Molds & Accessories

Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

Item Number : PMH

Price varies based on specs and customizations

- Heating temp

- 300-500 ℃

- Material

- Cr12Mov

- Indenter hardness

- HRC60-HRC62

- Cavity depth

- 45 mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Applications

Cylindrical Lab electric heating Press mold has the characteristics of small size, fast heating, high temperature and convenient operation.

The mold is widely used in battery, superconductor, cement, ceramics, catalysis, silicate, powder metallurgy, sea mud analysis, biochemical analysis and new material sample preparation research and development. In addition, the product can also be used with calcium iron, infrared, X-ray fluorescence and other testing instruments.

Special sizes press molds can be customized according to customer requirements.

Detail & Parts

![Cylindrical electric heating mold [300℃]](https://image.kindle-tech.com/images/products/121/7d8aa6ffeae9011897f839b84990ffc367bd713252963.jpg)

![Cylindrical electric heating mold [500℃]](https://image.kindle-tech.com/images/products/121/2771aa05e20ac12d6060a9d5da22cd9867bd715ccc907.jpg)

Operation interface - (Standard mode)

- Standard interface: You can set the mold heating temperature and constant temperature time separately in this interface.

- Water cooling button: The water cooling machine power supply is connected to the thermostat, and the thermostat can control the opening and closing of the water cooling machine.

- Heating button: You can start heating the mold.

- Stop button: You can stop the heating of the mold.

- Timing switch: You can turn the timing function on and off.

- Start button: You can heat up according to the multi-stage heating program.

- Stop button: During the heating process, you can stop the heating process.

- List curve: You can switch the current display state, list and curve chart.

Technical specifications

| Press the shape of the sample |  |

| Heatingtemperature | Room temperature-300.0C |

| Material of lint | Alloy tool steel:440C |

| indenter hardness | HRC60-HRC62 |

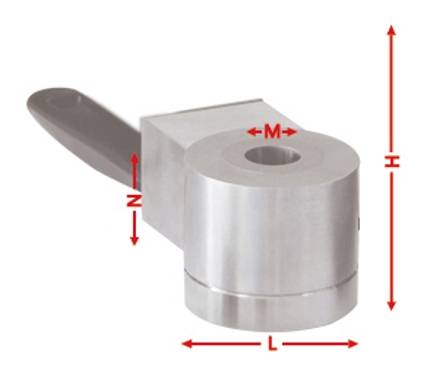

| Sample size | Φ10、Φ13、Φ15、Φ20、Φ30、Φ40mm(M) |

| Depth ofcavity | 40mm(N) |

| External dimansions | Φ78*138mm、Φ90*138mm(L**H) |

| Power supply | 300 W(220V/110V can be customized) |

| Mold weight | Approximately 9kg |

| Dimensional diagram |  |

Mold pressure conversion table

| Mold pressure [Mpa] | 50 | 100 | 300 | 400 | 600 | 800 | 1000 | 1200 | 1500 |

|---|---|---|---|---|---|---|---|---|---|

| Φ8 T | 0.25 | 0.5 | 1.5 | 2.01 | 3.01 | 4.02 | 5.02 | 6.03 | 7.53 |

| Φ10 T | 0.39 | 0.78 | 2.35 | 3.14 | 4.71 | 6.28 | 7.85 | 9.42 | 11.7 |

| Φ12 T | 0.56 | 1.13 | 3.39 | 4.52 | 6.78 | 9.04 | 11.3 | 13.5 | 16.9 |

| Φ13 T | 0.66 | 1.32 | 3.98 | 5.3 | 7.96 | 10.6 | 13.2 | 15.9 | 19.9 |

| Φ15 T | 0.88 | 1.76 | 5.3 | 7.06 | 10.6 | 14.1 | 17.6 | 21.2 | 26.5 |

| Φ20 T | 1.57 | 3.14 | 9.42 | 12.5 | 18.8 | 25.1 | 31.4 | 37.6 | 47.1 |

Tip: Molds are generally used within the range of100-800MPa, and the maximum limit of molds is1500MPa.

Operation steps

The cylindrical electric heating mold is a small, fast-heating mold that is easy to use. It can produce samples ranging in size from 5 to 40mm, and can reach heating temperatures of up to 500℃ with a heating rate of 10-15℃ per minute. Additionally, this mold can be equipped with a water cooling device for added convenience, and can be customized to meet specific customer requirements.

