Introduction to CVD Diamonds

Properties and Advantages

Diamond stands out as one of nature's most extraordinary materials, boasting unparalleled hardness. Its low coefficient of friction, high modulus of elasticity, and exceptional thermal conductivity make it a material of choice for numerous applications. Additionally, diamond exhibits high electrical insulation, a wide energy gap, and a high rate of acoustic propagation, coupled with excellent chemical stability. These properties are not just theoretical; they are harnessed in the form of diamond films, which integrate these superior physicochemical characteristics into a single, versatile material.

The synthetic diamond film, produced through Chemical Vapor Deposition (CVD), not only replicates these natural properties but also offers economic advantages over natural diamond. The cost-effectiveness of CVD diamond films is a significant factor driving their adoption in various industries. Moreover, these films can be prepared in a multitude of geometric shapes, providing flexibility in design and application. Theoretically, there is no limitation on the size of these films, enabling their use in large-scale industrial processes and high-demand applications.

| Property | Natural Diamond | CVD Diamond Film |

|---|---|---|

| Hardness | Highest | Equivalent |

| Coefficient of Friction | Low | Low |

| Modulus of Elasticity | High | High |

| Thermal Conductivity | High | High |

| Electrical Insulation | High | High |

| Energy Gap | Wide | Wide |

| Acoustic Propagation | High | High |

| Chemical Stability | Good | Good |

The synthesis of CVD diamond films opens new avenues for technological advancements, particularly in fields requiring robust, durable, and versatile materials. The ability to tailor these films to specific needs, combined with their cost-efficiency and scalability, positions CVD diamond films as a transformative material in the modern industrial landscape.

Market Potential

CVD diamonds hold immense promise across a multitude of industries, from electronics and optics to machinery and beyond. Their unique properties, such as high thermal conductivity, exceptional hardness, and chemical stability, make them indispensable in these sectors. In the electronics industry, CVD diamonds are being explored for use in high-power electronic devices and microelectromechanical systems (MEMS) due to their superior thermal management capabilities. In optics, their high transmittance in the infrared spectrum renders them ideal for applications like X-ray windows and infrared sensors.

Moreover, the versatility of CVD diamond technology extends to military and dual-use projects. For instance, CVD diamonds can be employed in the fabrication of robust components for defense applications, such as high-speed interceptor missile cowls and aerospace windows, enhancing the durability and performance of these critical systems. Additionally, their potential in dual-use projects bridges the gap between civilian and military applications, fostering innovation and technological advancement in both realms.

| Industry | Potential Applications |

|---|---|

| Electronics | High-power devices, MEMS |

| Optics | X-ray windows, infrared sensors |

| Machinery | Cutting tools, wear-resistant components |

| Military | Missile cowls, aerospace windows |

| Dual-use | Bridging civilian and military tech |

This broad spectrum of applications underscores the significant market potential of CVD diamonds, positioning them as a transformative material in the 21st century.

Background and Development of CVD Diamond Projects

Types of Artificial Diamonds

Artificial diamonds are primarily categorized into two main types: chemical vapor deposition (CVD) diamonds and high-temperature high-pressure (HTHP) diamonds. The CVD method stands out for its versatility, enabling the preparation of both diamond particles and diamond films. These synthetic diamonds possess significant application values and have seen rapid advancements in recent years.

One of the key advantages of CVD diamonds is their ability to be produced in various geometric shapes, offering flexibility in their use across different industries. Unlike natural diamonds, which are limited by their rarity and cost, CVD diamonds can be synthesized at a lower cost, making them more accessible for widespread use.

| Type | Preparation Method | Applications |

|---|---|---|

| CVD Diamond | Chemical Vapor Deposition | Diamond particles and films |

| HTHP Diamond | High-Temperature High-Pressure | Industrial and gem-quality diamonds |

The rapid development of CVD diamonds is attributed to their multifaceted applications, ranging from industrial uses to high-end jewelry. This method's ability to produce high-quality diamonds at a reduced cost has made it a preferred choice in sectors where durability and performance are paramount.

CVD Preparation Methods

The preparation of CVD (Chemical Vapor Deposition) diamonds involves several distinct methods, each with unique characteristics and applications. The primary techniques include the Hot Filament CVD (HFCVD) method, Direct Current Plasma Jet CVD (DC-PJ CVD) method, and Microwave Plasma CVD (MPCVD) method. Each of these methods offers distinct advantages and faces specific limitations, making them suitable for different applications and production requirements.

Hot Filament CVD (HFCVD) Method

The HFCVD method is known for its simplicity and cost-effectiveness. It utilizes a heated filament to decompose the precursor gases, typically methane and hydrogen, into their constituent atoms. These atoms then react on a substrate to form a diamond film. While this method is relatively straightforward and inexpensive, it often results in lower growth rates and can introduce impurities due to the filament's material.

Direct Current Plasma Jet CVD (DC-PJ CVD) Method

The DC-PJ CVD method employs a direct current plasma jet to ionize the gases, creating a highly reactive environment for diamond growth. This technique allows for precise control over the deposition process and can achieve higher growth rates compared to HFCVD. However, the equipment required for this method is more complex and expensive, limiting its widespread adoption.

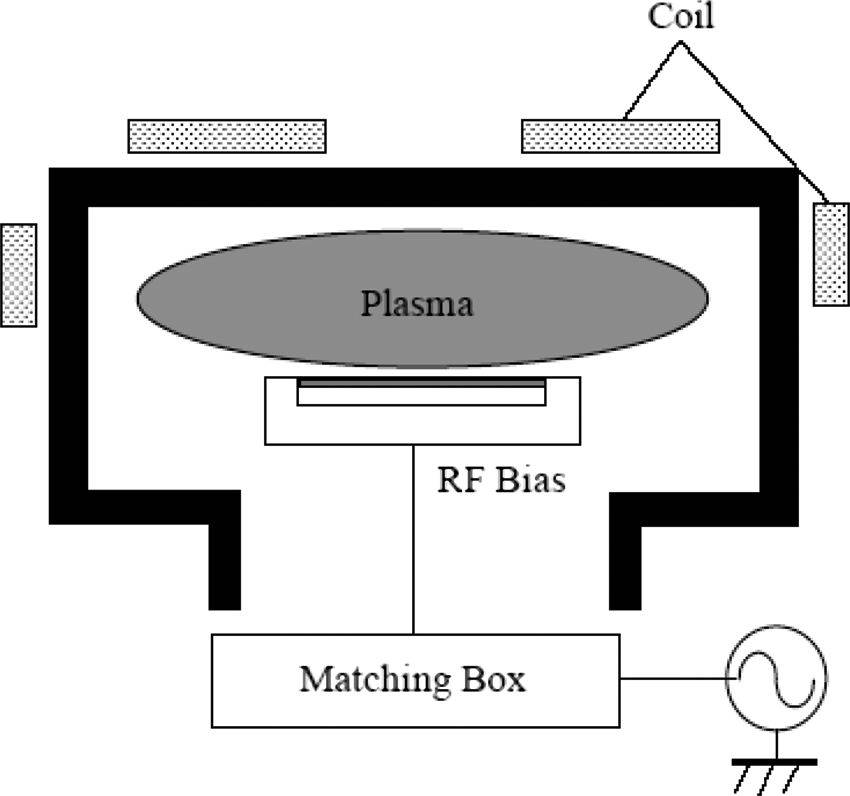

Microwave Plasma CVD (MPCVD) Method

The MPCVD method utilizes microwave energy to generate a plasma from the precursor gases, facilitating the deposition of diamond films. This technique is particularly effective for producing high-quality, single-crystal diamonds and can achieve rapid growth rates. Despite its advantages, the MPCVD method requires specialized equipment and can be more energy-intensive, making it less suitable for large-scale production.

