Vacuum Accessories

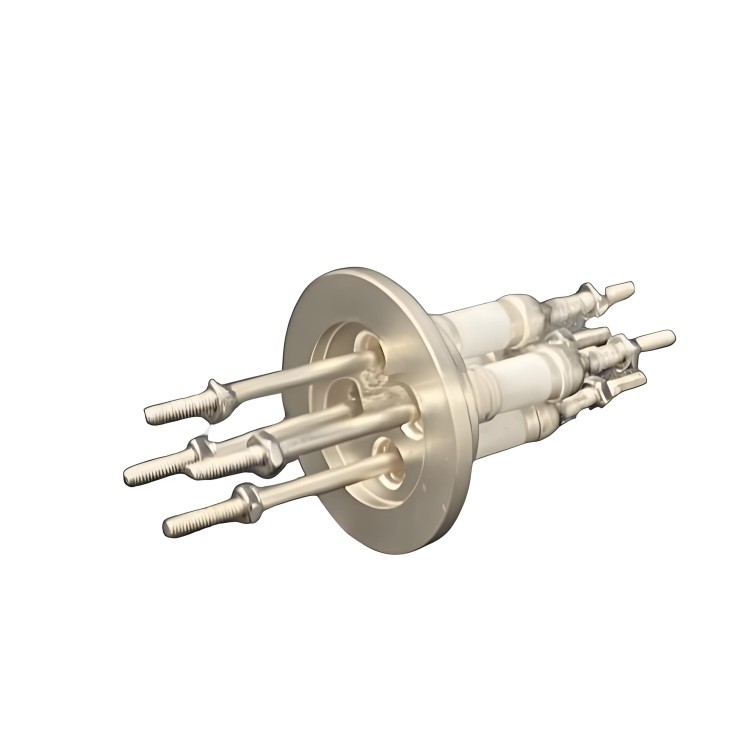

CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

Item Number : KT-VA08

Price varies based on specs and customizations

- Flange specifications

- CF16, CF25, CF40, CF63, CF100, KF16, KF25, KF40, KF50, KF63 (customizable)

- Lead length

- 100mm~1000mm (customizable)

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Product Application

The CF/KF flange vacuum electrode feedthrough lead sealing assembly is an essential component in various vacuum systems, designed to connect electrodes to external circuits while maintaining the integrity of the vacuum environment. This assembly is widely utilized in industries such as vacuum coating, vacuum smelting, and vacuum heat treatment. In vacuum coating equipment, it ensures the precise control of electrode connections, facilitating the deposition of thin films with high accuracy. Vacuum smelting equipment benefits from its high vacuum sealing capabilities, which are crucial for maintaining the purity of the metal during the smelting process. Similarly, in vacuum heat treatment, this assembly supports the efficient transfer of electrical signals without compromising the vacuum seal, thereby optimizing the treatment conditions for materials. Additionally, it finds applications in vacuum electronic devices and other areas where vacuum-sealed electrode connections are required.

Product Feature

The CF/KF flange vacuum electrode feedthrough lead sealing assembly boasts several key features that make it a superior choice for vacuum systems:

-

High Vacuum Sealing: Utilizing special ceramic or metal sealing technology, this assembly ensures that the vacuum sealing performance reaches an exceptional level, typically above 10^-8 Pa. This high level of sealing is critical for maintaining the integrity of the vacuum environment.

-

Excellent Conductivity: The lead material is crafted from high-purity oxygen-free copper or silver-plated copper, offering superior conductivity with minimal resistivity. This ensures efficient transfer of electrical signals without significant energy loss.

-

High Temperature and High Pressure Resistance: The sealing material is engineered to withstand high temperatures and pressures, allowing the assembly to operate stably for extended periods in demanding high-temperature vacuum environments.

-

Multiple Specifications Available: A wide range of CF/KF flange specifications and lead lengths are available, catering to the diverse needs of different vacuum systems. Common flange specifications include CF16, CF25, CF40, CF63, CF100, KF16, KF25, KF40, KF50, and KF63, with customizable options to suit specific requirements.

-

Easy Installation: The assembly features a well-thought-out structural design, facilitating quick and hassle-free installation. Its ease of maintenance further enhances its practicality in real-world applications.

Detail & Parts

Working Principle

The CF/KF flange vacuum electrode feedthrough lead sealing assembly operates on the principle of maintaining a high vacuum environment while securely connecting electrodes to external circuits. The assembly employs advanced sealing technologies, such as ceramic or metal seals, to achieve ultra-high vacuum levels (above 10^-8 Pa). These seals are designed to withstand high temperatures and pressures, ensuring long-term stability in demanding environments.

