Mobile Devices

Smartphones and Tablets

PECVD nano-coating technology is revolutionizing the durability and functionality of smartphones and tablets. This advanced coating not only provides hydrophobic properties, making the devices resistant to water and moisture, but also offers comprehensive stain protection. The technology ensures that the devices remain pristine even after prolonged use, as it repels dust, oils, and other contaminants that typically cause discoloration and blemishes.

Moreover, the wear-resistant anti-fingerprint treatment significantly enhances the user experience by minimizing the visibility of fingerprints and smudges. This feature is particularly beneficial in maintaining the aesthetic appeal and clarity of touchscreens, which are critical for both personal and professional use. The robustness of the coating also extends the lifespan of the devices, reducing the need for frequent maintenance or replacement.

In summary, PECVD nano-coating technology is integral to the modern smartphone and tablet, offering a blend of practical benefits that include enhanced durability, stain resistance, and anti-fingerprint properties, ultimately contributing to a more reliable and visually appealing user experience.

Computers and Peripherals

Laptops and Desktops

PECVD nano-coating technology plays a pivotal role in enhancing the durability of laptops and desktops, particularly in the areas of waterproofing and stain resistance. This advanced technology is applied to keyboards, significantly reducing the risk of liquid damage and making them easier to clean. The nano-coating forms an impermeable barrier that repels water and other liquids, preventing them from seeping into the delicate circuitry beneath.

Moreover, the same technology is employed to protect the motherboards of these devices from corrosion. Motherboards are critical components that house the central processing unit (CPU) and other essential electronic parts. By applying PECVD nano-coating, manufacturers can extend the lifespan of these boards, ensuring that they remain functional even in environments prone to moisture and dust.

| Component | Benefit of PECVD Nano-Coating |

|---|---|

| Keyboards | Waterproof and anti-stain |

| Motherboards | Corrosion protection |

The application of PECVD nano-coating in laptops and desktops not only enhances their performance and longevity but also provides peace of mind to users who frequently encounter spills or work in humid conditions.

Wearable Devices

Smart Watches and Fitness Trackers

PECVD nano-coating technology plays a pivotal role in enhancing the durability and functionality of smart watches and fitness trackers. This advanced coating process significantly improves several key properties of wearable devices, making them more reliable and user-friendly.

Firstly, the waterproofing capabilities of these devices are substantially enhanced. PECVD nano-coating creates a barrier that repels water, allowing users to wear their smart watches and fitness trackers during various activities without the fear of damage from water exposure. This is particularly beneficial for fitness enthusiasts who engage in swimming, running in the rain, or other water-related sports.

Secondly, the stain-resistant properties of wearable devices are markedly improved. The nano-coating acts as a shield against dirt, sweat, and other contaminants, ensuring that the devices remain clean and aesthetically pleasing. This not only extends the lifespan of the devices but also reduces the need for frequent cleaning and maintenance.

Lastly, PECVD nano-coating technology introduces anti-bacterial properties to smart watches and fitness trackers. By inhibiting the growth of bacteria, the coating helps maintain a hygienic environment on the device's surface, which is crucial for personal health and hygiene. This feature is particularly important for devices that come into close contact with the skin for extended periods.

In summary, PECVD nano-coating technology not only enhances the waterproof, stain-resistant, and anti-bacterial properties of smart watches and fitness trackers but also contributes to their overall durability and reliability.

Home Appliances

Washing Machines and Refrigerators

In the realm of home appliances, PECVD technology plays a pivotal role in safeguarding the intricate components that power washing machines and refrigerators. These devices, which are integral to modern living, often operate in environments prone to high humidity and corrosive agents, such as detergents and cleaning chemicals. The PECVD nano-coating acts as a robust shield, encapsulating control boards and sensors to prevent moisture ingress and corrosion.

By applying this advanced coating, manufacturers can significantly extend the operational lifespan of these appliances. The technology not only mitigates the risk of component failure due to environmental factors but also enhances the overall reliability and performance of the devices. This results in fewer service calls and reduced maintenance costs for consumers, making PECVD technology an invaluable asset in the design and production of contemporary home appliances.

Smart Home Equipment

Smart Door Locks and Thermostats

PECVD nano-coating technology plays a pivotal role in enhancing the durability and reliability of smart home devices, particularly smart door locks and thermostats. This advanced coating process significantly boosts the waterproof, dustproof, and anti-salt spray performance of these devices, ensuring they remain functional and secure in various environmental conditions.

For instance, smart door locks, which are often exposed to the elements, benefit immensely from PECVD nano-coating. This technology creates a protective barrier that prevents water ingress, safeguarding the internal mechanisms from corrosion and malfunction. Similarly, the dustproof properties of the coating ensure that the lock remains operational even in dusty or sandy environments, common in many outdoor settings.

