Introduction

Table of Contents

The Benchtop KBr Pellet Press is a versatile and essential tool in various laboratory settings. Whether you work in pharmaceuticals, biology, nutrition, or spectrography, this compact and user-friendly press will simplify your sample preparation process. With its space-saving design, you won't need to worry about dedicated mounting. The automatic alignment feature ensures quick reloading, saving you valuable time. In the following sections, we will explore the features, mechanism, and applications of this efficient pellet press. So, let's dive in and discover how this tool can enhance your laboratory workflow.

Compact and User-friendly Design

A hydraulic bench press is an essential tool for various pressing tasks. One of its main advantages is its compact and user-friendly design. Here are some key features that make it a great choice:

Compact, hand-operated press

The hydraulic bench press is designed to be compact and easy to operate. It doesn't take up much space on your workbench, making it suitable for workshops with limited area. Despite its small size, it offers ample force for heavy pressing tasks.

Requires little bench space

Unlike other heavy machinery, the hydraulic bench press requires little bench space. It can be easily placed on a workbench or table without the need for a dedicated mounting. This makes it a versatile tool that can be used in various work environments.

No fixed mounting required

With a hydraulic bench press, there is no need for fixed mounting. You can easily move it around and place it wherever you need it for your pressing tasks. This flexibility allows you to optimize your workspace and make the most out of your available area.

Automatic alignment with press ram for quick reloading

The hydraulic bench press is equipped with automatic alignment features that ensure quick and efficient reloading. This saves you time and effort, allowing you to focus on your pressing tasks without any hassle.

In conclusion, the compact and user-friendly design of a hydraulic bench press makes it a valuable tool for various pressing tasks. Its small size, easy operation, and flexibility make it suitable for any workshop or work environment. Whether you need to press bearings, remove gears, or perform other press-fit tasks, a hydraulic bench press is a reliable and efficient choice.

Pellet Form and Compression

Cylindrical pellets with flat ends

The benchtop KBr Pellet Press produces uniform pellets in a polished die. These pellets are cylindrical in shape with flat ends. The shape of the pellets ensures consistency and stability during analysis.

Pellet height depends on material volume and applied force

The height or thickness of the pellets depends on the amount of material compressed and the force applied. By adjusting these parameters, you can control the size and density of the pellets.

Smooth pellet ejection into a receiver

After compression, the pellets are smoothly ejected into a receiver without any contamination. This ensures the integrity of the pellets and prevents any interference with subsequent analysis.

What is a pellet die?

A pellet die is a tool used to form thin cylindrical pellets from a powder using a pellet press. It consists of a hollow cylindrical body capped at one end, forming a blind tube into which the powder sample is poured.

How does a pellet die work?

The pellet die is inserted into a press, which applies a load to the plunger inserted into the tube. The load compresses the powder against the base and walls of the tube. With sufficient pressure, the powder grains bind together to form a solid pellet. The pellet can then be removed by separating the base from the body and applying a small load to the plunger.

Laboratory pellet dies

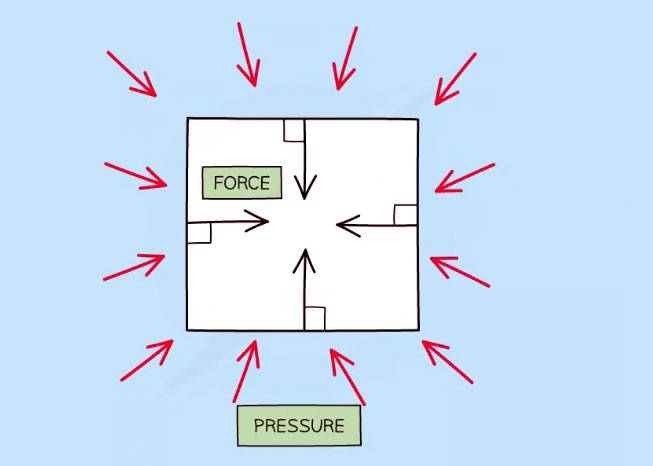

In laboratory settings, pellet dies are commonly used to prepare test specimens for analysis. The press applies a fixed load to the work between the platens. The pressure experienced by the work depends on the area over which the force is applied.

However, there is a trade-off between pellet size and compaction pressure that can be achieved. Pellet dies have a maximum rated load, which limits the pressure to under 1000 MPa. Achieving higher pressures may require a larger load or a larger die size.

Pressed pellets and sample characteristics

Pressed pellets are prepared by pressing loose powders filled in a ring or cup using a set of dies and a press machine. The selection of die type depends on the characteristics of the sample. Ease of pelletization can be improved by sufficient pulverization or by mixing the powder sample with a forming agent (binder).

When using spectroscopy for analysis, it is important to ensure that any binder used does not come into contact with the primary powder. Therefore, it is preferable to create pellets without the assistance of a binder.

Benefits of using a Pellet Press

KinTek's benchtop Pellet Press provides a convenient and economical solution for compressing powdered materials into pellet or tablet form. It is a compact, hand-operated press that requires very little bench space and no fixed mounting.

The Pellet Press produces uniform pellets in a polished die and ejects them smoothly into a receiver without any contamination. The cylindrical shape with flat ends ensures consistency and stability during analysis. The dies can be easily reloaded, making the process efficient and convenient.