1. Place the sample in the mold.

2. Place the mold in the tablet press.

3. Set the heating temperature.

4. Start heating.

5. Pressurize the heated sample.

6. Take out the pressed sample.

Precautions for mold maintenance

To ensure accurate test results, clean the mold surface with dust-free paper before each use to avoid the anti-rust oil from affecting the sample. Avoid exceeding the maximum pressure when applying pressure. Clean the mold and samples after use to prevent corrosion. Apply anti-rust oil and store the mold in a dry environment if not used for a long time to prevent damage.

Step 1: Placing the Mold.

To begin, place the mold in the center of the tablet press. It is important to note that the maximum pressure of the mold cannot be exceeded when pressurized. This will prevent any damage to the mold and ensure accurate test results.

Step 2: Cleaning the Mold.

After each use, it is essential to clean the mold to prevent any contamination of the sample. Using dust-free paper, wipe the surface of the mold clean. If there are sample residues on the surface that cannot be removed, please do not use chemical reagents to clean and soak. This could potentially damage the mold and impact the accuracy of the test results.

Step 3: Applying Anti-Rust Oil.

If the mold is not used for an extended period, it is recommended to apply anti-rust oil on the surface of the mold to prevent rusting. This step will help prolong the life of the mold and ensure that it remains in good condition for future use.

Step 4: Storing the Mold.

Lastly, if the mold is not used for a long time, it needs to be stored in a dry environment. This will prevent any moisture from accumulating on the mold and causing damage.

Full range of lab press types

Click to view our full range of lab press products.

Any question? Our experts have helped many laboratories choose their lab press, contact us now!

Full range of types of laboratory press molds

We have a full range of molds for you to choose from, and the molds fit the body perfectly.

If you need molds with special shapes, we can also customize them for you.

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is A Press Mold?

What Is Press Mould In Ceramics?

How Are Pellet Molds Used?

What Types Of Materials Can Be Pelletized Using Pellet Molds?

How Can One Select The Appropriate Pellet Mold For Their Specific Application?

4.8 / 5

The electric heating press mold is a fantastic tool for lab work. It heats up quickly and evenly, making it easy to get consistent results.

4.7 / 5

I've been using this press mold for a few months now and I'm really happy with it. It's well-made and durable, and it produces high-quality samples.

4.9 / 5

This press mold is a great value for the money. It's affordable and it works just as well as more expensive models.

4.6 / 5

I was impressed with the speed of delivery. I ordered the press mold on Monday and it arrived on Wednesday.

4.8 / 5

The customer service at KINTEK SOLUTION is excellent. I had a question about the press mold and they responded to my email within a few hours.

4.7 / 5

I'm very happy with the quality of the press mold. It's made of high-quality materials and it's built to last.

4.9 / 5

The press mold is very durable. I've been using it for several months now and it shows no signs of wear and tear.

4.6 / 5

I'm impressed with the technological advancements that KINTEK SOLUTION has made with this press mold. It's a very innovative product.

4.8 / 5

The press mold is very easy to use. I was able to set it up and start using it within a few minutes.

4.7 / 5

I'm very happy with the results that I'm getting from the press mold. It's producing high-quality samples that are consistent and repeatable.

4.9 / 5

The press mold is a great addition to my lab. It's a valuable tool that I use on a regular basis.

4.6 / 5

I would highly recommend the Cylindrical Lab electric heating Press Mold to anyone who needs a high-quality press mold for their lab.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Assemble Lab Cylindrical Press Mold

Get reliable and precise molding with Assemble Lab Cylindrical Press Mold. Perfect for ultra-fine powder or delicate samples, widely used in material research and development.

Anti-Cracking Press Mold for Lab Use

The anti-cracking press mold is a specialized equipment designed for molding various shapes and sizes of film using high pressure and electric heating.

Cylindrical Press Mold for Lab Applications

Efficiently form and test most samples with Cylindrical Press Molds in a range of sizes. Made of Japanese high-speed steel, with long service life and customizable sizes.

Special Heat Press Mold for Lab Use

Square, round and flat plate forming dies for hot presses.

Electric Heated Hydraulic Vacuum Heat Press for Lab

The Electric Vacuum Heat Press is a specialized heat press equipment that operates in a vacuum environment, utilizing advanced infrared heating and precise temperature control for high quality, rugged and reliable performance.

Double Plate Heating Press Mold for Lab

Discover precision in heating with our Double Plate Heating Mold, featuring high-quality steel and uniform temperature control for efficient lab processes. Ideal for various thermal applications.

Infrared Heating Quantitative Flat Plate Press Mold

Discover advanced infrared heating solutions with high-density insulation and precise PID control for uniform thermal performance in various applications.

Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

The electric tablet punching machine is a laboratory equipment designed for pressing various granular and powdery raw materials into discs and other geometric shapes. It is commonly used in pharmaceutical, healthcare products, food, and other industries for small batch production and processing. The machine is compact, lightweight, and easy to operate, making it suitable for use in clinics, schools, laboratories, and research units.

Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

KT-CTF14 Multi Heating Zones CVD Furnace - Precise Temperature Control and Gas Flow for Advanced Applications. Max temp up to 1200℃, 4 channels MFC mass flow meter, and 7" TFT touch screen controller.

Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

Experience the advantages of Silicon Carbide (SiC) Heating Element: Long service life, high corrosion and oxidation resistance, fast heating speed, and easy maintenance. Learn more now!

Vacuum Hot Press Furnace Machine for Lamination and Heating

Experience clean and precise lamination with Vacuum Lamination Press. Perfect for wafer bonding, thin-film transformations, and LCP lamination. Order now!

High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

Efficient and reliable, KinTek KHB Heating Circulator is perfect for your lab needs. With a max. heating temperature of up to 300℃, it features accurate temperature control and fast heating.

Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

The multi-punch rotary tablet press mold stands as a pivotal component in pharmaceutical and manufacturing industries, revolutionizing the process of tablet production. This intricate mold system comprises multiple punches and dies arranged in a circular fashion, facilitating rapid and efficient tablet formation.

Related Articles

Comprehensive Guide to Cylindrical Lab Electric Heating Press Mold: Technology and Applications

Explore the advanced features and applications of cylindrical lab electric heating press molds. Learn about their working principles, types of heating technologies, and key benefits for precise sample preparation.

How to choose lab press

In a laboratory environment, space is often limited, so the press must be designed to fit into the available space. The press must also be designed to be easy to use and easy to clean. The safety of the operator must be taken into account, as well as the safety of the equipment. Kindle Tech have summarized some of these conditions for you to consider how to choose a laboratory press.

Heat press operating steps and precautions

About the operating steps and precautions of the hot press machine.

Infrared Press Mold Techniques for Non-Demolding Applications

Explore advanced infrared press mold techniques without demolding. Learn about the benefits, applications, and best practices for non-demolding lab processes.

Understanding the Warm Isostatic Pressing Technique

Warm Isostatic Pressing (WIP) is a technique used in the manufacturing industry to form and press powder materials. It involves the use of a flexible material as the envelope die and hydraulic pressure as the medium to shape the material. Unlike traditional pressing methods, WIP utilizes a liquid medium that is heated and injected into a sealed pressing cylinder. This technique is particularly beneficial for materials with special temperature requirements or those that cannot be formed at room temperature.

The Benchtop KBr Pellet Press: An Efficient Tool for Laboratory Use

The benchtop KBr pellet press is a versatile and efficient tool that produces uniform pellets, ensuring consistent and reliable results. In addition, its adjustable mold can be used flexibly to accommodate a variety of sample sizes and shapes.

Pressing Powder Samples and Molding Polymer Films: A Comprehensive Guide

Pressing powder samples is done to create a solid material that remains intact even after the load is removed. This process involves pushing the powder grains closer together, closing the gaps between them and forcing them to flow and rearrange themselves into a more compact arrangement. As the available volume reduces, the flow of particles stops, and they undergo plastic and elastic deformations that result in bonding between the grains.

Advantages of the Rotating Electrode Method

Rotating electrode method involves rotating a small working electrode to increase the mass transport of reactants and products, allowing for more precise measurements and better control of reaction conditions.

Comprehensive Guide to Tube Furnaces: Types, Applications, and Considerations

Delve into the realm of tube furnaces, exploring their types, diverse applications in industries and laboratories, and crucial factors to consider for optimal usage.

CIP vs. Metal Mold Pressing What's the Difference

CIP and Metal Mold Pressing are used to create high-density components, but they differ in terms of the level of complexity required and the final outcome. Understanding these differences can help manufacturers determine which method is best suited for their needs.

Understanding Laboratory Press and its Functionality in Rubber Industry

In the rubber industry, laboratory presses play a crucial role in the manufacturing process. These presses are used for various purposes, such as rubber vulcanization and testing. Understanding how laboratory presses function is essential for ensuring efficient production and maintaining product quality. In this blog post, we will explore the functionality of laboratory presses in the rubber industry, including their role in the vulcanization process.

Operating of Automatic Lab xrf Pellet Press

How to use the Automatic Lab xrf Pellet Press, including steel ring, plastic ring, boric acid mold