You hold your breath as you pull the leather from the press. It was a perfect, expensive hide. But your company logo, the final touch, is a disaster. It’s either a faint, unreadable whisper or a scorched, blurry mess. All that time, effort, and valuable material—wasted in a single, frustrating moment.

If this scene is painfully familiar, you're not alone.

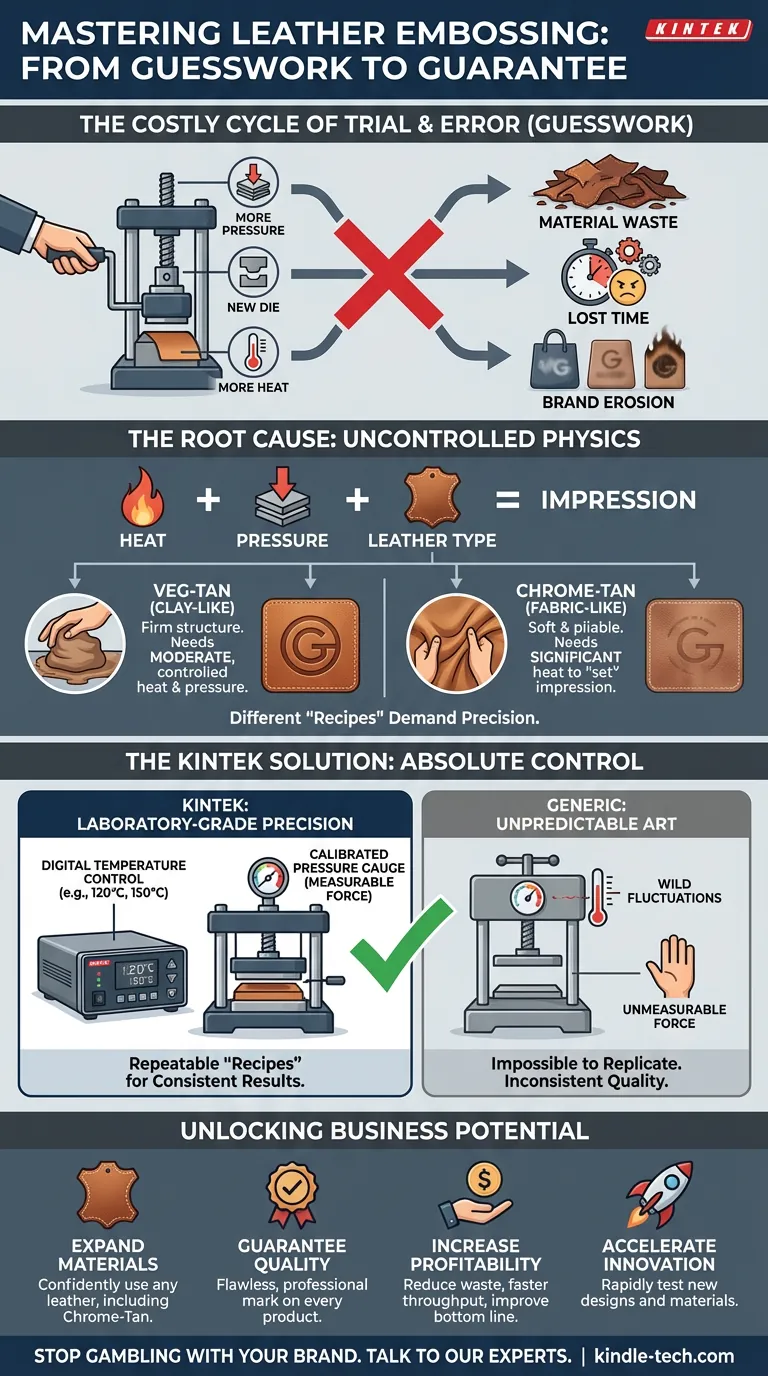

The Costly Cycle of Trial and Error

For workshops and manufacturers, inconsistent embossing is a persistent and expensive problem. When faced with a bad result, most of us run through the same checklist of "solutions":

- "Just add more pressure." You crank the press, hoping more force will fix it. Sometimes it helps, but other times it crushes the leather fibers or even damages the expensive brass die.

- "Maybe it's the die." You invest hundreds of dollars in a new, crisper die, only to find the same inconsistency plagues your results.

- "Let's try more heat." You increase the temperature, but without precise control, you quickly cross the fine line between a crisp impression and a burnt, unsalvageable piece of leather.

