Introduction

CIP (Cold Isostatic Pressing) and Metal Mold Pressing are two methods for pressurizing materials used in the manufacturing of various products. CIP is a process that involves applying pressure to a material in a liquid-filled container, while Metal Mold Pressing is a method that involves pressing a material between two dies. Both methods are used to create high-density components, but they differ in terms of the level of complexity required and the final outcome. Understanding these differences can help manufacturers determine which method is best suited for their needs.

Table of Contents

Definition of CIP and Metal Mold Pressing

CIP and metal mold pressing are two popular methods used to produce high-quality ceramic products. CIP, or cold isostatic pressing, is a technique that involves compressing a powder into a mold using high-pressure water or oil. The pressure is applied uniformly in all directions, resulting in a dense ceramic product that is free from defects. This method is ideal for producing complex shapes and large parts that require high strength and precision.

On the other hand, metal mold pressing involves using a metal mold to shape the ceramic powder into the desired form. The mold is filled with the powder and then pressed using a hydraulic press. This method is suitable for producing simple shapes and small parts that require high accuracy and consistency. The ceramic product produced using metal mold pressing is often less dense than that produced using CIP but is still of high quality.

In principle, CIP and metal mold pressing have different pressurization processes. CIP applies isostatic pressure to materials using liquid pressure, while metal mold pressing applies only uniaxial pressure. Therefore, CIP can produce a product with a uniform density and homogeneity due to no frictions with a metal mold.

CIP is a powder-based, near-net-shape technology for the production of metal and ceramic components. It is quite similar to another process known as metal mold processing. CIP functions based on a principle proposed by Blaise Pascal. This principle is popularly known as Pascal’s law and it states that pressure applied in an enclosed fluid is transmitted in all directions throughout the fluid without any change in the magnitude of the pressure.

In contrast, metal mold pressing is very similar to CIP. In this pressing method, powder materials are filled into a space enclosed by the metal mold and the lower punch. Then, they are compressed by narrowing the distance between the upper and lower punches. Metal mold pressing equipment for industrial use has a series of automated processes from powder filling to removal of a molded body.

In summary, CIP and metal mold pressing are two different techniques used to produce ceramic products, each with its advantages and disadvantages. The choice of which method to use depends on the specific requirements of the product being produced. CIP is suitable for producing complex shapes and large parts that require high strength and precision, while metal mold pressing is suitable for producing simple shapes and small parts that require high accuracy and consistency.

Principle of CIP and Metal Mold Pressing

CIP and metal mold pressing are two commonly used methods for producing ceramic materials. The key difference between these two methods is the mechanism used to shape the ceramic powder.

CIP

CIP, or cold isostatic pressing, uses a pressurized fluid to compress the ceramic powder into a desired shape. The process involves placing the powder into a flexible mold and then immersing it in a pressurized fluid. The pressure is applied uniformly in all directions, resulting in a uniform density and a high-quality product. This technique is best suited for relatively large, complex-shaped components that cannot be produced by other methods.

Metal Mold Pressing

On the other hand, metal mold pressing involves pressing the ceramic powder into a metal mold using a hydraulic press. This method is commonly used for producing small and intricate shapes. The metal mold is used to shape the ceramic powder, and then the product is sintered to achieve a high-density product.

Key Differences

The main difference between these two techniques is that CIP uses a pressurized fluid to shape the ceramic powder, while metal mold pressing uses a metal mold. CIP is a solid-state process that overcomes some of the challenges associated with casting, such as directional properties, nonuniform microstructure, and subsurface defects.

Advantages of CIP

CIP has several advantages over metal mold pressing. One of the primary advantages is that it allows for greater design freedom, making it possible to produce parts with undercuts, overhanging features, or partially enclosed cavities. It is also suitable for relatively large parts, with the only limitation being the pressure vessel size. Additionally, the CIP flexible tool is reusable, making it significantly cheaper than other processes that require a costly sacrificial metal tool for each part.

Advantages of Metal Mold Pressing

Metal mold pressing has advantages as well. It is commonly used for producing small and intricate shapes, making it ideal for mass production of components such as spark plug insulators, specialty wear components, and electrical insulators. Additionally, it is a relatively low-cost process that is ideal for shape complexity and large production runs.

