Introduction to Infrared Press Molds

Infrared press molds represent a groundbreaking approach in the realm of non-demolding applications, leveraging advanced infrared technology to revolutionize lab processes. This article delves into the fundamental principles of infrared press molds, exploring how their integration into laboratory equipment enhances efficiency and precision. We will uncover the unique benefits these molds offer, such as reduced handling steps and improved outcomes, setting the stage for a comprehensive understanding of their design, setup, and operational techniques. Join us as we navigate through the diverse applications and future trends of infrared press molds, highlighting their significance in various industries and research fields.

Advantages of Infrared Press Molds in Non-Demolding

Infrared press molds have revolutionized the non-demolding process in various industries, offering significant advantages over traditional methods. These benefits include enhanced efficiency, superior precision, and reduced handling steps, making them a preferred choice for manufacturers worldwide.

Enhanced Efficiency

One of the primary advantages of using infrared press molds is the substantial increase in efficiency. Traditional methods often require lengthy sintering times and high power consumption, which can be both time-consuming and costly. In contrast, infrared press molds significantly reduce these factors. For instance, the sintering time can be shortened to approximately 2.5 hours, a reduction of more than 20 hours compared to traditional methods. Additionally, the power consumption is significantly lower, averaging around 700 KW h, which is far less than what traditional methods demand.

Superior Precision

Precision is another critical advantage of infrared press molds. These molds allow for more accurate control over the sintering process, resulting in products with uniform density and minimal warpage. This level of precision is crucial in industries where dimensional accuracy is paramount. For example, in metal casting, infrared press molds can help parts reach more precise tolerances, reducing or even eliminating the need for manual rework. This not only saves time but also decreases the amount of scrap material, making the production process more cost-effective.

Reduced Handling Steps

Infrared press molds also streamline the production process by reducing the number of handling steps required. Traditional methods often involve multiple stages, including pre-heating, pressing, and cooling, each of which requires manual intervention. Infrared press molds, however, integrate these steps into a single, continuous process. This not only minimizes the risk of human error but also speeds up the overall production cycle. For instance, the ability to obtain a sintered body close to theoretical density with near-zero porosity in a shorter time frame is a significant advantage.

Shape Flexibility and Component Size

Another notable benefit of infrared press molds is their flexibility in producing a wide range of shapes and sizes. Isostatic pressing, a key component of infrared press molds, makes it practical to produce complex shapes and dimensions that are difficult or impossible to achieve with other methods. This flexibility extends to the size of the components as well, ranging from massive 30-ton near-net PM shapes to smaller densifying parts of less than 100 grams. The part sizes are limited only by the size of the isostatic pressure chamber, providing manufacturers with unprecedented versatility.

Cost-Effectiveness

Infrared press molds are also highly cost-effective. The low tooling cost for short production runs is a significant advantage compared to other manufacturing methods. Additionally, the ability to bond dissimilar metals cost-effectively is another benefit. Traditional diffusion bonding can be expensive, especially when working with dissimilar materials. Infrared press molds, however, offer a more economical solution, allowing industries to produce unique parts while saving significant money.

Lower Mould Costs

The new sintering method employed by infrared press molds also results in lower mould costs. The reduced sintering temperature has a minimal impact on the mould, allowing it to be used for 4-5 times. If the mould can be taken out after lining, its service life can be even longer. This not only reduces the overall production cost but also ensures a more sustainable and environmentally friendly manufacturing process.

Conclusion

In conclusion, infrared press molds offer a multitude of advantages in non-demolding scenarios. These benefits include enhanced efficiency, superior precision, reduced handling steps, shape flexibility, cost-effectiveness, and lower mould costs. By leveraging these advantages, manufacturers can achieve higher productivity, better product quality, and reduced operational costs, making infrared press molds an indispensable tool in modern manufacturing.

Applications of Infrared Press Molds

Infrared press molds have revolutionized the manufacturing processes in various industries, particularly in ceramics, composites, and material science. These molds utilize infrared radiation to heat materials rapidly, enabling precise control over temperature and pressure, which is crucial for achieving high-quality end products. This technology has found extensive applications in several sectors, each benefiting from the unique capabilities of infrared press molds.

Ceramics Manufacturing

In the ceramics industry, infrared press molds are used for the production of high-performance ceramic components such as boron carbide, titanium diboride, and sialon. These materials are critical for applications requiring high thermal and mechanical resistance. The use of metal powder in infrared molds ensures ideal conductivity, allowing for rapid heating of the workpiece. This is particularly beneficial for materials that require brief exposure to high temperatures or those needing rapid heating for increased productivity.

Direct hot pressing technology, facilitated by infrared molds, allows materials to be sintered to their final density, achieving near net-shape precision. This often eliminates the need for mechanical reworking, which is particularly advantageous for materials that are difficult to process. For instance, in the friction material industry, infrared press molds play a significant role in the production of sintered brake pads and clutches. These components are essential for high-speed train applications, motorcycles, wind energy, ATVs, mountain bikes, and industrial machinery.