This cycle of guesswork does more than just ruin individual items. It has significant business consequences:

- Material Waste: Every failed attempt discards valuable leather, directly eating into your profit margins.

- Lost Production Time: Your team spends hours troubleshooting and re-running jobs instead of meeting production targets.

- Brand Erosion: A weak or sloppy logo on a premium product screams low quality. It undermines customer trust and devalues your brand.

- Project Delays: The inability to reliably produce consistent quality can delay new product launches and damage relationships with clients waiting for their orders.

These "solutions" fail because they only address the symptoms. The real problem lies deeper, in the fundamental science of how leather responds to heat and pressure.

The Real Culprit: The Uncontrolled Physics of Embossing

The quality of your emboss isn't a matter of luck; it's a matter of physics. A perfect impression depends on the precise interplay of three factors: Heat, Pressure, and Leather Type. The root cause of inconsistency is not a bad die or a bad hide—it's a lack of control over this process.

Why Different Leathers Demand Different "Recipes"

Different tanning methods produce leathers with fundamentally different properties.

- Vegetable-Tanned ("Veg-Tan") Leather: This firm, structured leather behaves like modeling clay. It can be molded and will hold a crisp impression with moderate, controlled heat and pressure.

- Chrome-Tanned Leather: This leather is much softer and more pliable, like a dense fabric. To get it to hold a shape, you need significantly more heat to "set" the impression permanently. Without it, the mark will quickly fade and disappear.

The common approach of "more pressure" or "a bit more heat" is pure guesswork. It fails because it’s not repeatable or precise. You are trying to follow a delicate recipe without any measuring cups—a guaranteed path to failure. You aren't fighting a bad die; you are fighting uncontrolled variables.

From Guesswork to Guarantee: The Right Tool for the Right Job

To escape the cycle of trial and error, you must move from guesswork to a scientific, repeatable process. This doesn't mean you need a PhD in material science. It means you need tools that provide absolute control.

This is the core principle behind KINTEK's laboratory-grade equipment. Our heating and pressing solutions are engineered not just for power, but for the repeatable precision required to master the craft. They are the direct solution to the root cause of inconsistency.

-

Problem: Inconsistent Heat. A cheap press has wild temperature fluctuations, leading to faint marks one moment and scorched leather the next.

- The KINTEK Solution: Our systems feature digital temperature controllers that maintain a precise, stable temperature. You can set the exact heat required for veg-tan (e.g., 120°C) or chrome-tan (e.g., 150°C) and know it will be delivered consistently, every single time.

-

Problem: Uncalibrated Pressure. "Pressing harder" is not a unit of measurement. It’s impossible to replicate and leads to impressions that are either too deep or too shallow.

- The KINTEK Solution: Our presses are equipped with calibrated pressure gauges. You can set a specific, measurable force and record it. This allows any operator to replicate the perfect result by simply following a documented "recipe" of temperature and pressure settings.

Our equipment isn't just a more powerful version of what you have. It's an entirely different class of tool, designed to give you the control necessary to make perfect embossing a predictable science, not an unpredictable art.

Beyond the Perfect Mark: What Control Unlocks for Your Business

When you eliminate inconsistency, you do more than just solve a technical headache. You unlock new potential for your entire operation.

Suddenly, you can:

- Confidently Use Any Leather: Stop avoiding challenging but beautiful chrome-tanned leathers. With precise control, you can expand your product lines and design possibilities.

- Guarantee Brand Quality: Every wallet, bag, or portfolio that leaves your workshop will feature a flawless, professional mark that reinforces your commitment to quality.

- Increase Throughput and Profitability: Stop wasting time and materials on re-dos. Fulfill orders faster, increase your production capacity, and improve your bottom line.

- Accelerate Innovation: Rapidly test and document the ideal settings for new designs and materials, moving from prototype to market-ready product in record time.

By transforming embossing from an art of chance into a science of excellence, you build a more resilient, scalable, and profitable business.

If you're ready to stop gambling with your brand and materials, let's talk. Our team of experts can help you analyze your current workflow and identify the precise equipment you need to achieve flawless results. Discuss your unique challenges with us and discover how a precision-driven process can transform your production. Contact Our Experts to get started.

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

Related Articles

- Principles and Applications of Vacuum Hot Press Sintering Equipment

- Advanced Ceramics Hot Press Sintering Technology and Equipment

- Operation of Vacuum Hot Press Sintering Furnace

- Optimizing Laboratory Analysis with Split Automatic Heated Lab Pellet Press

- High Pressure Tube Furnace: Applications, Safety, and Maintenance