Diversified Applications of PECVD Nano-Coating

Waterproof and Anti-Staining Film

The PECVD nano-coating technology creates a robust, dense protective layer on various material surfaces, effectively repelling water, oil, dust, and other contaminants. This advanced film not only prevents these substances from adhering to or penetrating the surface but also ensures that the underlying materials remain pristine and functional. The impermeable nature of this coating makes it particularly advantageous for applications involving 3C electronics and smart home products.

In the realm of 3C electronics, the waterproof and anti-staining film significantly enhances the durability and longevity of devices. For instance, smartphones, tablets, and laptops, which are frequently exposed to various environmental conditions, benefit immensely from this protective layer. It safeguards these devices against accidental spills, rainwater, and everyday dust, thereby reducing the likelihood of internal damage and extending their operational life.

Smart home products, such as smart speakers, thermostats, and security cameras, also find substantial advantages in this technology. These devices often operate in environments where they are susceptible to moisture and dirt. The waterproof and anti-staining film ensures that these products remain operational and maintain their aesthetic appeal, even under challenging conditions. This resilience is crucial for maintaining the functionality and reliability of smart home ecosystems, ensuring that users can rely on these devices without constant worry about environmental degradation.

Moreover, the film's ability to prevent staining is particularly beneficial in settings where cleanliness and hygiene are paramount. For example, in healthcare environments, where smart devices are used for patient monitoring, the ability to maintain a sterile surface is crucial. The PECVD nano-coating ensures that these devices remain free from contaminants, contributing to a safer and more hygienic environment.

In summary, the waterproof and anti-staining film, enabled by PECVD nano-coating technology, offers a versatile and robust solution for protecting a wide range of products from environmental hazards. Its applications in 3C electronics and smart home products underscore its potential to enhance durability, maintain functionality, and ensure long-term reliability in various settings.

Anti-Corrosion and Anti-Aging Film

PECVD technology excels in creating a dense protective layer that significantly enhances the durability and lifespan of various components. This protective layer is highly effective in resisting environmental factors such as humidity, chemicals, and UV rays, making it an ideal solution for a wide range of applications.

In the automotive electronics sector, this anti-corrosion and anti-aging film ensures that critical components remain functional and reliable even under harsh conditions. Similarly, in smart home devices, the film helps to maintain performance and aesthetics over extended periods, reducing the need for frequent replacements or repairs.

LED lighting systems benefit from this technology by maintaining their luminous efficiency and preventing degradation due to environmental exposure. Security monitoring equipment, drones, aerospace components, and industrial control systems also find significant advantages in terms of longevity and reliability when protected by this advanced PECVD nano-coating.

The versatility and robustness of this film make it a valuable asset across multiple industries, contributing to the overall durability and longevity of the products it protects.

Antibacterial and Anti-Microbial Film

The PECVD nano-coating technology creates a robust protective layer that significantly inhibits the growth of bacteria, fungi, and viruses. This advanced coating ensures that surfaces remain hygienic and safe, making it an ideal solution for a variety of applications where cleanliness and safety are paramount.

For instance, in the realm of smart wearables, such as fitness trackers and smartwatches, this antibacterial film helps maintain the device's cleanliness, reducing the risk of skin infections and allergic reactions. Similarly, in medical devices, the coating ensures that equipment remains sterile, minimizing the risk of cross-contamination in clinical settings.

In addition to healthcare applications, this technology is also beneficial in everyday items like tableware and sanitary products. By preventing the proliferation of harmful microbes, the nano-coating enhances the safety and longevity of these products, making them more reliable and user-friendly.

Overall, the antibacterial and anti-microbial film not only addresses the immediate need for surface hygiene but also contributes to the broader goal of public health and safety, making it a versatile and essential component in modern technology.

Hydrophilic Film

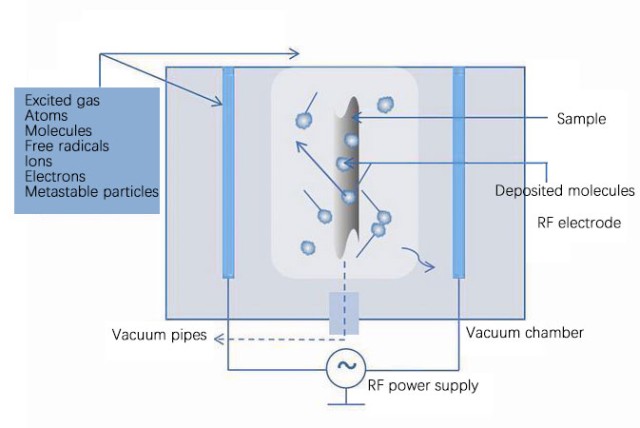

The hydrophilic film, a product of PECVD (Plasma Enhanced Chemical Vapor Deposition) technology, is specifically engineered to mitigate issues related to water vapor condensation. This innovative coating is designed to maintain clear visibility by preventing the formation of fog or mist on surfaces, thereby enhancing the functionality and longevity of various optical and reflective devices.

Suitable for a wide array of applications, the hydrophilic film finds its utility in critical components such as glass lenses, dome covers, automobile lampshades, rearview mirrors, and camera lenses. In each of these applications, the film's ability to repel water vapor ensures that the surfaces remain transparent and unobstructed, crucial for maintaining optimal performance in both dynamic and static environments.

| Application | Benefit |

|---|---|

| Glass Lenses | Prevents fogging, ensuring clear vision for optical instruments. |

| Dome Covers | Maintains transparency in surveillance and security systems. |

| Automobile Lampshades | Enhances visibility and safety by preventing moisture buildup. |

| Rearview Mirrors | Ensures clear rearward vision, crucial for driving safety. |

| Camera Lenses | Preserves image quality by preventing condensation that could distort views. |

The hydrophilic film's effectiveness is not merely limited to its anti-condensation properties; it also contributes to the overall durability and performance of the coated devices. By integrating this advanced nano-coating, manufacturers can significantly enhance the reliability and efficiency of their products, meeting the high standards demanded by modern technological applications.

Wear-Resistant Hardening Film

The wear-resistant hardening film, a product of PECVD technology, boasts an exceptionally high level of hardness and abrasion resistance. This unique property significantly enhances the surface hardness of various materials, thereby substantially reducing the risk of scratches. The film's robust characteristics make it an ideal choice for a wide array of applications, particularly those involving surfaces that are prone to wear and tear.

One of the primary applications of this film is in the protection of displays and touchscreens. In these contexts, the film's ability to maintain surface integrity under constant use is invaluable, ensuring that the screens remain clear and functional over extended periods. Similarly, glass screens benefit immensely from the film's protective qualities, as it fortifies the glass against everyday scratches and abrasions.

Automotive lampshades also stand to gain significantly from the application of this wear-resistant hardening film. The film not only protects the lampshades from scratches but also enhances their overall durability, ensuring that they remain in optimal condition even under harsh environmental conditions. Additionally, the film finds application in the protection of jewelry, where its ability to prevent scratches and maintain luster is particularly prized.

In summary, the wear-resistant hardening film's high hardness and abrasion resistance properties make it a versatile and indispensable tool in the protection and enhancement of various surfaces, from electronic displays to automotive components and beyond.

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Custom CVD Diamond Coating for Lab Applications

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Laboratory CVD Boron Doped Diamond Materials