Introduction

Table of Contents

The Benchtop KBr Pellet Press is a versatile and efficient tool that offers numerous benefits for laboratory use. Whether you're working in pharmaceutical, biological, or nutrition laboratories, this device is designed to make your job easier. With its compact design and convenience, it takes up minimal space while providing maximum functionality. The KBr Pellet Press is capable of producing uniform pellets, ensuring consistent and reliable results. Additionally, its adjustable dies allow for flexible use, accommodating various sample sizes and shapes. Say goodbye to tedious and time-consuming sample preparation – the KBr Pellet Press is here to streamline your laboratory workflow.

Features and Functionality of KBr Pellet Press

Compact design and convenience

The KBr Pellet Press is a compact, hand-operated press that can be used anywhere in the laboratory without the need for fixed mounting. It requires very little bench space, making it convenient for laboratories of all sizes. With its portable design, you can easily move it around as needed.

Production of uniform pellets

One of the key features of the KBr Pellet Press is its ability to produce uniform pellets. The press uses a polished die to compress powdered materials into cylindrical pellets with flat ends. The height or thickness of the pellets can be adjusted based on the amount of material compressed and the force applied. This uniformity ensures consistent results in your experiments and analyses.

Flexible use with adjustable dies

The KBr Pellet Press is designed for flexibility. The dies used in the press are not fastened down, allowing for easy alignment with the press ram. This means you can quickly reload the dies by simply slipping them out from under the ram. This feature saves time and makes the press more efficient for your laboratory operations.

In summary, the KBr Pellet Press offers a compact design and convenience, allowing you to use it anywhere in the laboratory. It produces uniform pellets with its polished die, ensuring consistent results in your experiments. The flexibility of adjustable dies makes reloading quick and easy. If you're in pharmaceutical, biological, nutrition, or spectrographic operations, the KBr Pellet Press is an excellent choice for fabricating pellets for your laboratory needs.

Working Mechanism of the KBr Pellet Press

Compressive force generation

The KBr Pellet Press is a benchtop device that provides a convenient and economical solution for compressing powdered materials into pellet or tablet form. It eliminates the need for expensive tablet making machinery. This compact and hand-operated press can be used in any laboratory, requiring minimal bench space and no fixed mounting.

To generate the compressive force, the press utilizes a lever attached to a large steel cam. As pressure is applied to the lever, the mechanical advantage steadily increases up to a ratio of approximately 50 to 1 at the end of the stroke. For example, a force of 20 pounds applied to the lever can develop approximately 1000 pounds of force on the press ram. This level of force is sufficient to produce firm pellets from most powdered materials, usually without the need for adding a binder.

Role of the lever and steel cam

The lever and steel cam play a crucial role in the operation of the KBr Pellet Press. When pressure is applied to the lever, it transfers the force to the steel cam. The cam then converts this rotational motion into linear motion, exerting a powerful force on the press ram. This mechanism ensures that the force applied is efficiently transmitted to the material being compressed.

Transference of force to the press ram

The press ram is responsible for applying the force to the material inside the die. The dies in the KBr Pellet Press are not fastened down but automatically align with the press ram. This design allows for quick reloading, as the dies can be easily slipped out from under the ram.

The height or thickness of the pellets produced depends on the amount of material compressed and the force applied. The KBr Pellet Press produces uniform pellets with cylindrical shape and flat ends. These pellets are ideal for various laboratory applications, including pharmaceutical, biological, nutrition, and spectrographic operations. Spectroscopists find this device particularly useful for preparing small samples to be analyzed in an emission spectrometer.

In summary, the KBr Pellet Press offers a simple yet effective working mechanism for compressing powdered materials into pellet form. With its compact size and hand-operated operation, it provides an affordable solution for laboratories looking to produce uniform and high-quality pellets without the need for expensive equipment.

Adjustable Anvil and its Benefits

Adjustability for desired pellet thickness

The anvil in a Pellet Press is attached to a heavy screw post, allowing it to be raised or lowered. This adjustability feature enables the production of pellets with any desired thickness using the maximum force of the press. By rotating the anvil to raise or lower the die, business professionals can easily customize the thickness of the pellets according to their specific requirements.

Compensation for volume reduction with fluffy materials

When compressing light or fluffy materials, the volume of the charge tends to reduce. However, with the adjustable anvil, this issue can be easily addressed. By raising the die after successive ram strokes, the anvil compensates for the reduction in the volume of the charge. This ensures that the resulting pellets maintain the desired volume and density.

Pressure adjustment for pellet production

The variable anvil setting also allows for the adjustment of the pressure applied to a pellet. This feature is particularly useful when business professionals require pellets of equal density. By using equal amounts of sample and leaving the anvil at a fixed setting, while taking the ram through its full stroke when forming each pellet, duplicate pellets of equal density can be achieved.

In addition to these benefits, the adjustable anvil offers other advantages for business professionals:

- The ability to produce pellets of different sizes, ranging from smaller diameters to larger ones.

