Introduction to Atmosphere Furnaces

Atmosphere furnaces are essential tools in the realm of controlled environment heating, playing a pivotal role in various industrial processes. Unlike conventional furnaces, these specialized systems offer precise temperature control and a protected atmosphere, crucial for maintaining material integrity and achieving desired physical and chemical transformations. This comprehensive guide delves into the intricacies of atmosphere furnaces, exploring their types, key components, and the diverse applications they serve, from metallurgy to advanced material processing. By understanding the unique features and benefits of atmosphere furnaces, industries can harness their full potential for enhanced efficiency and superior product quality.

Key Components of Atmosphere Furnaces

Atmosphere furnaces are essential tools in both laboratory and industrial settings, designed to provide controlled environments for heat treatment processes. These furnaces are equipped with several key components that ensure precise and efficient operation. This section delves into the detailed description of these main components, including the furnace body, heating elements, temperature control systems, gas supply systems, and atmosphere control systems.

Furnace Body

The furnace body is the foundational component of an atmosphere furnace, designed to house all other essential elements. It is typically constructed from high-temperature-resistant materials such as refractory bricks, ceramics, or high-grade steel. These materials ensure that the furnace can withstand extreme temperatures without compromising structural integrity. The design of the furnace body also focuses on providing excellent insulation to maintain a consistent temperature within the chamber and minimize heat loss.

Heating Elements

Heating elements are critical for generating the necessary heat within the furnace. These elements can include electric resistance heaters, which use electrical resistance to produce heat, or gas burners that utilize combustible gases like propane or natural gas. The choice of heating element often depends on the specific requirements of the heat treatment process, including temperature range and heating rate. These elements are strategically placed within the furnace to ensure uniform heat distribution throughout the chamber, which is crucial for achieving consistent results in material processing.

Temperature Control System

A sophisticated temperature control system is integral to an atmosphere furnace. This system is responsible for monitoring and regulating the temperature within the chamber to maintain the desired temperature profile. It typically includes temperature sensors, such as thermocouples or RTDs (Resistance Temperature Detectors), which provide real-time temperature data to the control unit. The control unit then adjusts the power supplied to the heating elements to maintain the set temperature. This precise temperature control ensures that the heat treatment process is carried out accurately, leading to consistent and reliable outcomes.

Gas Supply System

The gas supply system in an atmosphere furnace is crucial for introducing controlled atmospheres into the heating chamber. This system typically consists of gas cylinders, pressure regulators, flow meters, and gas distribution lines. Common gases used include nitrogen, argon, hydrogen, and various gas mixtures. The gas supply system ensures that the correct type and amount of gas are delivered to the furnace, creating the desired environment for heat treatment. This is particularly important for processes that require inert atmospheres to prevent oxidation or other chemical reactions.

Atmosphere Control System

The atmosphere control system governs the precise composition of gases within the furnace. It allows for the adjustment of gas flow rates, gas mixtures, and pressure levels to create the desired environment for heat treatment. This system ensures consistent and repeatable results in material processing. Advanced atmosphere control systems may include automated valves, controllers, and sensors that work together to maintain the optimal gas composition throughout the process. This level of control is essential for applications such as sintering, annealing, and heat treatment of metals, ceramics, and other materials.

Applications of Atmosphere Furnaces

Atmosphere furnaces are widely used in various industries for heat treatment processes that require controlled atmospheres. These applications include:

- Metal Processing: Atmosphere furnaces are used for annealing, sintering, and heat treatment of metals to improve their mechanical properties and microstructure.

- Ceramic Manufacturing: These furnaces are essential for the firing and sintering of ceramics, ensuring uniform heating and preventing oxidation.

- Glass Processing: Atmosphere furnaces are used for heat-treating glass to enhance its durability and optical properties.

- Laboratory Research: In research settings, atmosphere furnaces are used for experiments that require precise temperature and atmosphere control, such as material characterization and synthesis.

In summary, atmosphere furnaces are versatile and essential tools in various industries, thanks to their ability to provide controlled environments for heat treatment processes. The key components of these furnaces, including the furnace body, heating elements, temperature control systems, gas supply systems, and atmosphere control systems, work together to ensure precise and efficient operation, leading to consistent and reliable outcomes in material processing.