The lead material, made from high-purity oxygen-free copper or silver-plated copper, ensures minimal electrical resistance, facilitating efficient signal transfer. The assembly's modular design allows for various flange sizes and lead lengths, enabling customization to meet specific system requirements. During installation, the assembly's well-designed structure ensures that it can be quickly and easily integrated into existing systems, with minimal disruption to the vacuum environment.

Product Advantage

The CF/KF flange vacuum electrode feedthrough lead sealing assembly offers several compelling advantages:

-

Professional Customization: The assembly can be tailored to meet specific customer needs, with customizable options for flange specifications, lead materials, and lengths. This flexibility ensures that the product perfectly aligns with the requirements of diverse vacuum systems.

-

Quality Assurance: Crafted from high-quality raw materials and manufactured using advanced production processes, the assembly delivers stable and reliable performance. This commitment to quality ensures that the product can withstand the rigorous demands of various industrial applications.

-

Reasonable Price: Despite its high performance and durability, the assembly is offered at competitive prices, providing excellent value for money. This cost-effectiveness makes it an attractive option for businesses looking to optimize their equipment investments.

In summary, the CF/KF flange vacuum electrode feedthrough lead sealing assembly stands out for its superior sealing capabilities, excellent conductivity, high temperature and pressure resistance, and customizable options, making it an ideal choice for a wide range of vacuum system applications.

Technical specifications

| Parameter Description | Options / Specifications |

|---|---|

| Flange specifications | CF16, CF25, CF40, CF63, CF100, KF16, KF25, KF40, KF50, KF63 (customizable) |

| Lead length | 100mm, 200mm, 300mm, 500mm, 1000mm (customizable) |

| Maximum operating temperature | 400°C (customizable) |

| Maximum operating pressure | 10^-8 Pa |

| Sealing material | Ceramic, metal |

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is An Electrode In Electrochemistry?

What Are The 3 Electrodes In Electrochemistry?

What Are The Different Types Of Electrochemical Electrodes?

What Materials Are Commonly Used For Electrochemical Electrodes?

What Factors Should Be Considered When Selecting An Electrochemical Electrode?

How Can Electrochemical Electrodes Be Used In Various Applications?

4.7 / 5

Exceptional sealing performance, crucial for our high-vacuum applications. Worth every yen!

4.8 / 5

Top-notch conductivity, minimal signal loss. A must-have for precision vacuum systems.

4.9 / 5

Durable and resistant to high pressures. Perfect for our demanding vacuum furnace.

4.7 / 5

Highly customizable, fits our specific needs perfectly. Great value for money.

4.8 / 5

Easy installation and maintenance. Streamlined our setup process significantly.

4.9 / 5

Outstanding quality and reliability. Our vacuum systems have never been better.

4.7 / 5

Excellent customer support. They helped us customize the assembly to our exact specifications.

4.8 / 5

High-temperature resistance is impressive. Ideal for our vacuum heat treatment processes.

4.9 / 5

Best in class for vacuum sealing. Our experiments have never been more precise.

4.7 / 5

Quick delivery and excellent packaging. Product arrived in perfect condition.

4.8 / 5

Highly recommend for any vacuum system. Superior performance and durability.

4.9 / 5

Efficient conductivity and high vacuum sealing. A game-changer for our lab.

4.7 / 5

Customizable options are a huge plus. Fits our unique setup perfectly.

4.8 / 5

Excellent value for money. High-quality product at a competitive price.

4.9 / 5

High-temperature and pressure resistance. Ideal for our demanding applications.

4.7 / 5

Quick and easy installation. Minimal downtime for our vacuum systems.

4.8 / 5

Superior sealing capabilities. Our vacuum environment is now more stable than ever.

4.9 / 5

High-quality materials and craftsmanship. A reliable choice for any vacuum system.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

KF ISO Stainless Steel Vacuum Flange Blind Plate for High Vacuum Systems

Discover KF/ISO stainless steel vacuum flange blind plates, ideal for high vacuum systems in semiconductor, photovoltaic, and research labs. High-quality materials, efficient sealing, and easy installation.<|end▁of▁sentence|>

Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

Discover the Ultra-High Vacuum CF Knife-Edge Flange Aviation Plug, engineered for superior airtightness and durability in aerospace and semiconductor applications.

KF Ultra-High Vacuum Observation Window 304 Stainless Steel Flange High Borosilicate Glass Sight Glass

Discover KF Ultra-High Vacuum Observation Window: 304 Stainless Steel Flange & High Borosilicate Glass Sight Glass, Ideal for precise observation in ultra-high vacuum environments.