In conclusion, both CIP and metal mold pressing are important techniques used in the production of high-quality ceramic materials. The choice of which method to use depends on the specific requirements of the product. While CIP is best suited for relatively large, complex-shaped components, metal mold pressing is best for producing small and intricate shapes. Understanding the principles of these techniques is essential for anyone working in the field of laboratory equipment.

Comparison of Pressurization Processes

Introduction

In the world of laboratory equipment, two methods of pressurization are commonly used: CIP (cold isostatic pressing) and metal mold pressing. Both methods are used to compact powders into solid and dense objects that can be used as samples or for further testing.

Pressure Application

The main difference between the two methods lies in the way the pressure is applied. In CIP, the powder is placed in a flexible container and compressed with equal pressure from all directions, resulting in a uniform density. In metal mold pressing, the powder is placed in a rigid mold and compressed with a unidirectional force, resulting in a density gradient.

Preferred Applications

Metal mold pressing is often preferred when a specific shape is desired, while CIP is preferred when uniformity is necessary. Additionally, CIP is more suitable for materials that are difficult to compress or have a tendency to crack under pressure. Overall, the choice between CIP and metal mold pressing depends on the specific requirements of the experiment or application.

Advantages of CIP

CIP offers several advantages over other similar processes. One of these advantages is its versatility. CIP can be used to produce difficult shapes which cannot be produced by other methods. In addition, CIP can be used to produce large-sized materials. The only limitation to the size of materials produced by this method is the size of the pressure vessel.

Advantages of Metal Mold Pressing

Metal mold pressing is preferred when a specific shape is desired. This method is often used for mass production of simple shapes. Additionally, metal mold pressing is often faster than CIP, as it is a simpler process.

Applications of CIP in the Laboratory

CIP is commonly used in the laboratory for a variety of applications. For example, it is used when you want to reach a higher density before sintering, when your pellet keeps falling apart before you can sinter it, or when you have a large aspect ratio. CIP is also used when pressing an irregular shape such as a donut or a shape which changes dimensions along its length.

CIP Wetbags and Molds

Cold Isostatic Pressing is also termed "wetbag" pressing, because the outside of the bag gets wetted by the pressing fluid. CIP requires an appropriate bag to press your sample but you have a lot of pretty easy and low-cost options. Even thin flexible materials such as latex and rubber will stand up against very high pressures as they are not particularly highly strained (elongated) under this high pressure when pressed against something which does not elongate as much.

Conclusion

Both CIP and metal mold pressing have their own advantages and disadvantages. The choice of which method to use depends on the specific requirements of the experiment or application. However, CIP is more versatile and preferred when uniformity is necessary. Metal mold pressing is preferred when a specific shape is desired or for mass production of simple shapes.

Differences in density distribution

The two common methods of producing dense ceramic or metallic parts are CIP (Cold Isostatic Pressing) and Metal Mold Pressing. The main difference between these two methods is the way the powder is compressed, which results in differences in density distribution across the final part.

CIP

In CIP, the powder is placed into a rubber mold and subjected to high-pressure isostatic compression from all directions. This results in a uniform density distribution throughout the part. The absence of wall friction, as pressure is being applied from all directions, produces compacts of practically uniform grain structure and density, irrespective of shape. CIP is preferred when a uniform density distribution is required.

Metal Mold Pressing

On the other hand, in metal mold pressing, the powder is compacted under high pressure in a metal mold, resulting in a density gradient across the part. The highest density is at the center of the part, and the density decreases towards the edges. This is because the powder particles near the edges of the mold experience less pressure than those in the center. Powders with irregular particle morphology are generally preferred for CIP, which enhances green strength. However, in metal mold pressing, both coarse and fine powders have been successfully used.

Comparison

The choice between these two methods depends on the desired properties of the final product. CIP is preferred when a uniform density distribution is required. Metal mold pressing is commonly used when a gradient of density is desired. The densification behavior of metal powders during CIP, and, hence, the quality of the final part, are impacted by both the morphological and mechanical characteristics of metal powders.