Types of Atmosphere Furnaces

Atmosphere furnaces are essential tools in various industrial processes, particularly in metallurgy, ceramics, and materials science. These furnaces are designed to provide controlled environments for heating materials, ensuring precise temperature control and the ability to manipulate the atmosphere within the furnace. This section delves into the different types of atmosphere furnaces, including box-type, tube, and high-temperature atmosphere furnaces, highlighting their unique features and applications.

Box-Type Atmosphere Furnaces

Box-type atmosphere furnaces are versatile industrial furnaces used for a variety of applications, including firing, sintering, and melting of metals, ceramics, and other materials. These furnaces are characterized by their enclosed rectangular chambers, which allow for accurate temperature control and the maintenance of specific atmosphere conditions.

Working Principle: Box-type atmosphere furnaces typically utilize electric heating elements to generate heat. The temperature within the furnace is controlled automatically through a sophisticated temperature control system, ensuring consistent heating. Additionally, the atmosphere inside the furnace can be manipulated by introducing specific gases or inert gases to prevent oxidation or other undesirable reactions during the heating process.

Heat Transfer Modes: The primary heat transfer modes in box-type atmosphere furnaces include convection and radiation. Convection involves the transfer of heat through the mixing motion of a fluid, while radiation involves the transfer of energy through a transparent medium or empty space. These modes of heat transfer ensure efficient and uniform heating of the materials within the furnace.

Applications: Box-type atmosphere furnaces are widely used in industries such as metallurgy, ceramics, and materials science. They are particularly useful for processes that require precise temperature control and the prevention of oxidation or other chemical reactions. Examples of applications include the sintering of metal powders, the firing of ceramic products, and the heat treatment of metals.

Tube Atmosphere Furnaces

Tube atmosphere furnaces are another type of controlled atmosphere furnace, characterized by their cylindrical shape and the ability to process materials in a continuous flow. These furnaces are ideal for applications that require a controlled atmosphere throughout the heating process.

Design and Functionality: Tube atmosphere furnaces consist of a long, cylindrical tube made of high-temperature-resistant materials such as quartz or alumina. The tube is enclosed in a furnace chamber, which is heated using electric heating elements. The atmosphere within the tube can be controlled by introducing specific gases or inert gases through the inlet, ensuring that the materials being processed are protected from oxidation or other chemical reactions.

Applications: Tube atmosphere furnaces are commonly used in industries such as semiconductor manufacturing, metallurgy, and materials science. They are particularly useful for processes that require precise temperature control and a controlled atmosphere, such as the annealing of metals, the sintering of ceramic powders, and the growth of semiconductor materials.

High-Temperature Atmosphere Furnaces

High-temperature atmosphere furnaces are specialized furnaces designed to operate at extremely high temperatures, often exceeding 1000°C. These furnaces combine the features of both box-type and tube furnaces, providing a versatile solution for high-temperature applications.

Design and Functionality: High-temperature atmosphere furnaces are equipped with advanced heating elements and temperature control systems to achieve and maintain extremely high temperatures. They also feature air inlets and outlets, allowing for the control of the atmosphere within the furnace. The furnace seal welding includes a ring of high-temperature-resistant silica gel seal ring on the furnace door, ensuring excellent sealing and preventing leaks.

Applications: High-temperature atmosphere furnaces are used in a variety of high-temperature applications, including the melting of metals, the sintering of advanced ceramics, and the processing of refractory materials. They are particularly useful for large-scale sample manufacturing and experimentation, as well as processes that require precise control of the atmosphere.

Conclusion

In conclusion, atmosphere furnaces play a crucial role in various industrial processes, providing precise temperature control and the ability to manipulate the atmosphere within the furnace. Box-type, tube, and high-temperature atmosphere furnaces are the primary types of atmosphere furnaces, each with unique features and applications. Understanding the design, functionality, and applications of these furnaces is essential for selecting the appropriate furnace for specific industrial needs.

Working Principle of Atmosphere Furnaces

Atmosphere furnaces are critical tools in both laboratory and industrial settings, designed for precise heating treatments under controlled atmospheric conditions. These furnaces are essential for processes where maintaining the chemical and physical properties of materials is paramount. Understanding the working principle of atmosphere furnaces involves delving into their structure, the role of electric heating elements, the intricacies of control systems, and the management of gas mixtures.

Structure of Atmosphere Furnaces

Atmosphere furnaces typically consist of several key components: the furnace chamber, electric heating elements, a control system, and a gas supply system. The furnace chamber is insulated to retain heat efficiently, often using materials like ceramic fibers or refractory bricks. This insulation ensures that the heat generated is used effectively, minimizing energy loss.

