Milling Equipment

Hybrid High Energy Vibratory Ball Mill for Lab Use

Item Number : KT-BM400

Price varies based on specs and customizations

- Recommended maximum injection size

- < 8 mm

- Sample particle size range

- ~ 5um

- Vibration frequency

- 180-1800 r/min

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

KT-BM400 is used for rapid grinding or mixing of dry, wet and frozen small amount of samples in the laboratory. It can be configured with two 50ml ball mill jars, and can also be configured with a variety of cell wall breaking adapters of different specifications for biological cell wall breaking and DNA /RNA and protein extraction, its structure design is compact, simple in appearance, desktop operation, small in size, adopts frequency conversion LCD screen control interface to realize timing, speed regulation, intermittent grinding and other functions, and the setting is simple and fast, and the display is intuitive. It is safe and stable to complete the sample processing within a few minutes after pressing the key. It can be widely used in many types of samples including hard, medium and low hardness, brittle, dry, viscous, fibrous, soft and elastic.

- Processing principle: impact force | friction force

- Application sample characteristics: hard | medium-low hardness | brittle | dry | viscous | fibrous | soft | elastic

- Processing Type: Grinding | Blending | Homogenization | Cell Disruption | Freeze Grinding

- Main functions: continuous operation | intermittent operation | timing | speed regulation | data storage | power failure memory | overload protection

Applications

The Hybrid High Energy Vibratory Ball Mill is a versatile and efficient powder processing equipment that finds applications across various industries. This mill is particularly effective in grinding hard and brittle materials to ultra-fine particles, making it indispensable in research and development settings. Here are the main application areas of this product:

- Electronics and Ceramics: Used for grinding materials essential in the production of electronic components and ceramic products, ensuring high purity and fine particle size.

- Chemical Industry: Ideal for the preparation of chemical compounds, facilitating the production of fine powders used in various chemical processes.

- Powdered Metals and Alloys: Essential in the mechanical alloying process, helping in the synthesis of advanced materials and alloys with specific properties.

- Magnetic Materials: Used in the production of magnetic powders for applications in electronics and data storage technologies.

- Pharmaceuticals: Crucial in the grinding of pharmaceutical ingredients to precise particle sizes, which is critical for drug efficacy and consistency.

- High-Frequency Porcelain Materials: Used in the radio industry for the production of materials that require ultra-fine grinding for optimal performance.

- Rubber Compounds: Helps in the preparation of rubber compounds by grinding filler materials to the required fineness.

- Food and Edible Materials: With options for edible grade linings, it is suitable for grinding food ingredients and ensuring safety and purity.

Features

The Hybrid High Energy Vibratory Ball Mill is a cutting-edge powder making equipment designed for efficient and precise milling. This versatile machine is suitable for a wide range of applications, from electronics and ceramics to pharmaceuticals and magnetic materials. Its unique features not only enhance its performance but also ensure user safety and convenience. Here are the key benefits of this advanced laboratory equipment:

- Special Gear Design for Low Noise and Vibration: This feature ensures a quieter and smoother operation, making it ideal for laboratory environments where noise levels need to be minimized.

- LCD Control Panel: The intuitive LCD control panel allows for easy monitoring and adjustment of milling parameters, enhancing the precision and control over the milling process.

- Safety Mechanism: Equipped with a robust safety mechanism, this ball mill protects both the operator and the equipment from potential hazards, ensuring a secure working environment.

- Stable Rotation Speed: Maintaining a stable rotation speed is crucial for consistent milling results. This feature ensures that the materials are processed uniformly, leading to high-quality end products.

- Reliable Heavy-Duty Design: Built to withstand rigorous use, the heavy-duty design of this ball mill guarantees durability and longevity, making it a cost-effective choice for long-term use.

- Programmable Milling Segment: The programmable milling segment allows for customizing the milling process according to specific needs, enhancing the flexibility and adaptability of the equipment.

- Customized Power Supply: Available in 110V, 220V, or 380V, this ball mill can be adapted to different power supply requirements, making it suitable for various international settings and ensuring compatibility with local power grids.

These features collectively make the Hybrid High Energy Vibratory Ball Mill a high-performance and versatile tool for any laboratory involved in material synthesis and processing.

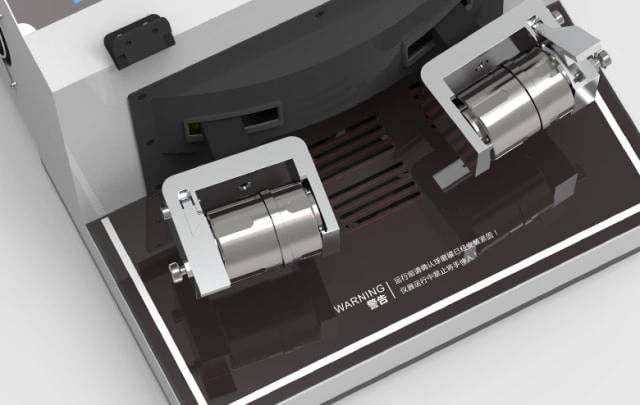

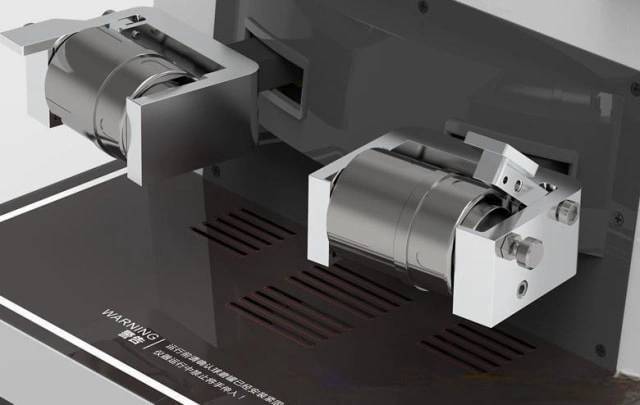

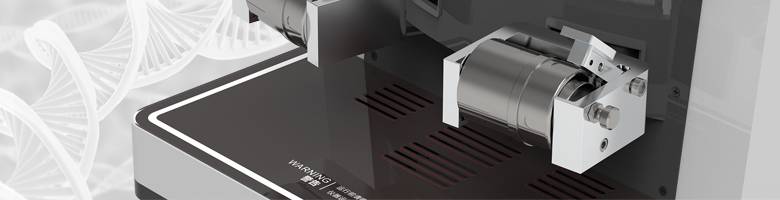

Detail & Parts

Advantages

The Hybrid High Energy Vibratory Ball Mill offers a range of significant advantages for laboratory and industrial applications, particularly in the processing of fine powders and mechanical alloying. Here are some of the key benefits:

- High Efficiency and Speed: This mill utilizes high kinetic energy to rapidly crush, grind, or impact materials, significantly reducing processing times compared to traditional methods. It can produce ultra-fine particles quickly, making it ideal for high-volume production environments.

- Versatility in Material Processing: The mill is capable of handling a wide variety of materials, including hard and brittle substances like metals, alloys, ceramics, and minerals. It can also be used for mechanical alloying, mixing, and homogenization, providing a versatile tool for diverse applications.

- Advanced Grinding Capabilities: With its unique design, the mill can achieve grinding efficiencies that are up to 40 times higher than those attained by gravitational acceleration alone. This results in more uniform and finer powders, which are crucial for many high-tech industries.

- Customizable Options: The mill can be customized with different tank linings such as stainless steel, ceramic (alumina), zirconia, tile, nylon, PTFE, edible grade rubber, or polyurethane, allowing it to be adapted for specific material requirements and to enhance the purity of the final product.

- Large Processing Capacity: The filling capacity of the medium in the grinding cylinder can reach up to 80%, which significantly increases the processing capacity compared to conventional ball mills. This feature is particularly beneficial for industries requiring large-scale production.

- Temperature Control: The mill can be equipped with jacketed grinding cylinders, enabling precise temperature control during the grinding process. This is crucial for maintaining the integrity of temperature-sensitive materials.

- Operational Flexibility: The mill supports both dry and wet ball milling, providing flexibility in operations. It is also easy to clean and maintain, adapting well to various working conditions.

- Compact and Lightweight Design: Despite its high-energy capabilities, the mill features a lightweight and compact design, which saves space and enhances mobility in laboratory settings.

- Continuous Production Capability: With the integration of sieves and collection devices, the mill can support continuous production, improving overall efficiency and throughput.