Vacuum Bellows for Efficient Connection and Stable Vacuum in High-Performance Systems

Discover high-quality vacuum bellows for stable vacuum in high-performance systems. Made from 304 and 316 stainless steel, these bellows ensure efficient connections and excellent sealing. Ideal for

KF/ISO/CF Ultra-High Vacuum Stainless Steel Flange Pipe/Straight Pipe/Tee/Cross

Discover KF/ISO/CF ultra-high vacuum stainless steel flange pipe systems, engineered for advanced applications. Ideal for laboratory, industrial, semiconductor, aerospace, and research needs.

304 316 Stainless Steel Vacuum Ball Valve Stop Valve for High Vacuum Systems

Discover 304/316 stainless steel vacuum ball valves, Ideal for high vacuum systems, Ensure precise control and durability. Explore now!

KF Ultra-High Vacuum Observation Window Stainless Steel Flange Sapphire Glass Sight Glass

Discover the KF Ultra-High Vacuum Observation Window, featuring sapphire glass and stainless steel flange for clear, reliable observation in ultra-high vacuum environments. Ideal for semiconductor, vacuum coating, and scientific research applications

Vacuum Cold Trap Chiller Indirect Cold Trap Chiller

Boost vacuum system efficiency and prolong pump life with our Indirect Cold Trap. Built-in chilling system with no need for fluid or dry ice. Compact design and easy to use.

Laboratory Vertical Water Circulating Vacuum Pump for Lab Use

Looking for a reliable water circulating vacuum pump for your lab or small-scale industry? Check out our Vertical Water Circulating Vacuum Pump with five taps and a larger air sucking amount, perfect for evaporation, distillation, and more.

Stainless Steel Quick Release Vacuum Chain Three-Section Clamp

Discover our stainless steel quick release clamp vacuum clamp, Ideal for high vacuum applications, Strong connections, reliable sealing, Easy installation, and durable design.

Vacuum Cold Trap Direct Cold Trap Chiller

Improve vacuum system efficiency and extend pump life with our Direct Cold Trap. No chilling fluid required, compact design with swivel casters. Stainless steel and glass options available.

Laboratory High Pressure Vacuum Tube Furnace

KT-PTF High Pressure Tube Furnace: Compact split tube furnace with strong positive pressure resistance. Working temp up to 1100°C and pressure up to 15Mpa. Also works under controller atmosphere or high vacuum.

CF Ultra-High Vacuum Observation Window Stainless Steel Flange Sapphire Glass Sight Glass

Discover CF ultra-high vacuum observation windows with sapphire glass and stainless steel flanges. Ideal for semiconductor manufacturing, vacuum coating, and more. Clear observation, precise control.

CF Ultra-High Vacuum Observation Window Window Flange High Borosilicate Glass Sight Glass

Discover CF ultra-high vacuum observation window flanges with high borosilicate glass, perfect for semiconductor manufacturing, vacuum coating, and optical instruments. Clear observation, durable design, easy installation.

Related Articles

Importance of Vacuum Leak Detection in Vacuum Atmosphere Furnaces

Explains the necessity of vacuum leak detection in vacuum atmosphere furnaces and the methods used for such detection.

How to use PTFE to improve the working efficiency of pumps and valves

Polytetrafluoroethylene (PTFE) has become a key material for improving the efficiency of pumps and valves due to its unique physical and chemical properties.

How Freeze-Drying Protects Delicate Biological Structures During Water Removal

Freeze-drying preserves biological samples by removing water without structural damage, ideal for vaccines, enzymes, and microbial cultures. Learn how it works.

Why Freeze-Drying is Indispensable for Preserving Sensitive Samples

Freeze-drying preserves sensitive samples by sublimation, maintaining molecular integrity and enabling stable, room-temperature storage. Essential for proteins, vaccines, and volatile compounds.

Basic Laboratory Reaction Equipment

Overview of essential lab equipment for chemical reactions under various conditions.

Freeze-Drying Decoded: The Science Behind Preserving Food, Medicine, and Research Materials

Discover how freeze-drying preserves food, medicine, and research materials with unmatched efficiency. Learn the science behind lyophilization and its applications.

Beyond the Spec Sheet: Matching Freeze Dryer Capabilities to Your Application's Critical Needs

Choose the right freeze dryer for pharma, food, or biotech. Key specs like cold trap temp, vacuum, and cooling rate impact drying speed and product quality.

How Freeze-Drying Cuts Transport Costs by 90% in Critical Logistics

Freeze-drying slashes transport costs by 90% in logistics for space, military, and disaster relief by reducing weight and volume. Learn how it works.

PTFE gasket: an all-around solution for flange sealing

Polytetrafluoroethylene (PTFE) gaskets have become an ideal choice in the field of flange sealing due to their unique chemical stability and high temperature resistance.