- Improved accuracy in applying force, especially for smaller pellets, ensuring precise and consistent results.

- Enhanced safety features, including a Perspex safety guard and pressure gauge, to minimize the risk of accidents during the pressing process.

- The option to use extremely hard tungsten carbide polished anvils for abrasive samples, ensuring high-quality pellets and briquettes.

Overall, the adjustable anvil in a Pellet Press provides business professionals with the flexibility and control needed to produce pellets of varying thickness, compensate for volume reduction with fluffy materials, and adjust pressure for pellet production. With these benefits, professionals can achieve desired pellet characteristics and improve the efficiency of their pellet production processes.

Applications of the KBr Pellet Press

The KBr Pellet Press has a wide range of applications in various laboratory settings. It is particularly useful in pharmaceutical, biological, and nutrition laboratories. Additionally, spectroscopists benefit greatly from using this device for their operations. One specific application of the KBr Pellet Press is in the preparation of samples for emission spectrometry.

Use in Pharmaceutical, Biological, and Nutrition Laboratories

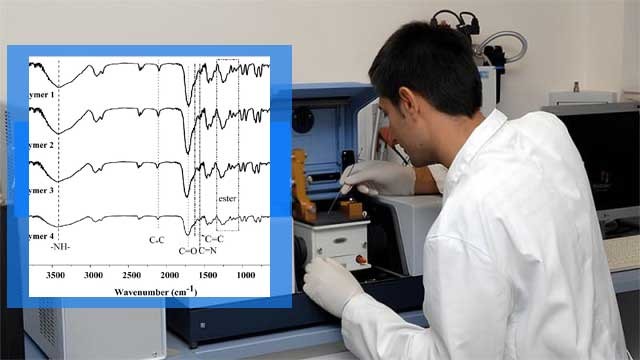

Laboratories in the pharmaceutical, biological, and nutrition industries often utilize the KBr Pellet Press for various tasks. One common application involves pressing sample pellets using a mixture of potassium bromide (KBr) and an organic sample. These pellets are then used for infrared spectroscopy, allowing researchers to analyze the chemical composition of substances. The KBr Pellet Press provides an efficient and cost-effective method of producing these pellets without the need for expensive laboratory presses and pellet dies.

Benefit for Spectroscopic Operations

Spectroscopists find the KBr Pellet Press to be a valuable tool for their operations. It enables them to prepare small samples that can be analyzed in an emission spectrometer. By compressing powdered materials into pellet form, spectroscopists can obtain uniform and consistent samples for their analyses. The KBr Pellet Press is compact, hand-operated, and requires minimal bench space, making it convenient for use in any laboratory setting.

Preparation of Samples for Emission Spectrometer

One specific application of the KBr Pellet Press is in the preparation of samples for emission spectrometry. This technique involves analyzing the light emitted by a sample when it is excited by an energy source. The KBr Pellet Press allows researchers to create uniform and well-formed pellets that can be easily analyzed in an emission spectrometer. This ensures accurate and reliable results in spectroscopic analyses.

In conclusion, the KBr Pellet Press is a versatile tool with various applications in pharmaceutical, biological, and nutrition laboratories. It is particularly beneficial for spectroscopists who require high-quality samples for their operations. The compact and hand-operated design of the press makes it a convenient and cost-effective choice for laboratories of all sizes.

Conclusion

In conclusion, the KBr Pellet Press proves to be an invaluable tool for laboratory use. Its compact design and convenience make it easy to use and store. The production of uniform pellets ensures accurate and reliable results in various applications. The adjustable dies provide flexibility for different sample sizes and shapes. The compressive force generation, lever, and steel cam work together seamlessly to transfer force to the press ram, ensuring efficient pellet production. With its adjustable anvil, the pellet press allows for desired pellet thickness, compensation for volume reduction with fluffy materials, and pressure adjustment. Overall, the KBr Pellet Press is a must-have for professionals in pharmaceutical, biological, and nutrition laboratories, as well as for spectroscopic operations and sample preparation for emission spectrometers.

If you are interested in this product you can browse our company website:https://kindle-tech.com/product-categories/heated-lab-press, we always insist on the principle of quality first. During the production process, we strictly control every step of the process, using high quality materials and advanced production technology to ensure the stability and durability of our products. to ensure that their performance meets the highest standards. We believe that only by providing customers with excellent quality can we win their trust and long-term cooperation.

Related Products

- kbr pellet press 2t

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

Related Articles

- Choosing the Right Lab Press: A Comprehensive Guide

- Manual Hydraulic Pellet Press: An Efficient Tool for Spectral Analyses Preparation

- A Comprehensive Guide on Pressing XRF Pellets Using a KinTek Automatic Hydraulic Press

- Automated laboratory XRF and KBR pellet press operating procedures

- Comprehensive Guide to Manual Hydraulic Pellet Press