Mechanism of Compressive Force

A hydraulic press is a powerful tool that utilizes Pascal's Law to generate a significant amount of force. Pascal's Law states that the pressure exerted on a confined fluid is transmitted undiminished, resulting in a magnified force. In the case of a hydraulic press, a small mechanical force is applied to a small area, which then generates a larger force on a larger area.

The mechanism of a hydraulic press involves the application of hand pressure on a lever attached to a steel cam. This lever system is designed to provide a steadily increasing mechanical advantage, reaching a force ratio of approximately 50 to 1 at the end of the stroke. For example, applying a force of 20 pounds on the lever can generate approximately 1000 pounds on the press ram.

The hydraulic press operates by exerting a force on a confined fluid, typically hydraulic oil or water. This force is transmitted through the fluid to a larger surface area, resulting in a magnified mechanical force. The press uses hydraulic pressure to achieve this amplification, with the initial effort creating the pressure that is then transmitted to the larger area.

A hydraulic press finds application in various industries, including laboratories. In a laboratory setting, it is commonly used to prepare samples for analysis. By compressing particles into pellets or thin films, a hydraulic press creates a homogenous sample that is ideal for spectroscopic examination.

One example of a hydraulic press is the KinTek Manual Hydraulic Press, which is a classic Bramah Press. It operates by applying pressure manually using a handle to pump pressure into the hydraulic fluid system. The resulting force can be as great as 25 tons, making it suitable for a wide range of applications.

In addition to the traditional hydraulic press, alternative compression technologies have been developed to address specific needs. For instance, shock compression, also known as shock-wave compaction, involves the generation of a short, high-pressure shock wave to deform particles and achieve full density without grain growth. Methods such as air guns and explosive shock waves are used to compress nanopowders, providing a unique solution for compressing micron-sized powders.

In summary, the mechanism of a hydraulic press relies on Pascal's Law to generate a significant compressive force. By applying a small mechanical force on a lever attached to a steel cam, the press system provides a steadily increasing mechanical advantage, resulting in a magnified force on the press ram. This force amplification enables the hydraulic press to be used for various applications, including sample preparation in laboratories.

Adjustable Anvil and Die Settings

An adjustable anvil and die setting is an essential feature in pellet presses, allowing for greater control and flexibility in pellet production. Here are some key points about adjustable anvil and die settings:

Anvil attached to a heavy screw post

The anvil, which supports the die in the pellet press, is attached to a heavy screw post. This design allows the anvil to be raised or lowered, enabling the production of pellets of varying thickness. By rotating the anvil, you can adjust the height of the die and utilize the maximum force of the press.

Ability to raise or lower the die

With the adjustable anvil and die settings, you have the ability to raise or lower the die during the pellet production process. This feature is particularly useful when compressing light or fluffy materials. By raising the die after successive ram strokes, you can compensate for the reduction in the volume of the charge. This ensures consistent pellet density and quality.

Can produce pellets of any desired thickness

One of the main advantages of adjustable anvil and die settings is the ability to produce pellets of any desired thickness. By rotating the anvil and adjusting the height of the die, you can control the thickness of the pellets with precision. This is important when working with different sample types and applications that require specific pellet thickness.

Anvil rotation used for adjusting pellet pressure

In addition to adjusting pellet thickness, the rotation of the anvil can also be used to adjust the amount of pressure applied to a pellet. This feature allows for fine-tuning the pellet density and hardness according to the requirements of your analysis or experiment. If you need duplicate pellets of equal density, you can achieve this by using equal amounts of sample and keeping the anvil at a fixed setting while forming each pellet.

Adjustable anvil and die settings provide the flexibility and control needed for producing high-quality pellets and briquettes. The ability to raise or lower the die, along with anvil rotation, allows for precise adjustments in pellet thickness and density. Whether you are conducting XRF analysis or other applications, these features ensure consistent and accurate results.

Note: The weight reduction in the die sets and the availability of optional tungsten carbide polished anvils are not mentioned in the provided content.

Conclusion

The Benchtop KBr Pellet Press is a compact and user-friendly tool that offers numerous benefits for various laboratory applications. Its hand-operated design requires little bench space and eliminates the need for fixed mounting. With automatic alignment, reloading is quick and efficient. The mechanism of compressive force, provided by a lever and steel cam, ensures a steadily increasing mechanical advantage. The adjustable anvil and die settings allow for precise control over pellet thickness and pressure. This versatile tool is widely used in pharmaceutical, biological, nutrition, and spectrographic laboratories, making it an essential asset for professionals in these fields.

If you are interested in our products, please visit our company website, where innovation has always been a priority. Our R&D team consists of experienced engineers and scientists who closely follow industry trends and are constantly pushing the boundaries of what is possible. Our laboratory equipment incorporates the latest technology to ensure that you can obtain accurate and repeatable results during your experiments. From high-precision instruments to intelligent control systems, our products will provide you with unlimited possibilities for your experimental work.

Related Products

- kbr pellet press 2t

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

Related Articles

- Benchtop KBr Pellet Press: A Comprehensive Overview

- The Benchtop KBr Pellet Press: An Efficient Tool for Laboratory Use

- An In-Depth Guide on Laboratory Presses and KBr Pellets Production

- Manual Hydraulic Pellet Press: An Efficient Tool for Spectral Analyses Preparation

- How to choose a laboratory hot press