These advantages make the Hybrid High Energy Vibratory Ball Mill an indispensable tool for laboratories and industries focused on material science, pharmaceuticals, electronics, and more, where precision and efficiency are paramount.

Technical specifications

| Recommended maximum injection size | < 8 mm |

| Sample particle size range | ~ 5um |

| Grinding method | Dry Grinding | Wet Grinding | Cryogenic Grinding |

| Grinding platform (number of cans) | 2 |

| Movement method | plane arc reciprocating motion |

| Vibration frequency | 180-1800 r/min |

| Control method | LCD display |

| Time setting | 59:59:59 (h/m/s) |

| Ball mill material | Tungsten carbide | zirconia | stainless steel | MC nylon|PTFE, etc. |

| Ball mill tank volume | 50ml | 30ml |

| The sealing method of the ball mill jar | Sealing ring + screw fastening |

| Grinding ball size | 1-25m optional |

| Grinding ball material | Tungsten carbide | Zirconium oxide | Agate | Stainless steel |

| Cell breaking adapter volume | 10x0.2ml | 5x2ml | 5x5ml |

| Electrical description | 100-120V/200-240V AC, 50-60Hz, 150W |

| Power port | National Standard | European Standard | American Standard | British Standard etc. |

| Net weight | 48kg |

| Dimensions (LWH) | 470*360*250 |

| Protection class | IP63 |

| Standard | CE |

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is A Hybrid High Energy Vibratory Ball Mill?

4.8 / 5

This ball mill is a marvel of engineering. The speed of delivery was impressive, and the quality is top-notch. It's a great value for the price.

4.9 / 5

The Hybrid High Energy Vibratory Ball Mill is a game-changer. Its technological advancements make it a must-have for any laboratory. Highly recommended!

4.7 / 5

I am thoroughly impressed with the Hybrid High Energy Vibratory Ball Mill. It's durable and efficient, and it has greatly enhanced our laboratory's productivity.

4.8 / 5

The Hybrid High Energy Vibratory Ball Mill is a reliable workhorse. It has exceeded our expectations in terms of quality and performance. Highly recommended!

5.0 / 5

The Hybrid High Energy Vibratory Ball Mill is a testament to innovation. It has revolutionized our laboratory processes, and we couldn't be happier with our purchase.

4.6 / 5

The Hybrid High Energy Vibratory Ball Mill is a solid investment. It's durable, efficient, and has significantly improved our laboratory's workflow.

4.7 / 5

The Hybrid High Energy Vibratory Ball Mill is a powerful tool that has transformed our laboratory. Its technological advancements are truly impressive.

4.9 / 5

The Hybrid High Energy Vibratory Ball Mill is a remarkable piece of equipment. Its speed, efficiency, and durability make it an indispensable asset to our laboratory.

5.0 / 5

The Hybrid High Energy Vibratory Ball Mill is a game-changer. It has revolutionized our sample preparation process, and we couldn't be more satisfied.

4.8 / 5

The Hybrid High Energy Vibratory Ball Mill is a solid investment. It's a reliable workhorse that has significantly improved our laboratory's efficiency.

4.7 / 5

The Hybrid High Energy Vibratory Ball Mill is a must-have for any laboratory. It's a powerful tool that has greatly enhanced our research capabilities.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

High Energy Vibratory Ball Mill for Lab Use

The high-energy vibrating ball mill is a high-energy oscillating and impacting multifunctional laboratory ball mill. The table-top type is easy to operate, small in size, comfortable and safe.

High Energy Planetary Ball Mill Milling Machine for Laboratory

The biggest feature is that the high energy planetary ball mill can not only perform fast and effective grinding, but also has good crushing ability

High Energy Planetary Ball Mill Milling Machine for Laboratory

Experience fast and effective sample processing with the F-P2000 high-energy planetary ball mill. This versatile equipment offers precise control and excellent grinding capabilities. Perfect for laboratories, it features multiple grinding bowls for simultaneous testing and high output. Achieve optimal results with its ergonomic design, compact structure, and advanced features. Ideal for a wide range of materials, it ensures consistent particle size reduction and low maintenance.

High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

The KT-P2000E is a new product derived from the vertical high-energy planetary ball mill with a 360°rotation function. The product not only has the characteristics of the vertical high-energy ball mill, but also has a unique 360°rotation function for the planetary body.

High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

The KT-P4000E is a new product derived from the vertical high-energy planetary ball mill with a 360° swivel function. Experience faster, uniform, and smaller sample output results with 4 ≤1000ml ball mill jars.

Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

The vertical cabinet structure combined with ergonomic design enables users to obtain the best comfortable experience in standing operation. The maximum processing capacity is 2000ml, and the speed is 1200 revolutions per minute.

Laboratory Ten-Body Horizontal Jar Mill for Lab Use

The Ten-body horizontal jar mill is for 10 ball mill pots (3000ml or less). It has frequency conversion control, rubber roller movement, and PE protective cover.

Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

Discover the versatile stainless steel dry powder/liquid horizontal ball mill with ceramic/polyurethane lining. Ideal for ceramic, chemical, metallurgical, and building materials industries. High grinding efficiency and uniform particle size.

Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

KT-T200TAP is a slapping and oscillating sieving instrument for laboratory desktop use, with 300 rpm horizontal circular motion and 300 vertical slapping motions to simulate manual sieving to help sample particles pass through better.

Laboratory Four-Body Horizontal Jar Mill

The four-body horizontal tank mill ball mill can be used with four horizontal ball mill tanks with a volume of 3000ml. It is mostly used for mixing and grinding laboratory samples.

Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

The KT-V200 product focuses on solving common sieving tasks in the laboratory. It is suitable for sieving 20g-3kg dry samples.

Laboratory Micro Tissue Grinding Mill Grinder

KT-MT10 is a miniature ball mill with a compact structure design. The width and depth are only 15X21 cm, and the total weight is only 8 kg. It can be used with a minimum 0.2ml centrifuge tube or a maximum 15ml ball mill jar.

Laboratory Grinding Mill Mortar Grinder for Sample Preparation

KT-MG200 mortar grinder can be used for mixing and homogenizing powder, suspension, paste and even viscous samples. It can help users realize the ideal operation of sample preparation with more regularization and higher repeatability.

No Demolding Lab Infrared Press Mold for Laboratory Applications

Effortlessly test your samples with no demolding required using our lab infrared press mold. Enjoy high transmittance and customizable sizes for your convenience.

Related Articles

Choosing the Best Material for Ball Mill: Essential Factors and Recommendations

Discover the best material for ball mill applications and grinding success. Learn about the features and benefits of stainless steel, ceramic, agate, and tungsten carbide media. Find out how to ensure grinding success and the ideal grinding jars and media for planetary ball milling. Explore the applications of ball mills and the advantages of high-energy ball mills for ultra-fine particles.

Planetary Ball Mills: Research Tools for Efficient Mixing and Nanoscale Grinding

Planetary ball mills are indispensable tools in modern laboratories, serving a crucial role in the mixing, fine grinding, and preparation of small samples. These mills are particularly adept at dispersing nanomaterials and facilitating the development and small-scale production of high-tech materials.

Advantages of Planetary Ball Mill in Laboratory Applications

Discover the advantages of using planetary ball mills in laboratory settings. Learn about its ability to produce fine powder, suitability for toxic materials, wide range of applications, continuous operation, and usage for milling abrasive materials. Explore how planetary ball mills differ from traditional milling machines and their function in creating ultrafine and nano-sized materials.

Maximizing Grinding Efficiency: The Power of Planetary Ball Mills

Discover why planetary ball mills offer higher grinding efficiency than ordinary ball mills. Learn about the technology behind their high-performance all-round capabilities. Find out the key factors influencing the productivity and specific energy consumption of ball mills.

Development and Principles of Frozen Tissue Crushers

Explore the history, classification, and principles of frozen tissue crushers, including grinding ball selection and how to choose the right crusher.

Understanding the Advantages and Disadvantages of Ball Mills in Laboratory and Industrial Applications

Discover the pros and cons of using ball mills for grinding materials. Explore the potential applications of ball mills for various industries.

PVD Sputtering Targets and Hot Isostatic Pressing: Part 1

Explores the use of hot isostatic pressing in producing high-quality sputtering targets and the applications of PVD sputtering technology.

PVD Sputtering Targets and Hot Isostatic Pressing: Part 2

This article discusses the manufacturing and optimization of PVD sputtering targets, focusing on techniques like hot isostatic pressing and high pressure heat treatment.