In conclusion, both CIP and metal mold pressing have their own advantages and disadvantages, and the selection of the appropriate method depends on the specific application. CIP is preferred when a uniform density distribution is required, while metal mold pressing is commonly used when a gradient of density is desired.

Types of CIP Processing

When it comes to producing high-quality laboratory equipment using the CIP process, there are two main types of processing methods: Hot Isostatic Pressing (HIP) and Cold Isostatic Pressing (CIP).

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing is a process that utilizes high temperatures and pressures to consolidate metal powders into solid parts. It involves the use of an argon atmosphere or other gas mixtures heated up to 3000º F and pressurized up to 100,000 psi to process powders and other materials into dense preformed metals, plastics and ceramics. HIP is used to create high-density materials, which makes it ideal for producing parts that require high strength, toughness, and resistance to wear and tear. HIP is commonly used in the production of high-performance ceramics, ferrites and cemented carbides, net-shape forming of nickel-base super alloy and titanium powders, compacting of high-speed tool steel, diffusion bonding of similar and dissimilar materials, and eliminating voids in aerospace castings.

Cold Isostatic Pressing (CIP)

Cold Isostatic Pressing is a process that involves compressing metal powders into solid parts using high pressure from all directions. The powder is placed in a rubber mold and then subjected to high pressure from all directions, resulting in a uniform density and shape. CIP is used to create materials that are more porous and lightweight. In contrast to HIP, CIP is used to create parts that require less density and more uniformity. CIP is used in various industries, including medical implants and stainless steel filter cartridges.

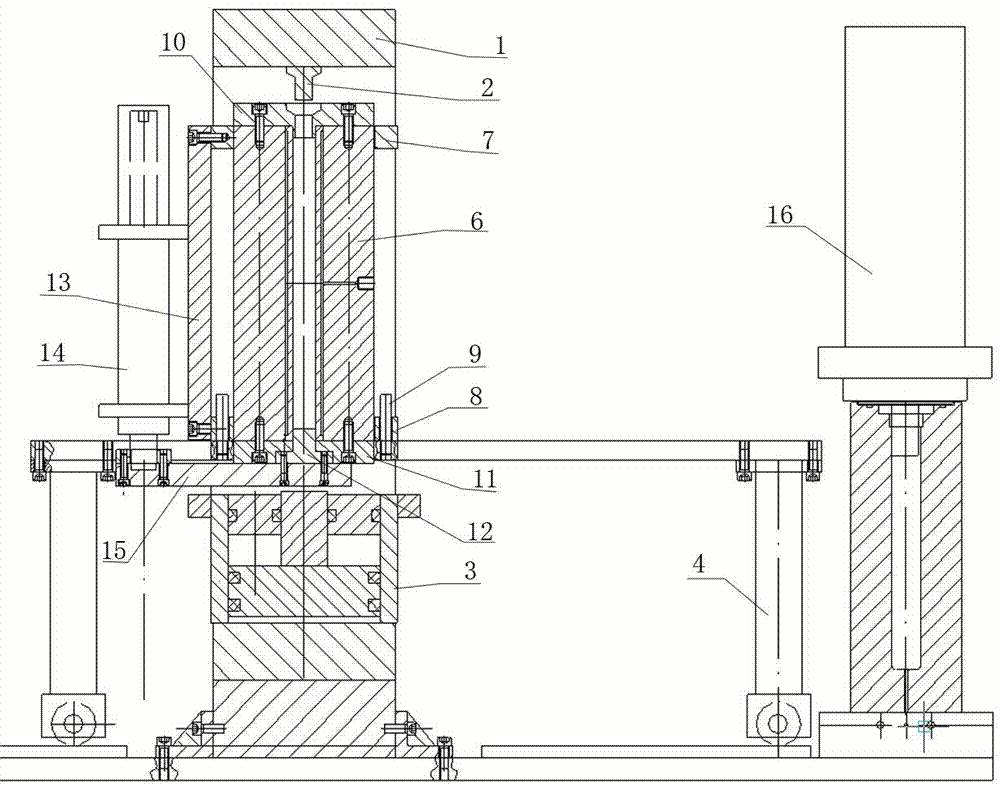

Wet Bag Processing

In wet bag cold isostatic pressing (CIP), the material is preformed then sealed in a flexible bag or mold. The bag is placed within a hydraulic fluid (e.g. oil or water) in a pressure vessel. Pressure is applied to the fluid, usually between 10,000 and 60,000 psi which is evenly distributed across the material. This method helps to reduce distortion, improve accuracy and reduce the risk of air entrapment and voids.

