. In contrast, materials with higher thermal expansion could lead to misalignment of components, ultimately reducing the efficiency and reliability of the system.

Moreover, the tungsten-copper substrate boasts high thermal conductivity. This property allows it to efficiently transfer heat away from critical components, thereby maintaining optimal operating temperatures. High thermal conductivity is particularly crucial in high computing power scenarios where the generation of heat is significant. By effectively dissipating this heat, the tungsten-copper substrate helps to prevent thermal throttling, ensuring that the optical modules can operate at peak performance without risk of overheating.

In summary, the tungsten-copper substrate material is a game-changer for optical modules in high computing power environments. Its combination of low thermal expansion and high thermal conductivity not only enhances the reliability and longevity of the modules but also ensures consistent and optimal performance under demanding conditions.

Related Products

- Advanced Engineering Fine Ceramics Aluminum Nitride (AlN) Ceramic Sheet

- Laboratory CVD Boron Doped Diamond Materials

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- CVD Diamond for Thermal Management Applications

- CVD Diamond Domes for Industrial and Scientific Applications

Related Articles

- The 5 Hottest Advanced Ceramic Powders Currently Available!

- Advanced Alumina Ceramics: Applications and Manufacturing Techniques

- Precision Ceramic Materials for Energy Conversion Applications

- Engineering Ceramic Materials: Applications in Aerospace, Electronic Information, New Energy, and Environmental Protection

- Advanced Alumina Ceramics: Applications and Manufacturing Techniques