Introduction to PECVD and HPCVD

Plasma-enhanced chemical vapor deposition (PECVD) and hot filament chemical vapor deposition (HPCVD) are two widely used methods for depositing thin films onto a substrate. PECVD operates at low pressures and involves the use of plasma to break down and deposit a gas mixture onto the surface. HPCVD, on the other hand, uses a hot filament to decompose the gas, creating a plasma. The resulting films have different properties and advantages depending on the method used. Understanding the differences and applications of each method is crucial in selecting the most appropriate technique for a specific coating application.

Table of Contents

Differences between PECVD and HPCVD

PECVD and HPCVD are two popular coating techniques used in various industries, including semiconductor, optical, and medical industries. Although both techniques are used for coating applications, they differ in terms of deposition methods, performance, and suitability for specific applications.

Deposition Method

The main difference between PECVD and HPCVD lies in the way the coatings are deposited onto the substrate. PECVD uses a low-pressure plasma to ionize and react the precursor gases, while HPCVD uses a high-power heat source to vaporize and react the precursor gases.

Performance

PECVD is known for its ability to produce high-quality and uniform coatings on a wide range of substrates. It also offers better control over the coating thickness and composition, making it suitable for applications that require precise coating parameters. On the other hand, HPCVD is preferred for high-temperature coating applications due to its ability to create dense and adherent coatings even at high temperatures. It also has a faster deposition rate than PECVD, making it more suitable for large-scale production.

Suitability for Specific Applications

PECVD is ideal for producing coatings for microelectronics, solar cells, and optical devices, while HPCVD is preferred for producing coatings for cutting tools, wear-resistant coatings, and thermal barrier coatings. The choice between PECVD and HPCVD depends on the specific application requirements, the substrate material, and the desired coating properties.

Film Properties

By varying the parameters of the plasma, PECVD can produce films with excellent control of the material properties including density and hardness, purity, roughness, or the refractive index of optical films. PECVD can produce unique compounds and films that cannot be created by common CVD techniques alone, and produce films that demonstrate a very high solvent and corrosion resistance with chemical and thermal stability.

In comparison, HPCVD is capable of producing dense and adherent coatings even at high temperatures, making it suitable for high-temperature coating applications. The coatings produced by HPCVD are preferred for their wear-resistance and thermal barrier properties, making it ideal for cutting tools and wear-resistant coatings.

In summary, both PECVD and HPCVD have their own unique advantages and limitations, and the choice between the two depends on the specific application requirements, substrate material, and desired coating properties. PECVD is ideal for producing coatings for microelectronics, solar cells, and optical devices, while HPCVD is preferred for producing coatings for cutting tools, wear-resistant coatings, and thermal barrier coatings.

Advantages of PECVD

Low Temperature Deposition

PECVD generally operates at a low temperature in between 100˚C and 400˚C. This is a significant advantage over HPCVD, which operates at much higher temperatures. The PECVD process uses both thermal energy and RF-induced glow discharge to control the chemical reactions. The glow discharge creates free electrons to collide with reactant gases and dissociate them to generate the reaction and deposit the solid film on the substrate. Since part of the energy to initiate the chemical reactions is provided by the glow discharge, the system requires less thermal energy. Therefore, the temperature can be maintained at a relatively low level compared to other CVD processes.

Good Properties of the Films Deposited

Some other advantages of the PECVD process are the good properties of the films being deposited. The PECVD process can deposit thin films with good dielectric properties. This is important in integrated circuit fabrication because the transistor needs a good dielectric layer to maintain its characteristics and performance.

Low Mechanical Stress

The thin films being deposited also have low mechanical stress. This can prevent the films from deforming and becoming non-uniform because of the uneven mechanical stress on the films. Good conformal step coverage and excellent uniformity are also provided by the PECVD process. The film thickness over the step edge and flat surface can be maintained uniform. This is a great advantage of the PECVD when the fabrication process requires high step coverage because some of the fabrication processes may have a substrate with several steps on the surface.

Versatile Deposition

PECVD is suitable for the fabrication of films with different compositions and microstructures, allowing one to continuously vary film characteristics as a function of depth (graded or inhomogeneous films). This can be used for the fabrication of a very attractive category of optical devices such optical rugate filters as well as hard and tough protective coatings and biomedical materials. Different substrate shapes (including 3D) can be uniformly coated (flat, hemispherical, cylindrical shapes, interior of tubes, etc.).