Electric Heating Elements

The heart of an atmosphere furnace is its electric heating elements. These elements generate heat by converting electrical energy into thermal energy. The choice of heating elements is crucial and depends on the type of atmosphere within the furnace. For instance, in environments where natural gas is unavailable or during processes like low-pressure carburizing, specific types of electric heating elements are selected to ensure reliable performance. These elements are designed to withstand the particular conditions within the furnace, such as exposure to certain gases or high temperatures.

Control Systems

The control system of an atmosphere furnace is sophisticated, comprising temperature controllers and atmosphere regulators. The temperature controller automatically adjusts the heating temperature, ensuring precise control over the process. It can dynamically modify control parameters to maintain the stability and reliability of the heating effect. The atmosphere regulator, on the other hand, manages the composition and pressure of the gases within the furnace. This regulator can adjust the flow of gases like nitrogen, argon, hydrogen, or specific mixtures, creating the ideal environment for the material being processed.

Gas Supply System

The gas supply system is integral to the operation of an atmosphere furnace. It involves gas cylinders, pressure regulators, flow meters, and distribution lines. This system introduces controlled atmospheres into the heating chamber, which is essential for preventing oxidation, decarburization, or other unwanted chemical reactions. The precise control of gas mixtures and flow rates ensures consistent and repeatable results in material processing.

Applications of Atmosphere Furnaces

Atmosphere furnaces find extensive applications in various industries, particularly in the heat treatment of metals, ceramics, and glass. They are ideal for processes where the integrity of the material must be preserved, such as in the manufacturing and processing of high-value components. Compared to traditional heating equipment, atmosphere furnaces offer advantages like higher thermal efficiency, uniform heating, and improved stability of material properties during heating.

Conclusion

In summary, the working principle of atmosphere furnaces revolves around creating a controlled environment for heating materials. By utilizing electric heating elements, sophisticated control systems, and precise gas supply systems, these furnaces ensure that materials are heated without compromising their chemical and physical properties. This makes atmosphere furnaces indispensable in industries where precision and quality are paramount.

Applications in Metallurgy

Atmosphere furnaces play a pivotal role in metallurgical processes, offering precise control over environmental conditions that are essential for modifying and enhancing the properties of metals. These furnaces are designed to maintain specific atmospheres, which can range from inert gases to controlled oxidizing or reducing environments, ensuring that the metals undergo the desired transformations without unwanted side effects.

Annealing

Annealing is a fundamental process in metallurgy where metals are heated and then slowly cooled to modify their physical and mechanical properties. The primary goal of annealing is to soften the metal, reduce hardness, improve ductility, and enhance machinability. Atmosphere furnaces are crucial in this process as they provide a controlled environment that prevents oxidation and decarburization. For instance, stainless steels and most non-ferrous metals require a controlled atmosphere during annealing to avoid surface scale formation and ensure uniform properties across the metal's structure.

Hardening

Hardening is another critical application of atmosphere furnaces in metallurgy. This process involves heating the metal above its upper critical temperature and then rapidly cooling it through quenching. The rapid cooling increases the hardness and strength of the steel by transforming its microstructure. Atmosphere furnaces in this context are essential for maintaining a neutral or protective atmosphere to prevent surface oxidation and ensure that the hardening process is consistent and effective. This is particularly important for high-stress components where the combination of strength and toughness is crucial.

Tempering

Tempering is a heat treatment process that follows hardening. It involves heating the hardened metal to a lower temperature to reduce brittleness and enhance toughness without significantly compromising hardness. Atmosphere furnaces are used to control the tempering atmosphere, ensuring that the metal does not oxidize or lose carbon content during the process. This controlled environment helps in achieving the desired balance between hardness and ductility, which is critical for the performance of metal components in various applications.

Carburizing

Carburizing is a surface hardening process where the surface of low carbon steel is enriched with carbon. This is typically done in an endothermic atmosphere furnace, which provides a carbon-rich environment. The steel is heated to a specific temperature, allowing carbon to diffuse into the surface layers, thereby increasing the hardness and wear resistance of the metal. Atmosphere furnaces are essential in this process to maintain the precise carbon potential and prevent any oxidation or decarburization.

Sintering

Sintering is a process used to create objects from powder particles by heating them to just below their melting point under a protective atmosphere. Atmosphere furnaces are used to provide this protective environment, which is crucial for preventing oxidation and ensuring that the particles bond properly without melting. This process is widely used in the production of metal components with complex geometries and high precision.

Brazing

Brazing is a joining process where metals are heated to high temperatures and joined using a filler metal with a lower melting point than the base metals. Atmosphere furnaces are used to provide a pure hydrogen or dissociated ammonia atmosphere, which ensures that the brazing process is carried out without oxidation and with precise temperature control. This is particularly important for metals like silver and copper, where the integrity of the joint is critical.

In conclusion, atmosphere furnaces are indispensable in metallurgy, providing the controlled environments necessary for a variety of heat treatment processes. These furnaces ensure that metals undergo the desired transformations without compromising their structural integrity or surface quality. The ability to control the atmosphere precisely makes atmosphere furnaces a vital tool in achieving repeatable and high-quality metallurgical results across various industries.

Other Industrial Applications

Vacuum furnaces, known for their precision and ability to operate under controlled atmospheres, have found extensive applications beyond their traditional use in metallurgy and materials science. These versatile systems are now integral in various industries, including ceramics, glass, and advanced materials processing, where they contribute to the development and manufacturing of high-performance products.

Ceramics Industry

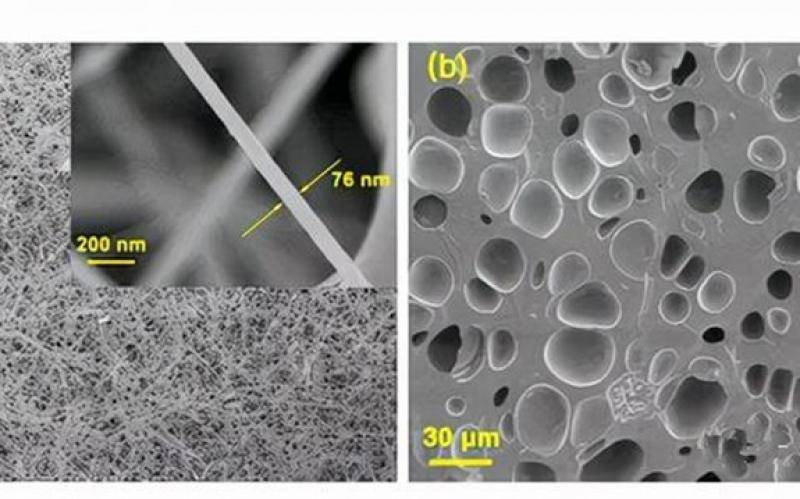

The ceramics industry leverages vacuum furnaces for high-temperature sintering and firing processes. These furnaces enable the production of advanced ceramics with exceptional properties, such as high strength, wear resistance, and thermal stability. For instance, alumina ceramics, zirconia ceramics, and honeycomb ceramics are processed in vacuum environments to achieve precise microstructures and desired mechanical properties. The aerospace industry, among others, utilizes these ceramics in applications ranging from thermal protection systems to structural components.

Glass Industry

In the glass industry, vacuum furnaces play a crucial role in the production of specialty glasses and optical components. These furnaces are used for melting, refining, and homogenizing glass materials under vacuum conditions, which helps eliminate bubbles and inclusions, resulting in high-quality, transparent glass products. Applications include infrared glass, optical glass, and quartz glass, which are essential in optics, electronics, and telecommunications.

Advanced Materials Processing

Vacuum furnaces are also pivotal in the processing of advanced materials, such as composites, semiconductors, and thermoelectric materials. For example, in the semiconductor industry, vacuum furnaces are used for the deposition of thin films and the annealing of silicon wafers, ensuring high purity and minimal contamination. Thermoelectric materials, such as bismuth telluride and silicon germanium alloys, are processed under vacuum to enhance their efficiency and performance in energy harvesting and cooling applications.

Metal Processing

Beyond ceramics and glass, vacuum furnaces are extensively used in metal processing, particularly for heat treatment and brazing of high-performance alloys. These processes are critical in industries such as aerospace, where components must withstand extreme conditions. Vacuum heat treatment ensures uniform heating, minimal oxidation, and precise control of phase transformations, leading to superior mechanical properties. Brazing under vacuum conditions allows for the assembly of dissimilar materials, such as ceramic-metal composites, with high integrity and reliability.