Each of these methods plays a crucial role in the synthesis of CVD diamonds, catering to different industry needs and production scales. The choice of method depends on various factors, including the desired quality, growth rate, and cost considerations.

Market Applications of Microwave CVD Diamond Products

Jewelry Industry

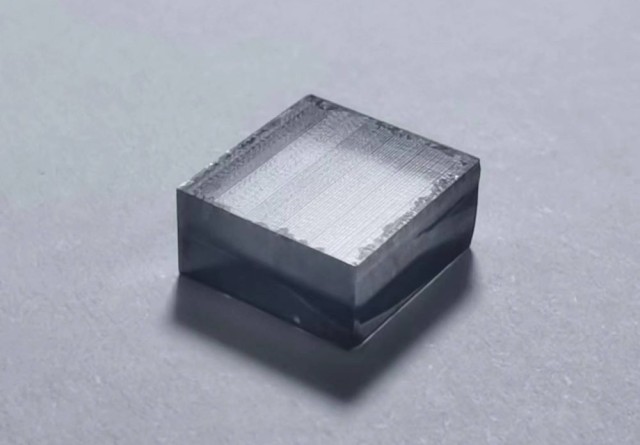

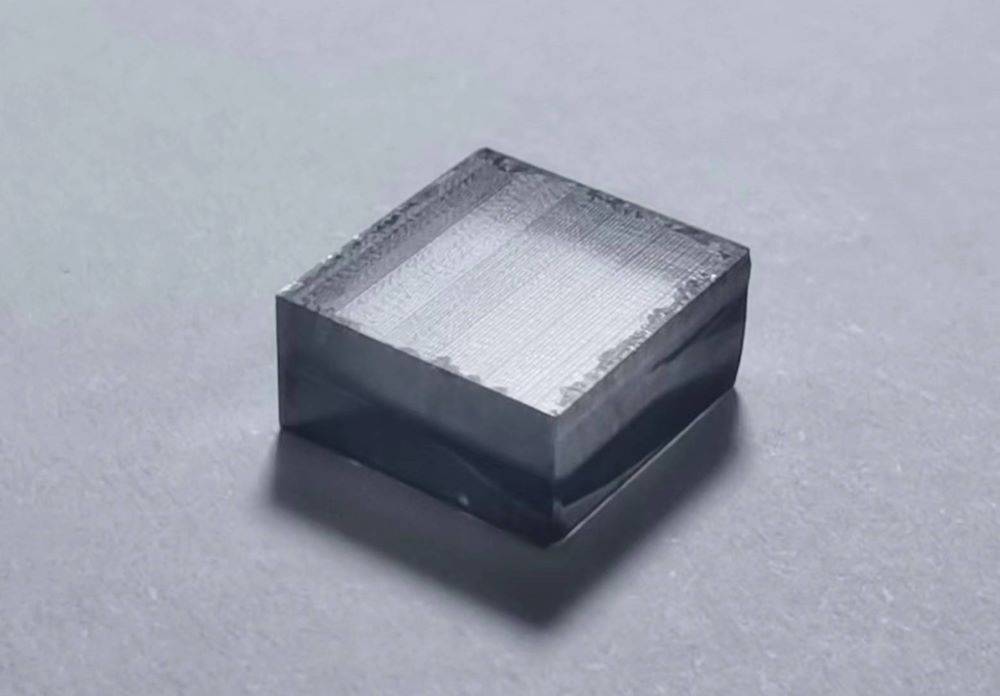

The primary application of the Microwave Plasma Chemical Vapor Deposition (MPCVD) device in the jewelry industry involves the homogeneous epitaxial growth method. This method leverages small particles of natural diamond as "seeds" to cultivate larger, gem-quality single-crystal diamonds. These grown diamonds are then meticulously processed to achieve the brilliance and sparkle characteristic of high-quality diamonds.

