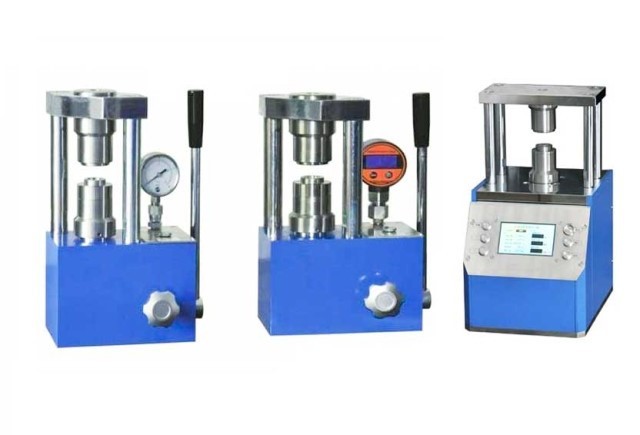

In the dynamic landscape of battery manufacturing, the battery sealing machine emerges as a crucial player, sealing energy within compact casings. As this intricate machinery takes center stage, understanding the precise operating steps and necessary precautions becomes imperative. Join us on a journey into the heart of the battery sealing process, exploring the intricacies that ensure the seamless encapsulation of power within these indispensable energy sources.

Battery sealing machine operation steps

1.Assemble the button battery case.

2.Place into sealing mold.

3.Tighten the oil drain valve stem.

4.Shake the handle to start applying pressure.

Turn on and off: short press "ON/OFF". Unit switching: long press "ON/OFF". Peak value clear: short press "ZERO". Display clear: long press "ZERO".

5.Press the pressure to about 1000kg-1200kg.

6.Loosen the oil release valve to release pressure and lower the mold back to its original position.

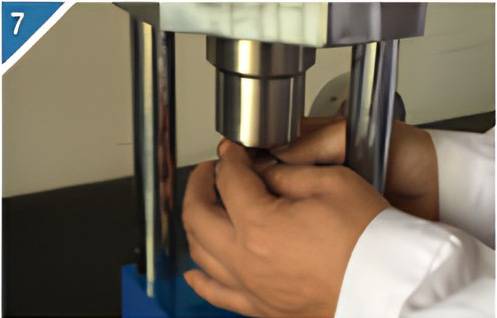

7.Press the positioning sub-port of the sealing mold.

8.Remove the sealed button battery.

9.Shake the handle to start applying pressure.

10.Place the battery into the disassembly mold.

11.Tighten the drain valve stem.

12.Shake the handle to start applying pressure.

13.Press the pressure to about 500kg and separate the sealed battery.

14.Loosen the drain valve stem to relieve pressure.

15.Press the disassembly mold to position the sub-port.

16.Remove the separated button battery.

precautions

Question 1: Sealing pressure

Generally, the pressure is pressed to about 6MPa-8MPa, about 1000kg-1200kg. If it is too large, the battery case will be deformed, and if it is too small, the battery will not be sealed tightly.

Question 2: Disassembly pressure.

Generally, the pressure is pressed to about 2MPa-5MPa, and the sealed button battery is separated.

Question 3: Battery quality.

The battery case must be of good quality. Some inferior battery cases are very thin and may collapse in the center when sealed.

Question 4: Pressure Gauge Settings.

Turn on and off: short press "ON/OFF". Unit switching: long press "ON/OFF". Peak value clear: short press "ZERO". Display clear: long press "ZERO".

Question 5: Pressure and Temperature.

When the equipment is heated, the hydraulic oil expands due to the increase in the host temperature, and the system pressure will rise. Generally, the temperature of the equipment is constant before the pressure is pressed to the value we need.

Question 6: Replace the mold

When replacing the mold of the sealing machine, please note that it is best to place a battery case on the sealing mold and then apply pressure to allow the mold to align itself, and finally tighten the fixing screws of the mold.Related Products

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

Related Articles

- Applications and Importance of Hydraulic Press in Laboratories

- A Comprehensive Guide on Pressing XRF Pellets Using a KinTek Automatic Hydraulic Press

- Manual Hydraulic Pellet Press: An Efficient Tool for Spectral Analyses Preparation

- Automatic flat plate heat press operating steps

- Fully automatic tablet press operating steps and replacement accessories