Dry Bag Processing

In dry bag cold isostatic pressing (CIP), the material is placed in a mold and subjected to high pressure from all directions. Unlike wet bag processing, no hydraulic fluid is used in this method. The mold is placed in a chamber and pressurized to create a uniform density and shape.

Warm Isostatic Pressing (WIP)

Warm Isostatic Pressing is a process that involves compressing metal powders into solid parts at a temperature of around 200-400°C. WIP is used to create parts that require a higher density than CIP but less dense than HIP. It is commonly used in the production of components for medical, aerospace and automotive applications.

In conclusion, both CIP and HIP are effective ways to produce high-quality laboratory equipment. The choice of method will depend on the specific needs of the product being produced, as well as factors such as cost and production time. It is important to work with a reputable laboratory equipment manufacturer who has experience with both methods and can help guide you in making the best decision for your specific needs.

Wet Bag Process

CIP and Metal Mold Pressing are two commonly used methods for manufacturing ceramic and metal parts. The Wet Bag Process is a specific application of these methods, where a slurry of ceramic or metal powder is poured into a flexible bag and then subjected to high pressure to compress the powder into a solid shape.

Wet Bag Process Overview

The Wet Bag Process is particularly well-suited for producing parts with a high level of purity and uniformity. It eliminates the need for binders or additives that can affect the properties of the final product. The process involves several stages:

- Tool Design: A tool or "bag" is made out of an elastomeric material and designed to the shape of the final part, taking in-process shrinkage into consideration.

- Powder Loading: A specific amount of metal powder is placed into the tool, which is calculated based on the apparent and packing densities of the powder used.

- Compaction: The tool is temporarily closed with a bung and gently vibrated to allow the powder particles to reconfigure and pack. Upon reaching its packing density, the powder decreases in volume and the bung is fully pushed against the powder to compensate for reduced volume. The bag is then sealed.

- Isostatic Pressing: The encapsulated powder is placed inside a pressure vessel filled with a hydraulic fluid, which increases the pressure to compress the powder isostatically. The powder is left under peak pressure for a short dwell period allowing for the powder particles to consolidate.

- Pressure Release: The pressure is released gradually, such that the flexible tool retracts to its original shape, while the powder is converted from a loose aggregate into a partially dense compact.

- Part Extraction: The consolidated part is extracted from the tool with a typical density of 75 – 85%, providing sufficient green strength to permit careful handling and transfer to the following process. Subsequent post-processing aims at consolidating the green part to full density.

Advantages and Limitations

The Wet Bag Process has several advantages over other methods. It is a solid-state processing technique that produces parts with uniform microstructure, shape complexity, and low tooling cost. It is scalable, allowing for potential to produce near-net-shape parts with minimal material waste. The process is well-suited for production of large parts, and it is capable of producing parts with higher densities than some other techniques.

However, the Wet Bag Process has some limitations. It is comparatively manual and limited to processing certain types of powders. The vessel capability and capacity are also limited, which can impact the size and shape of parts that can be produced.

In conclusion, the Wet Bag Process is a versatile and effective method for producing high-quality ceramic and metal parts with a high level of purity and uniformity. The choice between CIP and Metal Mold Pressing will depend on the specific requirements of the part being produced, and it is important to carefully consider the advantages and limitations of each method.

Dry Bag Process

The Dry Bag Process is a method to mold powder filled in a forming rubber mold by transmitting pressure through a pressing rubber mold in the high-pressure vessel. This method is suitable for mass production of simple and limited variety of products with its labor-saving automatic operation.

Two Systems of Dry Bag Process

The Dry Bag process is classified into two systems: the circumferential + axial pressurization system and the circumferential pressurization system. The circumferential + axial pressurization system applies pressure from the outer surfaces of the mold and the top surface of the cap-shaped pressing rubber mold. On the other hand, the circumferential pressurization system applies pressure only from the outer surfaces of the forming rubber mold through a cylindrical pressing rubber mold. However, due to the fluid-like property of the powder, the pressure applied to the green compact is almost equal to isostatic pressure.

Dry Bag Process vs. Wet Bag Process

Dry Bag Process and Wet Bag Process are the two isopressing methods. Wet bag isopressing involves compacting a powder in a sealed elastomeric mold that is completely submerged in pressurized fluid. Wet bag isopressing is used for low-volume production of specialty parts, for prototyping, and for research and development. In dry bag isopressing, the elastomeric mold is an integral part of the isostatic press. As such, the applied pressure is mostly biaxial. A major advantage of dry bag isopressing is that it can be automated for high-volume production, such as in spark plug insulator manufacturing.

Advantages of Dry Bag Process

Dry bag isostatic pressing is an efficient method for producing relatively small carbide articles with axisymmetric geometry. The pressure is built up by means of a high-pressure pump; it is transmitted to the elastic pressing mold filled with the WC–Co powder radially via a membrane installed in the bore of the pressing chamber. The major advantage of the dry bag presses is the possibility of their automation, allowing the cost-effective mass or semimass production of carbide articles with complex geometry, for example, rods, tubes, bushes, balls, plungers, drills, screws, nozzles, etc. With the aid of dry isostatic pressing, it is also possible to press almost net-shape hollow green compacts with the precise outer and internal dimensions resulting in the significantly reduced amount of machining such green compacts, which leads to the consequently reduced swarf generation.

Components of Dry Bag Presses

Dry bag presses usually consist of a pressing frame, pressure vessel, pressing mold change system, powerful oil pressure pump, cleaning device, and modern computer control system.

In conclusion, the Dry Bag Process is a cost-effective and efficient method of producing high-quality laboratory equipment. Its ability to be automated for high-volume production makes it an ideal choice for mass production of simple and limited variety of products. The dry bag presses are also capable of producing almost net-shape hollow green compacts with precise outer and internal dimensions. The process is suitable for producing relatively small carbide articles with axisymmetric geometry.

Conclusion

Both CIP and metal mold pressing are effective methods for producing high-quality products with precise density distribution, but they differ in their approach. CIP provides a more cost-effective and flexible option, allowing for the production of complex shapes and designs with minimal waste. Metal mold pressing, on the other hand, is more suitable for producing large quantities of simple geometries with high accuracy and uniformity. Ultimately, the choice between the two methods will depend on the specific needs and requirements of the application.

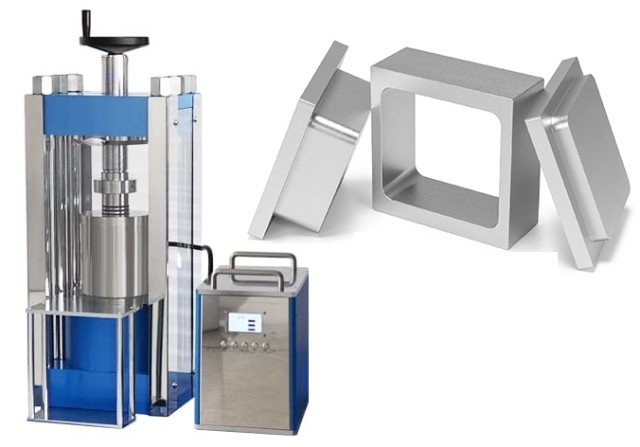

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

Related Articles

- Understanding Cold Isostatic Pressing and Its Applications

- Cold Isostatic Pressing: An Overview and its Industrial Applications

- Cold Isostatic Pressing (CIP): A Proven Process for High-Performance Parts Manufacturing

- Electric Lab Cold Isostatic Press (CIP): Applications, Benefits, and Customization

- How Isostatic Presses Improve the Efficiency of Material Processing