Composites and Advanced Materials

Infrared press molds are also instrumental in the fabrication of advanced composites and materials. They are used to create protective coatings, abrasive pastes, polishing powders, and various metal-ceramic welding applications. The rapid heating capabilities of infrared molds are particularly suited for processes like self-propagating high-temperature synthesis (SHS), where high efficiency and energy savings are paramount. This technology is moving from the experimental stage to industrial production, thanks to its advantages in efficiency and energy conservation.

Material Science Research

In the realm of material science research, infrared press molds are used for various sintering techniques, including microwave sintering and spark plasma sintering (SPS). Microwave sintering, for example, utilizes the dielectric loss of ceramic materials in microwave electromagnetic fields to achieve sintering and densification. This method offers rapid heating, uniform internal temperature distribution, and significant improvements in mechanical properties. It has broad application prospects in ceramic material preparation, including the production of sub-micron level ceramic materials.

SPS technology, another innovative sintering method, introduces DC pulse current into the sintering process. This technology offers low sintering temperatures, short holding times, and fast heating rates, making it suitable for a wide range of materials, including ultra-high temperature ceramics and refractory metals. SPS also enables the preparation of functionally graded materials and nanocrystalline transparent ceramics, showcasing its versatility in advanced material research.

High-Temperature Ceramic Applications

High-temperature ceramic applications, such as dental implants and advanced ceramic components, also benefit from infrared press molds. In dental implant manufacturing, ceramic composites are heated to extremely high temperatures with precise temperature control, ensuring that the final product does not shrink or distort. This level of precision is critical for dental applications, where the uniformity of the ceramic material directly impacts the functionality and longevity of the implant.

In summary, infrared press molds have become indispensable in various industries and research fields due to their ability to provide rapid, controlled heating and precise temperature management. From high-performance ceramic components to advanced composites and materials, the applications of infrared press molds continue to expand, driving innovation and improving the quality of end products across multiple sectors.

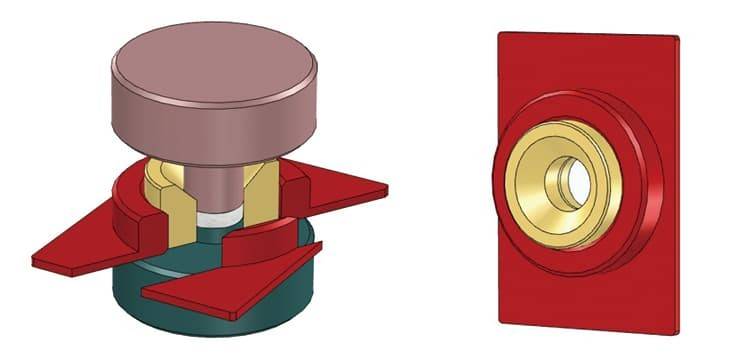

Design and Features of Infrared Press Molds

Infrared press molds are a specialized type of molding equipment that utilizes infrared heating technology to facilitate non-demolding processes. These molds are designed with specific characteristics that enhance their functionality, efficiency, and safety, making them ideal for various industrial applications.

Materials

Infrared press molds are typically constructed from high-quality materials that can withstand the high temperatures and pressures involved in the molding process. Common materials include:

- Graphite: Known for its excellent thermal conductivity and resistance to high temperatures, graphite is often used for molds that require precise temperature control. It is particularly suitable for hot pressing refractory metals.

- Super alloys: These materials are designed to maintain structural integrity under extreme conditions of temperature and pressure. They are commonly used in molds for hot pressing most powders.

- Ceramics: Ceramic materials offer high thermal resistance and are often used in molds where high temperatures and chemical resistance are required.

Heating Elements

The heating elements in infrared press molds are critical for achieving uniform and controlled heating. These elements are typically designed to emit infrared radiation, which penetrates the material being molded, resulting in efficient and rapid heating. Key features of the heating elements include:

- Infrared Emitters: These are strategically placed within the mold to ensure even distribution of heat. They can be adjusted to emit specific wavelengths of infrared radiation, optimizing the heating process for different materials.

- Temperature Control Systems: Advanced temperature control systems allow for precise regulation of the heating elements. This ensures that the mold reaches and maintains the desired temperature throughout the molding cycle.

Safety Features

Safety is a paramount consideration in the design of infrared press molds. Several features are incorporated to protect both the equipment and the operators:

- Thermal Protection: Insulation materials are used to prevent heat loss and protect surrounding areas from high temperatures. This includes heat-resistant coatings and barriers around the mold.

- Pressure Relief Systems: Mechanisms are in place to safely release pressure in case of overpressure situations. This prevents damage to the mold and ensures operator safety.

- Emergency Shutdown: Infrared press molds are equipped with emergency shutdown systems that can quickly deactivate the heating elements and pressure systems in case of an emergency.

Non-Demolding Capabilities

One of the key advantages of infrared press molds is their ability to facilitate non-demolding processes. This is achieved through several design features:

- Smooth Surface Finish: The inner surfaces of the molds are meticulously finished to ensure a smooth surface that minimizes the adhesion of the molded material. This allows for easy removal of the molded product without damage.

- Controlled Cooling: A controlled cooling system is integrated into the mold to solidify the molded material at the appropriate temperature before demolding. This ensures that the product maintains its shape and integrity.

- Pressure Control: The pressure applied during the molding process is carefully regulated to prevent deformation and ensure uniform compaction of the material. This results in a high-quality product that can be easily removed from the mold.

Applications

Infrared press molds are versatile and can be used in a wide range of applications, including:

- Ceramic Molding: For producing high-quality ceramic products with precise dimensions and smooth surfaces.

- Metal Powder Compaction: For creating dense and uniform metal parts with excellent mechanical properties.

- Thermoplastic Molding: For molding thermoplastic materials into complex shapes with controlled cooling and minimal stress.

Conclusion

Infrared press molds are a sophisticated and efficient solution for various molding processes. Their design characteristics, including high-quality materials, advanced heating elements, and robust safety features, make them ideal for achieving high-quality products with minimal effort. By leveraging the unique capabilities of infrared heating, these molds offer a reliable and cost-effective method for non-demolding processes in a wide range of industries.

Future Trends in Infrared Press Mold Technology

Infrared press mold technology is poised for significant advancements, driven by innovations in materials, process optimization, and computational simulations. These developments are set to expand the applications of infrared press mold technology, particularly in non-demolding contexts.

Material Innovations for Sintering Molds

The current standard for sintering molds in technologies like Spark Plasma Sintering (SPS) is graphite due to its high-temperature resistance and excellent electrical and thermal conductivity. However, graphite molds suffer from low strength, short lifespan, and potential contamination of sintered materials. To address these issues, research is exploring alternative materials such as cemented carbide molds, conductive ceramic molds, and carbon fiber graphite molds. These new materials aim to provide higher strength, longer reusability, and reduced contamination, thereby enhancing the overall performance and reliability of infrared press mold technology.

Advancements in Finite Element Simulation

Finite element simulation is emerging as a critical tool in understanding and optimizing the sintering processes within infrared press mold technology. Traditional methods often fall short in accurately analyzing the complex interactions within the sintering environment. Simulation software like ABAQUS, MATLAB, and MSC.MARC allows for detailed modeling of temperature and electric field distributions during the sintering process. This capability enables researchers to analyze the specific impacts of various sintering parameters and gain deeper insights into the sintering mechanism. Such simulations are invaluable for predicting test results and providing theoretical guidance for production, thereby reducing the need for extensive experimental trials.

Integration with Metal 3D Printing and Hot Isostatic Pressing

The integration of infrared press mold technology with metal 3D printing and hot isostatic pressing (HIP) is a promising trend. Metal 3D printing has revolutionized the production of complex geometries, but post-processing steps like HIP are often necessary to eliminate internal porosity and micro-cracks. The combination of these technologies forms a comprehensive process package, particularly for materials like titanium and nickel-based alloys. This integration ensures that the final products meet the highest standards of performance and reliability, opening up new possibilities in aerospace, automotive, and other high-tech industries.

Applications in High-Performance Ceramics and Friction Materials

Infrared press mold technology is also making significant strides in the production of high-performance ceramics and friction materials. For instance, the manufacture of sputtering targets and advanced ceramic components like boron carbide and titanium diboride is now feasible with this technology. The ability to achieve high heating rates and precise temperature control makes infrared press mold technology ideal for these applications. Additionally, direct hot pressing technology is increasingly used in the production of sintered brake pads and clutches, which are critical for high-speed trains, motorcycles, and industrial applications. These advancements not only enhance the performance of these components but also streamline the manufacturing process, reducing costs and improving efficiency.

Automation and Control Systems

The future of infrared press mold technology also involves advancements in automation and control systems. Features such as digital pressure regulation systems and controlled cooling devices are becoming standard, allowing for precise control over the molding process. These systems enable the storage and execution of multiple molding cycles, each with up to 24 steps, including displacements, temperature setups, and pressure setups. Such precision and automation are essential for maintaining consistent quality and performance across a wide range of applications.

Conclusion

The future of infrared press mold technology is bright, with significant advancements on the horizon. Innovations in materials, computational simulations, integration with other technologies, and improvements in automation and control systems are set to expand the capabilities and applications of this technology. As these trends continue to evolve, infrared press mold technology will play an increasingly vital role in various industries, driving innovation and improving the performance and reliability of critical components.

Related Products

- No Demolding Lab Infrared Press Mold for Laboratory Applications

- Infrared Heating Quantitative Flat Plate Press Mold

- Lab Infrared Press Mold

- Anti-Cracking Press Mold for Lab Use

- Special Shape Press Mold for Lab