PTFE material

Versatile PTFE Solutions for Semiconductor and Medical Wafer Processing

Item Number : PTFE-18

Price varies based on specs and customizations

- Material

- PTFE

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

PTFE flower baskets (Teflon flower baskets) are made of high-purity experimental grade PTFE, with excellent chemical stability, corrosion resistance, sealing and high and low temperature resistance (-180°C to +250°C).

We provide customized services such as PTFE cleaning racks and flower baskets for glass substrates (such as ITO, FTO, silicon wafers, etc.), and provide free design and drawing services based on your description or sketch to ensure that various industry needs are met.

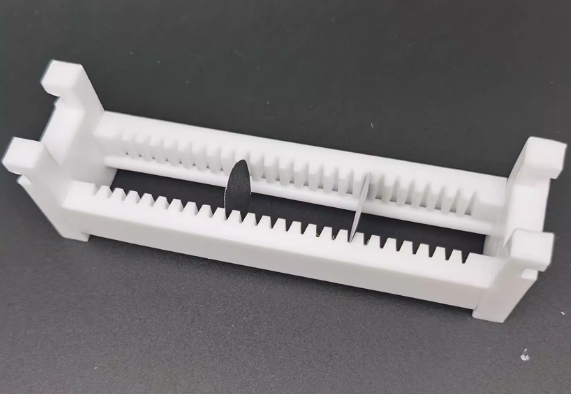

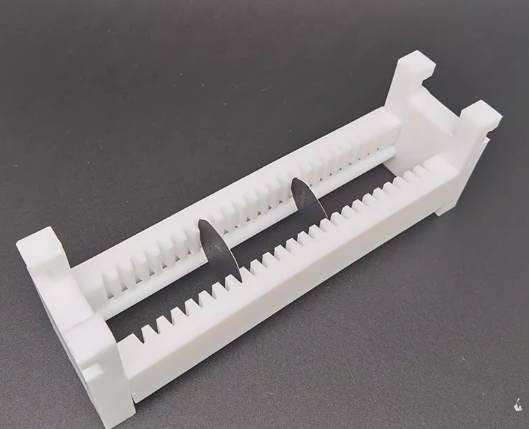

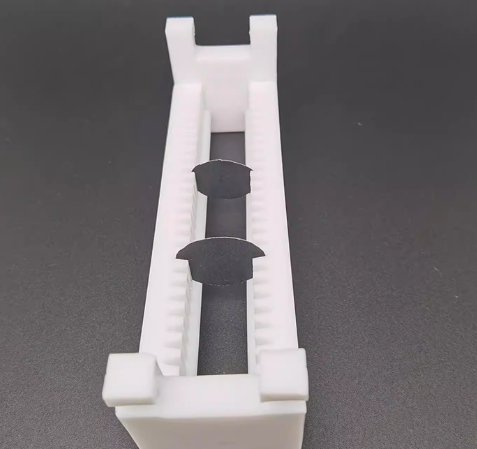

Detail & Parts

Application

PTFE cleaning frame is a high molecular compound polymerized by tetrafluoroethylene, which has excellent chemical stability and corrosion resistance. Teflon series utensils have been used in laboratories for long-term storage of standard solutions, standard samples, organic solvents, highly corrosive samples, and scientific research samples due to their extremely low metal element blank value and superior chemical properties.

- Laboratory Storage: Suitable for long-term storage of standard solutions, organic solvents, and corrosive samples.

- Photovoltaic and Semiconductor Industries: Essential for cleaning and handling delicate components without causing damage.

- Solar Energy Industry: Used to protect and preserve components in solar energy systems during cleaning.

- Scientific Research: Vital for corrosion-free handling and storage of sensitive materials and samples.

- PTFE cleaning baskets offer superior chemical properties, wide temperature tolerance, and non-adhesive characteristics, making them invaluable in various industrial and laboratory applications.

Advantages

- Excellent Chemical Resistance: PTFE/PTFE is highly resistant to all chemical solvents, including strong acids and alkalis.

- Wide Temperature Range: It withstands extreme temperatures from -200°C to +250°C.

- Non-Adhesive: PTFE does not stick to any substance, making it easy to clean.

- Safe Sample Handling: Ideal for sample digestion, pickling, boiling, and drying processes.

- Non-Toxic and Biocompatible: Physiologically inert and safe for contact with sensitive materials and biological samples.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is Polytetrafluoroethylene (PTFE)?

What Are The Key Properties And Characteristics Of PTFE?

What Are The Applications Of PTFE?

What Are The Advantages Of Using PTFE?

Are There Any Limitations Or Considerations When Using PTFE?

4.9 / 5

The temperature range is incredible! From cryogenic to high heat, our wafers are perfectly safe. A game-changer for our lab.

4.8 / 5

Custom design service was flawless. They turned our rough sketch into a perfect PTFE basket. Exceptional value!

4.7 / 5

Zero contamination on our semiconductor samples. The chemical resistance is absolute peace of mind.

4.9 / 5

Delivery was faster than promised! The non-stick surface makes cleaning an absolute breeze. Highly efficient.

4.8 / 5

Durability is outstanding. These baskets withstand daily aggressive acid baths without any degradation.

4.9 / 5

The purity level is exceptional. Finally, a solution that doesn't leach metals into our sensitive medical samples.

4.7 / 5

Technologically superior. The biocompatibility is crucial for our medical wafer processing. A brilliant investment.

4.8 / 5

Worth every penny. The quality is evident from the first use. It has streamlined our entire cleaning process.

4.9 / 5

The high-purity PTFE is a lifesaver for long-term storage. Our research samples are completely secure.

4.8 / 5

Perfect for photovoltaic applications. Protects delicate components flawlessly during rigorous cleaning cycles.

4.7 / 5

A robust workhorse. Handles extreme temperatures and corrosive solvents day in, day out. Unbeatable.

4.9 / 5

The non-adhesive property is magical. Nothing sticks, which saves us hours of tedious cleaning time.

4.8 / 5

Precision engineering at its finest. The custom fit for our silicon wafers is perfect. No more damage!

4.7 / 5

Transformed our sample digestion process. Safe, reliable, and incredibly consistent results every time.

4.9 / 5

A cornerstone of our lab. The versatility from semiconductor to medical use is truly impressive. Top-tier product.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

The PTFE hollow cleaning flower basket is a specialized laboratory tool designed for efficient and safe cleaning processes. Made from high-quality polytetrafluoroethylene (PTFE), this basket offers exceptional resistance to acids, alkalis, and organic solvents, ensuring durability and reliability in various chemical environments.

Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

The PTFE cleaning rack, also known as the PTFE flower basket cleaning flower basket, is a specialized laboratory tool designed for the efficient cleaning of PTFE materials. This cleaning rack ensures thorough and safe cleaning of PTFE items, maintaining their integrity and performance in laboratory settings.

Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

PTFE adjustable height flower basket (Teflon flower baskets) are made of high-purity experimental grade PTFE, with excellent chemical stability, corrosion resistance, sealing and high and low temperature resistance.

Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

The flower basket is made of PTFE, which is a chemically inert material. This makes it resistant to most acids and bases, and it can be used in a wide variety of applications.

Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

The PTFE culture dish evaporating dish is a versatile laboratory tool known for its chemical resistance and high-temperature stability. PTFE, a fluoropolymer, offers exceptional non-stick properties and durability, making it ideal for various applications in research and industry, including filtration, pyrolysis, and membrane technology.

Vacuum Hot Press Furnace Machine for Lamination and Heating

Experience clean and precise lamination with Vacuum Lamination Press. Perfect for wafer bonding, thin-film transformations, and LCP lamination. Order now!

Three-dimensional electromagnetic sieving instrument

KT-VT150 is a desktop sample processing instrument for both sieving and grinding. Grinding and sieving can be used both dry and wet. The vibration amplitude is 5mm and the vibration frequency is 3000-3600 times/min.

Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

A vacuum molybdenum wire sintering furnace is a vertical or bedroom structure, which is suitable for withdrawal, brazing, sintering and degassing of metal materials under high vacuum and high temperature conditions. It is also suitable for dehydroxylation treatment of quartz materials.

High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

Enhance lab efficiency with our high-speed Laboratory Emulsifier Homogenizer for precise, stable sample processing. Ideal for pharmaceuticals & cosmetics.

Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

Precision metallographic mounting machines for labs—automated, versatile, and efficient. Ideal for sample prep in research and quality control. Contact KINTEK today!

Vacuum Cold Mounting Machine for Sample Preparation

Vacuum Cold Mounting Machine for precise sample prep. Handles porous, fragile materials with -0.08MPa vacuum. Ideal for electronics, metallurgy, and failure analysis.

Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

Efficient Laboratory Disc Rotary Mixer for Precise Sample Mixing, Versatile for Various Applications, DC Motor and Microcomputer Control, Adjustable Speed and Angle.

Vacuum Cold Trap Chiller Indirect Cold Trap Chiller

Boost vacuum system efficiency and prolong pump life with our Indirect Cold Trap. Built-in chilling system with no need for fluid or dry ice. Compact design and easy to use.

Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

The single-punch electric tablet press is a laboratory-scale tablet press suitable for corporate laboratories in pharmaceutical, chemical, food, metallurgical and other industries.

Graphite Vacuum Continuous Graphitization Furnace

High-temperature graphitization furnace is a professional equipment for graphitization treatment of carbon materials. It is a key equipment for the production of high-quality graphite products. It has high temperature, high efficiency and uniform heating. It is suitable for various high-temperature treatments and graphitization treatments. It is widely used in metallurgy, electronics, aerospace, etc. industry.

Laboratory High Throughput Tissue Grinding Mill Grinder

KT-MT is a high-quality, small, and versatile tissue grinder used for crushing, grinding, mixing, and cell wall breaking in various fields, including food, medical, and environmental protection. It is equipped with 24 or 48 2ml adapters and ball grinding tanks and is widely employed for DNA, RNA, and protein extraction.

Laboratory Hybrid Tissue Grinding Mill

KT-MT20 is a versatile laboratory device used for rapid grinding or mixing of small samples, whether dry, wet, or frozen. It comes with two 50ml ball mill jars and various cell wall breaking adapters for biological applications such as DNA/RNA and protein extraction.

High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

High temperature wear-resistant insulating alumina plate has excellent insulation performance and high temperature resistance.

Vacuum Cold Trap Direct Cold Trap Chiller

Improve vacuum system efficiency and extend pump life with our Direct Cold Trap. No chilling fluid required, compact design with swivel casters. Stainless steel and glass options available.

Related Articles

Innovative Application of PTFE in Mechanical Seals

PTFE has become one of the core materials in the field of mechanical seals due to its unique chemical stability, low friction coefficient (0.04-0.15), wide temperature range (-268°C to +315°C) and excellent corrosion resistance (pH 0-14).

The key role of PTFE in semiconductor manufacturing: from gas pipelines to electrical insulation

From high-purity gas delivery pipelines to precision electrical insulation components, the multi-faceted application of PTFE in the semiconductor industry chain provides important guarantees for the purity, stability and reliability of the manufacturing process.

Comprehensive Guide to Atmosphere Furnaces: Types, Applications, and Benefits

Explore the world of atmosphere furnaces with our detailed guide. Learn about their types, applications in metallurgy and beyond, and the benefits they offer for precise material heat treatment.

Controlling Color and Applications of Evaporated Silicon Oxide Films

Exploring color variation, control methods, and practical applications of silicon oxide thin films.

Thin Film System Design: Principles, Considerations, and Practical Applications

An in-depth exploration of thin film system design principles, technological considerations, and practical applications in various fields.

The Rise of Glass Substrates in Advanced Semiconductor Packaging

Explores the shift towards glass substrates in advanced semiconductor packaging, their advantages, and challenges.

Application of Isostatic Graphite in the Photovoltaic Industry

An overview of the use of isostatic graphite in various stages of photovoltaic production and its market demand.

PTFE seals: the invisible guardian of industrial leakage prevention

PTFE Seals are used to prevent liquid or gas leakage and are widely used in valves, pumps, and piping systems.

Electron Beam Evaporation Coating: Principles, Characteristics, and Applications

An in-depth analysis of electron beam evaporation coating technology, its advantages, disadvantages, and applications in thin film manufacturing.

Common Abnormal Causes and Solutions for PECVD Coating in Crystalline Silicon Solar Cells

Analyzes common PECVD coating issues in solar cells and provides solutions to improve quality and reduce costs.

Preparation and Transfer Technology of Graphene by Chemical Vapor Deposition

This article reviews the preparation methods of graphene, with a focus on CVD technology, its transfer techniques, and future prospects.

Chemical Vapor Deposition (CVD) Thin Film Deposition Technology

Overview of CVD technology, its principles, types, applications, process characteristics, and advantages.