Color Variation in Evaporated Silicon Oxide Films

Factors Affecting Film Color

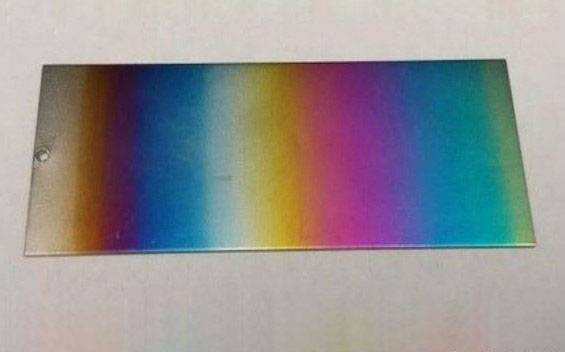

The color of evaporated silicon oxide films is influenced by a variety of factors, each playing a crucial role in determining the final appearance of the film. Film thickness is a primary determinant, as it directly affects the interference and reflection of light, leading to different perceived colors. This phenomenon is akin to how oil slicks on water create iridescent patterns due to varying film thicknesses.

Preparation conditions also significantly impact the film's color. The vapor deposition temperature, atmosphere, and deposition rate all contribute to the structural and optical properties of the film. For instance, higher deposition temperatures can lead to denser films with different optical characteristics compared to those formed at lower temperatures.

Optical properties such as the refractive index and extinction coefficient are influenced by impurities and defects within the film. These properties are critical as they dictate how light interacts with the film, thereby affecting its color. A higher refractive index can enhance the interference effects, resulting in more pronounced color variations.

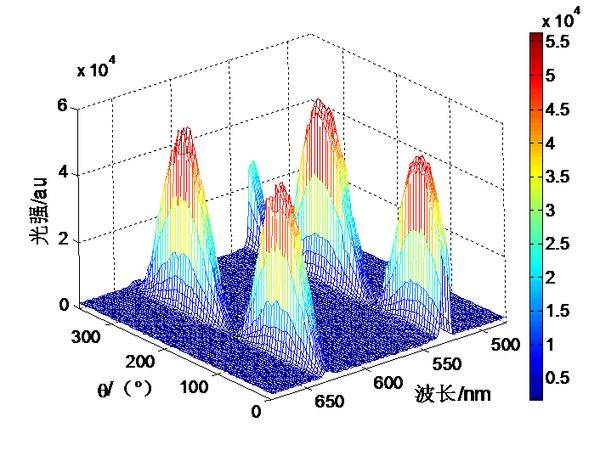

Lastly, environmental conditions such as the angle and intensity of light incidence can alter the observed color of the film. This is particularly relevant in practical applications where the film's appearance may change under different lighting conditions, necessitating careful consideration during design and implementation.

In summary, the color of evaporated silicon oxide films is a complex interplay of film thickness, preparation conditions, optical properties, and environmental factors, each contributing uniquely to the final visual outcome.

Thickness Influence

The thickness of evaporated silicon oxide films plays a pivotal role in determining their optical properties, particularly the colors they exhibit. This phenomenon is primarily due to the interference and reflection of light within the film. When light strikes the film, it interacts with the material, leading to constructive and destructive interference based on the film's thickness and the wavelength of the light.

For instance, a thin film may allow certain wavelengths to pass through while reflecting others, resulting in a specific color being visible to the observer. As the film thickness increases or decreases, the wavelengths that undergo constructive interference shift, leading to a change in the observed color. This effect is akin to how oil slicks on water create iridescent patterns due to varying film thicknesses.

| Thickness Range (nm) | Observed Color |

|---|---|

| 10-50 | Blue |

| 50-100 | Green |

| 100-150 | Red |

Understanding this relationship between film thickness and color allows for precise control over the optical properties of silicon oxide films, which is crucial for applications ranging from optical filters to display technologies. By carefully adjusting the film thickness, it is possible to achieve a desired color, thereby enhancing the functionality and aesthetic appeal of various devices and systems.

Preparation Conditions

The preparation conditions during the vapor deposition process significantly influence the structural and optical properties of silicon oxide films, thereby determining their color. Specifically, the vapor deposition temperature, atmosphere, and deposition rate are critical parameters that need meticulous control.

-

Vapor Deposition Temperature: This parameter directly affects the mobility of the deposited molecules. At higher temperatures, molecules have greater kinetic energy, leading to more uniform film structures and improved optical properties. Conversely, lower temperatures may result in non-uniform films with varying refractive indices and extinction coefficients, which can alter the perceived color.

-

Atmosphere: The gaseous environment during deposition can either enhance or degrade the film quality. For instance, an inert atmosphere like nitrogen or argon can prevent oxidation and contamination, ensuring the film retains its intended optical characteristics. On the other hand, reactive gases like oxygen can introduce impurities, affecting the film's refractive index and color.

-

Deposition Rate: The speed at which the film is deposited impacts its structural integrity. A controlled deposition rate ensures a smooth and continuous film, which is crucial for maintaining consistent optical properties and color. Rapid deposition, however, can lead to defects and non-uniformities, compromising the film's overall performance.

In summary, precise control over these preparation conditions is essential for achieving the desired structural and optical properties, which in turn dictate the color of the silicon oxide film.

Optical Properties

The refractive index and extinction coefficient of evaporated silicon oxide films are pivotal in determining their color. These optical properties are significantly influenced by the presence of impurities and defects within the film. Impurities, whether introduced during the vapor deposition process or inherent in the raw materials, can alter the refractive index by affecting the density and uniformity of the film. Similarly, defects such as voids or structural irregularities can enhance the extinction coefficient, leading to increased light absorption at specific wavelengths.

To illustrate, consider a table that outlines the typical effects of common impurities and defects on the optical properties of silicon oxide films:

| Impurity/Defect | Effect on Refractive Index | Effect on Extinction Coefficient |

|---|---|---|

| Metallic Contaminants | Increases due to higher density | Increases due to localized absorption |

| Organic Residues | Slightly decreases due to lower density | Minimal effect |

| Microvoids | Decreases due to lower density | Increases due to scattering |

| Structural Irregularities | Variable, depending on severity | Increases due to enhanced absorption |

Understanding these relationships is crucial for the precise control of film color. By minimizing impurities and defects through careful material selection and process optimization, it is possible to achieve a more predictable and consistent refractive index and extinction coefficient, thereby ensuring the desired color outcome. This level of control is essential for applications ranging from optical filters to display technologies, where color accuracy and consistency are paramount.

Environmental Conditions

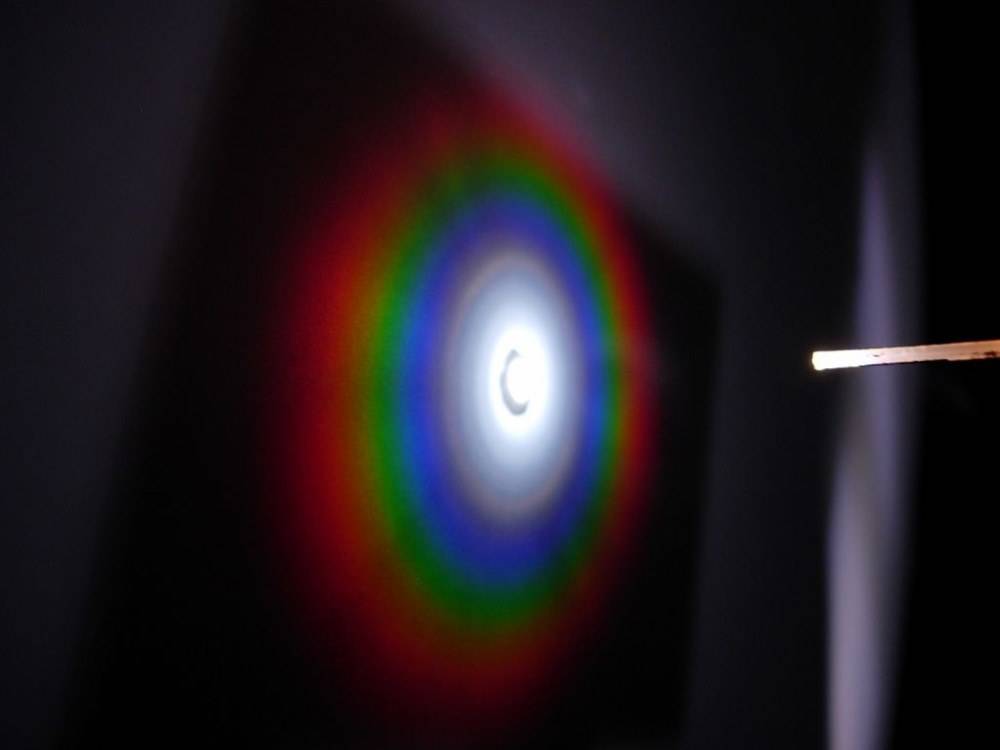

Environmental conditions play a significant role in determining the observed color of evaporated silicon oxide films. Among these conditions, the angle at which light strikes the film and the intensity of the incident light are particularly influential. When light interacts with the film at different angles, it can cause variations in the interference patterns that dictate the perceived color. This phenomenon is akin to how a soap bubble changes color as you tilt it under different lighting conditions.

