What is PECVD(Plasma-Enhanced Chemical Vapor Deposition)

PECVD is a useful technique for creating thin film coatings because it allows for the deposition of a wide variety of materials, including oxides, nitrides, and carbides. It is also able to deposit films at low temperatures, making it useful for coating temperature-sensitive substrates.

Vapor deposition systems are used to create thin film coatings through the process of PECVD. These systems typically consist of a vacuum chamber, a gas delivery system, and a RF energy source. The substrate to be coated is placed in the vacuum chamber, and the precursor gases are introduced and ionized by the RF energy source to create the plasma. As the plasma reacts with the gases, the thin film coating is deposited on the substrate.

PECVD is widely used in the semiconductor industry for creating thin film coatings on wafers, as well as in the production of thin film solar cells and touch screen displays. It is also used in a variety of other applications, including coatings for optical components and protective coatings for automotive and aerospace parts.

How do PECVD create coatings

One of the main benefits of using PECVD is the ability to deposit thin film coatings at lower temperatures compared to traditional CVD techniques. This allows for the coating of temperature-sensitive materials, such as plastics and polymers, that would be damaged by the high temperatures used in traditional CVD processes.

In addition to the ability to deposit films at lower temperatures, PECVD also allows for a wider range of materials to be deposited compared to traditional CVD. This is because the plasma used in PECVD can dissociate and ionize the precursor gases, creating a larger variety of reactive species that can be used to create thin film coatings.

These energetic species are then able to react and condense on the surface of the substrate, leading to the formation of a thin film coating. The type of plasma generated and the resulting energetic species can be controlled by adjusting the frequency and power of the RF or DC energy source.

One of the benefits of using PECVD is the ability to precisely control the chemical reactions occurring during the deposition process. This allows for the creation of highly uniform and conformal thin film coatings with a high degree of control over the film's properties.

PECVD is widely used in the semiconductor industry for creating thin film coatings on wafers, as well as in the production of thin film solar cells and touch screen displays. It is also used in a variety of other applications, including coatings for optical components and protective coatings for automotive and aerospace parts.

One of the benefits of using plasma-enhanced chemical vapor deposition (PECVD) is the ability to create thin film coatings with a wide range of properties. One such coating is diamond-like carbon (DLC), a popular performance coating known for its hardness, low friction, and corrosion resistance.

DLC coatings can be created using PECVD by dissociating a hydrocarbon gas, such as methane, in a plasma. The plasma activates the gas molecules, breaking them down into smaller species, including carbon and hydrogen. These species then react and condense on the surface of the substrate, forming the DLC coating.

One of the unique characteristics of DLC coatings is that, once the initial nucleation of the film has occurred, the growth rate of the coating is relatively constant. This means that the thickness of the DLC coating is proportional to the deposition time, allowing for precise control over the thickness of the coating.

In addition to its hardness, low friction, and corrosion resistance, DLC coatings also have a low coefficient of thermal expansion, making them useful for applications where thermal expansion and contraction need to be minimized.

DLC coatings are widely used in a variety of applications, including as protective coatings for automotive and aerospace parts, as well as in the production of medical implants and devices. They are also used in the semiconductor industry for creating thin film coatings on wafers.

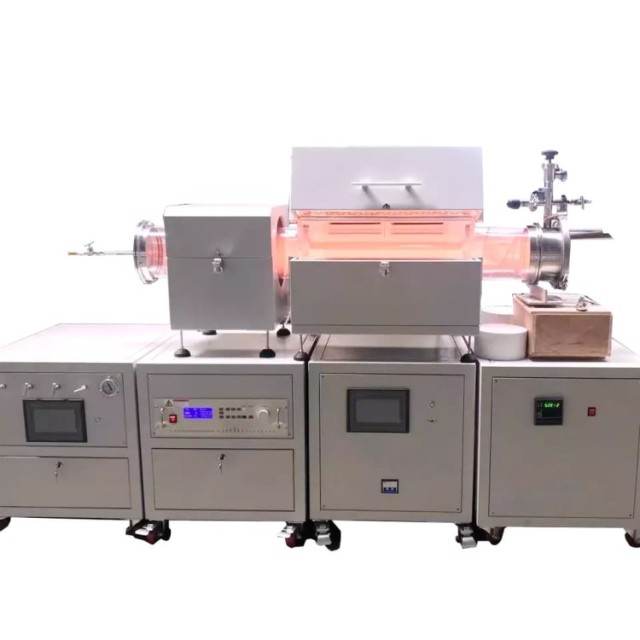

PECVD Machine

PECVD equipment consists of a vacuum chamber, a gas distribution system, a power source, and a pump system to maintain a vacuum in the chamber. The substrate to be coated is placed in the chamber, and a flow of reactant gases is introduced into the chamber. The power source, typically a radio frequency (RF) generator, is used to create a plasma by ionizing the gas molecules. The plasma reacts with the reactant gases and the substrate surface, resulting in the deposition of a thin film on the substrate.

PECVD is widely used in the semiconductor industry to produce thin films for use in electronic and optoelectronic devices, such as thin-film transistors (TFTs) and solar cells. It is also used to produce diamond-like carbon (DLC) for use in mechanical and decorative coatings. Hybrid PECVD-PVD (physical vapor deposition) systems, which can perform both PECVD and PVD processes, are also available.

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine