battery material

Cylindrical Battery Steel Case for Battery Lab

Item Number : BC-03

Price varies based on specs and customizations

- Material

- Nickel Nitrate Plated A3 Steel

- Specification

- See the form

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

Lithium battery explosion-proof cap:

- Self-produced hardware structural parts and injection molded structural parts, each component is well matched.

- Stable internal resistance <1mΩ.

- Disconnect pressure balance at 10-15Mpa.

- The opening pressure is stable at 2.0-2.8Mpa; the explosion-proof performance is excellent and stable.

- Automated process control production, coated with high-tech sealant inside and outside, excellent air tightness.

- The shape design of the sealing ring fits beautifully with the roller groove of the steel shell of the battery, and the battery seal is smooth and tight, which is not easy to changeshape, no leakage.

- The environmental protection of the product complies with the ROHS standard.

Detail & Parts

Technical specifications

| Product ingredients | name | Battery shell 18650 explosion-proof type |

| Assembly parts | steel shell | 18.0(D)*67(H)*0.25(T)mm |

| Explosion-proof caps | 3.7(T)*17.3(D)mm | |

| pressure limit | 18-22MPa |

| technical indicators 26650 | |

| Cap Cap PTC | riot cap |

| Steel shell, cap material | Nitrate-plated A3 steel |

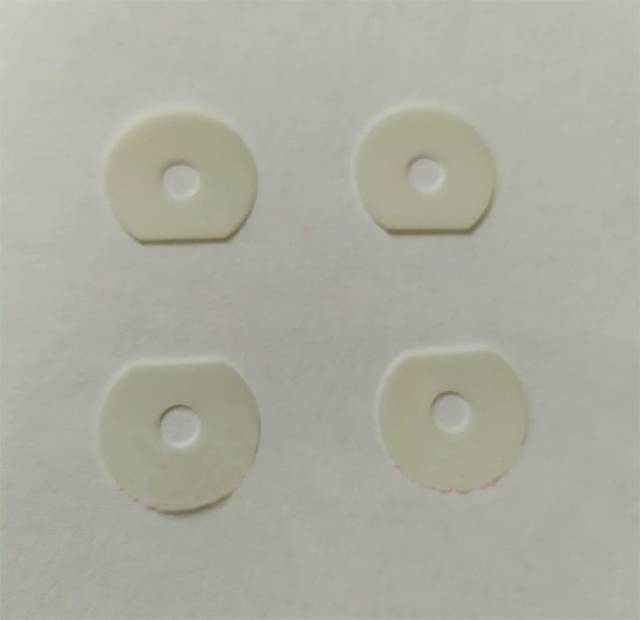

| Seal O-ring and Gasket Material | nylon |

| washer | PET |

| Shell Dimensions (Diameter x Height) | 26mm(OD)x25.5mm(ID)x68mm(H) |

| Cap Dimensions (Diameter x Height) | 25.5mm(D)x5mm(H) |

| Dimensions of upper insulating spacer (diameter x thickness) | 24.5mm(D)x0.25mm(T) |

| Dimensions of lower insulating spacer (diameter x thickness) | 24.5mm(D)x0.25mm(T) |

| weight | 18.75g/pcs |

The size is increased from 18650 to 21700, and the benefits are as follows:

- When the energy density is appropriately increased, conventional materials can be selected, with stable performance and high cost performance;

- The design of the multi-pole ear mechanism can be properly carried out to reduce the internal resistance;

- Under the same energy density, fast charging graphite can be selected to improve the fast charging performance;

- Appropriately increasing the diameter and height can obtain more effective volume.

- The capacity of the single battery cell is increased, the proportion of auxiliary components is reduced, and the cost of the pack is reduced.

Advantage

- Inhibit battery polarization, reduce thermal effects, and improve rate performance;

- Lithium-ion battery shell greatly reduces the internal resistance of the battery, and significantly reduces the dynamic internal resistance increase during the configuration process;

- Improve the uniformity and newly increase the configuration life of the battery;

- Lithium-ion battery shell improves the adhesion between active material and current collector, greatly reducing the manufacturing cost of tabs;

- Protect the current collector from being corroded by the electrolyte;

- Improve the high and low temperature performance of lithium-ion batteries, and improve the processing performance of lithium iron phosphate and lithium titanate materials.

Trusted by Industry Leaders

FAQ

What Is A Battery Case?

What Are The Benefits Of Using Battery Boxes?

What Safety Precautions Should Be Followed When Using Battery Boxes?

What Considerations Should Be Made For Battery Case Gaskets?

What Are The Main Types Of Battery Materials?

What Is The Role Of Battery Case Gaskets?

What Are The Applications Of Battery Materials?

What Are Lithium-air Battery Cases?

How Do Battery Materials Enhance Battery Performance?

How Should Button Battery Cases Be Chosen For Specific Applications?

What Is The Role Of Polyethylene Separators In Lithium-ion Batteries?

Why Are Conductive Carbon Cloths/papers/felts Important In Battery Applications?

What Are The Advantages Of Using Aluminum-plastic Flexible Packaging Films For Lithium Batteries?

How Does The Lithium Cobaltate Material Contribute To Battery Performance?

What Is The Function Of Battery Internal Resistance Testers?

Why Are Nickel-aluminum Tabs Important In Battery Manufacturing?

4.8 / 5

The cylindrical battery steel case from KINTEK SOLUTION exceeded my expectations. Its precise construction ensures perfect fit and performance. Highly recommended!

4.9 / 5

KINTEK SOLUTION's cylindrical battery steel case is a game-changer! Its exceptional quality and durability make it worth every penny. A must-have for any battery project.

4.7 / 5

The cylindrical battery steel case from KINTEK SOLUTION is a lifesaver! Its robust design provides unparalleled protection for my batteries. Highly satisfied!

4.6 / 5

KINTEK SOLUTION's cylindrical battery steel case is a fantastic choice. Its sleek design and easy installation make it a breeze to use. Highly recommend!

5.0 / 5

The cylindrical battery steel case from KINTEK SOLUTION is simply amazing! Its superior quality and attention to detail are unmatched. Highly impressed!

4.8 / 5

KINTEK SOLUTION's cylindrical battery steel case is a winner! Its innovative design and seamless integration make it a must-have for any battery enthusiast. Highly recommend!

4.7 / 5

The cylindrical battery steel case from KINTEK SOLUTION is a fantastic investment. Its rugged construction and reliable performance make it worth every penny. Highly satisfied!

4.9 / 5

KINTEK SOLUTION's cylindrical battery steel case is a lifesaver! Its exceptional durability and ease of use make it a must-have for any battery application. Highly recommend!

5.0 / 5

The cylindrical battery steel case from KINTEK SOLUTION is simply outstanding! Its sleek design and remarkable performance make it a game-changer. Highly recommend!

4.6 / 5

KINTEK SOLUTION's cylindrical battery steel case is a solid choice. Its robust construction and reliable performance make it a great value for the price. Highly recommend!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Button Battery Case Gasket for Battery Lab Applications

The gasket prevents the deformation of the internal material, and the spring sheet is conducive to the tight contact inside the battery to prevent loosening.

Cylindrical Press Mold for Lab Applications

Efficiently form and test most samples with Cylindrical Press Molds in a range of sizes. Made of Japanese high-speed steel, with long service life and customizable sizes.

Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

Efficiently prepare samples with Cylindrical Lab Electric Heating Press Mold. Fast heating, high temp & easy operation. Custom sizes available. Perfect for battery, ceramic & biochemical research.

Battery Lab Equipment 304 Stainless Steel Strip Foil 20um Thick for Battery Test

304 is a versatile stainless steel, which is widely used in the production of equipment and parts that require good overall performance (corrosion resistance and formability).

Button Battery Case for Battery Lab Applications

Button batteries are also known as micro batteries. It looks like a small button-shaped battery. Usually larger in diameter and thinner in thickness.

Button Battery Storage Box for Battery Lab

Button-type battery storage box, detachable, high-quality PP environmental protection material; suitable for small objects/chemicals, etc., thickened, compressive, durable, and available in a variety of styles.

Assemble Lab Cylindrical Press Mold

Get reliable and precise molding with Assemble Lab Cylindrical Press Mold. Perfect for ultra-fine powder or delicate samples, widely used in material research and development.

Battery Lab Equipment Battery Capacity and Comprehensive Tester

The scope of application of the battery comprehensive tester can be tested: 18650 and other cylindrical, square lithium batteries, polymer batteries, nickel-cadmium batteries, nickel-metal hydride batteries, lead-acid batteries, etc.

Platinum Sheet Electrode for Battery Lab Applications

Platinum sheet is composed of platinum, which is also one of the refractory metals. It is soft and can be forged, rolled and drawn into rod, wire, plate, tube and wire.

Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

Cylindrical Crucibles Cylindrical crucibles are one of the most common crucible shapes, suitable for melting and processing a wide variety of materials, and are easy to handle and clean.

Button Battery Disassembly and Sealing Mold for Lab Use

The simple sealing and disassembly mold can be directly used on ordinary tablet presses, which can save costs, is convenient and fast, and can be used to encapsulate and disassemble button batteries. Other specifications can be customized.

Button Battery Tablet Press Sealing Mold for Lab Use

The sealing die is essential for assembling button batteries, ensuring components like the anode, cathode, and electrolyte are securely enclosed.

High Purity Zinc Foil for Battery Lab Applications

There are very few harmful impurities in the chemical composition of zinc foil, and the surface of the product is straight and smooth; it has good comprehensive properties, processability, electroplating colorability, oxidation resistance and corrosion resistance, etc.

Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

Toray carbon paper is a porous C/C composite material product (composite material of carbon fiber and carbon) that has undergone high-temperature heat treatment.

Lithium Battery Tab Tape for Battery Lab Applications

PI polyimide tape, generally brown, also known as gold finger tape, high temperature resistance 280 ℃, to prevent the influence of heat sealing of soft pack battery lug glue, suitable for soft pack battery tab position glue.

Laboratory Hydraulic Press Lab Pellet Press for Button Battery

Efficiently prepare samples with our 2T Button Battery Press. Ideal for material research labs and small-scale production. Small footprint, lightweight, and vacuum-compatible.

Related Articles

Battery sealing machine operating steps and precautions

Introduction to the operating steps and precautions of the battery sealing machine

Design and Application of Reference Electrodes in Lithium Batteries

This article discusses the selection and design of reference electrodes for lithium batteries, focusing on active materials like lithium metal, lithium alloys, and lithium-embedded oxides.

Technical Overview of Silicon-Carbon Anode Materials Prepared by CVD Method

This article discusses the key technical aspects of silicon-carbon anode materials prepared via CVD, focusing on their synthesis, performance improvements, and industrial application potential.

Carbon Coating for Surface Modification of Silicon-Based Materials in Lithium-Ion Batteries

This article discusses the application of carbon coatings to improve the performance of silicon-based anode materials in lithium-ion batteries.

Design Principle and Application of Reference Electrodes for Lithium Batteries

Discusses the design principles, types, applications, and future directions of reference electrodes in lithium batteries.