Emerging Applications

The versatility of vacuum furnaces continues to drive their adoption in emerging fields. For example, in the biomedical industry, vacuum furnaces are used for the fabrication of implants and medical devices that require high precision and biocompatibility. The textile and plastic industries also utilize vacuum furnaces for processing fibers and polymers, enhancing their performance and durability.

Conclusion

The exploration of additional industrial applications for vacuum furnaces underscores their critical role in modern manufacturing. From advanced ceramics and specialty glasses to high-performance metals and emerging materials, vacuum furnaces enable the production of components with superior properties and reliability. As industries continue to innovate, the demand for sophisticated processing techniques will drive the further integration of vacuum furnaces into new and diverse applications, reinforcing their position as indispensable tools in advanced materials processing.

Benefits of Using Atmosphere Furnaces

Atmosphere furnaces offer a multitude of advantages over traditional heating methods, particularly in terms of enhancing material properties and achieving greater energy efficiency. These specialized furnaces are designed to operate under controlled atmospheric conditions, which allows for precise manipulation of the environment within the furnace. This capability is crucial for a variety of industrial and laboratory applications where the integrity and properties of materials must be maintained or improved upon during the heating process.

Enhanced Material Properties

One of the primary benefits of using atmosphere furnaces is the ability to control the chemical reactions that occur during heating. By introducing specific gases into the furnace, it is possible to prevent undesirable reactions such as oxidation and decarburization, which can degrade the quality of materials like metals and ceramics. For instance, in metallurgical processes, the use of inert gases like argon or nitrogen can protect the metal from reacting with oxygen, thereby preserving its mechanical properties. This is particularly important in the production of high-quality steel, where even minor oxidation can significantly affect the strength and durability of the final product.

Moreover, atmosphere furnaces can also facilitate more complex chemical reactions that can improve material properties. For example, the introduction of hydrogen gas can reduce oxides on the surface of metals, a process known as carburizing, which can enhance the hardness and wear resistance of the material. Similarly, in the ceramics industry, controlled atmospheres can be used to achieve precise sintering conditions, leading to products with superior mechanical strength and thermal stability.

Improved Energy Efficiency

Another significant advantage of atmosphere furnaces is their energy efficiency. Traditional furnaces often rely on open flames or electric resistance heating, which can result in significant heat loss due to convection and radiation. In contrast, atmosphere furnaces are designed to minimize such losses by creating a sealed environment where the heat is contained and utilized more effectively. This not only reduces the overall energy consumption but also lowers operational costs and environmental impact.

Furthermore, the precise control over temperature and atmosphere in atmosphere furnaces allows for more efficient heat treatment processes. This means that materials can be heated to the required temperatures more quickly and maintained at those temperatures for the optimal duration, reducing the overall cycle time and increasing productivity. For instance, in the automotive industry, where the heat treatment of components is critical, the use of atmosphere furnaces can lead to substantial savings in energy and time, contributing to more sustainable manufacturing practices.

Versatility and Application

The versatility of atmosphere furnaces is another key benefit. These furnaces can be adapted to suit a wide range of applications across various industries, from metallurgy and ceramics to electronics and aerospace. The ability to customize the atmosphere within the furnace means that it can be tailored to meet the specific requirements of different materials and processes. This flexibility makes atmosphere furnaces an invaluable tool in both research and industrial settings.

In summary, the benefits of using atmosphere furnaces are manifold. They offer enhanced control over material properties, improved energy efficiency, and a high degree of versatility, making them a superior choice for a wide array of heating applications. As industries continue to seek more efficient and sustainable methods of production, the role of atmosphere furnaces is likely to become even more prominent.

Conclusion

The future of atmosphere furnaces is bright, with numerous innovations poised to enhance their efficiency, precision, and sustainability. Advanced control systems, energy-efficient designs, novel atmospheres, integration with additive manufacturing, smart monitoring, and enhanced safety features are just a few of the trends that will drive the evolution of this technology. As industries continue to push for more advanced and environmentally friendly processes, atmosphere furnaces will play a crucial role in shaping the future of material processing.

Related Products

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Mesh belt controlled atmosphere furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

Related Articles

- Controlled Atmosphere Furnace: Comprehensive Guide to Advanced Heat Treatment

- Introducing the Lab Vacuum Tube Furnaces

- Hydrogen Atmosphere Furnaces: Applications, Safety, and Maintenance

- The Benefits of Controlled Atmosphere Furnaces for Sintering and Annealing Processes

- Muffle Furnace: Unraveling the Secrets of Uniform Heating and Controlled Atmosphere