Thermostats, another critical component of smart homes, also see substantial improvements with PECVD nano-coating. These devices, which often operate in areas prone to humidity and salt spray, such as near coastal regions, require robust protection. The nano-coating provides an impermeable layer that resists moisture and salt, preventing damage to the electronic components and extending the device's lifespan.

In summary, PECVD nano-coating technology is indispensable for maintaining the performance and longevity of smart door locks and thermostats, making it a key innovation in the smart home sector.

Electric Vehicles

Battery Components and ECUs

PECVD nano-coating technology offers a robust solution for enhancing the longevity and reliability of electric vehicle components, particularly focusing on battery components and electronic control units (ECUs). This advanced coating process is instrumental in mitigating the effects of corrosion and aging, which are critical factors affecting the performance and lifespan of electric vehicles.

Key Benefits of PECVD Nano-Coating in Electric Vehicles

| Benefit | Description |

|---|---|

| Corrosion Resistance | The nano-coating forms a protective barrier against environmental elements such as moisture, salt, and chemicals, preventing corrosion. |

| Anti-Aging Protection | By reducing the rate of chemical reactions and physical degradation, the coating helps in maintaining the integrity of the components over time. |

| Enhanced Durability | The protective layer significantly extends the operational life of battery components and ECUs, ensuring consistent performance. |

In addition to these core benefits, PECVD nano-coating also contributes to the overall efficiency and safety of electric vehicles. By safeguarding against potential failures due to environmental exposure, the technology supports the reliability of critical systems, thereby enhancing user confidence and satisfaction.

The application of PECVD nano-coating in electric vehicles is a testament to its versatility and effectiveness in various electronic devices, reinforcing its role as a cornerstone technology in the modern automotive industry.

Internet of Things (IoT)

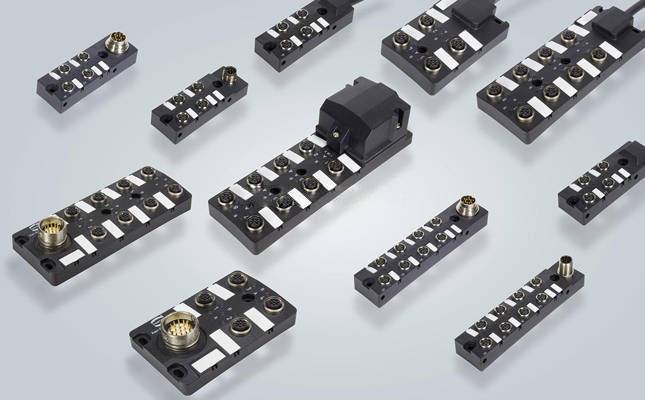

Sensors and Actuators

PECVD nano-coating technology significantly enhances the operational reliability of sensors and actuators in IoT devices by improving their waterproof, dustproof, and corrosion resistance capabilities. This advanced coating acts as a protective barrier, shielding these critical components from environmental factors such as moisture, dust, and corrosive agents, which are common in various IoT deployment scenarios.

For instance, in outdoor environments where IoT devices are exposed to rain, humidity, and airborne particles, the PECVD nano-coating ensures that the sensors remain functional and accurate. Similarly, in industrial settings where corrosive chemicals are present, the coating provides an additional layer of protection, extending the lifespan of the actuators and ensuring consistent performance.

Moreover, the durability provided by PECVD nano-coating technology is crucial in harsh conditions where IoT devices are subject to extreme temperatures and physical stress. By maintaining the integrity of sensors and actuators, this technology not only enhances the reliability of individual devices but also contributes to the overall robustness and efficiency of IoT networks.

In summary, PECVD nano-coating technology plays a vital role in ensuring the longevity and performance of sensors and actuators in IoT devices, making it an indispensable tool in the development of reliable and durable IoT systems.

Medical Devices

Electrocardiographs and Surgical Instruments

PECVD nano-coating technology plays a pivotal role in enhancing the safety and efficacy of medical devices, particularly in electrocardiographs and surgical instruments. This advanced coating method not only fortifies these instruments against microbial contamination but also ensures their longevity by preventing staining and corrosion.

The antimicrobial properties of PECVD coatings are crucial in a healthcare setting, where the risk of infection is a significant concern. By inhibiting the growth of bacteria, fungi, and other pathogens, these coatings help to maintain a sterile environment, reducing the likelihood of post-operative infections and cross-contamination. This is particularly important in surgical instruments, which are often exposed to bodily fluids and tissues, making them prime breeding grounds for harmful microorganisms.

In addition to its antimicrobial benefits, PECVD nano-coating technology also offers superior anti-staining capabilities. Medical devices, especially those used in surgical settings, are prone to staining from blood, tissue, and other biological materials. Traditional cleaning methods can be labor-intensive and may not fully restore the device's original appearance. PECVD coatings, however, make it easier to clean and maintain these instruments, ensuring they remain visually clear and functional for extended periods.