The process begins by selecting natural diamond particles that serve as the foundational "seeds." These seeds are placed in a controlled environment within the MPCVD device, where they are subjected to specific conditions of temperature and pressure. Under these conditions, the natural diamond particles act as templates, facilitating the deposition of carbon atoms from a gaseous precursor. This deposition process leads to the gradual growth of the diamond particles into larger, single-crystal structures.

Once the diamonds have reached the desired size and quality, they undergo a series of cutting and polishing steps to enhance their visual appeal. These steps are crucial in transforming the raw, grown diamonds into the sparkling gemstones that are highly sought after in the jewelry market. The result is a synthetic diamond that rivals the beauty and durability of natural diamonds, making it a viable and attractive option in the jewelry industry.

The use of MPCVD technology in diamond synthesis offers several advantages. It allows for the production of large, high-quality diamonds at a lower cost compared to natural diamonds. Additionally, the process can be scaled up to meet the increasing demands of the jewelry market, providing a sustainable and economically viable solution for diamond production.

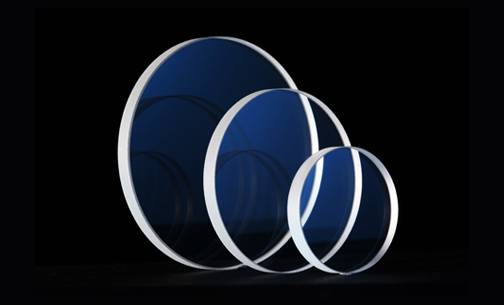

Optical Field

Diamond's exceptional light transmission performance in the infrared region makes it an ideal material for various critical applications. Notably, it serves as a superior X-ray window material for armored vehicles, enabling clear and undistorted imaging even under high-stress conditions. Similarly, its use as an infrared window material ensures precise thermal imaging and detection capabilities.

In the realm of defense, diamond is integral to high-speed interceptor missile cowls, where its transparency to infrared radiation is crucial for maintaining missile guidance systems' accuracy. Aerospace applications also benefit from diamond's optical properties, with aircraft windows and fighter nose detection windows leveraging its superior transmission characteristics. This ensures that these aircraft can operate effectively in diverse environmental conditions, from high-altitude flights to close-quarter combat scenarios.

| Application | Material Benefit |

|---|---|

| Armored Vehicle X-ray Windows | High light transmission |

| Infrared Window Materials | Superior thermal imaging |

| Interceptor Missile Cowls | Infrared transparency |

| Aerospace Aircraft Windows | Wide environmental adaptability |

| Fighter Nose Detection Windows | Enhanced detection capabilities |

These applications underscore diamond's versatility and its indispensable role in modern optical systems, particularly where high performance and reliability are paramount.

High Power Laser Windows

CVD diamond stands out as an exceptional material for high-power industrial laser windows, addressing a common challenge faced by other materials: the thermal lens effect. This phenomenon occurs when the window material experiences significant temperature increases under high-power laser operation, leading to optical distortions and potential damage. However, CVD diamond's superior thermal conductivity offers a compelling solution.

The thermal conductivity of CVD diamond is significantly higher than that of conventional window materials, such as silicon or germanium. This means that under high-power laser conditions, the temperature rise in a CVD diamond window is markedly lower. As a result, the thermal lens effect, which is a critical concern in high-power laser applications, is virtually negligible. This not only ensures stable and efficient laser operation but also extends the lifespan of the laser system by reducing thermal stress and potential window failure.

In comparison, traditional window materials often require additional cooling mechanisms to manage thermal effects, adding complexity and cost to the system. CVD diamond's inherent thermal management capabilities simplify the design and operation of high-power laser systems, making it a superior choice for demanding industrial applications.

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Laboratory CVD Boron Doped Diamond Materials

- CVD Diamond Cutting Tool Blanks for Precision Machining

- CVD Diamond Domes for Industrial and Scientific Applications

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor