battery material

Lithium Battery Tab Tape for Battery Lab Applications

Item Number : BC-19

Price varies based on specs and customizations

- Material

- Polyimide Film

- Size

- Length 33M/roll

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

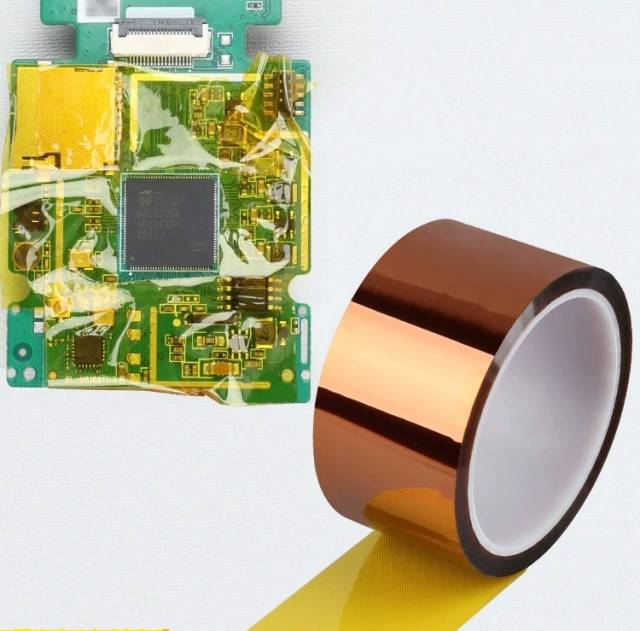

PI polyimide tape, generally brown, also known as gold finger tape, high temperature resistance 280 ° C, to prevent the influence of heat sealing of the tabs of soft pack batteries, suitable for pasting the tabs of soft pack batteries. Use special special film insulation The material is the base material, and the special pressure-sensitive glue is coated on the base material, which is specially used for the insulation and protection of the positive electrode part of the Ni-MH battery.

- Solder is used to connect capacitors and other components. Goldfinger high temperature tape has a melting point of around 230°C and is used for auxiliary soldering.

- Insulation materials are often used in electronic products to protect and insulate them to ensure their normal operation in the manufacturing and communication maintenance markets.

- Large-scale factories use gold finger tape to make slices of high-temperature insulating gaskets for die-cutting and punching to improve production efficiency and reduce costs.

- It is used for motor heat insulation to protect the circuit board from the heat generated during the operation of the motor.

- Gold finger high temperature tape is also used to fix the battery and provide heat insulation between the protective plate and the battery cell.

- High temperature spray paint has the characteristics of high temperature resistance, tensile strength, chemical resistance, easy peeling, and no residue. It is ideal for protecting metal surfaces during high temperature painting and blasting coating processes.

Detail & Parts

Technical specifications

| Substrate | Polyimide film |

| Total tape thickness | 0.060mm |

| tape length | 33m |

| width | 2 / 3 / 5 / 6 / 8 / 10 / 12 / 15 / 16 / 18 / 20 / 25 / 30 / 35 / 40 / 50mm(optional) |

| Tape Adhesion | 5.39 (550) N (gf)/w.25mm |

| Tape Tensile Strength | 122.6 (12.5) N (kgf)/w.25mm |

| Tape elongation | 50% |

| Temperature resistance | 220°C,10min, |

| chemical resistance | 20% HCI, NaOH/10Hrs good |

The products we show are available in different sizes and custom sizes are available on request.

Advantages

- Block electron migration, anti-corrosion, reduce leakage current.

- Increase mechanical properties, improve moisture resistance.

- It reduces circuit breakage in subsequent processing, and its characteristics are related to polyimide materials.

- Adjusting the fluorine content of the copolymer can control the refractive index of polyimide film, which is suitable for waveguide core and cladding.

Trusted by Industry Leaders

FAQ

What Considerations Should Be Made For Battery Case Gaskets?

The Difference Between PET Tape And PET Tape.

What Is The Role Of Battery Case Gaskets?

What Are Lithium-air Battery Cases?

How Should Button Battery Cases Be Chosen For Specific Applications?

4.8 / 5

Wow! Arrived in no time, I got it the next day after ordering.

4.9 / 5

Exceptional quality at a price you can't beat. I'm glad I found this.

4.7 / 5

I'm very satisfied with the quality, and it works perfectly for my batteries.

4.6 / 5

Highly recommended! The tape is durable and works exactly as advertised.

4.8 / 5

I'm impressed with the fast delivery and the quality of the product.

4.7 / 5

The tape is easy to use and provides excellent insulation for my batteries.

4.9 / 5

I'm amazed by the quality and durability of this tape. It's a great value for the price.

4.6 / 5

I've been using this tape for a while now and it's held up great. Highly recommend.

4.8 / 5

Super fast delivery, and the tape is exactly what I needed. Thanks!

4.7 / 5

This tape is a lifesaver for my battery projects. It's high quality and very easy to use.

4.9 / 5

I'm very happy with this purchase. The tape is durable and works perfectly for my needs.

4.6 / 5

This tape is amazing! It's strong, durable, and easy to work with. I highly recommend it.

4.8 / 5

I'm very impressed with the quality of this tape. It's exactly what I needed.

4.7 / 5

This tape is a must-have for any battery project. It's strong, durable, and easy to use.

4.9 / 5

I'm very happy with this purchase. The tape is high quality and works perfectly for my needs.

4.6 / 5

This tape is amazing! It's strong, durable, and easy to work with. I highly recommend it.

4.8 / 5

I'm very impressed with the quality of this tape. It's exactly what I needed.

4.7 / 5

This tape is a must-have for any battery project. It's strong, durable, and easy to use.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Nickel Aluminum Tabs for Soft Pack Lithium Batteries

Nickel tabs are used to manufacture cylindrical and pouch batteries, and positive aluminum and negative nickel are used to produce lithium-ion and nickel batteries.

Button Battery Tablet Press Sealing Mold for Lab Use

The sealing die is essential for assembling button batteries, ensuring components like the anode, cathode, and electrolyte are securely enclosed.

Button Battery Case Gasket for Battery Lab Applications

The gasket prevents the deformation of the internal material, and the spring sheet is conducive to the tight contact inside the battery to prevent loosening.

Battery Lab Equipment Battery Capacity and Comprehensive Tester

The scope of application of the battery comprehensive tester can be tested: 18650 and other cylindrical, square lithium batteries, polymer batteries, nickel-cadmium batteries, nickel-metal hydride batteries, lead-acid batteries, etc.

Cylindrical Battery Steel Case for Battery Lab

Lithium-ion battery casing suppresses battery polarization, reduces thermal effects, and improves rate performance.

Button Battery Case for Battery Lab Applications

Button batteries are also known as micro batteries. It looks like a small button-shaped battery. Usually larger in diameter and thinner in thickness.

Button Battery Disassembly and Sealing Mold for Lab Use

The simple sealing and disassembly mold can be directly used on ordinary tablet presses, which can save costs, is convenient and fast, and can be used to encapsulate and disassemble button batteries. Other specifications can be customized.

Battery Lab Equipment 304 Stainless Steel Strip Foil 20um Thick for Battery Test

304 is a versatile stainless steel, which is widely used in the production of equipment and parts that require good overall performance (corrosion resistance and formability).

Platinum Sheet Electrode for Battery Lab Applications

Platinum sheet is composed of platinum, which is also one of the refractory metals. It is soft and can be forged, rolled and drawn into rod, wire, plate, tube and wire.

High Purity Zinc Foil for Battery Lab Applications

There are very few harmful impurities in the chemical composition of zinc foil, and the surface of the product is straight and smooth; it has good comprehensive properties, processability, electroplating colorability, oxidation resistance and corrosion resistance, etc.

Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

Toray carbon paper is a porous C/C composite material product (composite material of carbon fiber and carbon) that has undergone high-temperature heat treatment.

Button Battery Storage Box for Battery Lab

Button-type battery storage box, detachable, high-quality PP environmental protection material; suitable for small objects/chemicals, etc., thickened, compressive, durable, and available in a variety of styles.

Polyethylene Separator for Lithium Battery

The polyethylene separator is a key component of lithium-ion batteries, located between the positive and negative electrodes. They allow the passage of lithium ions while inhibiting electron transport. The performance of the separator affects the capacity, cycle and safety of the battery.

Laboratory Hydraulic Press Lab Pellet Press for Button Battery

Efficiently prepare samples with our 2T Button Battery Press. Ideal for material research labs and small-scale production. Small footprint, lightweight, and vacuum-compatible.

Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

Efficiently prepare samples with Cylindrical Lab Electric Heating Press Mold. Fast heating, high temp & easy operation. Custom sizes available. Perfect for battery, ceramic & biochemical research.

Related Articles

Pressing Powder Samples and Molding Polymer Films: A Comprehensive Guide

Pressing powder samples is done to create a solid material that remains intact even after the load is removed. This process involves pushing the powder grains closer together, closing the gaps between them and forcing them to flow and rearrange themselves into a more compact arrangement. As the available volume reduces, the flow of particles stops, and they undergo plastic and elastic deformations that result in bonding between the grains.

Applications of PECVD Nano-Coating Technology in Electronic Devices

PECVD nano-coating technology enhances durability and reliability in various electronic devices.

PECVD Nano-Coating Applications Beyond Waterproofing and Corrosion Prevention

Explores diverse PECVD nano-coating applications including waterproofing, anti-corrosion, antibacterial, hydrophilic, and wear-resistant films.

Impact of Various Power Supplies on Sputtered Film Morphology

This article discusses how different power supplies affect the morphology of sputtered film layers, focusing on DC, PDC, and RF power supplies.

Factors Affecting the Adhesion of Magnetron Sputtered Films

An in-depth analysis of the key factors influencing the adhesion of films prepared via magnetron sputtering technology.

Types of Bias Power Supplies in Magnetron Sputtering and Their Purposes

Overview of bias power supply types in magnetron sputtering and their roles in improving film adhesion and density.