Moreover, the intensity of the incident light can also alter the observed color. Higher light intensities can amplify the interference effects, leading to more pronounced color shifts. This effect is similar to how a prism disperses white light into a spectrum of colors, each with varying intensities. Therefore, environmental factors such as these must be carefully considered when aiming for consistent color outcomes in silicon oxide films.

In practical applications, such as optical filters and display technologies, understanding and controlling these environmental conditions is crucial for achieving the desired visual effects. For instance, in display screens, adjusting the angle and intensity of ambient light can significantly impact the perceived color and overall visual quality. Thus, while environmental conditions may introduce variability, they also offer avenues for creative control and optimization in various technological applications.

Methods to Control Film Color

Thickness Control

Controlling the thickness of evaporated silicon oxide films is a critical aspect of achieving the desired color. This process involves fine-tuning the vaporization time or rate to precisely manage the film's thickness. The relationship between film thickness and color is rooted in the optical phenomenon of interference, where light waves interact with the film, creating a spectrum of colors.

For instance, a thinner film might exhibit a blue hue due to constructive interference of shorter wavelengths, while a thicker film could appear red or green, reflecting the constructive interference of longer wavelengths. This interplay between thickness and color allows for a nuanced control over the visual appearance of the film.

| Film Thickness | Observed Color | Interference Effect |

|---|---|---|

| Thin | Blue | Constructive interference of shorter wavelengths |

| Moderate | Red, Green | Constructive interference of longer wavelengths |

| Thick | Various hues | Complex interference patterns |

Adjusting the vaporization parameters not only influences the film's color but also its optical properties, such as refractive index and extinction coefficient. These properties are crucial for applications in optical filters, coatings, and sensors, where precise color control is essential.

In summary, by meticulously managing the vaporization process, researchers can tailor the thickness of silicon oxide films to achieve specific colors, thereby enhancing their utility in various optical technologies.

Material Purity

Ensuring the purity of raw materials is paramount in the fabrication of evaporated silicon oxide films, as impurities can significantly influence the final color and consistency of the films. High-purity raw materials minimize the presence of unwanted elements that could introduce defects or alter the optical properties of the film. These impurities, if left unchecked, can lead to variations in the refractive index and extinction coefficient, both of which are critical determinants of the film's color.

| Impurity Type | Potential Impact on Film Color | Mitigation Strategy |

|---|---|---|

| Metals (e.g., Fe, Cu) | Can cause localized absorption bands, leading to color deviations. | Use ultra-pure starting materials and rigorous filtration processes. |

| Gases (e.g., O2, N2) | May affect the stoichiometry of the film, altering its optical constants. | Control deposition atmosphere and use high-vacuum conditions. |

| Organic Contaminants | Can introduce scattering centers, affecting transparency and color uniformity. | Ensure cleanroom conditions and use pre-cleaning procedures. |

By employing high-purity raw materials, manufacturers can achieve greater color consistency across batches, which is essential for applications requiring precise color control, such as optical filters and display technologies. The reduction of impurity-related variability not only enhances the aesthetic quality of the films but also improves their performance in critical optical applications.

Environmental Control

Controlling the environmental conditions during the vapor deposition process is crucial for achieving the desired color in silicon oxide films. This involves meticulous management of parameters such as temperature and atmosphere, which directly influence the structural and optical properties of the film.

Temperature Control

Temperature plays a pivotal role in the vapor deposition process. At elevated temperatures, the kinetic energy of the vaporized particles increases, leading to more rapid and uniform film formation. This uniformity is essential for obtaining consistent color across the film surface. Conversely, lower temperatures can result in non-uniform deposition, causing variations in film thickness and color.

Atmosphere Influence

The atmosphere within the deposition chamber also significantly impacts the film's final color. Common atmospheres include inert gases like argon and nitrogen, as well as reactive gases such as oxygen. The choice of atmosphere can affect the film's refractive index and optical properties. For instance, a controlled oxygen atmosphere can help to minimize the formation of impurities and defects, leading to a more uniform and desired color.

Process Parameters

Other environmental factors, such as pressure and gas flow rates, must also be carefully regulated. High pressure can lead to denser films with different optical characteristics compared to those formed under low pressure. Additionally, the flow rate of the deposition gas can influence the rate of film growth and the resulting color.

By fine-tuning these environmental parameters, researchers and engineers can achieve precise control over the color of silicon oxide films, enabling a wide range of applications from optical filters to display technologies.

Film Structure Modulation

Modulating the structure of silicon oxide films introduces advanced techniques to manipulate their optical properties, thereby altering their color. One such method involves the creation of a multilayer structure, where alternating layers of different materials or varying thicknesses are deposited. This multilayer approach leverages the principle of optical interference, enhancing specific wavelengths of light while suppressing others, leading to a distinct color shift.

Another innovative approach is the doping of nanoparticles into the silicon oxide matrix. These nanoparticles, often composed of metals like gold or silver, exhibit plasmonic resonances that interact with light in unique ways. When embedded within the film, these nanoparticles can scatter or absorb light at specific wavelengths, significantly influencing the film's perceived color. This method not only broadens the spectrum of achievable colors but also imparts additional functionalities, such as enhanced light absorption or emission, depending on the application.

The integration of these structural features allows for a more precise and versatile control over the optical properties of silicon oxide films. By carefully designing the arrangement and concentration of these structural elements, researchers can achieve a wide array of colors, opening up new possibilities for applications in optical devices, sensors, and display technologies.

Optical Coating Design

Optical coating design is a sophisticated process that leverages the principles of interference film design and optical filters to achieve precise color effects. This method involves meticulously optimizing the thickness and refractive index of the film layers to manipulate light interactions. By carefully controlling these parameters, designers can create films that selectively reflect or transmit specific wavelengths of light, thereby producing desired colors.

The process begins with a thorough understanding of the optical properties of the materials used. The refractive index, which is a measure of how much the speed of light is reduced inside the material, plays a crucial role. Different materials have different refractive indices, and by layering these materials in specific sequences and thicknesses, it is possible to create interference effects that filter out unwanted wavelengths and enhance others.

For instance, in the production of optical filters, the thickness of each layer is often tuned to a fraction of the wavelength of the light it is designed to interact with. This ensures that constructive and destructive interference patterns are formed, leading to the desired color effect. The refractive index of each layer is also critical; a higher refractive index layer will reflect more light, while a lower one will transmit more.

In summary, optical coating design is a nuanced art that combines scientific precision with creative intent. By mastering the interplay between film thickness and refractive index, designers can engineer coatings that not only achieve specific color effects but also enhance the performance of various optical devices and applications.

Practical Applications of Color-Controlled Silicon Oxide Films

Optical Filters

In the realm of optical filters, the precise control of film thickness and refractive index is paramount to achieving specific colors that are essential for applications in displays and photography. This meticulous adjustment allows for the creation of filters that selectively transmit or block certain wavelengths of light, thereby enhancing the visual quality and performance of devices.

The process involves optimizing the interference and reflection of light within the film, which is governed by its thickness and the refractive index. By fine-tuning these parameters, it is possible to manipulate the interference effect, leading to the manifestation of different colors. For instance, a film with a specific thickness and refractive index might exhibit a vibrant blue, while another configuration could result in a deep red.

Moreover, the refractive index, which is influenced by the material's composition and structural properties, plays a crucial role in determining the optical behavior of the film. By carefully selecting and adjusting the refractive index, engineers can design filters that meet the stringent requirements of various applications, from enhancing the color accuracy in high-definition displays to improving the light filtration in advanced photographic equipment.

In summary, the interplay between film thickness and refractive index is the cornerstone of optical filter design, enabling the creation of filters with tailored spectral characteristics that are indispensable in modern optical technologies.

Optical Coatings

Optical coatings are indispensable in various industries, playing a crucial role in enhancing the performance of optical devices and systems. One of the most notable applications is in solar cells, where silicon oxide films are employed to create anti-reflective coatings. These coatings are designed to optimize light transmission and reflection, thereby maximizing the efficiency of solar energy conversion.

The use of thin film coatings extends beyond solar cells to encompass a wide array of optical applications. For instance, these coatings are integral to optical data storage devices, where they serve as protective layers, shielding against temperature fluctuations that could otherwise degrade performance. Similarly, in optical fibers, thin film coatings are utilized to enhance the refractive index and absorption coefficient, ensuring optimal signal transmission and minimal loss.

In the realm of laser optics, high reflective coatings are essential for achieving the precise reflectivity required for laser operation. These coatings are typically achieved through the deposition of thin films made from highly reflective materials. Additionally, infrared reflecting coatings are employed in filament lamps to increase luminous flux intensity, thereby improving the overall efficiency and brightness of the light source.

Moreover, thin film coatings are also applied to everyday items such as window glass and mirrors. These coatings help to regulate the passage of heat, providing both insulation and enhanced visual clarity. In essence, the versatility and efficacy of thin film coatings make them a cornerstone of modern optical technology, influencing everything from energy capture to data storage and beyond.

Optical Sensors

The integration of silicon oxide films into optical fiber sensors represents a significant advancement in the field of optical sensing technology. These films are instrumental in fine-tuning the coupling efficiency of light signals, which is crucial for optimizing sensor performance. By precisely controlling the thickness and composition of the silicon oxide layers, researchers can manipulate the interaction between light and the sensor material, thereby enhancing the sensitivity and responsiveness of the device.

One of the key advantages of using silicon oxide films in optical sensors is their ability to modulate the refractive index. This property allows for the efficient coupling of light into the optical fiber, ensuring that the sensor can detect even the slightest changes in the optical signal. Additionally, the thermal stability and mechanical robustness of silicon oxide films contribute to the durability and reliability of the sensors, making them suitable for a wide range of applications, from environmental monitoring to biomedical diagnostics.

Moreover, the incorporation of silicon oxide films in optical sensors enables the development of more compact and versatile sensing systems. The ability to tailor the optical properties of these films through controlled deposition techniques opens up new possibilities for designing sensors with specific response characteristics. This adaptability is particularly valuable in applications where high precision and dynamic range are essential, such as in chemical analysis and structural health monitoring.

In summary, the application of silicon oxide films in optical fiber sensors offers a powerful means of enhancing light signal coupling efficiency and sensor response characteristics, paving the way for more advanced and reliable optical sensing technologies.

Display Technology

Silicon oxide films have emerged as pivotal components in modern display technologies, particularly in Organic Light Emitting Diodes (OLEDs) and Liquid Crystal Displays (LCDs). These films are integral in enhancing the visual experience by significantly improving color vibrancy and contrast. The incorporation of silicon oxide films in these displays leverages their unique optical properties, which are finely tuned through precise control of film thickness and structural integrity.

In OLEDs, silicon oxide films serve as critical layers that optimize the emission spectrum of organic materials, leading to more vivid and accurate colors. This is achieved by modulating the refractive index and thickness of the silicon oxide layer, which in turn affects the interference patterns of light emitted by the OLEDs. Similarly, in LCDs, these films are used to enhance the contrast ratio by minimizing light leakage and improving the overall optical efficiency of the display.

The application of silicon oxide films in display technologies is not limited to color enhancement; they also play a crucial role in improving the durability and reliability of these displays. By acting as protective barriers, these films help to prevent degradation of the underlying organic materials in OLEDs and enhance the longevity of LCDs by reducing wear and tear.

Moreover, the advancements in deposition techniques and material science have enabled the creation of silicon oxide films with tailored properties, making them increasingly versatile for a wide range of display applications. This adaptability ensures that future innovations in display technology can continue to benefit from the unique attributes of silicon oxide films, driving the development of even more advanced and visually appealing displays.

Related Products

- Float Soda-Lime Optical Glass for Laboratory Use

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Infrared High Resistance Single Crystal Silicon Lens

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Versatile PTFE Solutions for Semiconductor and Medical Wafer Processing

Related Articles

- The Rise of Glass Substrates in Advanced Semiconductor Packaging

- How To Clean Laboratory Glassware - Part 1

- Glassware vs. Plasticware - Which is the Better Choice for Your Needs?

- Optical Quartz Plate: A Comprehensive Guide to Applications, Specifications, and Usage

- Understanding Fused Silica: Properties, Applications, and Advantages