High Deposition Rates

PECVD provides high deposition rates (rD ∼ 1–10 nm/s, or more), substantially higher than other, more traditional vacuum-based techniques (e.g. PVD). This is the basis for a reliable low-cost fabrication technology.

Overall, PECVD has several advantages over HPCVD, including lower temperature deposition, good properties of the films being deposited, low mechanical stress, versatile deposition, and high deposition rates. These advantages make it the preferred option for coating applications in the laboratory equipment industry.

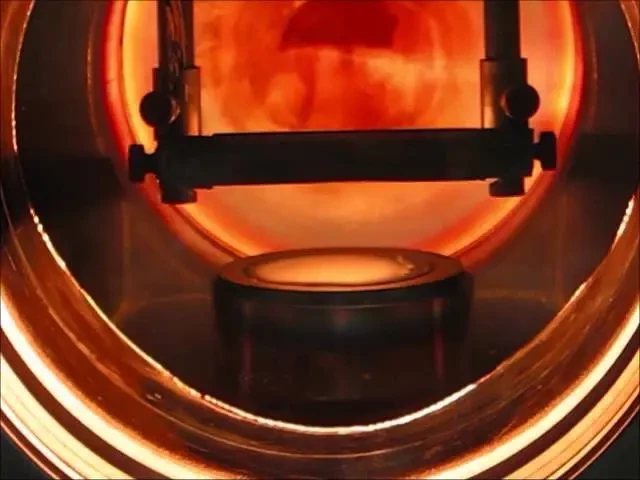

Advantages of HPCVD

Hot filament chemical vapor deposition (HPCVD) has emerged as an efficient and reliable option for coating applications in various industries. Some of the key advantages of HPCVD are as follows:

Coating a wider range of materials

HPCVD has the ability to coat a wider range of materials as compared to PECVD. While PECVD is limited to silicon-based materials, HPCVD can coat alloys, ceramics, and polymers, making it a more versatile option.

Higher deposition rates

HPCVD offers higher deposition rates than PECVD, which means that coatings can be applied more quickly, reducing production time and costs. This advantage makes HPCVD the preferred option for industries that require high throughput and efficiency.

Producing coatings with superior mechanical properties

HPCVD can be used to produce coatings with superior mechanical properties like hardness, wear resistance, and adhesion. This feature makes HPCVD ideal for high-stress applications in the aerospace and automotive industries.

Great for high-end applications

Due to its ability to produce coatings with superior mechanical and thermal properties, HPCVD is ideal for high-end applications like touch-sensitive screens, light/photo-sensitive semiconductors, and bio-medical implants.

In summary, HPCVD has emerged as a more efficient and reliable option for coating applications in various industries due to its ability to coat a wider range of materials, higher deposition rates, superior mechanical properties, lower operating temperatures, and suitability for high-end applications.

Applications of PECVD

PECVD is a highly versatile thin-film deposition technique that finds wide application in the semiconductor industry. The process is used to deposit a range of materials on a substrate, including silicon dioxide (SiO2), silicon nitride (Si3N4), and amorphous silicon (a-Si). In this section, we will discuss some of the most common applications of PECVD in detail.

Microelectronic Devices

PECVD is widely used in the manufacture of microelectronic devices, including integrated circuits (ICs) and microelectromechanical systems (MEMS). The process is used to deposit a range of materials, including SiO2, Si3N4, and polysilicon, that are essential for the fabrication of these devices. PECVD is preferred over other deposition techniques as it allows for the deposition of thin films with high aspect ratios, making it ideal for creating complex geometries.

Photovoltaic Cells

PECVD is also used in the production of photovoltaic cells or solar cells. The technique is used to deposit thin films of amorphous silicon and silicon nitride that are used as buffer layers and anti-reflection coatings. These films improve the efficiency and durability of the solar cells and are essential for their long-term performance.

Display Panels

PECVD is widely used in the production of display panels, including LCD and OLED displays. The process is used to deposit thin films of SiO2 and Si3N4 that are used as passivation layers and encapsulation layers. These layers protect the underlying components of the display and improve their performance and durability.

Thin-Film Transistors

PECVD is also used in the production of thin-film transistors (TFTs) for displays and other electronic devices. TFTs are an essential component of modern displays, and PECVD is a key technology for their fabrication. The process is used to deposit thin films of amorphous silicon that act as the active layer of the TFT.