Moreover, the durability provided by PECVD coatings extends the operational life of medical devices. This is particularly beneficial in high-stress environments like operating rooms, where instruments are frequently sterilized and subjected to rigorous use. By protecting against corrosion and wear, PECVD coatings help to maintain the precision and reliability of electrocardiographs and surgical instruments, ultimately contributing to better patient outcomes.

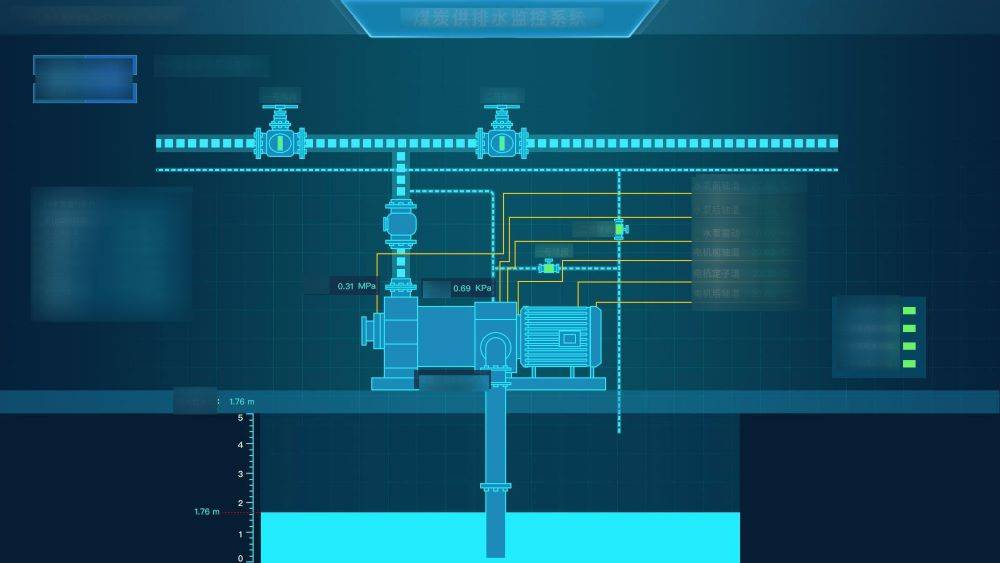

Industrial Control Systems

PLC and SCADA Systems

PECVD nano-coating technology plays a crucial role in enhancing the durability and reliability of industrial control systems, particularly in environments that are prone to harsh conditions. This advanced technology is instrumental in improving the waterproof, dustproof, and corrosion-resistant properties of industrial control equipment.

In PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition) systems, the reliability of components is paramount. These systems are often exposed to moisture, dust, and corrosive substances, which can lead to equipment failure and downtime. By applying PECVD nano-coating, manufacturers can significantly reduce the risk of these issues, ensuring that PLC and SCADA systems operate efficiently and reliably in even the most challenging environments.

The benefits of PECVD nano-coating in industrial control systems are manifold. For instance, it provides an impermeable barrier that prevents moisture and dust from infiltrating sensitive electronic components. This not only extends the lifespan of the equipment but also reduces maintenance costs and downtime. Additionally, the corrosion-resistant properties of the coating help protect against chemical and environmental degradation, further enhancing the overall durability of the systems.

Moreover, the application of PECVD nano-coating in PLC and SCADA systems aligns with the growing demand for industrial automation and smart manufacturing. As industries increasingly rely on these systems for real-time data acquisition and process control, ensuring their robustness and longevity becomes even more critical. The use of PECVD nano-coating technology in these systems not only meets but exceeds the stringent requirements for performance and reliability in industrial settings.

Military Equipment

Aerospace and Weaponry

PECVD nano-coating technology plays a critical role in enhancing the durability and reliability of military electronic equipment, particularly in aerospace and weaponry applications. In these sectors, electronic components are subjected to extreme conditions, including high temperatures, intense vibrations, and corrosive environments. The nano-coating provides a robust barrier that protects sensitive electronics from these harsh conditions, ensuring their continued functionality.

For instance, in aerospace, the nano-coating is applied to avionics systems, which must operate reliably in the high-altitude, temperature-fluctuating environment of aircraft. Similarly, in weaponry, the coating shields critical components like guidance systems and communication modules from the corrosive effects of chemicals and the abrasive nature of sand and dust. This protection is essential for maintaining the precision and effectiveness of military operations.

| Application | Benefits of PECVD Nano-Coating |

|---|---|

| Avionics Systems | Protection from temperature fluctuations and vibrations |

| Guidance Systems | Resistance to chemical corrosion and abrasive elements |

| Communication Modules | Enhanced reliability in harsh, corrosive environments |

The use of PECVD nano-coating technology in military applications not only extends the lifespan of electronic equipment but also reduces maintenance costs and downtime, contributing to the overall efficiency and effectiveness of military operations.

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory CVD Boron Doped Diamond Materials