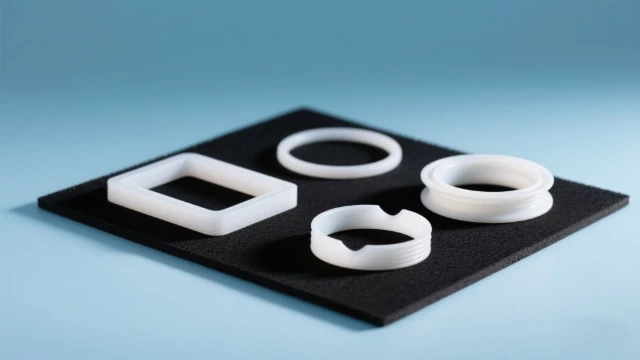

In the chemical, energy, pharmaceutical and other industrial fields, reliable sealing of liquids and gases is the lifeline for the safe operation of the system. Among the many sealing materials, polytetrafluoroethylene (PTFE) has become the "ultimate solution" to solve the leakage problem under extreme working conditions with its unique performance combination. This material, known as the "king of plastics", is protecting the stable operation of millions of key equipment around the world in the form of seals.

I. Molecular code of PTFE: Born for sealing

In the molecular structure of PTFE, the protective layer composed of fluorine atoms wraps around the carbon chain skeleton like armor. This special arrangement gives it four core characteristics:

- The king of chemical inertness: It can withstand 98% of industrial chemicals, including concentrated sulfuric acid, strong alkali, organic solvents, etc. (except molten alkali metals only)

- Temperature tolerance span of 260℃: Maintain stable performance in the range of -200℃ to +260℃

- Friction coefficient as low as 0.04: Lubricity better than ice friction reduces sealing surface wear

- Extremely low surface energy (18.5mN/m): Achieve a truly non-sticky surface

II. Sealing revolution in industrial scenarios

1. The "last line of defense" of chemical valves In the chlorine valves of the chlor-alkali industry, PTFE lip seals increase the service life of traditional rubber seals from 3 months to more than 5 years by virtue of their resistance to Cl₂ corrosion. Its unique rebound memory function can compensate for 0.15mm valve stem wear and avoid leakage of highly toxic gases.

2. Breakthrough in mechanical seals for pumps After a refinery used carbon fiber reinforced PTFE sealing rings in high-temperature oil pumps:

- Leakage rate dropped from 10ppm to 0.5ppm

- Start-stop tolerance increased by 300%

- Annual maintenance costs reduced by 67%

3. Dynamic adaptation of pipeline systems The expansion joint seal used in LNG transmission pipelines adopts a multi-layer PTFE composite structure, which can absorb 15mm axial displacement and 8° angular deviation, and still maintain elasticity at low temperatures of -162℃.

III. The road to advancement of modification technology

In order to overcome the cold flow defects of pure PTFE (long-term deformation under pressure), material engineers have developed three major modification directions:

- Filling and reinforcement type: Adding 25% glass fiber to increase the compressive strength to 35MPa

- Nano-composite type: Graphene modification increases the thermal conductivity by 5 times to avoid heat accumulation

- Porous structure type: 15-30μm micropore design realizes pressure self-compensation function

IV. Future trends: The dawn of intelligent sealing

With the development of Industry 4.0, PTFE seals are evolving towards functional integration:

- Embedded sensor: Real-time monitoring of sealing stress distribution

- Self-healing coating: Microcapsule technology realizes automatic repair of damaged points

- Bio-based PTFE: Using renewable fluorine sources to reduce carbon footprint

In the depths of the invisible industrial world, PTFE seals are taking on the safety responsibility of hundreds of billions of equipment with millimeter-level precision structures. From deep-sea drilling platforms to space station fluid systems, this material continues to break through the physical limits of sealing technology. As the carbon neutrality goal drives industrial equipment towards higher parameters, the innovative evolution of PTFE is destined to write a new legend in the future industrial blueprint.

Related Products

- Custom PTFE Teflon Parts Manufacturer PTFE Beaker and Lids

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

- Custom PTFE Teflon Parts Manufacturer for Reagent Wide Mouth Fine Mouth Sample High Temperature Bottles

- Custom PTFE Teflon Parts Manufacturer for Sampling Filters

Related Articles

- How to use PTFE to improve the working efficiency of pumps and valves

- The key role of PTFE in semiconductor manufacturing: from gas pipelines to electrical insulation

- PTFE's high temperature and corrosion resistance: Why it is indispensable in industry

- Understanding Isostatic Pressing: Process, Benefits, Limitations, and Applications

- Isostatic Pressing Technology: Revolutionizing Ceramic Material Densification