Other Applications

PECVD finds a range of other applications in the semiconductor industry, including the deposition of dielectric materials for interlayer insulation, the deposition of barrier layers to prevent diffusion, and the deposition of anti-reflective coatings for optical devices.

In conclusion, PECVD is a versatile thin-film deposition technique that finds wide application in the semiconductor industry. The process is used to deposit a range of materials on substrates, including SiO2, Si3N4, and a-Si, and is preferred over other deposition techniques due to its ability to create thin films with high aspect ratios. The most common applications of PECVD include the production of microelectronic devices, photovoltaic cells, display panels, and thin-film transistors. However, the process also finds use in a range of other applications, including the deposition of dielectric materials, barrier layers, and anti-reflective coatings.

Applications of HPCVD

HPCVD is a versatile coating technique that can be used to deposit a wide range of materials, including metals, alloys, and ceramics. This makes it a valuable tool in many different industries, including:

Aerospace

HPCVD is commonly used in the aerospace industry to deposit coatings on turbine blades and other high-temperature components. These coatings help to improve the durability and performance of the components, allowing them to withstand the extreme conditions of flight.

Electronics

HPCVD is also used in the electronics industry to deposit coatings on components such as circuit boards and sensors. These coatings can provide protection against moisture and other environmental factors, as well as improving the electrical conductivity of the components.

Medical Devices

HPCVD is used in the medical device industry to deposit coatings on a variety of materials, including plastics and polymers. These coatings can provide protection against degradation and wear, as well as improving the biocompatibility of the materials.

Automotive

HPCVD is used in the automotive industry to deposit coatings on engine components, such as pistons and valves. These coatings can help to improve the performance and efficiency of the engine, as well as reducing wear and extending the lifespan of the components.

Energy

HPCVD is used in the energy industry to deposit coatings on components such as heat exchangers and turbines. These coatings help to improve the efficiency and durability of the components, allowing them to operate at higher temperatures and pressures.

In conclusion, HPCVD is a valuable coating technique that can be used in a wide range of industries. Its ability to deposit a variety of materials at low temperatures makes it particularly useful for coating temperature-sensitive materials, while its versatility allows it to be used in many different applications.

Performance Comparison between PECVD and HPCVD

Process Temperature

PECVD operates at low temperatures, typically between 150°C and 400°C. This makes it suitable for depositing films on temperature-sensitive substrates. On the other hand, HPCVD operates at high temperatures, between 700°C and 1200°C. This makes it suitable for depositing high-quality, dense coatings on materials that can withstand high temperatures.

Deposition Rate

HPCVD has a higher deposition rate than PECVD, making it more suitable for depositing thicker coatings in a shorter time. However, it can lead to higher residual stress, which can affect the mechanical properties of the coating. PECVD has a lower deposition rate but produces high-quality, uniform coatings with excellent adhesion and low porosity.

Coating Properties

PECVD produces coatings with excellent adhesion and low porosity, making them suitable for applications that require high-quality, uniform coatings. HPCVD produces dense, conformal coatings with high purity and excellent mechanical properties. However, the high residual stress in HPCVD coatings can affect their mechanical properties.

Substrate Material

The choice between PECVD and HPCVD depends on the substrate material. PECVD is suitable for depositing films on temperature-sensitive substrates such as polymers, glass, and ceramics, while HPCVD is suitable for depositing films on materials that can withstand high temperatures such as metals and alloys.

In conclusion, both PECVD and HPCVD have their unique advantages and limitations. Choosing between the two techniques depends on the specific application requirements, including the substrate material, coating thickness, and desired properties. Understanding the differences between PECVD and HPCVD is essential for selecting the best coating method for each application.

Conclusion

In conclusion, both PECVD and HPCVD have their advantages and disadvantages in coating applications. PECVD is suitable for deposition of thin films on complex shapes and low-temperature substrates, while HPCVD is ideal for high-temperature deposition of thick films on large substrates. Although PECVD has a higher deposition rate and better conformal coating, HPCVD provides better film purity and adhesion. Therefore, the choice of CVD method will depend on the specific coating requirements of the application. Overall, both techniques are essential for various industries, and their continued development will lead to further improvements in coating technology.

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Custom CVD Diamond Coating for Lab Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine