Introduction

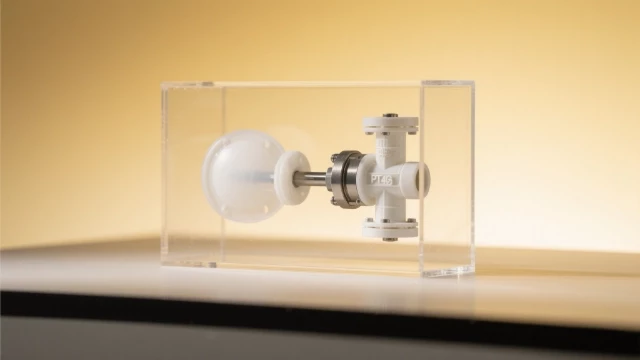

Polytetrafluoroethylene (PTFE) has become a key material for improving the efficiency of pumps and valves due to its unique physical and chemical properties. Its chemical stability, low friction coefficient, corrosion resistance and self-lubricating properties provide innovative solutions to solve the problems of wear, leakage and energy consumption in industrial fluid control. The following elaborates on its efficiency-enhancing mechanism from the aspects of material properties, structural optimization, application scenarios and maintenance strategies.

I. Efficiency-enhancing properties of polytetrafluoroethylene

-

Low friction and self-lubricating property The dynamic and static friction coefficients of PTFE are extremely small (close to 0.04) and have excellent self-lubricating properties. When used in valve sealing pairs, it can significantly reduce the opening and closing resistance and reduce the operating torque by more than 30%. For example, after the fluorine-lined valve adopts the PTFE sealing pair, the opening and closing smoothness is improved, and the life of the seal is extended.

-

Super corrosion resistance PTFE can withstand all chemicals except molten sodium and liquid fluorine, including strong acids, strong alkalis and organic solvents. This property makes it the material of choice for handling corrosive media in the chemical and pharmaceutical industries. For example, PTFE pumps can safely transport highly toxic media such as liquid chlorine without the risk of leakage.

-

Wide temperature range adaptability PTFE maintains stable performance in the range of -180°C to +250°C, and the temperature resistance can be extended to 700°F (about 371°C) after filling and modification. Specially designed dry lubricated metal valve seats (such as Yangzi pump valve products) can even operate stably at high temperatures of 180°C.

II. Key technologies for improving pump efficiency

- Structural optimization and material modification

- Magnetic drive design: PTFE magnetic pumps adopt a shaft seal-free structure to avoid leakage caused by mechanical seal failure, and reduce maintenance costs by more than 50%.

- Enhanced wear resistance: For particle-containing media, PTFE filled with glass fiber or carbon fiber can improve wear resistance and extend the life of the pump body.

- High-pressure adaptability: The PTFE diaphragm pump system can achieve continuous 3.4 bar pressure output, which is suitable for chemical metering and high-pressure pumping scenarios.

- Intelligent control and monitoring Optimizing the PTFE valve control system by adjusting rules (such as the Bhaskaran tuning method) can reduce process fluctuation errors and improve stability in servo mode. Combined with intelligent sensors to monitor pump pressure and flow in real time, overload and dry-run risks can be prevented.

III. Design innovation for improving valve efficiency

- Sealing structure innovation

- Sliding seal and eccentric design: The PTFE "sliding seal" structure is equipped with a rubber O-ring, and the sealing pressure difference can reach 103 bar (1500 psi). The eccentric valve disc design allows the valve disc to detach from the valve seat at the beginning of rotation, eliminating unbalanced loads and extending the life of the seal.

- Dynamic compensation mechanism: The spring washer provides constant pressure to compensate for the thermal expansion and contraction of PTFE, ensuring sealing reliability at high temperatures.

- Extended application of lining technology Lining the inner wall of the valve with PTFE can not only retain the mechanical strength of the metal valve body, but also give it corrosion resistance. For example, fluorine-lined butterfly valves can replace high-priced corrosion-resistant alloys in chemical pipelines, reducing costs by more than 40%.

IV. Maintenance and use recommendations

- Avoid extreme working conditions

- Prevent PTFE pumps from running dry or overloaded, and regularly check seals and transmission components.

- Control the valve operating temperature within the range of -50°C to 150°C (standard PTFE), and use modified materials for high-temperature conditions.

- Preventive maintenance measures

- Fluorine-lined valves should avoid replacing packing under pressure to prevent the fluoroplastic layer from being damaged by mechanical impact.

- Use special lifting points to install valves to reduce the impact of pipeline stress on the lining.

V. Comprehensive benefits and industry prospects

According to statistics, the use of PTFE-optimized pump and valve systems can reduce industrial energy consumption by 15-20%. In the future, with the development of PTFE composite materials (such as PFA and FEP), their application in high-end fields such as nuclear energy and microfluidic control will be further expanded. Through continuous material innovation and intelligent upgrading, PTFE will continue to enable the efficiency and greenness of fluid control equipment.

Related Products

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Custom PTFE Teflon Parts Manufacturer PTFE Beaker and Lids

- Cylindrical Press Mold with Scale for Lab

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Ultra-Vacuum Electrode Feedthrough Connector Flange Power Electrode Lead for High-Precision Applications

Related Articles

- Polytetrafluoroethylene (PTFE): How low friction coefficient promotes industrial progress

- The key role of PTFE in semiconductor manufacturing: from gas pipelines to electrical insulation

- Performance and application of polytetrafluoroethylene (PTFE) in high temperature environment

- Exploring the Multifunctional Electrolytic Cell Water Bath: Applications and Benefits

- PTFE's high temperature and corrosion resistance: Why it is indispensable in industry